-

储能是发展新能源不可或缺的核心要素,是构建新型电力系统的基础装备,是实现碳达峰碳中和的重要支撑。近年来,抽水蓄能和新型储能蓬勃发展,诸如电化学储能、压缩/液化空气储能、飞轮储能、重力储能等新技术、新产品不断取得突破[1]。截止2021年底,我国已投运电力储能项目累计装机规模46.1 GW,占全球市场总规模的22%,其中,抽水蓄能累计装机规模39.8 GW,新型储能累计装机规模5 729.7 MW[2]。从储能产业现状来看,抽水蓄能仍然是最主要的储能方式,占全国储能装机总规模的86.3%,占全球储能装机总规模的86.2%[2]。因此,抽水蓄能依然是储能的重中之重[3]。

抽水蓄能以水为储能介质,借助上、下两个水库,运用重力势能和电能相互转换原理,实现电力储能,通常在电力负荷低谷期抽水至上库,在电力负荷高峰期放水至下库发电[4]。抽水蓄能运行过程简单,但其选址对地理条件有很高要求[5]:上、下库的容量可达数百万至上千万方以上;上、下库高度差往往要求400 m以上,有的已达700 m以上。符合这些要求的厂址资源比较稀缺,且大多数都在偏远的山区。为此,学者们提出多种创新形式的抽水蓄能电站,包括:海水抽水蓄能电站[6],其上库在岸上,下库为海洋;地下抽水蓄能电站[6],其上库在地面,下库在地下;废弃矿坑或矿井抽水蓄能电站[7],其上库在地面,下库在矿坑或矿井的下部。这些创新有助于扩大抽水蓄能选址范围,不过,具备开发条件与经济价值的厂址仍十分有限,并未根本上解决抽水蓄能选址的难题。因此,还需要探索新的方法,更大程度提升抽水蓄能选址灵活性。

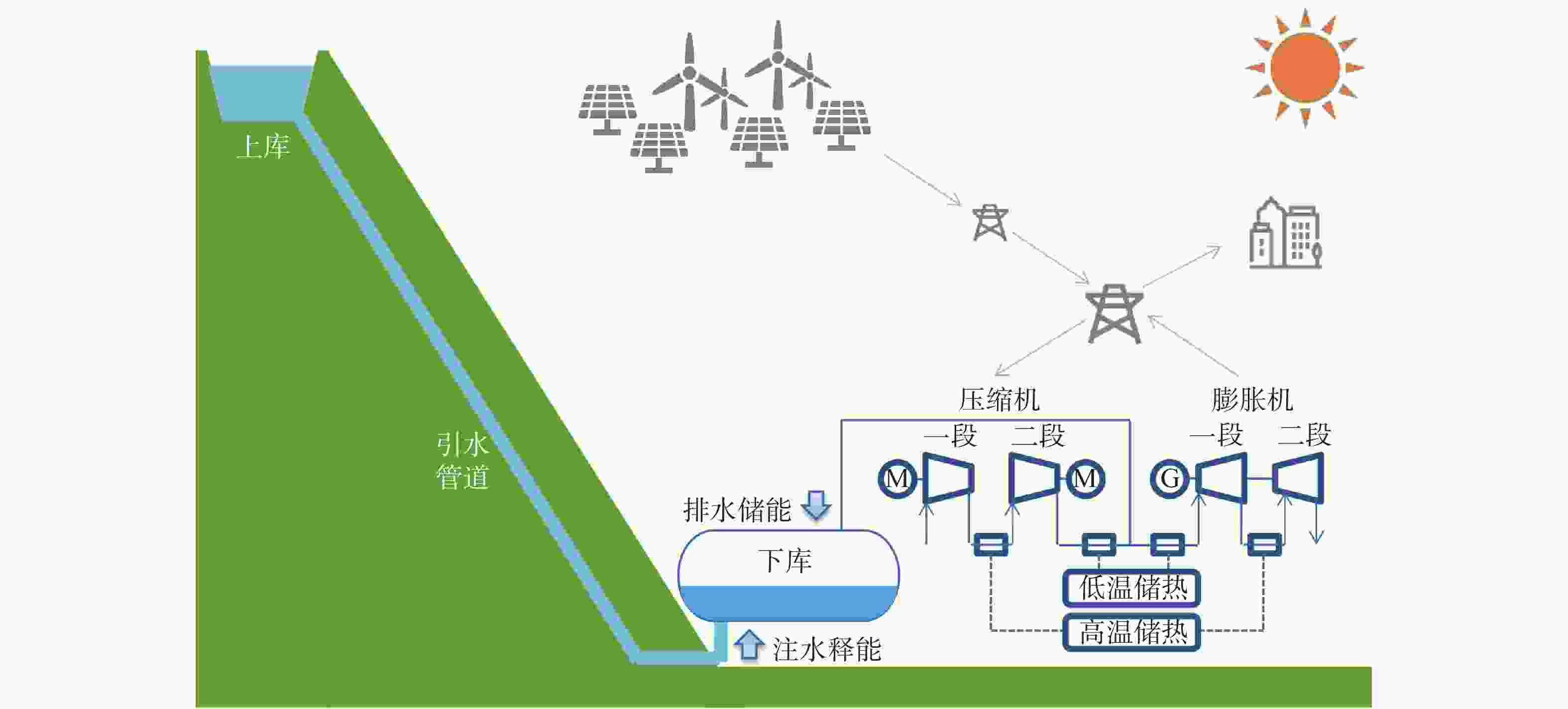

本文提出在现有抽水蓄能技术基础上,引入压缩空气技术,形成耦合抽水蓄能的压缩空气储能电站。耦合抽水蓄能的压缩空气储能电站的能量密度可提升数倍,厂址要求大大降低,甚至可使发展抽水蓄能受限的地区具备开发条件。

-

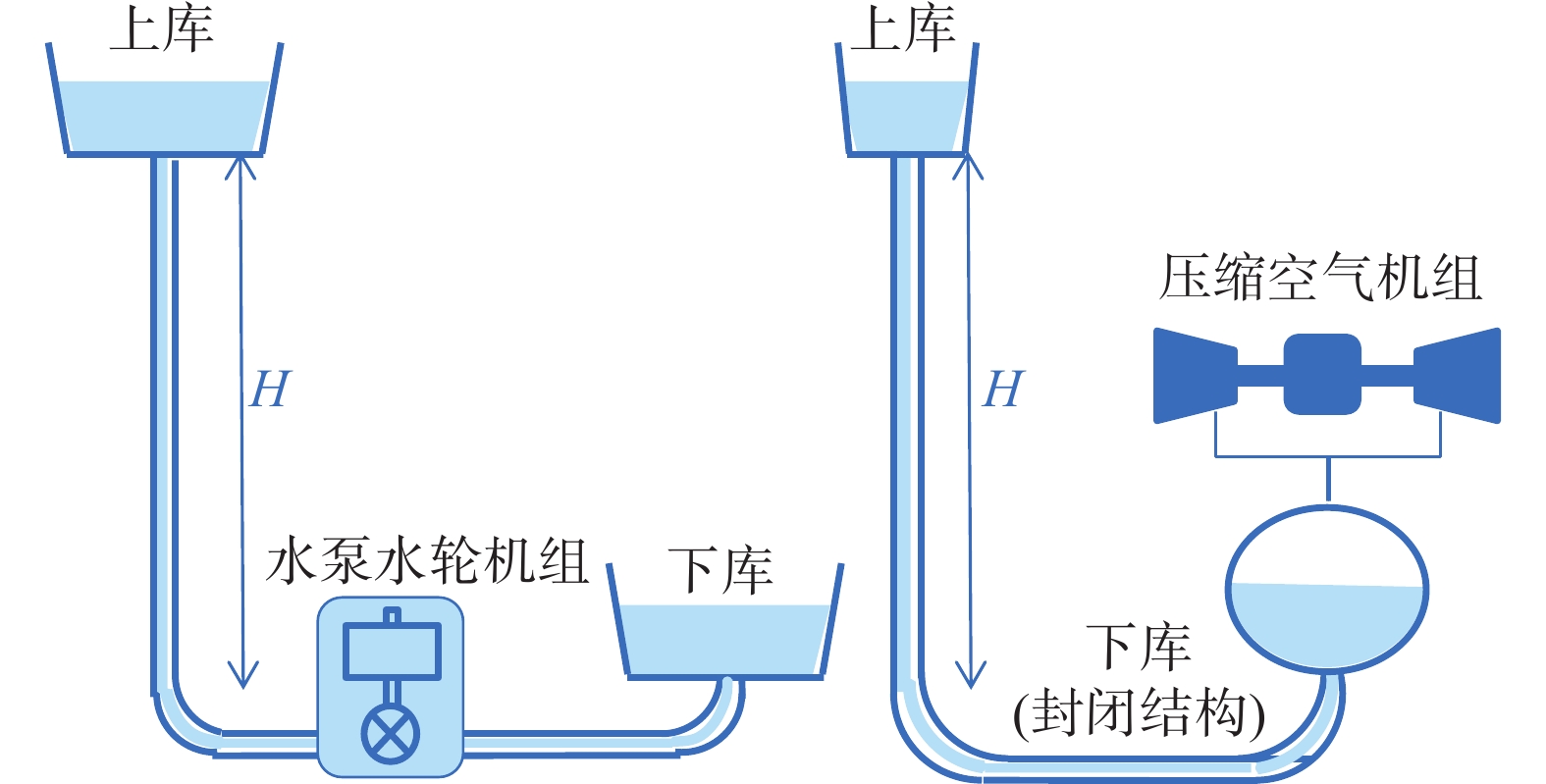

常规抽水蓄能的储能、释能设备是水泵水轮机,通过水泵水轮机上、下“搬运”水来实现能量转换。若要降低抽水蓄能厂址要求,必须想方设法减小库容或上、下库高度差。如果能够使“搬运”单位水量所转换的能量增大,对于给定的储能容量和上、下库高度差,则需要“搬运”的水量就可以减少,库容相应地减小。对于给定的储能容量和库容,则有可能使上、下库高度差减小。

除了使用水泵外,用压缩气体也可以推动液体,这在许多领域都有运用,例如:核电厂在发生事故时,非能动安全系统采用预先储存的高压氮气将安注箱中的水注入堆芯,以避免使用需要外部电力驱动的水泵[8]。如果将常规抽水蓄能电站的下库改成封闭结构的承压容器,将水泵抽水改成压缩空气排水,水轮机发电改成膨胀机发电,则可产生一种耦合抽水蓄能的压缩空气储能方式,两者的对比如图1所示。从原理上,耦合抽水蓄能的压缩空气储能方式借助压缩空气机组,运用压缩空气与水的相互作用力来上、下“搬运”水;同时,储能形式也由单独的抽水蓄能变成抽水蓄能和压缩空气储能耦合,储能介质既有水也有空气。如果压缩空气的能量相比水的重力势能是一个足够大的量级,则耦合抽水蓄能的压缩空气储能电站可达到改良目标。

图 1 常规抽水蓄能(左)与耦合抽水蓄能的压缩空气储能(右)对比

Figure 1. Comparison between conventional pumped hydro storage (left) and compressed air energy storage power plant coupled with pumped hydro storage (right)

按照上述想法,进一步对耦合抽水蓄能的压缩空气储能系统的能量转换进行量化分析。压缩空气做功近似地按照理想气体可逆等温压缩过程来计算:

$$ W_{{\rm{c}}}=m{\rm{R}}T{\rm{ln}}\varepsilon$$ (1) 式中:

Wc ——空气压缩耗功(kJ);

m ——空气质量(kg);

R ——空气气体常数0.287 kJ/(kg·K);

T ——空气的绝对温度,取298 K;

ε ——压缩空气的压比。

水泵做功近似为水的重力势能。选择100~600 m高度差,下库压力取1~6 MPa(忽略上库表面大气压),抽水1 m3,压缩空气排水耗功与水泵抽水耗功的对比列于表1,相同高度差条件下,压缩空气排水耗功是水泵抽水耗功的2.3~4.1倍。同理,在上述条件下,也可推导出放水过程空气膨胀做功也是水轮机做功的同等倍数。由表1也可见,高度差100 m压缩空气排水耗功相当于高度差约230 m水泵抽水耗功,高度差200 m压缩空气排水耗功相当于高度差约600 m水泵抽水耗功。因此,采取这种新方法可使抽水蓄能单位水量的能量转换增加数倍,从而达到减小库容或上、下库高度差的目的。

表 1 压缩空气排水耗功与水泵抽水耗功对比

Table 1. Comparison of power consumption between water drainage by compressed air and water pumping by water pump

抽水量/

m3高度差/

m压比 压缩空气排水

耗功/kJ水泵抽水

耗功/kJ能量比 1 100 10 2.3×103 9.8×102 2.3 1 200 20 6.0×103 2.0×103 3.0 1 300 30 1.0×104 2.9×103 3.4 1 400 40 1.5×104 3.9×103 3.7 1 500 50 2.0×104 4.9×103 4.0 1 600 60 2.5×104 5.9×103 4.1 -

耦合抽水蓄能的压缩空气储能电站包括:两个相互连接且位于不同高度的水库,即上、下库,以及压缩空气机组(压缩机、膨胀机以及用于回收压缩热的储热装置),引水管道连接上、下库。上库位于高位,为常规的水库。下库位于低位,为封闭结构的承压容器储库,用于储存水和压缩空气。上、下库高差宜在100 m以上,优选200 m以上。

耦合抽水蓄能的压缩空气储能电站的运行过程如下:储能过程中,由压缩机将空气压缩至高压,压缩热通过换热器回收并储存于储热装置,常温的高压空气充入下库,并推挤下库内的水经引水管道输送至上库,由上库通过引水管道为下库中的压缩空气提供基本恒定的水封压力。

释能过程中,上库中的水经引水管道返回到下库,下库内的压缩空气不断被推挤出下库,储热装置释放热量并通过换热器回热压缩空气,回热后的压缩空气经膨胀机完成做功后释放至大气,释能过程中,下库中的空气压力也基本恒定。

耦合抽水蓄能的压缩空气储能电站与采用排水空间的恒压式压缩空气储能电站相似,而区别于常规的压缩空气储能电站[9-10]:压缩空气储能电站储气压力可达10 MPa或更高、运行过程储气库压力变化、储气库垫底气量可达70%以上,耦合抽水蓄能的压缩空气储能电站储气压力低、运行压力恒定、无垫底气量。因此,耦合抽水蓄能的压缩空气储能电站实现了抽水蓄能与压缩空气储能的优势互补。

-

耦合抽水蓄能的压缩空气储能电站概念方案中,以确保机组安全、可靠为首要原则,采用现有成熟的工艺和设备。

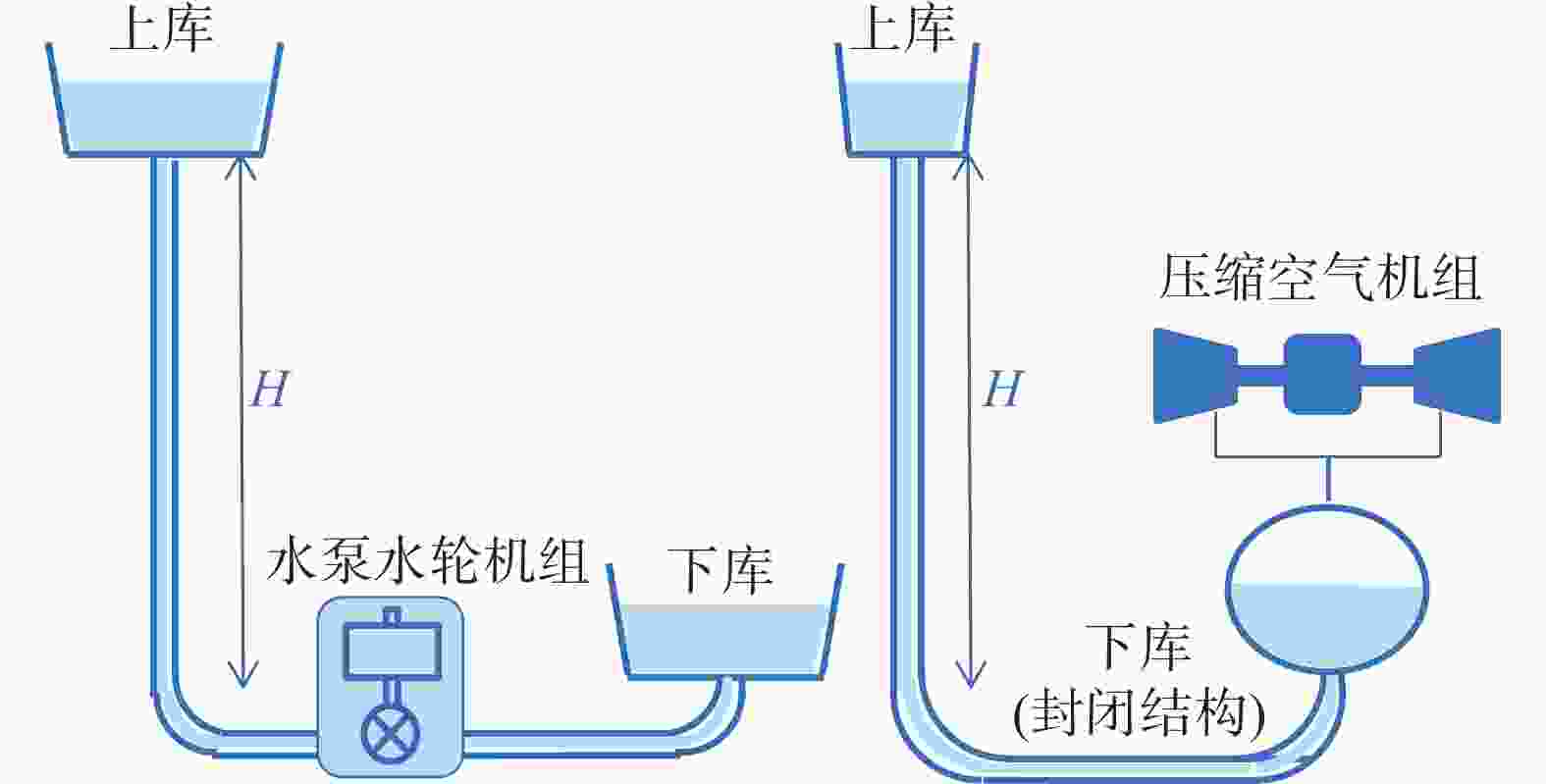

首先是上、下库高度差的选取。假设选址区域为山岭,上库位于山顶,下库位于山脚,两者高度差300 m,对应的工作压力为3 MPa(忽略上库表面大气压)。这对于压缩机的工作压力和下库的承压能力来说也都比较合适。大型空气压缩机在深冷空分装置中广泛应用,排气压力可达7 MPa[11],国产设备技术已成熟。更高压力的大型空气压缩机已开始在压缩空气储能示范电站应用[9-10],压力可达10 MPa以上[11-12]。下库可采用洞穴或压力容器,前者包括废弃矿洞或人造洞穴的方式[13-14],后者包括球罐或管道的方式[15]。对于3 MPa压力,球罐和管道(如高压天然气管道)均可适用,且产品成熟,应用广泛,无特殊选址要求。人造洞穴可在山体内或地下开挖,以减少下库占地。

其次是储能容量的选取。传统抽水蓄能电站往往由多台300 MW等级的水泵水轮机组成,发电时长5 h以上。但是,对于单机容量300 MW等级,耦合抽水蓄能的压缩空气储能电站还没有成熟的配套压缩机。考虑到国内空分行业最高等级的空分装置为12万Nm3/h[9],对应的空气压缩机流量60万Nm3/h以上,本文概念方案中保守地选取约20万Nm3/h流量,对应约40 MW容量等级,5 h的发电量200 MWh,可确保压缩机设备成熟可靠。

最后是压缩空气机组的布置。最高压力3 MPa,对应的压比30,从降低设备复杂性的角度,采用两段压缩和两段膨胀。第一段压缩机压比10,第二段压缩机压比3,两段压缩机单独配套电动机。第一段膨胀机膨胀比3,第二段膨胀机膨胀比10,两段膨胀机共同驱动1台发电机。压缩机排气热量用储热方法回收,并用于回热膨胀机进气。第一段压缩机排气热量温度高,可采用导热油储热,第二段压缩机排气热量温度低,可采用高压水储热。考虑高温储热成本高,也可采用三段压缩和三段膨胀方式。

根据上述参数,耦合抽水蓄能的压缩空气储能电站概念方案如图2所示。需要说明的是,实际方案应根据厂址条件因地制宜选择以及优化各项参数,并根据所需储能容量选择设备型号和设备布置。

-

耦合抽水蓄能的压缩空气储能电站的储能效率主要取决于压缩空气机组的性能,水输送过程的损耗和其他微量损失可控制到很小。选取两套性能参数如表2所示,对储能效率及其他指标进行计算。第一套基于现有成熟设备的技术水平;第二套总体性能比第一套高,这些性能指标通过进一步研发可以达到。两套参数的膨胀机等熵效率和电机效率相同,这是由于膨胀机和电机技术水平已基本到顶。

表 2 耦合抽水蓄能的压缩空气储能电站概念方案设备性能参数

Table 2. Performance parameters of equipment under the conceptual scheme of compressed air energy storage power plant coupled with pumped hydro storage

设备性能参数 设备性能参数值 设备低性能 设备高性能 一段压缩机等熵效率 0.820 0.845 二段压缩机等熵效率 0.835 0.860 一段压缩机机械效率 0.980 0.990 二段压缩机机械效率 0.980 0.990 一段压缩机电动机效率 0.980 0.980 二段压缩机电动机效率 0.980 0.980 一段膨胀机等熵效率 0.900 0.900 二段膨胀机等熵效率 0.930 0.930 膨胀机机械效率 0.980 0.990 发电机效率 0.980 0.980 换热器压损/MPa 0.100 0.050 高温回热温差/℃ 40 35 低温回热温差/℃ 25 20 根据表2的设备性能参数,通过热力学分析方法,运用干空气的物性数据,获得图2所示耦合抽水蓄能的压缩空气储能电站概念方案在额定工况下流量、温度、压力等关键状态参数,并进一步获得设备做功参数,相关数据列于表3。上、下库液位变化引起的高度差的变化,相比总的高度差而言非常小,为便于计算,计算过程中忽略此影响。引水管道的流动阻力损失取0.1 MPa。储能过程时长8 h,释能过程时长5 h。储能效率为:

表 3 耦合抽水蓄能的压缩空气储能电站概念方案额定工况状态参数

Table 3. State parameters of rated condition under the conceptual scheme of compressed air energy storage power plant coupled with pumped hydro storage

额定工况状态参数 状态参数值 设备低性能 设备高性能 压缩机流量/(Nm3·h−1) 2.05×105 2.02×105 一段压缩机进口温度/℃ 20.00 20.00 一段压缩机进口压力/MPa 0.098 0.098 一段压缩机出口温度/℃ 349.62 340.17 一段压缩机出口压力/MPa 1.00 1.00 一段电动机功率/MW 25.94 24.82 二段压缩机进口温度/℃ 35.00 35.00 二段压缩机进口压力/MPa 0.90 0.95 二段压缩机出口温度/℃ 195.61 181.06 二段压缩机出口压力/MPa 3.20 3.15 一段电动机功率/MW 12.48 11.17 储能输入电量/MWh 307.29 285.00 膨胀机流量/(Nm3·h−1) 3.28×105 3.24×105 一段膨胀机进口温度/℃ 170.61 161.06 一段膨胀机进口压力/MPa 2.80 2.85 一段膨胀机出口温度/℃ 77.01 67.82 一段膨胀机出口压力/MPa 1.10 1.10 二段膨胀机进口温度/℃ 309.62 305.17 二段膨胀机进口压力/MPa 1.00 1.05 二段膨胀机出口温度/℃ 53.54 47.01 二段膨胀机出口压力/MPa 0.103 0.103 发电机功率/MW 40.37 40.37 释能输出电量/MWh 201.83 201.83 储能效率/% 65.68 70.81 水量/m3 5.90×104 5.82×104 能量密度/(kWh·m−3) 1.67 1.67 $$ \eta =E_{{\rm{out}}}/E_{{\rm{in}}}$$ (2) 式中:

η ——储能效率;

Eout ——释能过程输出电量(kWh);

Ein ——储能过程输入电量(kWh)。

能量密度近似为:

$$ D=E_{{\rm{out}}}/(V_{{\rm{up}}}+ V_{{\rm{low}}})$$ (3) 式中:

D ——能量密度(kWh/m3);

Vup ——上库容量(m3);

Vlow ——下库容量(m3)。

这里,Vup与Vlow相等。

表3给出了40 MW/200 MWh耦合抽水蓄能的压缩空气储能电站概念方案的各项指标,其中,压缩机流量约20万Nm3/h,膨胀机流量约32万Nm3/h。在低性能参数条件下,系统的储能效率65.68%,在高性能参数条件下,系统的储能效率70.81%。耦合抽水蓄能的压缩空气储能电站概念方案的储能效率低于常规抽水蓄能75%的储能效率。

由表3中水量数据,概念方案的上、下库容各约6万m3,能量密度1.67 kWh/m3。在同样的300 m高度差条件下,常规抽水蓄能的能量密度约为0.4 kWh/m3,即上、下库的库容各25万m3,才能达到200 MWh的储能容量。或者,在6万m3库容条件下,高度差约为1 200 m的常规抽水蓄能电站才能达到1.67 kWh/m3的能量密度和200 MWh的储能容量。

运用同样方法,也可分析其他高度差下的情况,如200 m高度差下,储能效率与300 m高度差条件下接近,库容10.5万m3,储能密度0.95 kWh/m3,相同高度差下的常规抽水蓄能库容需40万m3,或者相同库容下的常规抽水蓄能高度差需750 m。

上述计算证实,耦合抽水蓄能的压缩空气储能方法可以达到减小库容或上、下库高度差的效果。

-

耦合抽水蓄能的压缩空气储能电站运用压缩空气的方法使“搬运”水的过程所涉及的能量转换量增加数倍,从而大幅提升系统的能量密度,同等高度差下,库容仅为常规抽水蓄能的1/4左右,或者同等库容条件下,高度差仅为常规抽水蓄能的1/4左右,可根本性缓解抽水蓄能厂址资源需求与自然资源稀缺的矛盾,也可以使原先发展抽水蓄能受限的地区具备开发条件。

就工程可实施性而言,具备100 m以上高度差的地区,如有储能需求,即可选址开发耦合抽水蓄能的压缩空气储能电站。我国丘陵地带广,海拔在200 m以上,500 m以下,有大片山岭,以及众多山塘水库,还有一大批小水电站,均属于选址资源,其中具备200 m以上高度差的厂址就是优良的耦合抽水蓄能的压缩空气储能电站厂址。对于现有的抽水蓄能电站,还可以利用其小部分的上库容量,配套下库和压缩空气机组,即可扩建耦合抽水蓄能的压缩空气储能电站,使整个电站的储能容量扩大。因此,对于100~300 m区间,不太适合常规抽水蓄能选址的地区,耦合抽水蓄能的压缩空气储能电站恰好能发挥作用,既可建设集中式大型电站,也可建设分布式小型电站。

-

耦合抽水蓄能的压缩空气储能电站的关键设备是压缩机、膨胀机,其中前者是制约性因素。根据空分装置压缩机发展现状,现有压缩机技术水平可支撑单机100 MW的耦合抽水蓄能的压缩空气储能电站。现有的膨胀机技术水平发展比较成熟,大型的空气膨胀机还可以借鉴火力发电汽轮机和燃气轮机技术。根据压缩空气储能技术的发展,60 MW和100 MW压缩空气储能示范电站已建成并网,但还有待后续运行考验。因此,在现阶段,耦合抽水蓄能的压缩空气储能电站单机容量宜在100 MW等级以内,更大容量的电站可采取多套机组并联方案。

-

建设上文装机容量40 MW的低性能参数的耦合抽水蓄能的压缩空气储能电站,均采用成熟技术,相关设备均已实现国产化。下库的选型对于经济性有重要影响:一方面,人造洞穴比较有发展前途[13],单位造价2 500~3 000元/kW;另一方面,天然气长输管道也有一定竞争力,特别是随着钢铁价格回落,管道储气单位造价约3 000元/kW,也具备较好的技术经济性。初步估算,上、下库及引水管道等水工部分的单位造价约4 500元/kW,压缩机、膨胀机及储热装置等机组部分的单位造价约2 500元/kW,电站单位造价约7 000元/kW。批量化或规模化建造,单价造价可降低至6 000元/kW。对于高性能参数的系统,技术成熟后的单位造价也在同等水平。近年来,大型抽水蓄能电站单位造价已高于6 000元/kW,甚至达到7 000元/kW[16]。

耦合抽水蓄能的压缩空气储能电站运行过程中产生的损耗绝大部分为中低温余热形式,若加以综合利用(如冬季采暖),则可显著提高其能效,而常规抽水蓄能损耗无法回收。耦合抽水蓄能的压缩空气储能电站选址和建造难度降低,项目周期可缩短至2~3 a,而常规抽水蓄能项目周期在5 a以上。两种储能电站的服役寿期均可达到30 a以上。总体上,耦合抽水蓄能的压缩空气储能电站具有良好的技术经济性。

-

压缩空气储能具有规模大、成本低、效率高等优势,被认为是最具有发展前景的大规模储能技术。近年来,压缩空气储能与可再生能源耦合系统研究进展显著[17],涌现出压缩空气储能与风能耦合系统[18-19],压缩空气储能-太阳能耦合系统[20-21],压缩空气储能与生物质能耦合系统[22-23] ,压缩空气储能-地热能耦合系统[24] ,压缩空气储能-氢能耦合系统[25]等多种技术。本文为了缓解抽水蓄能厂址资源需求与自然资源稀缺的矛盾,提出了一种压缩空气储能与抽水蓄能耦合系统,并从研究思路、概念方案和工程可行性进行分析,从而为抽水蓄能产业发展提供创新解决方案。

1)耦合抽水蓄能的压缩空气储能电站用压缩机和膨胀机取代了水泵水轮机,储、释能过程的能量转换量放大,可使其库容或高度差大幅减小,降低建造抽水蓄能电站对于厂址资源的要求,可使发展抽水蓄能受限的地区具备开发条件。

2)耦合抽水蓄能的压缩空气储能电站上、下库高度差100 m以上即可,上库可利用山岭、山塘水库、小水电站以及现有抽水蓄能电站等,下库可采用洞穴或地面容器。

3)对于本文40 MW/200 MWh耦合抽水蓄能的压缩空气储能电站概念方案,高度差300 m,在低性能参数条件下,储能效率65.68%,在高性能参数条件下,储能效率70.81%,能量密度1.67 kWh/m3。

4)耦合抽水蓄能的压缩空气储能电站单位造价与常规抽水蓄能电站相近,但后者厂址资源稀缺、项目建设周期长,因此,有必要因地制宜发展更加灵活的耦合抽水蓄能的压缩空气储能电站作为补充,以满足新型电力系统的储能需求。

耦合抽水蓄能的压缩空气储能电站概念研究

DOI: 10.16516/j.gedi.issn2095-8676.2023.02.003

CSTR: 32391.14.j.gedi.issn2095-8676.2023.02.003

Concept Research of Compressed Air Energy Storage Power Plant Coupled with Pumped Hydro Storage

-

摘要:

目的 储能是发展新能源、实现碳达峰碳中和目标的基础条件,其中抽水蓄能是最主要的储能方式,但是抽水蓄能依赖地理条件,需要占用大量自然资源,优良的厂址资源十分有限。为了缓解抽水蓄能厂址资源需求与自然资源稀缺的矛盾,提出了一种耦合抽水蓄能的压缩空气储能系统,并从研究思路、概念方案和工程可行性进行分析,从而为抽水蓄能产业发展提供创新解决方案。 方法 围绕提高能量密度,以减小水库容量、降低水库高度差为突破点,运用压缩空气排水的方法,将水泵水轮机替换为压缩机和膨胀机,下库改为封闭结构的承压容器。储能时,压缩机将空气压缩至高压充入下库,并推挤下库内的水至上库。释能时,水从上库返回下库,下库内的压缩空气被推挤出,并经膨胀机释放。这可使相同条件下抽水蓄能的能量转换量提高数倍。为了论证耦合抽水蓄能的压缩空气储能电站的储能效果,设置上、下库高度差300 m,按照低性能和高性能两套设备参数,对40 MW/200 MWh的概念方案进行热力学分析和储能效率计算。 结果 结果表明:在低性能参数条件下,储能效率65.68%,在高性能参数条件下,储能效率70.81%;能量密度1.67 kWh/m3。 结论 耦合抽水蓄能的压缩空气储能系统可使水库容量或高度差大幅减小,大大降低厂址要求,并可使发展抽水蓄能受限的地区具备开发条件,且关键设备成熟,单位造价与常规抽水蓄能相近,技术经济上可行。 Abstract:Introduction Energy storage is the basic condition for the development of new energy and the realization of carbon neutrality, where the pumped hydro storage is the most important energy storage method. However, pumped hydro storage depends on geographical conditions and needs to occupy a lot of natural resources, and excellent site resources are very limited. In order to alleviate the contradiction between the demand for pumped hydro storage plant site resources and the scarcity of natural resources, a compressed air energy storage system coupled with pumped hydro storage is proposed and analyzed from the perspective of research idea, conceptual scheme and engineering feasibility so as to provide innovative solutions for the development of the pumped hydro storage industry. Method By focusing on the improvement of the energy storage density, with the reduction of the reservoir capacity and height difference as the breakthrough point, the method of water drainage with compressed air was adopted. The pump turbine was replaced with compressor and expander, and the upper reservoir was changed into a pressure vessel with closed structure. When storing energy, air compressed by the compressor to high pressure and then filled into the lower reservoir to push the water from the lower reservoir to the upper reservoir. When releasing energy, the water returned from the upper reservoir to the lower reservoir, and the compressed air in the lower reservoir was pushed out and released by the expander. This could increase the energy conversion quantity of pumped hydro storage by several times under the same conditions. In order to demonstrate the energy storage effect of the compressed air energy storage power plant coupled with pumped hydro storage, a height difference of 300 m was set between the upper and lower reservoirs, and the thermodynamic analysis and energy storage efficiency calculation of the conceptual scheme of 40 MW/200 MWh were carried out according to the two sets of equipment parameters with low performance and high performance. Result The results show that the energy storage efficiency is 65.68% under the condition of low performance parameters and 70.81% under the condition of high performance parameters; the energy density is 1.67 kWh/m3. Conclusion The compressed air energy storage system coupled with pumped hydro storage can greatly reduce the reservoir capacity or height difference, significantly reduce the site demand and enable the areas with limited development of pumped hydro storage to have development conditions. Besides, the key equipment are mature, and the unit cost is close to that of the conventional pumped hydro storage. Therefore, this kind of compressed air energy storage system is technically and economically feasible. -

Key words:

- energy storage /

- pumped hydro storage /

- compressed air /

- energy density /

- energy storage efficiency /

- compressor /

- expander

-

表 1 压缩空气排水耗功与水泵抽水耗功对比

Tab. 1. Comparison of power consumption between water drainage by compressed air and water pumping by water pump

抽水量/

m3高度差/

m压比 压缩空气排水

耗功/kJ水泵抽水

耗功/kJ能量比 1 100 10 2.3×103 9.8×102 2.3 1 200 20 6.0×103 2.0×103 3.0 1 300 30 1.0×104 2.9×103 3.4 1 400 40 1.5×104 3.9×103 3.7 1 500 50 2.0×104 4.9×103 4.0 1 600 60 2.5×104 5.9×103 4.1 表 2 耦合抽水蓄能的压缩空气储能电站概念方案设备性能参数

Tab. 2. Performance parameters of equipment under the conceptual scheme of compressed air energy storage power plant coupled with pumped hydro storage

设备性能参数 设备性能参数值 设备低性能 设备高性能 一段压缩机等熵效率 0.820 0.845 二段压缩机等熵效率 0.835 0.860 一段压缩机机械效率 0.980 0.990 二段压缩机机械效率 0.980 0.990 一段压缩机电动机效率 0.980 0.980 二段压缩机电动机效率 0.980 0.980 一段膨胀机等熵效率 0.900 0.900 二段膨胀机等熵效率 0.930 0.930 膨胀机机械效率 0.980 0.990 发电机效率 0.980 0.980 换热器压损/MPa 0.100 0.050 高温回热温差/℃ 40 35 低温回热温差/℃ 25 20 表 3 耦合抽水蓄能的压缩空气储能电站概念方案额定工况状态参数

Tab. 3. State parameters of rated condition under the conceptual scheme of compressed air energy storage power plant coupled with pumped hydro storage

额定工况状态参数 状态参数值 设备低性能 设备高性能 压缩机流量/(Nm3·h−1) 2.05×105 2.02×105 一段压缩机进口温度/℃ 20.00 20.00 一段压缩机进口压力/MPa 0.098 0.098 一段压缩机出口温度/℃ 349.62 340.17 一段压缩机出口压力/MPa 1.00 1.00 一段电动机功率/MW 25.94 24.82 二段压缩机进口温度/℃ 35.00 35.00 二段压缩机进口压力/MPa 0.90 0.95 二段压缩机出口温度/℃ 195.61 181.06 二段压缩机出口压力/MPa 3.20 3.15 一段电动机功率/MW 12.48 11.17 储能输入电量/MWh 307.29 285.00 膨胀机流量/(Nm3·h−1) 3.28×105 3.24×105 一段膨胀机进口温度/℃ 170.61 161.06 一段膨胀机进口压力/MPa 2.80 2.85 一段膨胀机出口温度/℃ 77.01 67.82 一段膨胀机出口压力/MPa 1.10 1.10 二段膨胀机进口温度/℃ 309.62 305.17 二段膨胀机进口压力/MPa 1.00 1.05 二段膨胀机出口温度/℃ 53.54 47.01 二段膨胀机出口压力/MPa 0.103 0.103 发电机功率/MW 40.37 40.37 释能输出电量/MWh 201.83 201.83 储能效率/% 65.68 70.81 水量/m3 5.90×104 5.82×104 能量密度/(kWh·m−3) 1.67 1.67 -

[1] 郑琼, 江丽霞, 徐玉杰, 等. 碳达峰、碳中和背景下储能技术研究进展与发展建议 [J]. 中国科学院院刊, 2022, 37(4): 529-540. DOI: 10.16418/j.issn.1000-3045.20220311001. ZHENG Q, JIANG L X, XU Y J, et al. Research progress and development suggestions of energy storage technology under background of carbon peak and carbon neutrality [J]. Bulletin of Chinese Academy of Sciences, 2022, 37(4): 529-540. DOI: 10.16418/j.issn.1000-3045.20220311001. [2] 陈海生, 俞振华, 刘为. 储能产业研究白皮书2022 [M]. 北京: 中国能源研究会储能专委会, 2022. CHEN H S, YU Z H, LIU W. White paper on energy storage industry research 2022 [M]. Beijing: China Energy Storage Alliance, 2022. [3] 中国能源报. 国网南网抽蓄电站建设计划雄心勃勃 [EB/OL]. (2022-03-08)[2022-05-20]. https://baijiahao.baidu.com/s?id=1728480101196728180&wfr=spider&for=pc. China Energy News. The state grid southern grid project is ambitious[EB/OL]. (2022-03-08)[2022-05-20]. https://baijiahao.baidu.com/s?id=1728480101196728180&wfr=spider&for=pc. [4] TER-GAZARIAN A G. Energy storage for power systems [M]. London: Institution of Engineering and Technology, 2011. [5] 赵会林, 鲁新蕊. 抽水蓄能电站的选点原则 [J]. 东北水利水电, 2012, 30(4): 1-2. DOI: 10.14124/j.cnki.dbslsd22-1097.2012.04.030. ZHAO H L, LU X R. Principles of site selection for pumped storage power station [J]. Water Resources & Hydropower of Northeast China, 2012, 30(4): 1-2. DOI: 10.14124/j.cnki.dbslsd22-1097.2012.04.030. [6] SLOCUM A H, MAY W M, MAY A H, et al. Innovative pumped storage hydropower configurations and uses [M]. America: Pumped Storage Hydropower International Forum, 2021. [7] PUJADES E, ORBAN P, BODEUX S, et al. Underground pumped storage hydropower plants using open pit mines: how do groundwater exchanges influence the efficiency? [J]. Applied Energy, 2017, 190: 135-146. DOI: 10.1016/j.apenergy.2016.12.093. [8] 孙汉虹, 程平东, 缪鸿兴, 等. 第三代核电技术AP1000(2版) [M]. 北京: 中国电力出版社, 2016. SUN H H, CHENG P D, LIAO H X, et al. The third generation nuclear power technology AP1000 (2nd ed. ) [M]. Beijing: China Electric Power Press, 2016. [9] 张新敬, 陈海生, 刘金超, 等. 压缩空气储能技术研究进展 [J]. 储能科学与技术, 2012, 1(1): 26-40. ZHANG X J, CHEN H S, LIU J C, et al. Research progress in compressed air energy storage system: a review [J]. Energy Storage Science and Technology, 2012, 1(1): 26-40. [10] 郭祚刚, 马溪原, 雷金勇, 等. 压缩空气储能示范进展及商业应用场景综述 [J]. 南方能源建设, 2019, 6(3): 17-26. DOI: 10.16516/j.gedi.issn2095-8676.2019.03.003. GUO Z G, MA X Y, LEI J Y, et al. Review on demonstration progress and commercial application scenarios of compressed air energy storage system [J]. Southern Energy Construction, 2019, 6(3): 17-26. DOI: 10.16516/j.gedi.issn2095-8676.2019.03.003. [11] 吴丰, 石雷雷, 李晓锋. 国内空分技术的现状与进展 [J]. 中氮肥, 2016(5): 52-56. DOI: 10.16612/j.cnki.issn1004-9932.2016.05.015. WU F, SHI L L, LI X F. Present situation and development of domestic air separation technology [J]. M-Sized Nitrogenous Fertilizer Progress, 2016(5): 52-56. DOI: 10.16612/j.cnki.issn1004-9932.2016.05.015. [12] 李广阔, 王国华, 薛小代, 等. 金坛盐穴压缩空气储能电站调相模式设计与分析 [J]. 电力系统自动化, 2021, 45(19): 91-99. DOI: 10.7500/AEPS20210120006. LI G K, WANG G H, XUE X D, et al. Design and analysis of condenser mode for Jintan salt cavern compressed air energy storage plant of China [J]. Automation of Electric Power Systems, 2021, 45(19): 91-99. DOI: 10.7500/AEPS20210120006. [13] 蒋中明, 唐栋, 李鹏, 等. 压气储能地下储气库选型选址研究 [J]. 南方能源建设, 2019, 6(3): 6-16. DOI: 10.16516/j.gedi.issn2095-8676.2019.03.002. JIANG Z M, TANG D, LI P, et al. Research on selection method for the types and sites of underground repository for compressed air storage [J]. Southern Energy Construction, 2019, 6(3): 6-16. DOI: 10.16516/j.gedi.issn2095-8676.2019.03.002. [14] 郭朝斌, 李采, 杨利超, 等. 压缩空气地质储能研究现状及工程案例分析 [J]. 中国地质调查, 2021, 8(4): 109-119. DOI: 10.19388/j.zgdzdc.2021.04.12. GUO C B, LI C, YANG L C, et al. Research review and engineering case analysis of geological compressed air energy storage [J]. Geological Survey of China, 2021, 8(4): 109-119. DOI: 10.19388/j.zgdzdc.2021.04.12. [15] 郭丁彰, 尹钊, 周学志, 等. 压缩空气储能系统储气装置研究现状与发展趋势 [J]. 储能科学与技术, 2021, 10(5): 1486-1493. DOI: 10.19799/j.cnki.2095-4239.2021.0356. GUO D Z, YIN Z, ZHOU X Z, et al. Status and prospect of gas storage device in compressed air energy storage system [J]. Energy Storage Science and Technology, 2021, 10(5): 1486-1493. DOI: 10.19799/j.cnki.2095-4239.2021.0356. [16] 中华人民共和国中央人民政府. 江苏句容抽水蓄能电站开建[EB/OL]. (2016-12-09) [2022-05-20]. http://www.gov.cn/xinwen/2016-12/09/content_5145531.htm. Central People's Government of the People's Republic of China. Pumped storage power station began construction in Jurong, Jiangsu Province [EB/OL]. (2016-12-09) [2022-05-20]. http://www.gov.cn/xinwen/2016-12/09/content_5145531.htm. [17] 孙晓霞, 桂中华, 张新敬, 等. 压缩空气储能与可再生能源耦合研究进展[J/OL]. 中国电机工程学报: 1-20 [2023-03-02]. DOI: 10.13334/j.0258-8013.pcsee.221437. SUN X X , GUI Z H , ZHANG X J, et al. Research Progress on Compressed Air Energy Storage Coupled with Renewable Energy[J/OL]. Proceedings of the CSEE: 1-20 [2023-03-02]. DOI: 10.13334/j.0258-8013.pcsee.221437. [18] ZHANG Y, XU Y, GUO H, et al. A hybrid energy storage system with optimized operating strategy for mitigating wind power fluctuations [J]. Renewable Energy, 2018, 125: 121-3. DOI: 10.1016/j.renene.2018.02.058. [19] ZHANG Y, XU Y, ZHOU X, et al. Compressed air energy storage system with variable configuration for accommodating large-amplitude wind power fluctuation [J]. Applied Energy, 2019, 239: 957-968. DOI: 10.1016/j.apenergy.2019.01.250. [20] MOHAMMADI A, MEHRPOOYA M. Exergy analysis and optimization of an integrated micro gas turbine, compressed air energy storage and solar dish collector process [J]. Journal of Cleaner Production, 2016, 139: 372-83. DOI: 10.1016/j.jclepro.2016.08.057. [21] 韩中合, 安鹏, 郭森闯, 等. 基于太阳能辅热的AA-CAES热力性能分析 [J]. 太阳能学报, 2020, 41(8): 243-250. DOI: 10.19912/j.0254-0096.2020.08.033. Han Z H, An P, Guo S C, et al. Thermaldynamic performance analysis of advanced adiabatic compressed air energy storage system based on solar auxiliary heating [J]. Acta Energiae Solaris Sinica, 2020, 41(8): 243-250. DOI: 10.19912/j.0254-0096.2020.08.033. [22] RAZMI A R, HEYDARI A H, POURAHMADIYAN A, et al. Investigation of a combined heat and power (CHP) system based on biomass and compressed air energy storage (CAES) [J]. Sustainable Energy Technologies and Assessments, 2021, 46: 101253. DOI: 10.1016/j.seta.2021.101253. [23] LLAMAS B, ORTEGA M F, BARTHELEMY G, et al. Development of an efficient and sustainable energy storage system by hybridization of compressed air and biogas technologies (BIO-CAES) [J]. Energy Conversion and Management, 2020, 210: 112695. DOI: 10.1016/j.enconman.2020.112695. [24] ALIRAHMI S M, RAZMI A R, ARABKOOHSAR A. Comprehensive assessment and multi-objective optimization of a green concept based on a combination of hydrogen and compressed air energy storage (CAES) systems [J]. Renewable and Sustainable Energy Reviews, 2021, 142: 110850. DOI: 10.1016/j.rser.2021.110850. [25] BARTELA U. A hybrid energy storage system using compressed air and hydrogen as the energy carrier [J]. Energy, 2020, 196: 117088. DOI: 10.1016/j.energy.2020.117088. -

下载:

下载: