-

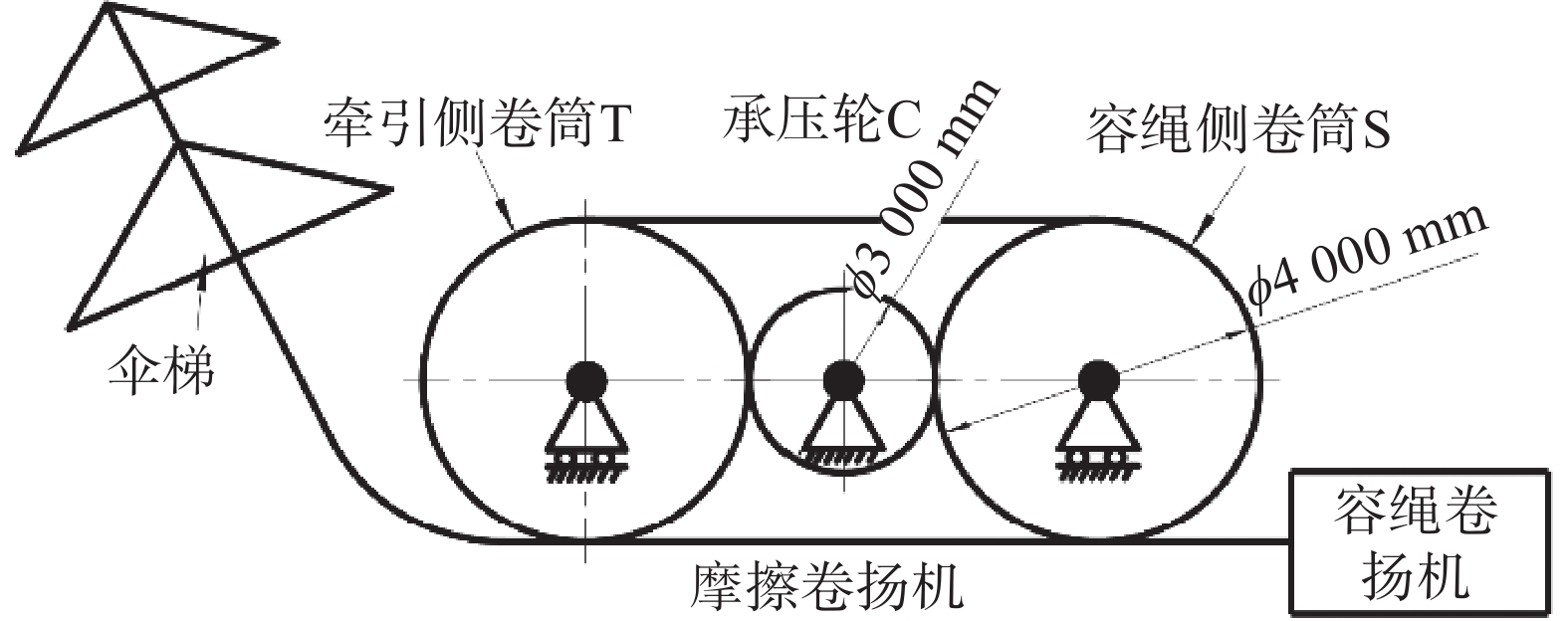

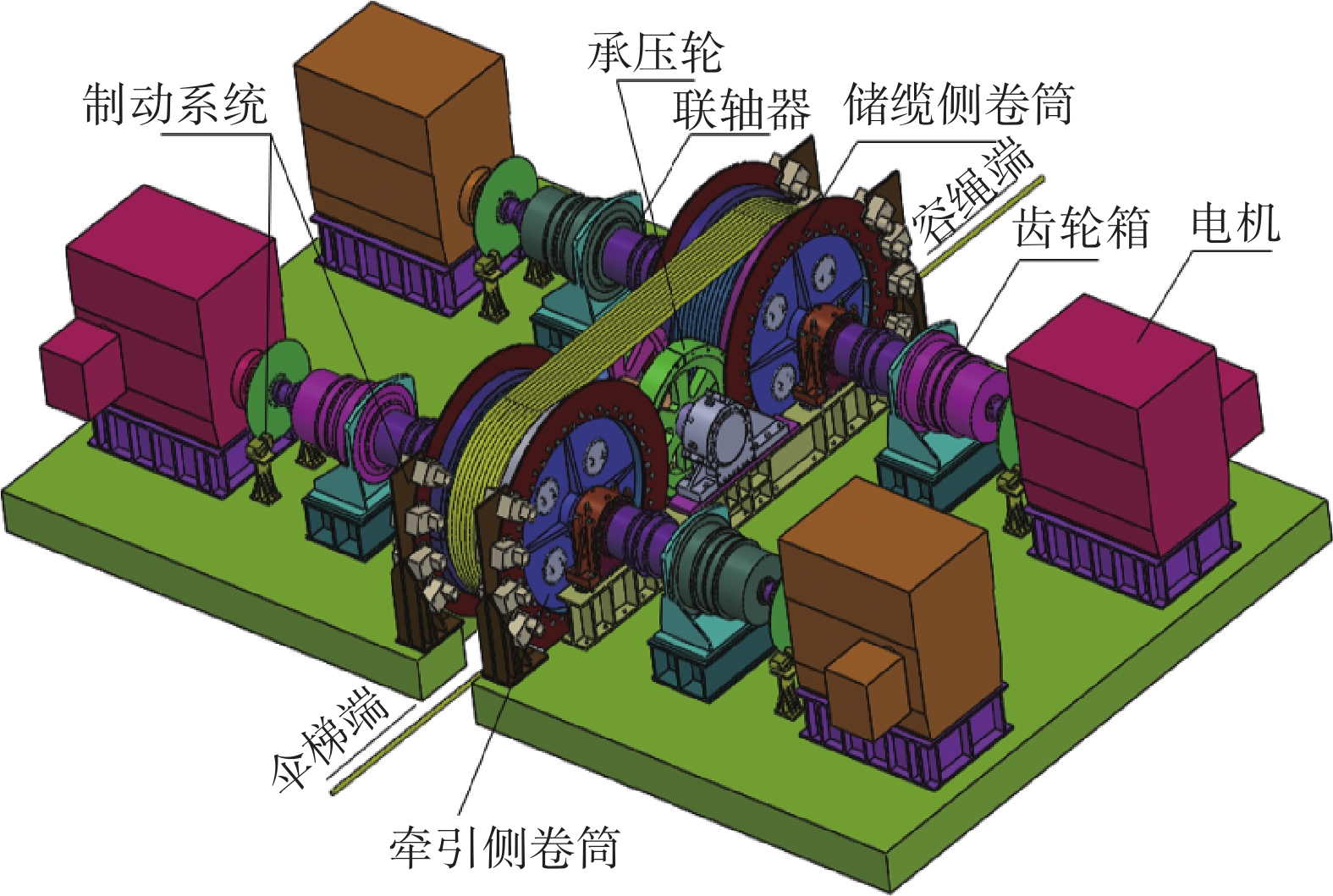

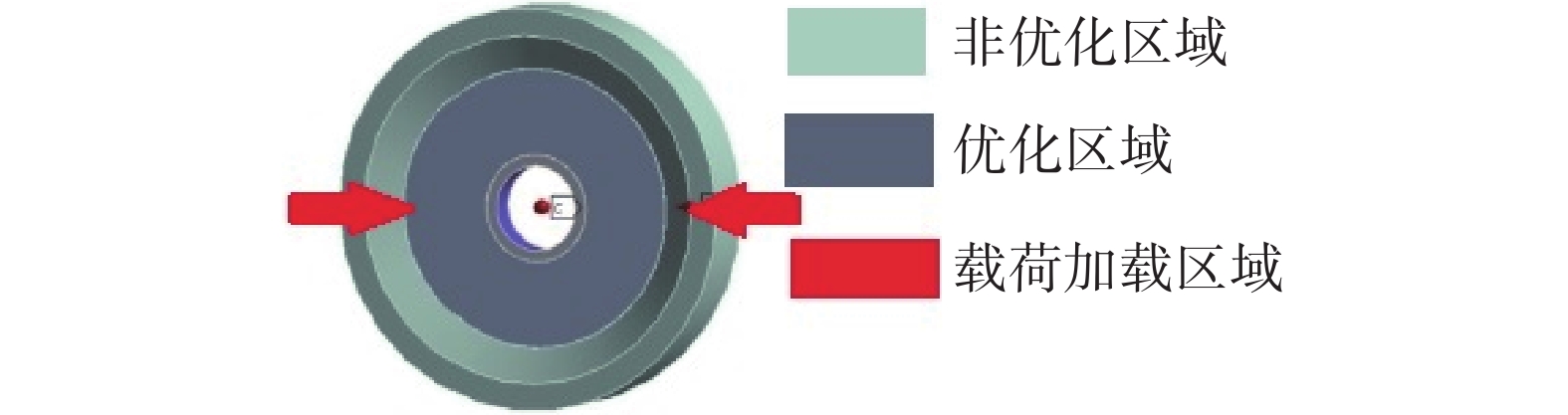

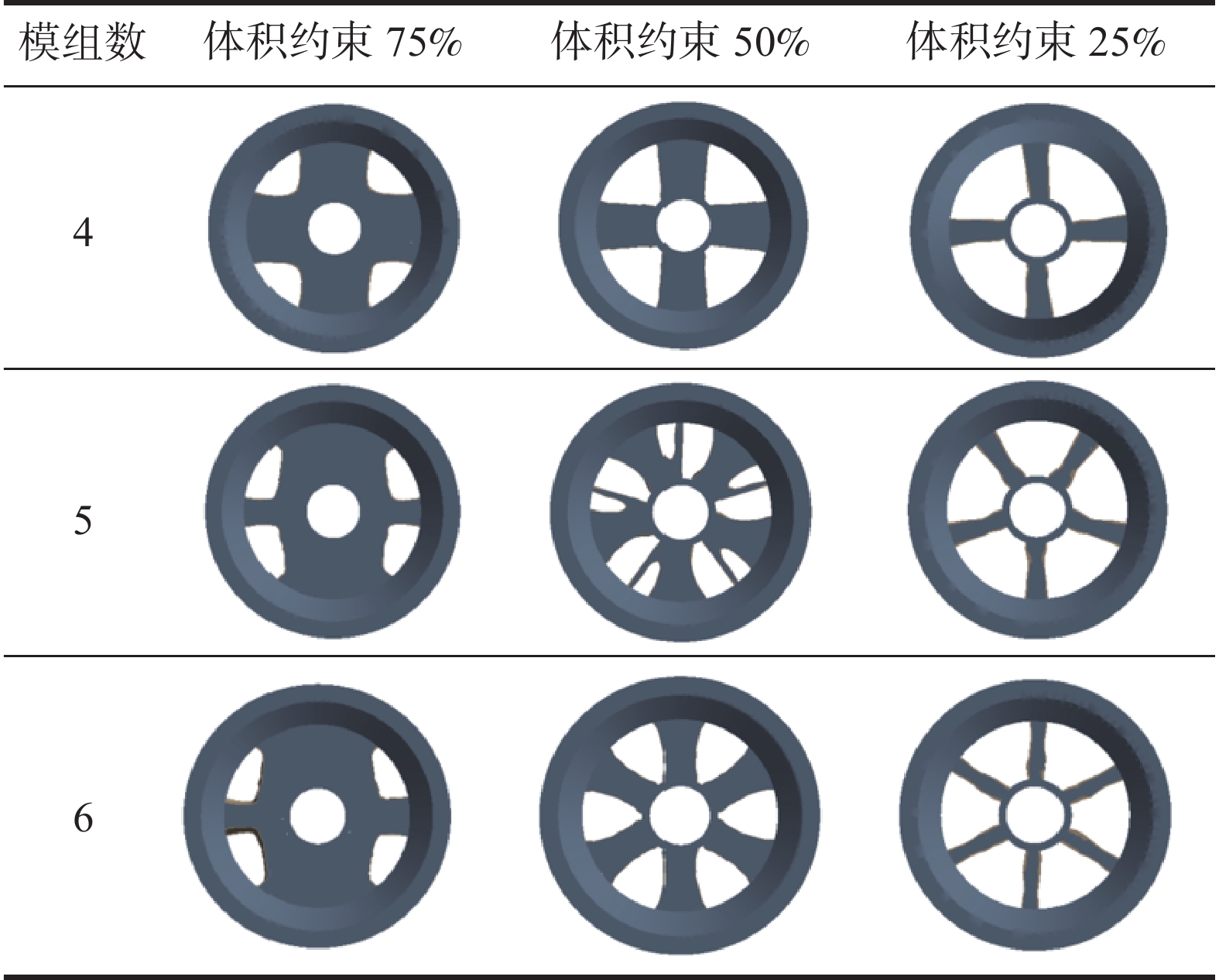

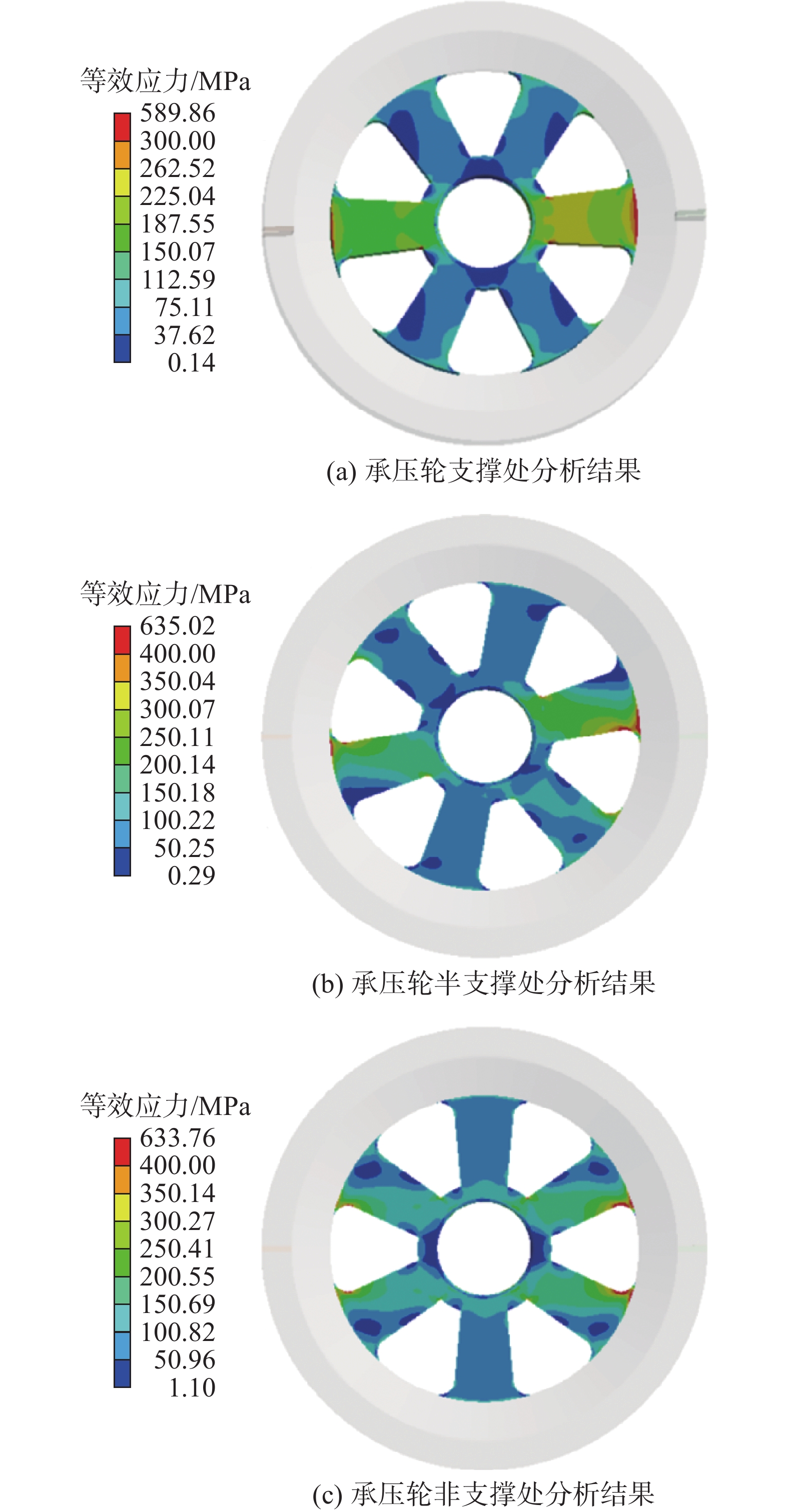

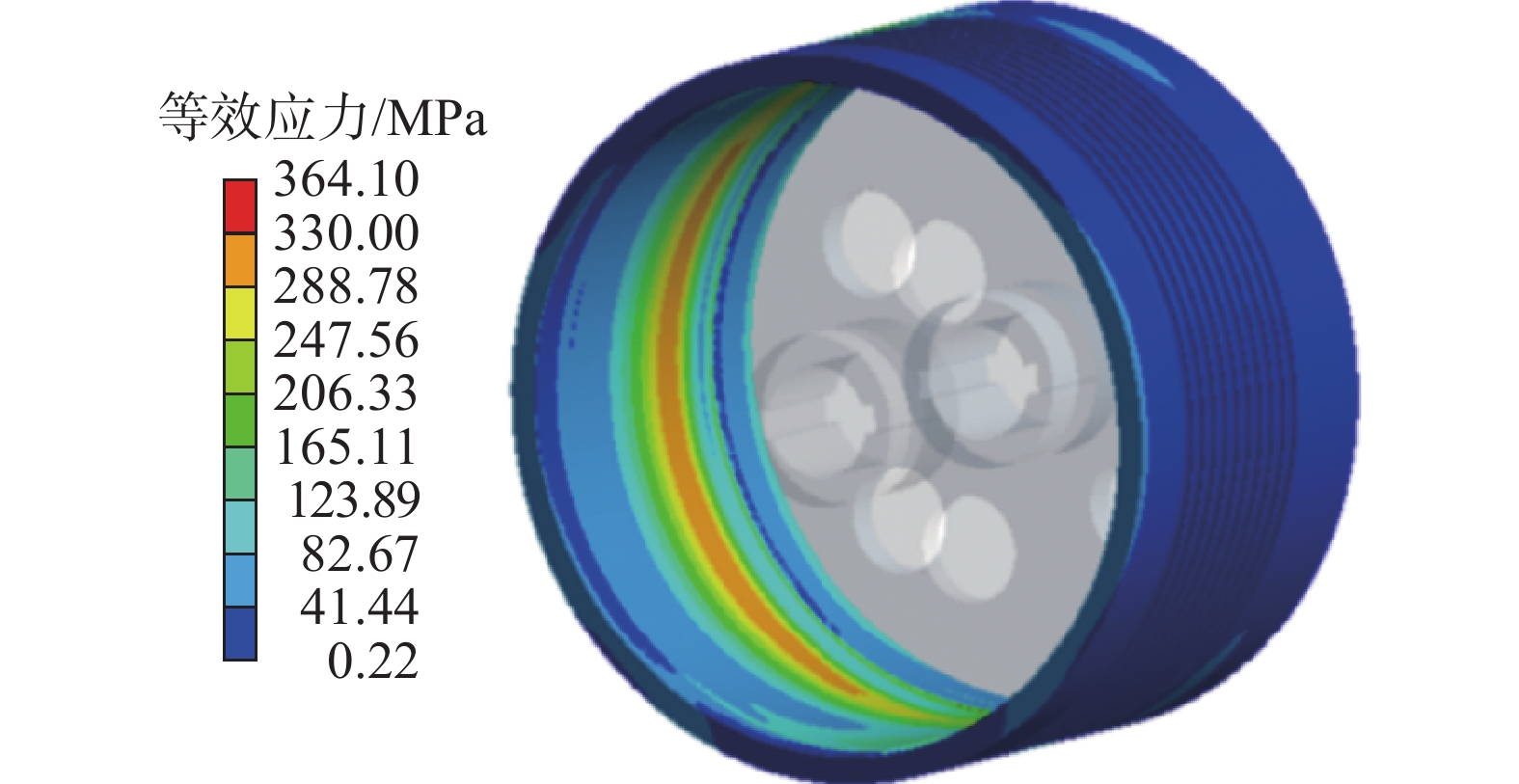

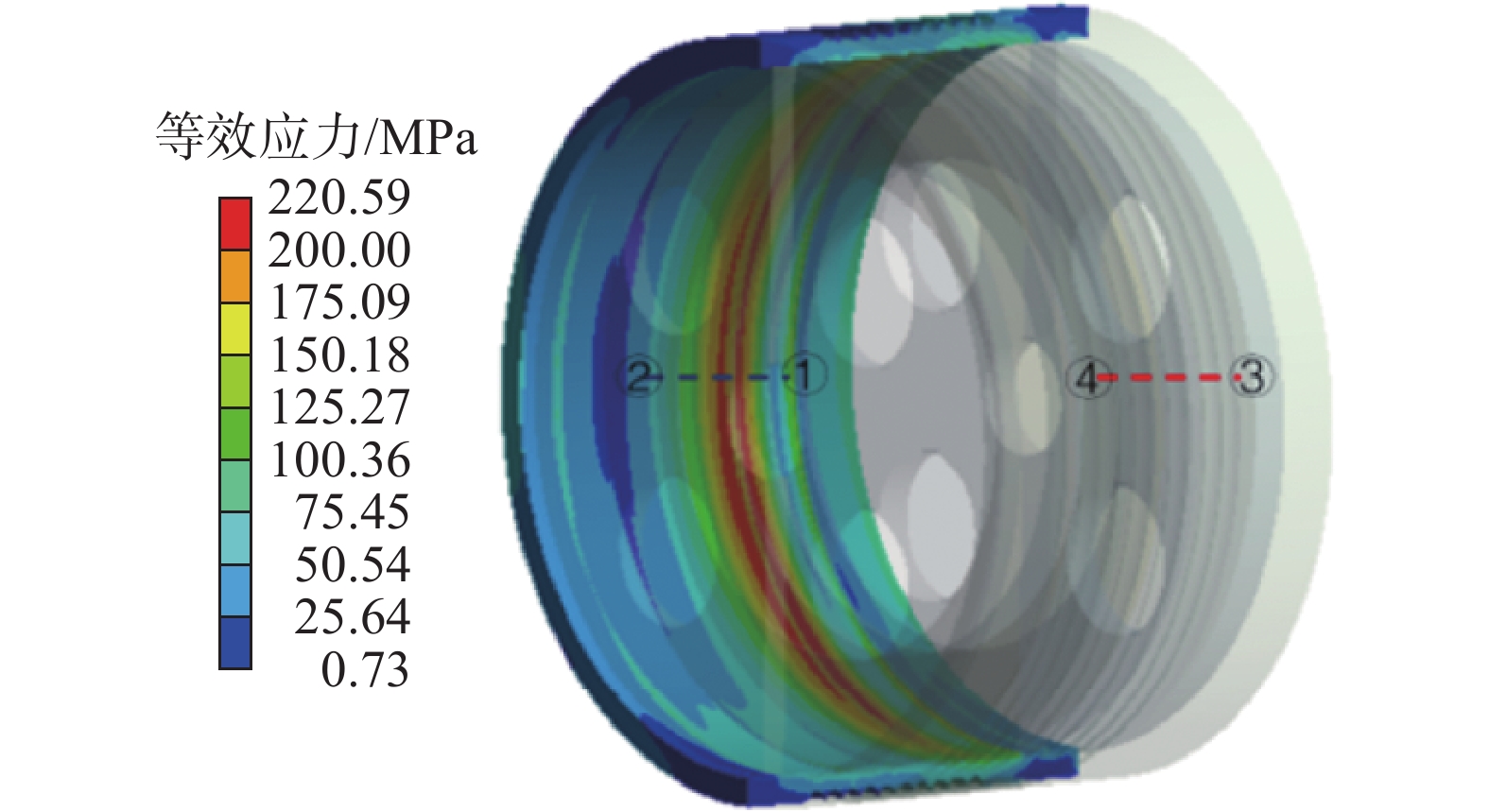

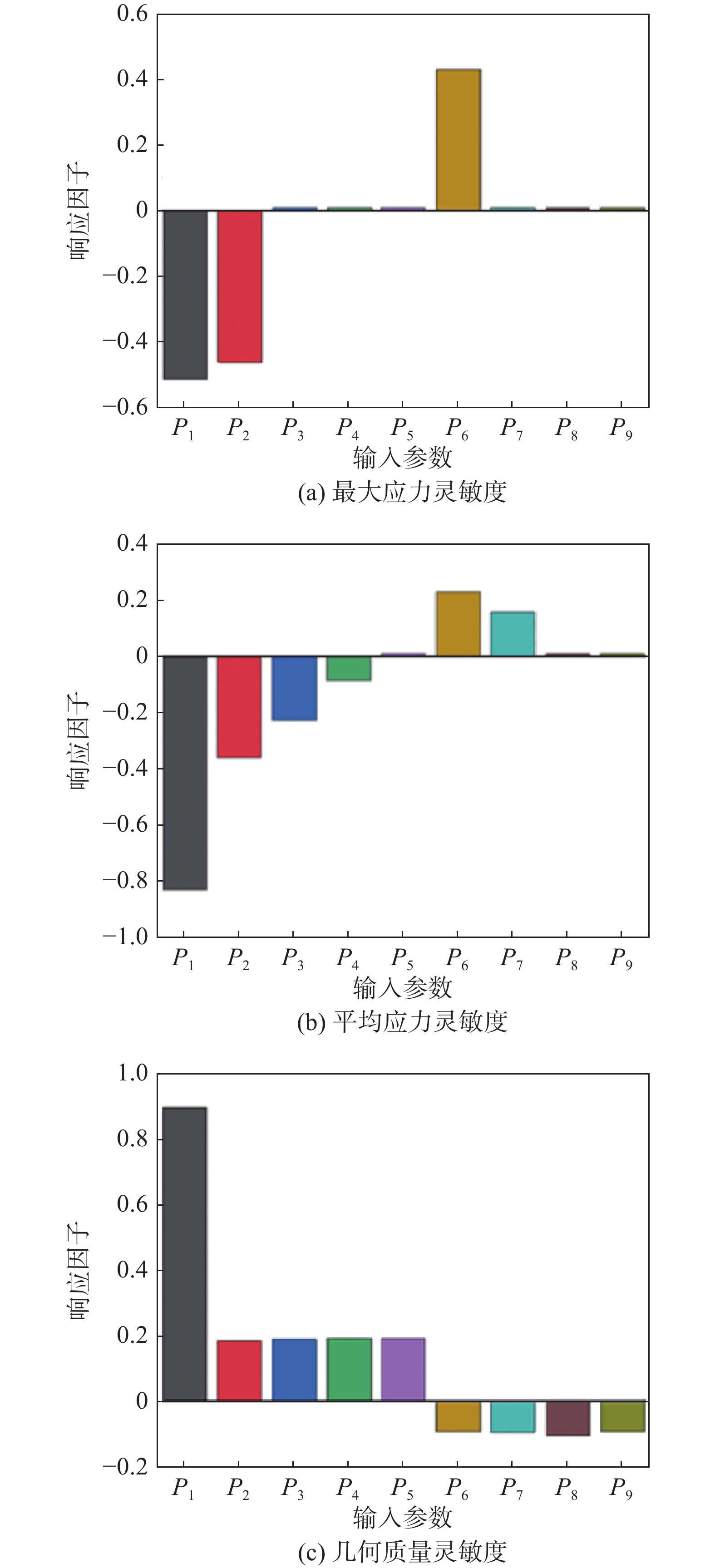

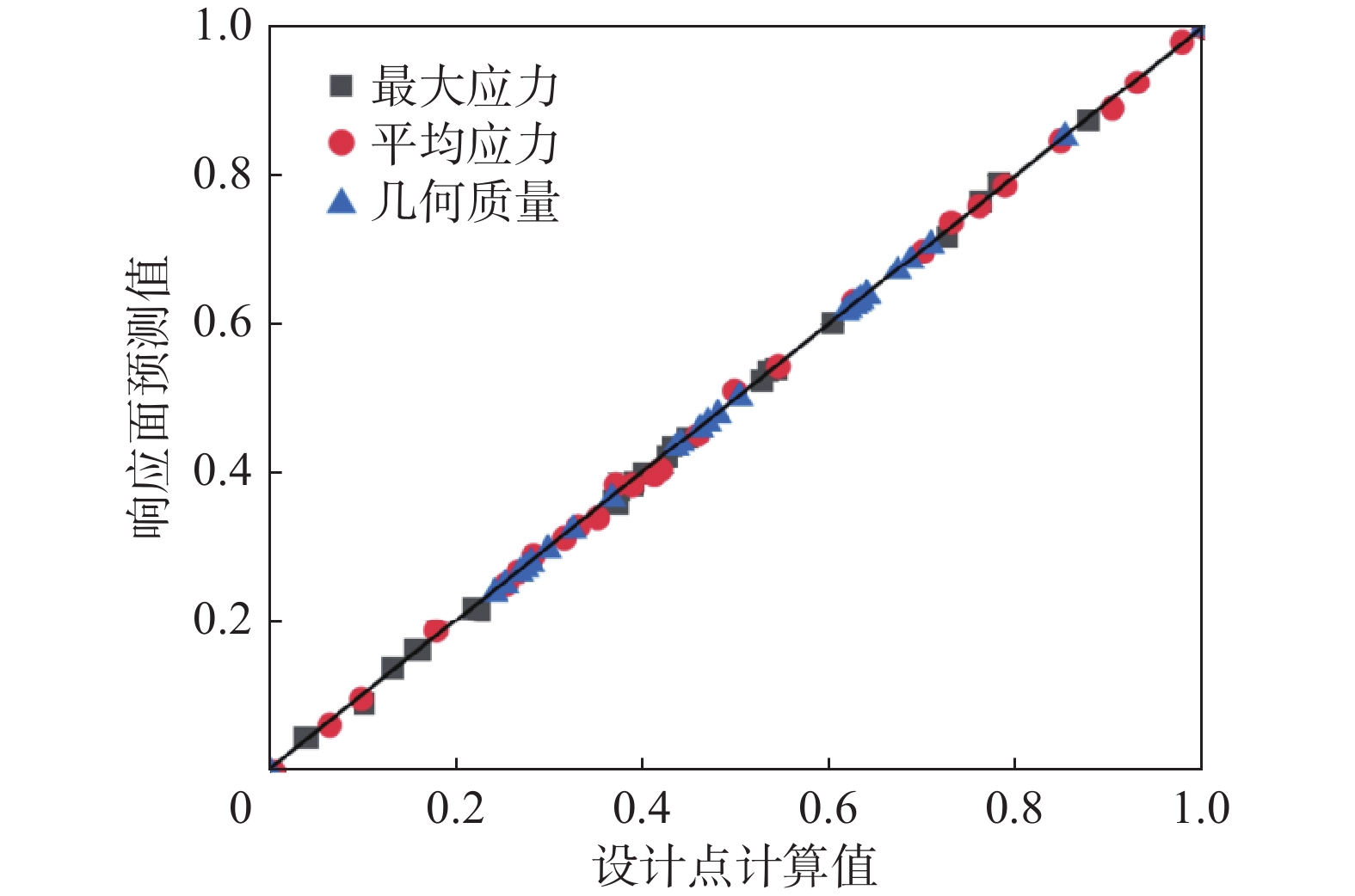

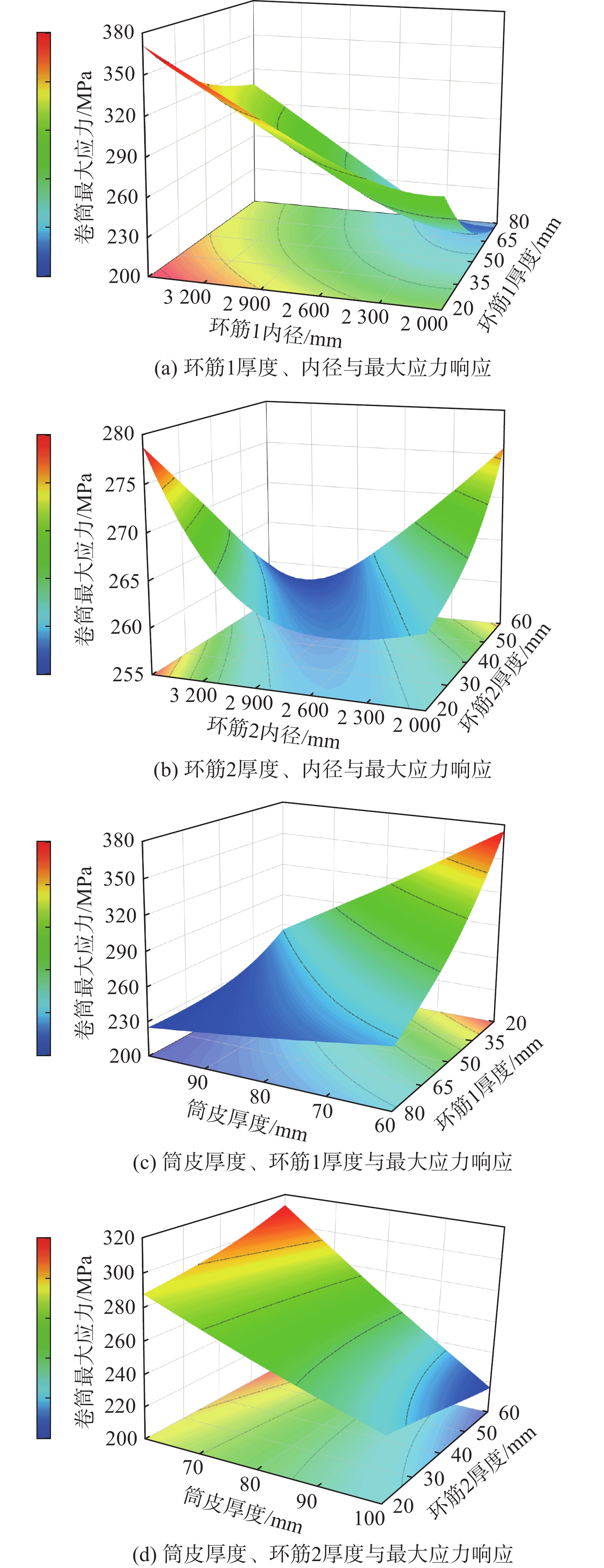

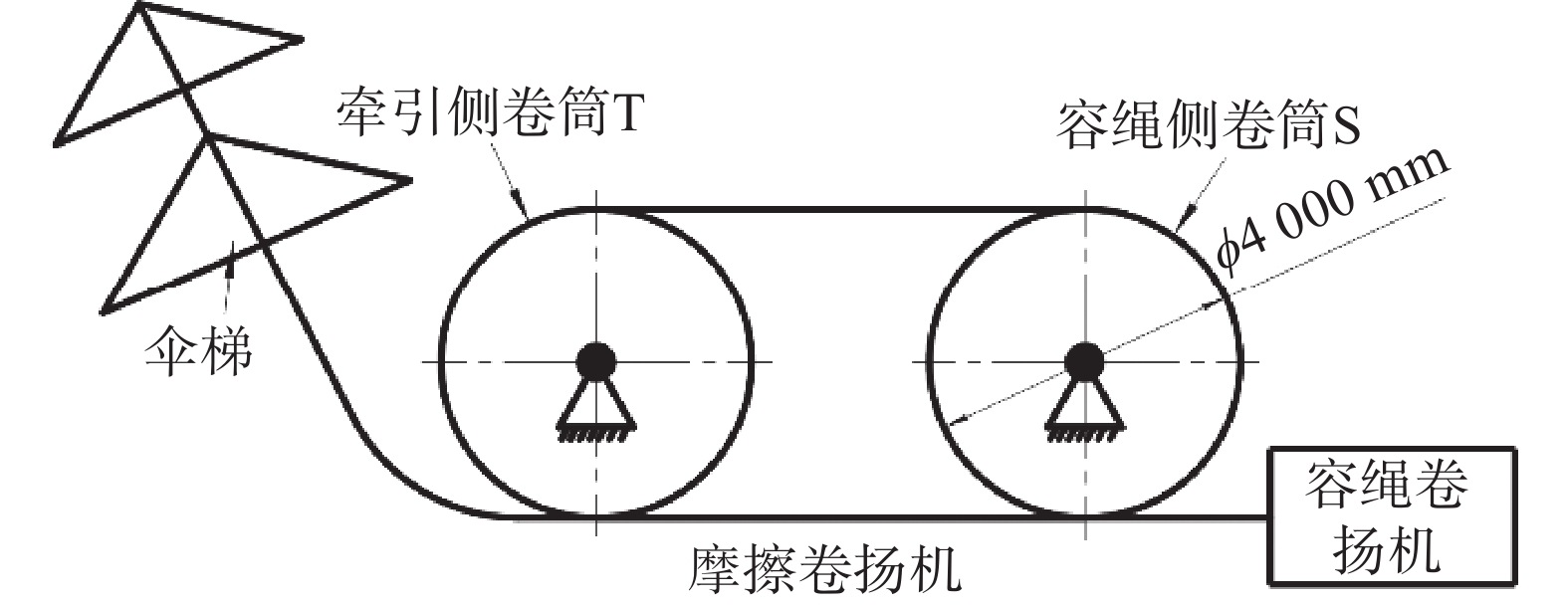

摘要:目的 摩擦卷扬机是高空风能发电(Airborne Wind Energy Systems, AWES)的主要做功设备,为克服其工作过程中所受缆绳拉力大、线速度高、工况复杂的难点,同时满足长寿命、高可靠性、高安全性的需求。方法 提出一种基于承压轮的浮动双卷筒摩擦卷扬机构型。通过有限元分析软件对关键部件承压轮和卷筒进行优化设计,建立摩擦卷扬机受力分析模型并进行力学分析,采用变密度法,对承压轮内部支撑体进行拓扑优化;对卷筒参数化建模,进行灵敏度分析,筛选出对最大应力、平均应力和几何质量的灵敏度较大的结构参数,采用中心复合试验设计法,建立了卷筒应力、质量与主要设计结构参数的响应面模型。结果 通过以应变能最小为目标,以承压轮内部支撑体体积为约束条件,实现了承压轮结构质量下降36%的优化效果,并通过在不同部位施加载荷验证了其强度符合要求;使用灵敏度分析法筛选卷筒结构参数,以此建立卷筒响应面模型并进行多目标优化,得到卷筒优化方案,在满足强度要求的前提下实现质量减轻16.6%的优化效果。结论 基于有限元分析仿真软件对摩擦卷扬机关键部件进行优化并验证了以上构型的可行性,同时降低了制造成本,兼具经济性,并解决了高速重载卷扬机的轴承选型、振动和热膨胀等难题。Abstract:Objective Friction winch is the main working equipment for Airborne Wind Energy Systems (AWES). To overcome the difficulties of high cable tension, high linear velocity and complex working conditions during its operation to meet the requirements of long service life, high reliability and high safety, a floating double drum friction winch mechanism based on pressure bearing wheels is proposed.Method The key components of the pressure bearing wheel and drum were optimized using finite element analysis software. A force analysis model for the friction winch was established and subjected to mechanical analysis. The variable density method was used to optimize the topology of the internal support structure of the pressure bearing wheel. Parameterized modeling of the drum was conducted, followed by sensitivity analysis to screen out structural parameters with significant sensitivity to maximum stress, mean stress and geometric mass. Using the central composite experimental design method, a response surface model was established for the drum's stress, mass and main design structural parameters.Result By taking the minimum strain energy as the objective and the internal support volume of the pressure bearing wheel as the constraint, the optimization achieves a 36% reduction in the structural mass of the pressure bearing wheel, and its strength is verified to meet the requirements by applying loads at different locations. Sensitivity analysis is used to screen the structural parameters of the drum, and a response surface model of the drum is established for multi-objective optimization. This results in a drum optimization design that achieves a 16.6% reduction in mass while meeting strength requirements.Conclusion Based on finite element analysis simulation software, the key components of the friction winch are optimized and the feasibility of the above configuration was verified. This not only reduces manufacturing costs and improves economic efficiency but also addresses challenges such as bearing selection, vibration and thermal expansion in high-speed, heavy-duty winches.

-

-

表 1 摩擦卷扬机设计输入参数

Table 1 Design input parameters for friction winch

序号 运行工况 缆绳拉力/kN 缆绳速度/(m·s−1) 轴承寿命/h 1 发电,放绳 3 250 10 50 000 2 耗电,收绳 110 23.6 — 表 2 卷筒传动轴设计参数

Table 2 Design parameters of drive shaft of the drum

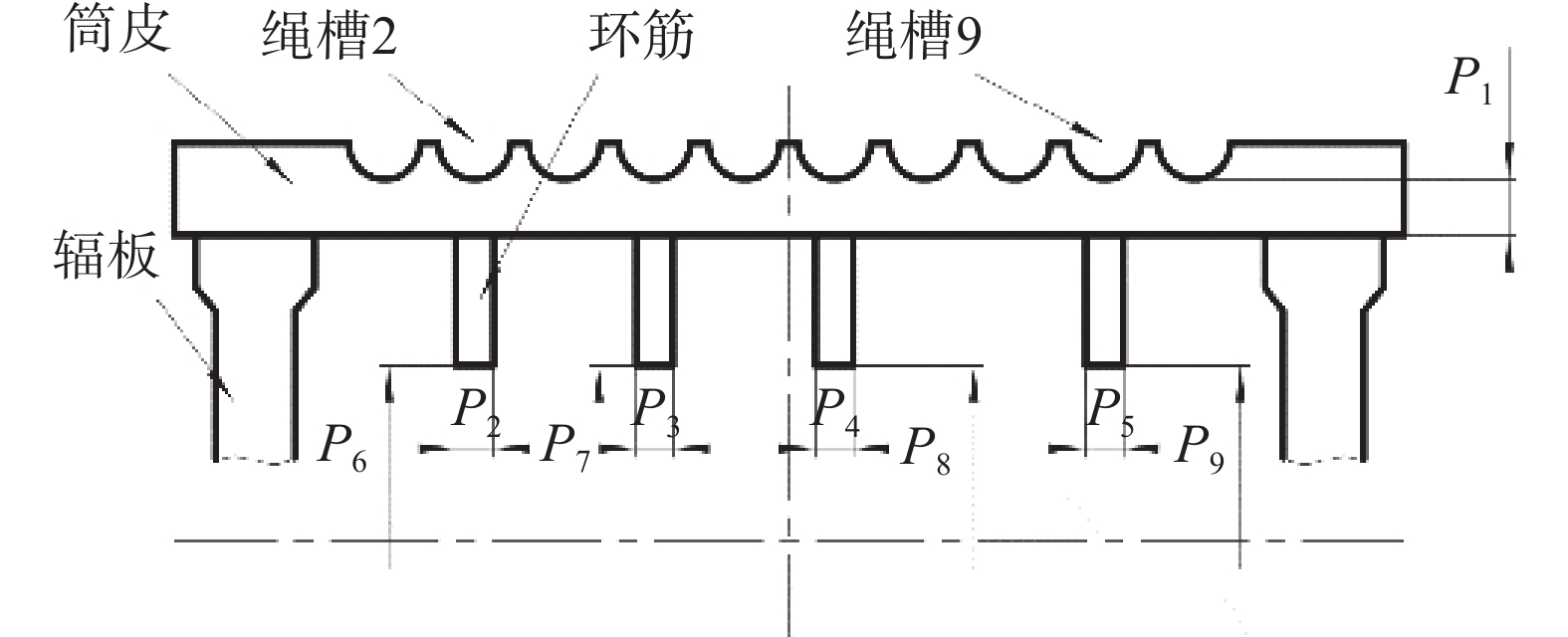

名称 最大弯矩M/(kN·m) 最大扭矩T/(kN·m) 数值 8 460 3 530 表 3 卷筒输入参数

Table 3 Input parameter of drum

输入参数 初始值/mm 筒皮厚度P1 100 绳槽2环筋厚度P2 50 绳槽4环筋厚度P3 50 绳槽6环筋厚度P4 50 绳槽9环筋厚度P5 50 绳槽2环筋内径P6 2 600 绳槽4环筋内径P7 2 600 绳槽6环筋内径P8 2 600 绳槽9环筋内径P9 2 600 表 4 卷筒优化结果

Table 4 Optimization results of the drum

参数 方案一 方案二 方案三 P1/mm 60.04 60.17 60 P2/mm 20.09 58.63 20.11 P3/mm 20.12 21.18 20.06 P6/mm 2 580 3 496 2 464 P7/mm 3 464 3 497 3 460 P15/MPa 349.74 348.34 339.69 P17/kg 52 852 52 874 52 912 -

[1] 邵垒, 毛虹霖, 邢胜, 等. 高空风力发电发展现状及关键技术研究综述 [J]. 新能源进展, 2020, 8(6): 477-485. DOI: 10.3969/j.issn.2095-560X.2020.06.005. SHAO L, MAO H L, XING S, et al. Review on development status and key technology of airborne wind energy system [J]. Advances in new and renewable energy, 2020, 8(6): 477-485. DOI: 10.3969/j.issn.2095-560X.2020.06.005.

[2] CANALE M, FAGIANO L, MILANESE M. KiteGen: a revolution in wind energy generation [J]. Energy, 2009, 34(3): 355-361. DOI: 10.1016/j.energy.2008.10.003.

[3] 刘耀广, 王耀坤, 万志强, 等. 系留悬浮式风力发电技术的研究进展与展望 [J]. 航空工程进展, 2021, 12(4): 36-43. DOI: 10.16615/j.cnki.1674-8190.2021.04.04. LIU Y G, WANG Y K, WAN Z Q, et al. Research progress and prospect of tethered floating wind energy generation technology [J]. Advances in aeronautical science and engineering, 2021, 12(4): 36-43. DOI: 10.16615/j.cnki.1674-8190.2021.04.04.

[4] 王若钦, 严德, 李柳青, 等. 切风模式风力发电飞行器的进展与挑战 [J]. 航空工程进展, 2018, 9(2): 139-146. DOI: 10.16615/j.cnki.1674-8190.2018.02.001. WANG R Q, YAN D, LI L Q, et al. Advances and challenges of crosswind mode airborne wind energy aircrafts [J]. Advances in aeronautical science and engineering, 2018, 9(2): 139-146. DOI: 10.16615/j.cnki.1674-8190.2018.02.001.

[5] 张晨星, 岳泽锴. 中国龙多伞内嵌式风筝发电装置结构设计 [J]. 科技创新与应用, 2022, 12(16): 46-48, 52. DOI: 10.19981/j.CN23-1581/G3.2022.16.009. ZHANG C X, YUE Z K. Structural design of Chinese loong multi umbrella embedded kite power generation device [J]. Technology innovation and application, 2022, 12(16): 46-48, 52. DOI: 10.19981/j.CN23-1581/G3.2022.16.009.

[6] 魏辽国, 齐悦, 钟明, 等. 高空风能发电地面设备的研究 [J]. 工程机械, 2023, 54(5): 72-77. DOI: 10.3969/j.issn.1000-1212.2023.05.014. WEI L G, QI Y, ZHONG M, et al. Research on ground equipment for high altitude wind energy generation [J]. Construction machinery and equipment, 2023, 54(5): 72-77. DOI: 10.3969/j.issn.1000-1212.2023.05.014.

[7] 吴建民, 陆品, 王定亚. 国外铺管绞车技术研究与国产化发展建议 [J]. 石油机械, 2009, 37(6): 84-87. WU J M, LU P, WANG D Y. Foreign pipeline laying winch technology research and suggestions for domestic development [J]. China petroleum machinery, 2009, 37(6): 84-87.

[8] 喻开安, 王晓波, 钟朝廷, 等. 用于深水海管铺设的双滚筒绞车设计研究 [J]. 石油机械, 2011, 39(2): 41-44. DOI: 10.16082/j.cnki.issn.1001-4578.2011.02.014. YU K A, WANG X B, ZHONG C T, et al. Design study of a double-drum winch for deepwater subsea pipeline laying [J]. China petroleum machinery, 2011, 39(2): 41-44. DOI: 10.16082/j.cnki.issn.1001-4578.2011.02.014.

[9] 王硕锋, 陈雷. 大型双滚筒摩擦绞车的设计要点 [J]. 船舶工程, 2023, 45(增刊1): 216-219, 233. DOI: 10.13788/j.cnki.cbgc.2023.S1.043. WANG S F, CHEN L. Winch design points of large double-drum friction [J]. Ship engineering, 2023, 45(Suppl.1): 216-219, 233. DOI: 10.13788/j.cnki.cbgc.2023.S1.043.

[10] 江祺琦, 孟光, 王建明. 卷扬机钢丝绳欧拉公式及欧拉衰减的研究 [J]. 力学研究, 2016, 5(1): 10-16. DOI: 10.12677/IJM.2016.51002. JIANG Q Q, MENG G, WANG J M. Theoretical study of Euler's formula and loss elimination effect on rope windings of winch drum [J]. International journal of mechanics research, 2016, 5(1): 10-16. DOI: 10.12677/IJM.2016.51002.

[11] 徐强, 张亭森, 李靖, 等. 卷扬机乱绳问题分析及解决方法 [J]. 建筑机械化, 2023, 44(5): 85-87. DOI: 10.3969/j.issn.1001-1366.2023.05.024. XU Q, ZHANG T S, LI J, et al. Analysis and solution to rope disorder of winch with rope guide [J]. Construction mechanization, 2023, 44(5): 85-87. DOI: 10.3969/j.issn.1001-1366.2023.05.024.

[12] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 滚动轴承 游隙 第1部分: 向心轴承的径向游隙: GB/T 4604.1—2012 [S]. 北京: 中国标准出版社, 2013. General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Rolling bearings-internal clearance-part 1: radial internal clearance for radial bearings: GB/T 4604.1—2012 [S]. Beijing: Standards Press of China, 2013.

[13] 丁卯, 耿达, 周明东, 等. 基于变密度法的结构强度拓扑优化策略 [J]. 上海交通大学学报, 2021, 55(6): 764-773. DOI: 10.16183/j.cnki.jsjtu.2019.301. DING M, GENG D, ZHOU M D, et al. Topology optimization strategy of structural strength based on variable density method [J]. Journal of Shanghai Jiaotong University, 2021, 55(6): 764-773. DOI: 10.16183/j.cnki.jsjtu.2019.301.

[14] 王端奇, 解志坚, 杨臻, 等. 基于变密度法的武器站塔台发射支架拓扑优化 [J]. 兵器装备工程学报, 2023, 44(3): 60-66. DOI: 10.11809/bqzbgcxb2023.03.009. WANG D Q, XIE Z J, YANG Z, et al. Topology optimization of the launching bracket for weapon station towers based on the variable density method [J]. Journal of ordnance equipment engineering, 2023, 44(3): 60-66. DOI: 10.11809/bqzbgcxb2023.03.009.

[15] 焦洪宇, 周奇才, 李文军, 等. 基于变密度法的周期性拓扑优化 [J]. 机械工程学报, 2013, 49(13): 132-138. DOI: 10.3901/JME.2013.13.132. JIAO H Y, ZHOU Q C, LI W J, et al. Periodic topology optimization using variable density method [J]. Journal of mechanical engineering, 2013, 49(13): 132-138. DOI: 10.3901/JME.2013.13.132.

[16] 程前进. 卷筒筒绳直径比、卷筒钢丝绳偏角与倍率间的设计关系 [J]. 起重运输机械, 2022(1): 75-77. DOI: 10.3969/j.issn.1001-0785.2022.01.014. CHENG Q J. Relationship between the diameter ratio of the rope and the deflection angle of wire rope and multiplying power in design [J]. Hoisting and conveying machinery, 2022(1): 75-77. DOI: 10.3969/j.issn.1001-0785.2022.01.014.

[17] 张质文, 王金诺, 程文明, 等. 起重机设计手册(2版) [M]. 北京: 中国铁道出版社, 2013. ZHANG Z W, WANG J N, CHENG W M, et al. Crane design handbook (2nd ed.) [M]. Beijing: China railway publishing house, 2013.

[18] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 起重机设计规范: GB/T 3811—2008 [S]. 北京: 中国标准出版社, 2008. General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Design rules for cranes: GB/T 3811—2008 [S]. Beijing: Standards Press of China, 2008.

[19] 苏祺, 王海波. 光伏组件安装设备摩擦卷筒分析与优化 [J]. 机械设计与研究, 2023, 39(4): 252-256. DOI: 10.13952/j.cnki.jofmdr.2023.0163. SU Q, WANG H B. Analysis and optimization of friction drum for photovoltaic module installation equipment [J]. Machine design & research, 2023, 39(4): 252-256. DOI: 10.13952/j.cnki.jofmdr.2023.0163.

[20] 叶辉, 胡平, 申国哲, 等. 基于灵敏度和碰撞仿真的汽车车身轻量化优化设计 [J]. 农业机械学报, 2010, 41(10): 18-22, 27. DOI: 10.3969/j.issn.1000-1298.2010.10.004. YE H, HU P, SHEN G Z, et al. Lightweight optimization design of car body based on sensitivity and side crash simulation [J]. Transactions of the Chinese society for agricultural machinery, 2010, 41(10): 18-22, 27. DOI: 10.3969/j.issn.1000-1298.2010.10.004.

[21] 胡启国, 何奇, 陈思祥, 等. 基于响应面法-改进人工蜂群算法的绞车滚筒多目标优化设计 [J]. 机床与液压, 2022, 50(16): 75-81. DOI: 10.3969/j.issn.1001-3881.2022.16.015. HU Q G, HE Q, CHEN S X, et al. Winch drum multi-objective optimization design based on response surface method-improved artificial bee colony algorithm [J]. Machine tool & hydraulics, 2022, 50(16): 75-81. DOI: 10.3969/j.issn.1001-3881.2022.16.015.

下载:

下载: