-

风能、太阳能等可再生能源的大规模利用已成为大势所趋。截至2022年底,全国累计风电装机容量约370 GW,同比增长11.2%;太阳能发电装机容量约390 GW,同比增长28.1%[1]。相关机构预测,到2050年可再生能源在我国能源体系中占比有望达到78.0%[2]。但可再生能源发电存在不稳定、波动性强等缺点,因此储能技术成为解决新能源发电大规模并网问题的有效手段[3-5]。截至2021年底,全国储能装机规模达到42.66 GW,其中新型储能装机6.268 GW,同比增长56.4%[6]。

常见储能技术有抽水蓄能(Pumped Hydro Storage,PHS)、锂离子电池储能(Lithium-ion Battery Energy Storage,LBES)、压缩空气储能(Compressed Air Energy Storage,CAES)、二氧化碳储能(Carbon dioxide EnergyStorage,CES)等。其主要性能指标对比如表1[7-10]所示。其中压缩空气储能技术因其储能容量大等优点受到广泛关注,但其储能密度较低,对地理条件依赖大。将空气液化储存可提升储能密度,但该过程耗能巨大,㶲损严重。因此,寻找一种替代工质是推动压缩气体储能技术高效发展的关键。

储能技术 容量成本/[元·(kWh)−1] 寿命/a 循环效率/% 储能密度 应用时间 应用状态 抽水蓄能 1000~1200 30~40 70~80 - 日级 商用 锂离子电池储能 1000~2000 10~15 85~95 0.13~0.2 kWh/kg 小时级 商用 压缩空气储能 1500~2000 25~30 60~75 2~6 kWh/m3 日级 示范 二氧化碳储能 1250~1600 25~30 60~75 5~10 kWh/m3 日级 示范 液态二氧化碳储能 1200~1500 25~30 55~65 20~40 kWh/m3 日级 研究 此外,碳捕集、利用与封存(Carbon Capture,Utilization and Storage,CCUS)成为应对全球气候变化的关键技术之一,CO2当前已被应用在驱油、化工生产等多个领域。考虑到CO2临界点(7.39 MPa和31.4 ℃)相对空气(3.77 MPa和−140.5 ℃)更易达到,且超临界二氧化碳(SCO2)具有黏度小、密度大、导热性能好等性质,同时无毒、不易燃、安全等级高,已有学者提出了以CO2为循环工质的二氧化碳储能技术[11]。进一步,郝佳豪等[12]总结了当前二氧化碳储能系统的研究现状,指出待突破的关键技术有系统热力学循环构建理论、CO2临界转换特性、动态运行控制策略等。

吴思成[13]分别以CO2和空气为储能介质,使用Aspen Hysys软件构建了几种典型的压缩气体储能系统并进行对比。结果显示在液态气体储能系统中使用CO2相较于空气循环效率高出2.4%,同时工作温度更接近环境温度,冷能损失小。Cao等人[14]提出了一种采用废弃矿井和地下洞穴分别作为高低压储气室的CES系统,循环效率最高达53.75%。Bartela等人[15]提出了一种矿坑作为储气室的CES系统,储能效率可高达80%,度电成本可低至314.6 ℃/MWh。郝银萍等人[16]建立了一种基于地下储气室的多级回热式CES系统,储能效率和㶲效率分别为58.41%和67.89%,均高于绝热CAES系统。当前意大利和中国已经建成了MW级CES示范项目,实现了较高的循环效率[17-18]。但当前CES系统高压侧一般采用超临界或液态存储,而低压侧仍采用气态存储,这极大限制了储能密度的提升,也受限于地理环境。因此将CO2以双侧液相存储的液态二氧化碳储能(Liquid Carbon dioxide Energy Storage,LCES)技术因其储能密度大、结构灵活紧凑、对地理环境要求小等优点而具有广阔的发展前景。李玉平[19]对比了不同存储方式下的CES系统,证明了CO2以双侧液相存储时储能密度最高。典型设计工况下可达15.495 kWh/m3,而两侧分别采用气态和超临界态存储的CES系统仅有0.195 kWh/m3。储能时压缩机出口CO2压力较高,采用环境水即可液化。而随着压力降低,其相变潜热显著增加,液化困难。因此如何实现释能时低压CO2的高效液化成为LCES系统的关键技术难题。

文章首先介绍了LCES系统的运行原理和当前CO2液化的主要工艺以及系统关键评价指标。其次分析了实现LCES系统低压侧CO2液化的主要方式及其特点,并指出蓄冷液化是最具竞争力的方式,最后总结了蓄冷液化面临的技术挑战和发展前景。

-

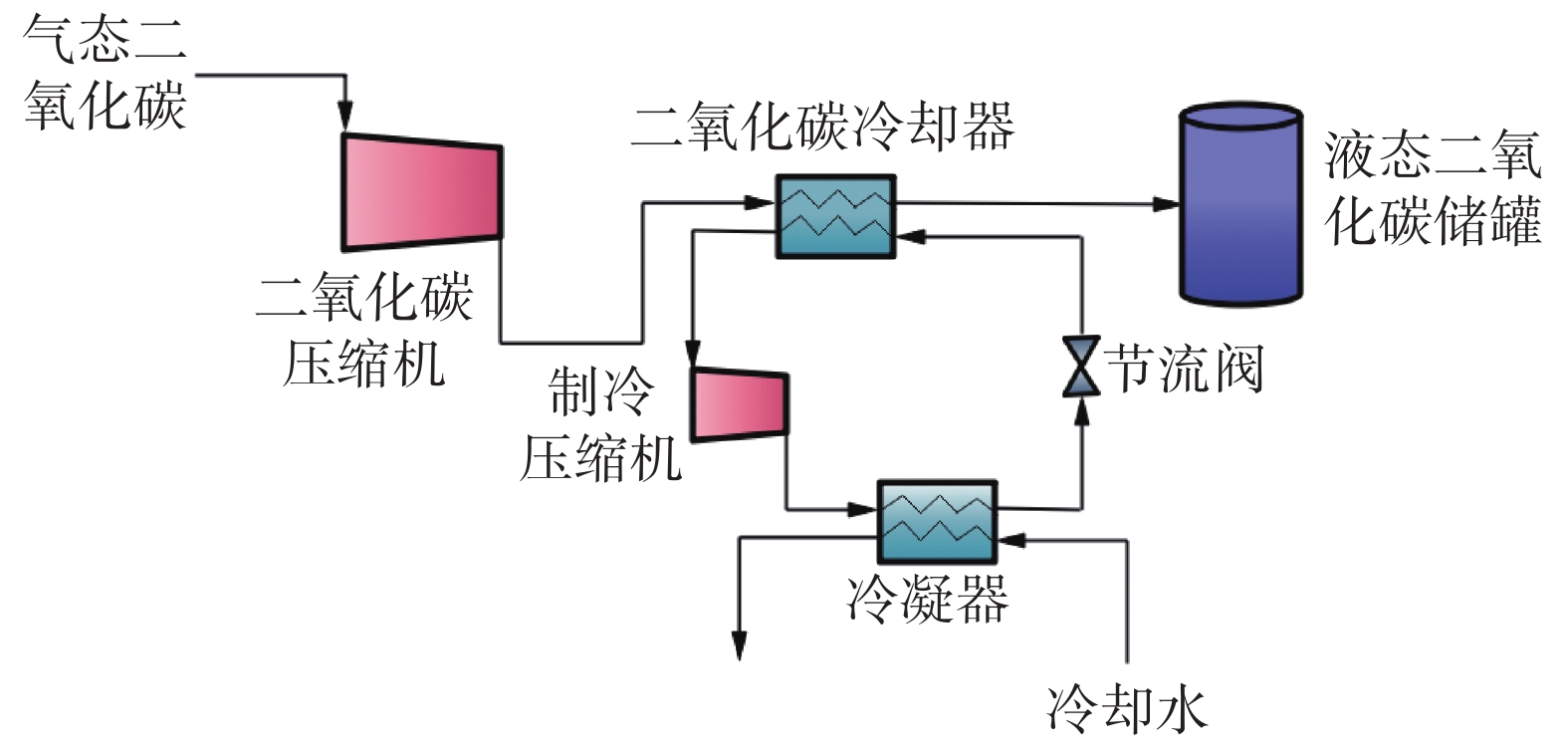

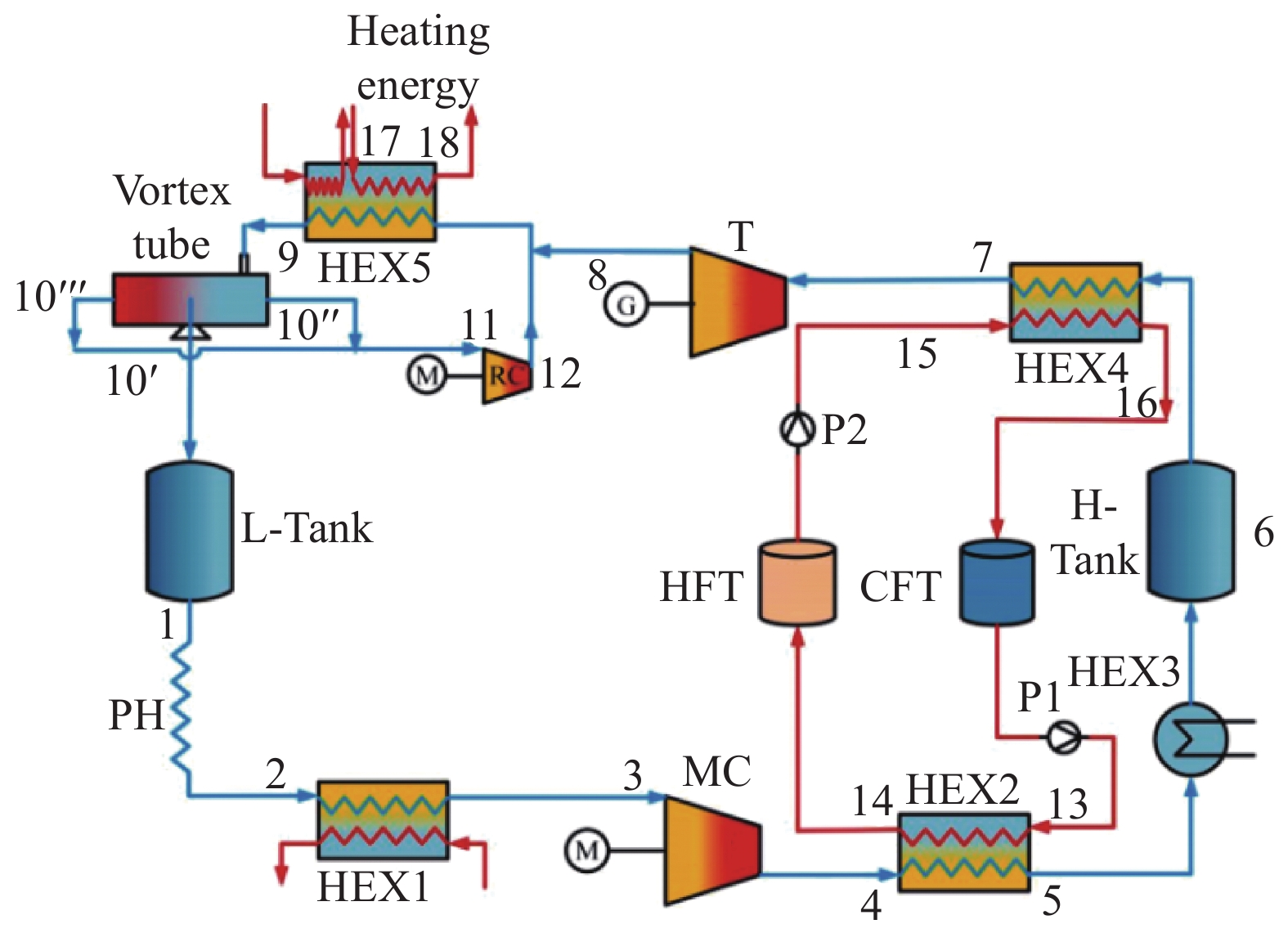

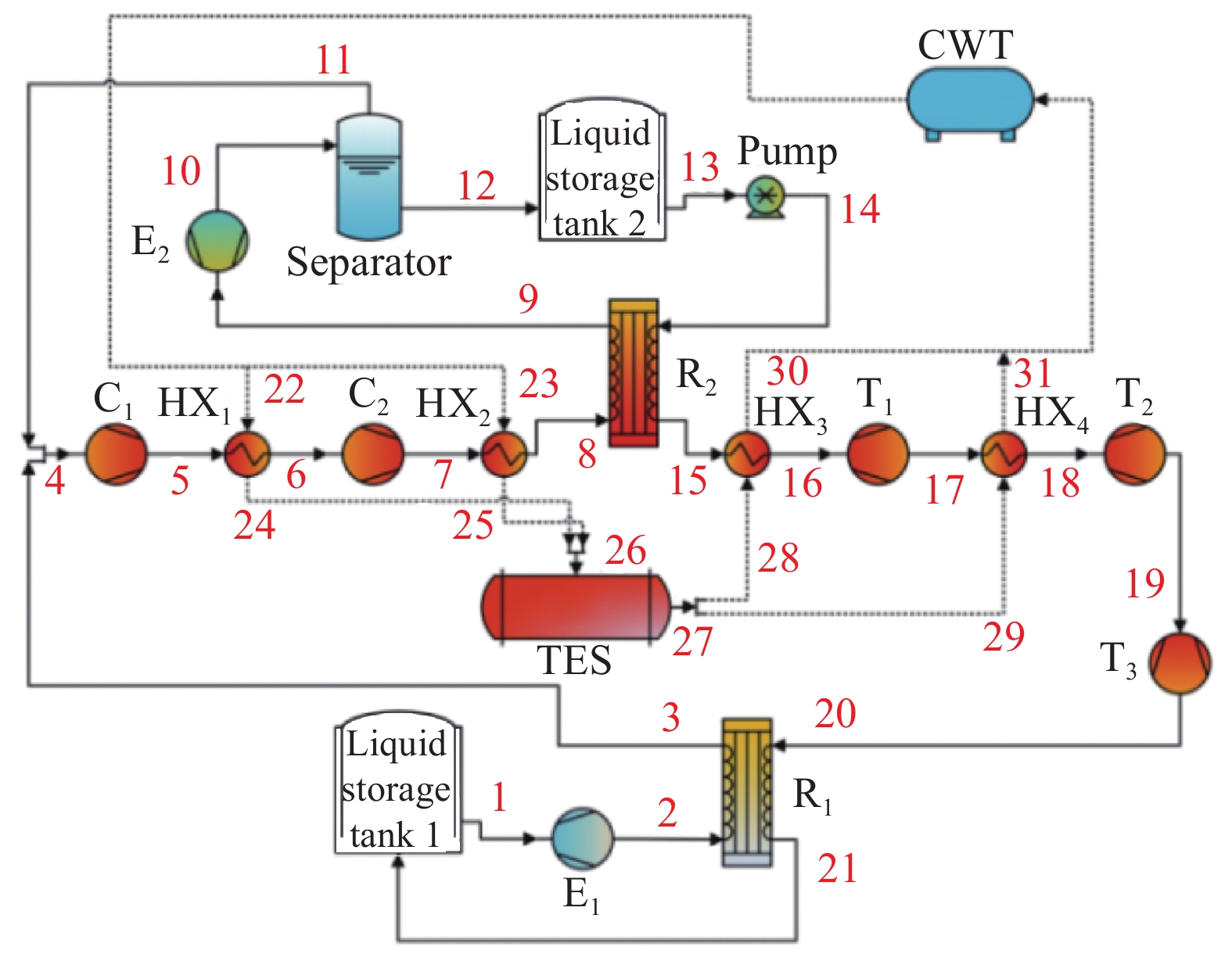

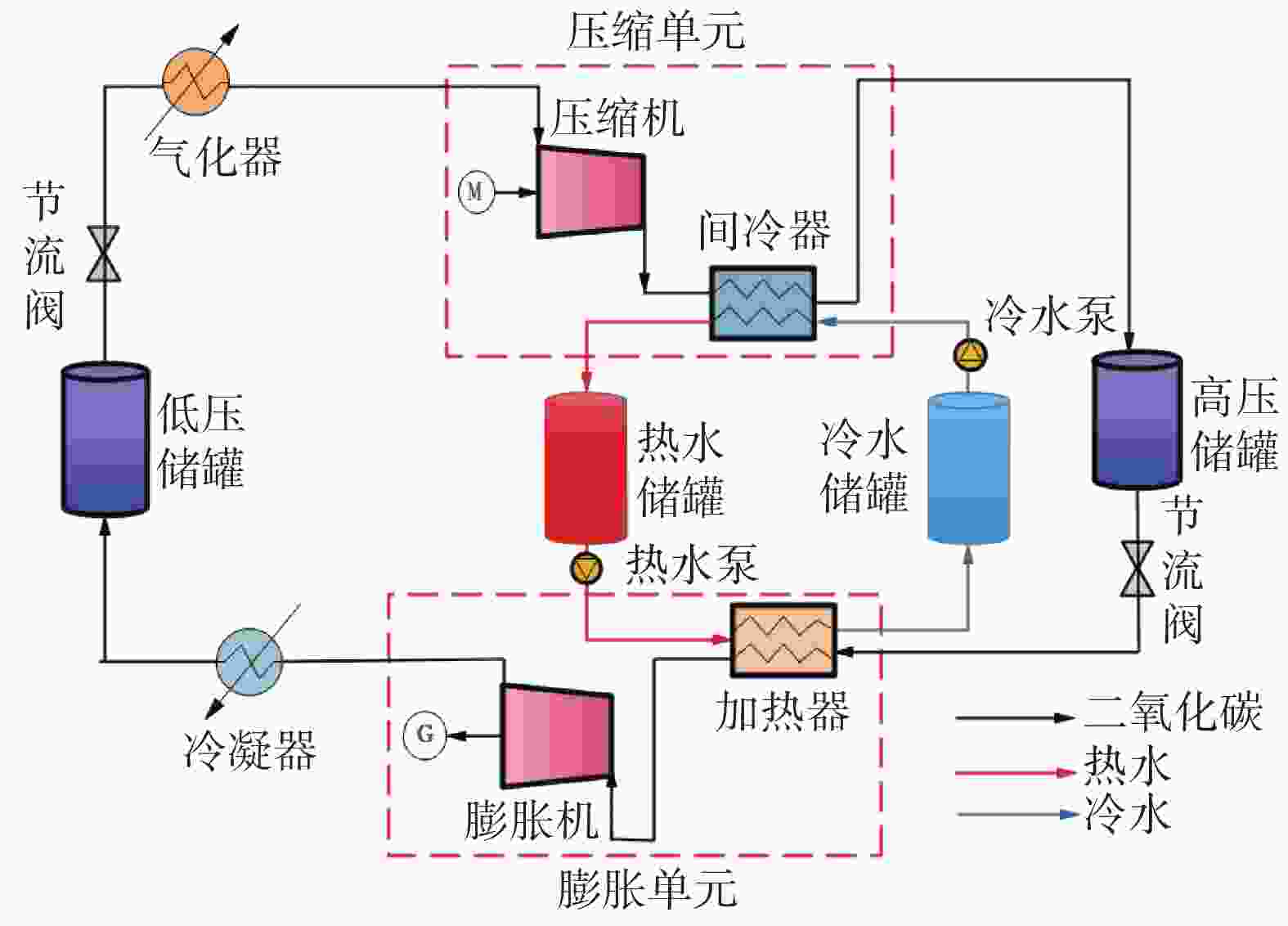

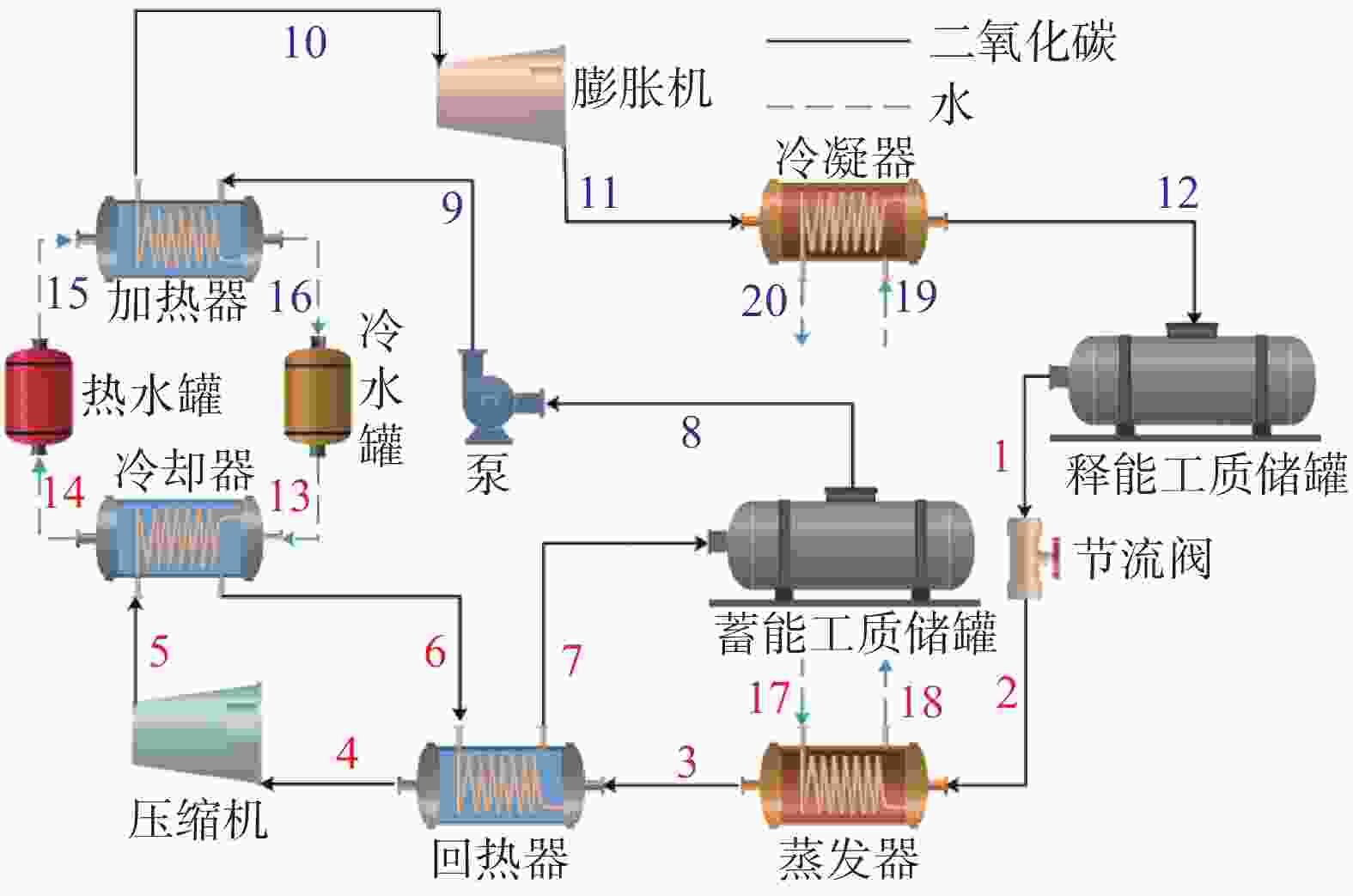

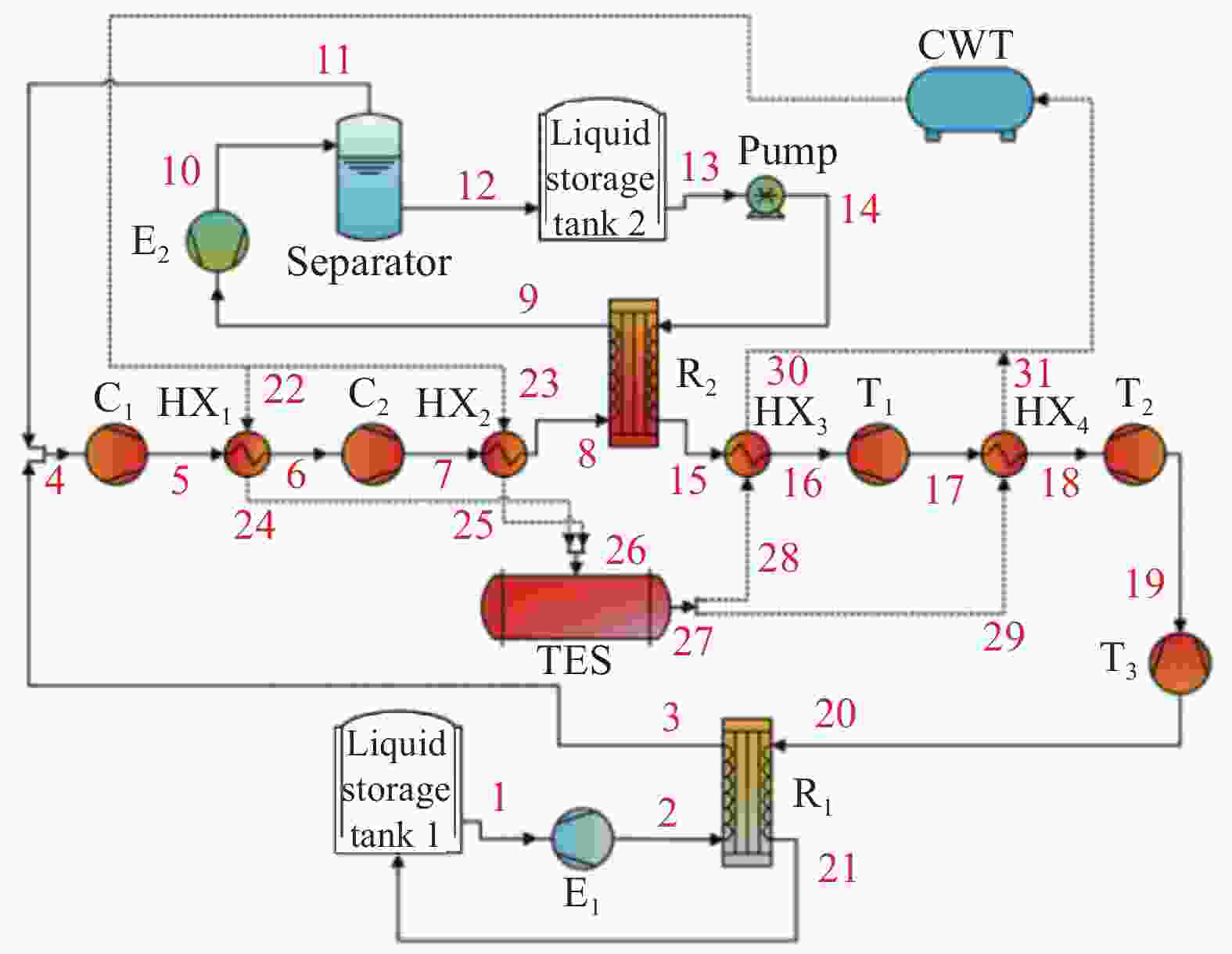

LCES技术是在CES技术原理的基础上提出的,其原理如图1所示。

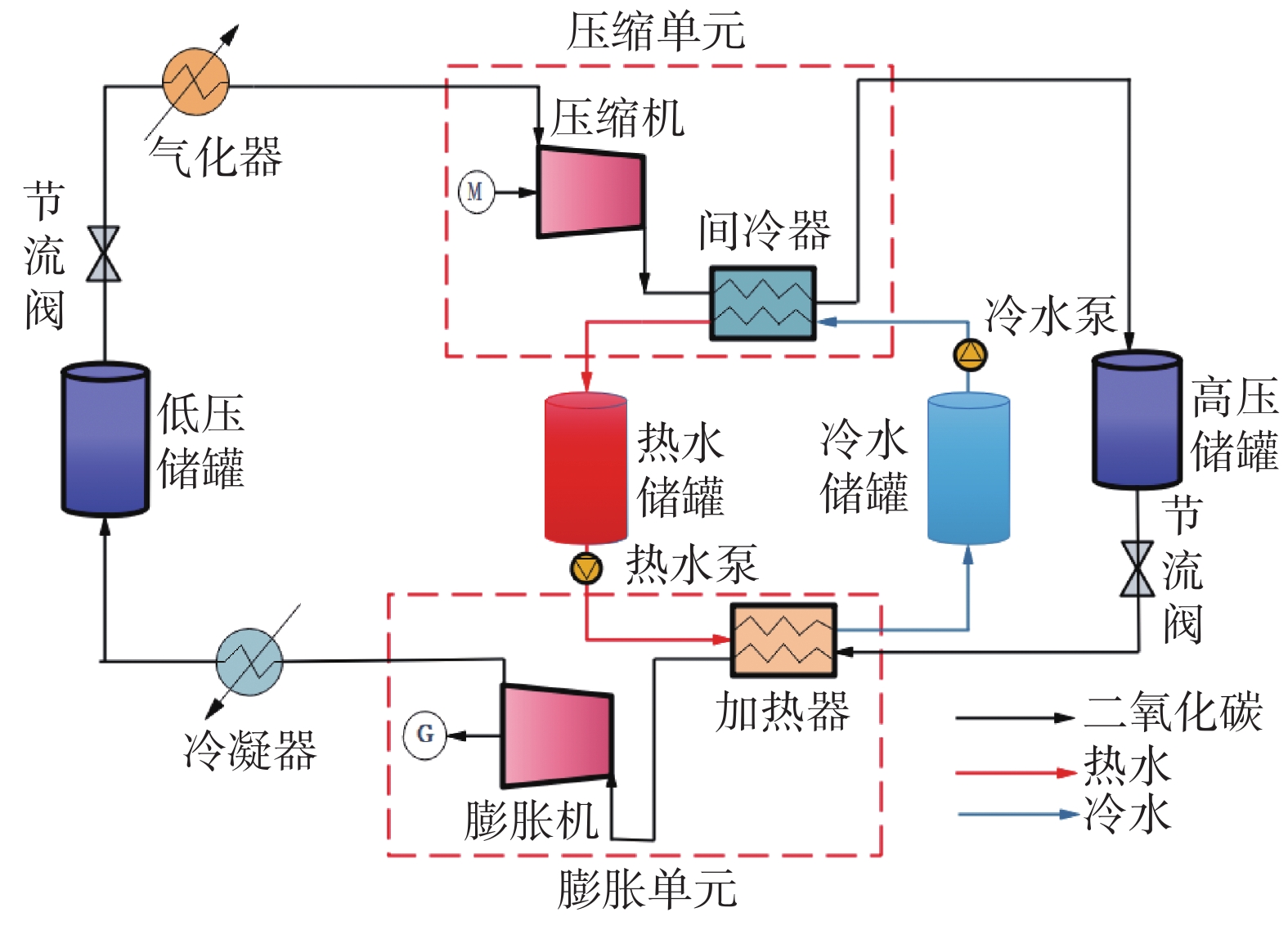

系统主要由压缩单元、膨胀单元、存储单元和蓄热单元组成。压缩单元由一级或多级压缩机及相应的间冷器组成。膨胀单元由一级或多级膨胀机及相应的加热器组成。存储单元采用高低压储罐分别存储压缩后的高压液态二氧化碳(LCO2)和膨胀后的低压LCO2。蓄热单元吸收并存储压缩热,在膨胀阶段用于加热工质。此外还包括一个冷凝器和一个气化器,分别用于将膨胀后的CO2进一步冷凝成液态和在压缩机前将LCO2加热气化。运行原理如下:

储能环节:低压储罐中的LCO2经节流阀调节压力后进入气化器,加热气化后进入压缩机被压缩至超临界状态,同时利用环境水吸收压缩热并储存在热水储罐中,然后SCO2经间冷器冷却液化后进入高压储罐。释能环节:高压储罐中的LCO2经节流阀调节压力后,进入加热器蒸发气化并进一步升温后进入透平中膨胀发电。热量来自于储存的压缩热,热水释放热量后进入冷水储罐。膨胀机出口CO2进入冷凝器被冷却液化后进入低压储罐。

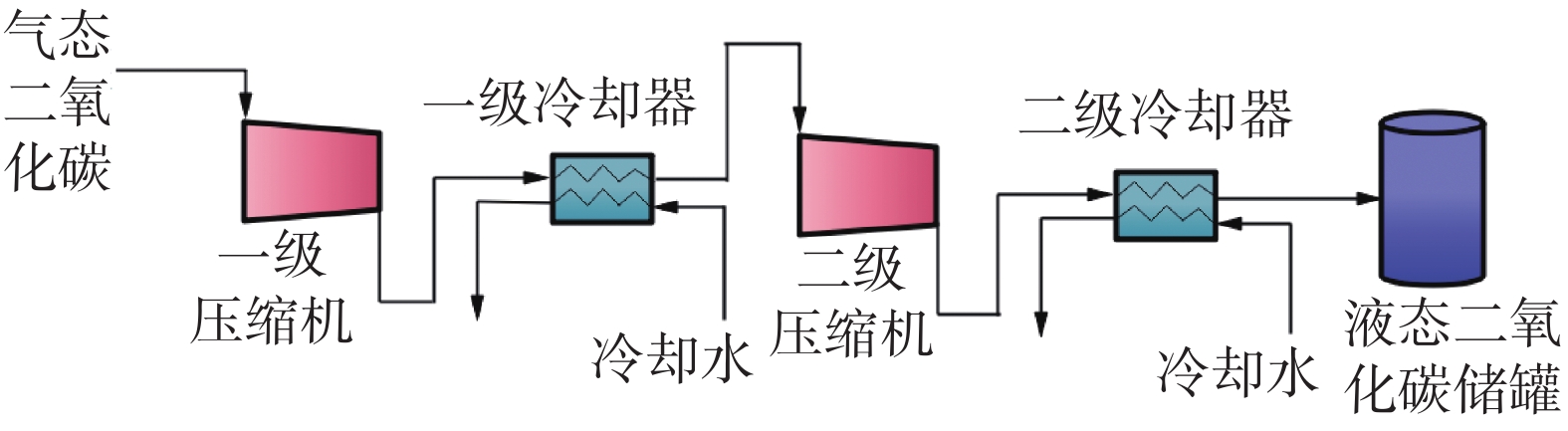

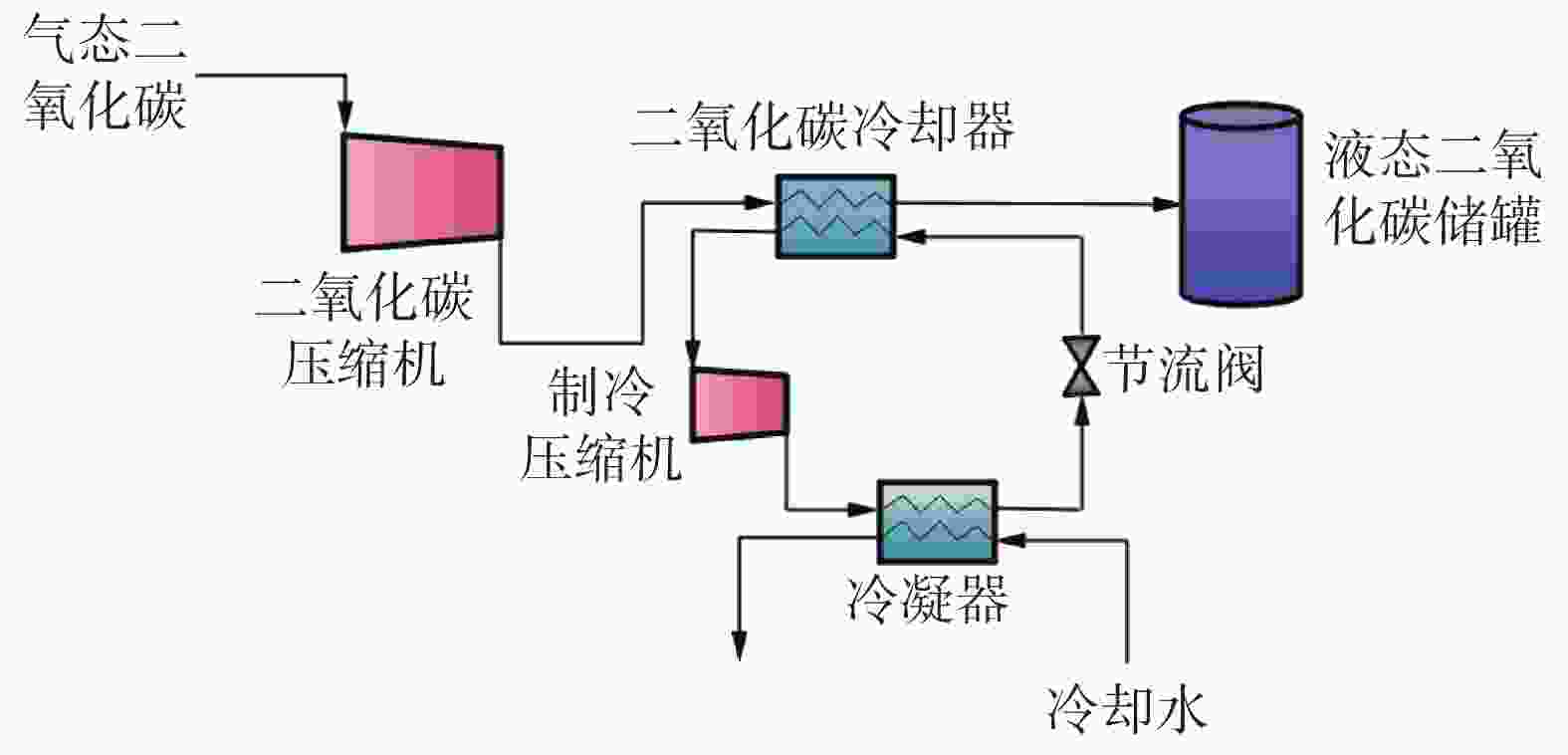

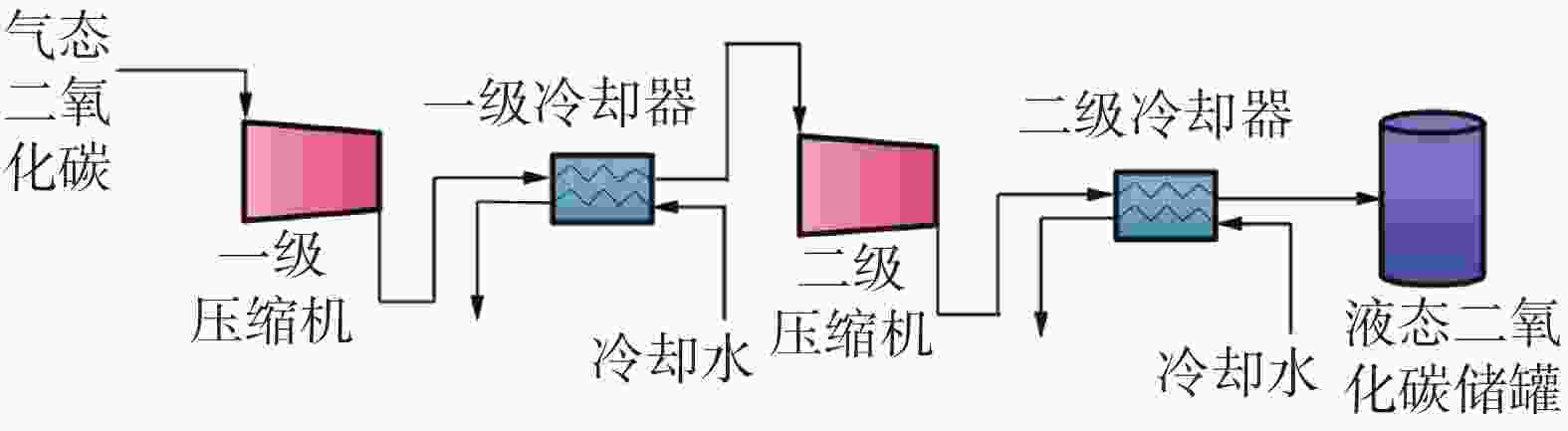

相较于传统的CES技术,LCES技术强调将系统两侧的CO2均以液相存储。当前针对CO2液化主要有低温低压法和常温高压法2种工艺,其原理分别如图2和图3所示。前者是指将常压气相CO2加压至约2 MPa,对应饱和温度约−20 ℃,再用制冷机组吸收潜热,致其液化。该工艺液化压力低,安全性强,但需要配备制冷机组。后者是通过提高压力,在常温下液化后储存在压力为15 MPa、容积为38~42 L的高压钢瓶中,不需要专门制冷机组,系统简单,但系统及储罐耐压要求高。

-

液态二氧化碳储能系统主要热力学评价指标有系统循环效率(Round Trip Efficiency,RTE)和储能密度(Energy Storage Density,ESD)[14]。

RTE是指系统总输出功与总输入功之比(记为ηRTE):

$$ \eta_{{\mathrm{RTE}}} = \frac{{{W_{{\mathrm{outlet}}}}}}{{{W_{{\mathrm{inlet}}}}}} = \frac{{{P_{\mathrm{T}}} \cdot {t_{\mathrm{d}}}}}{{\left( {{P_{\mathrm{C}}} + {P_{\mathrm{P}}}} \right) \cdot {t_{\mathrm{c}}}}} $$ (1) 式中:

$ {W_{{\mathrm{outlet}}}} $ ——系统总输出功(kWh);

$ {W_{{\mathrm{inlet}}}} $ ——系统总输入功(kWh);

$ {P_{\mathrm{T}}} $ ——膨胀机功率(kW);

$ {P_{\mathrm{C}}} $ ——压缩机功率(kW);

$ {P_{\mathrm{P}}} $ ——泵耗功率(kW);

$ {t_{\mathrm{d}}} $ ——释能时间(h);

$ {t_{\mathrm{c}}} $ ——储能时间(h)。

ESD是指系统总输出功与储罐总体积之比(记为UESD,单位为kWh/m3):

$$ U_{{{\mathrm{ESD}}}} = \frac{{{W_{{\mathrm{outlet}}}}}}{{{V_{{\mathrm{hpt}}}} + {V_{{\mathrm{lpt}}}}}} = \frac{{{P_{\mathrm{T}}} \cdot {t_{\mathrm{d}}}}}{{{V_{{\mathrm{hpt}}}} + {V_{{\mathrm{lpt}}}}}} $$ (2) 式中:

$ {V_{{\mathrm{hpt}}}} $、$ {V_{{\mathrm{lpt}}}} $——高压储罐和低压储罐的体积(m3)。

储能密度受膨胀机功率和储罐体积的影响,因而CO2的储存密度是影响系统储能密度的关键因素。CES系统中CO2可以气态、液态或超临界态存储。相同压力下LCO2的密度是气态形式的几十倍,因此液相存储可明显减小储罐体积,大幅提高储能密度。

-

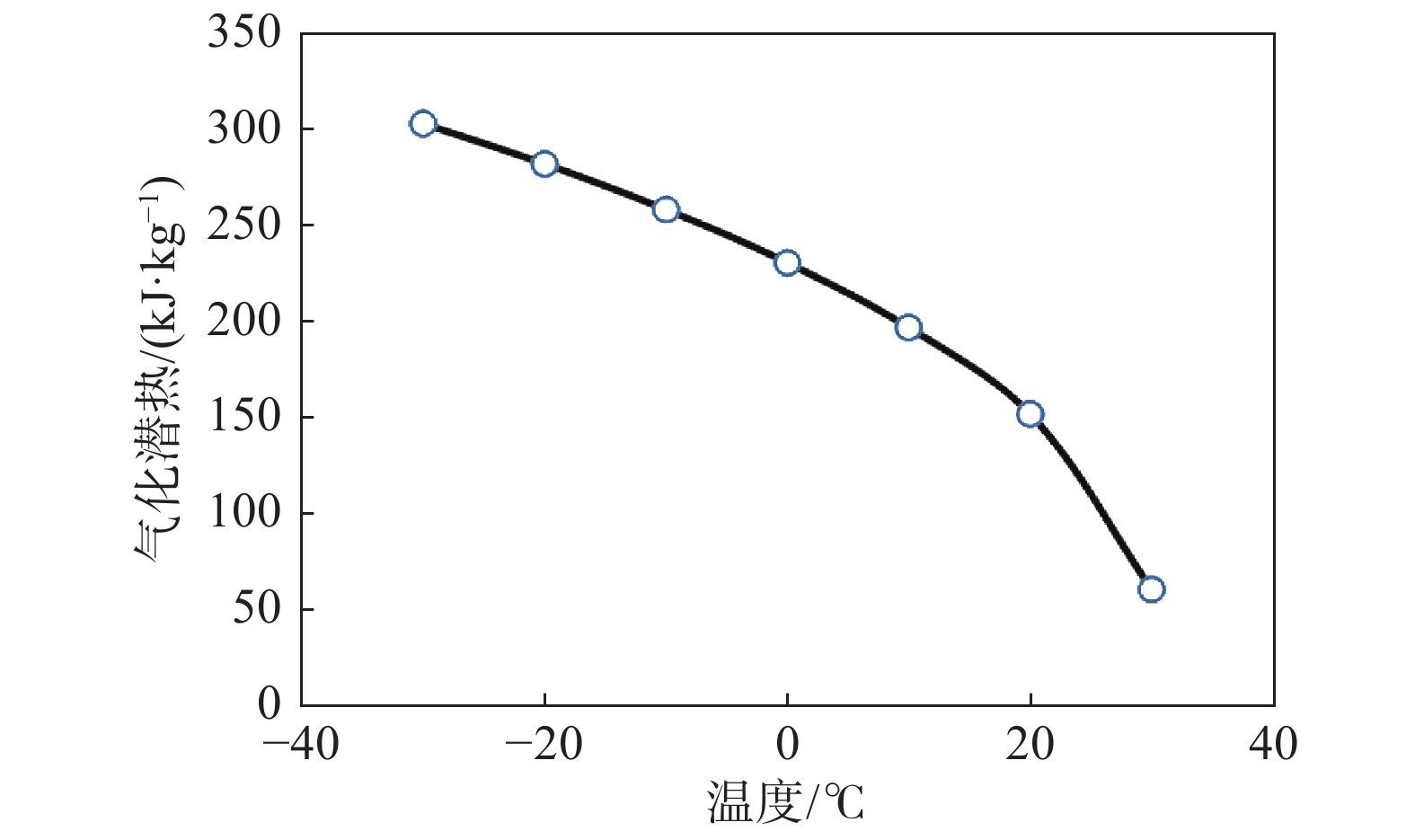

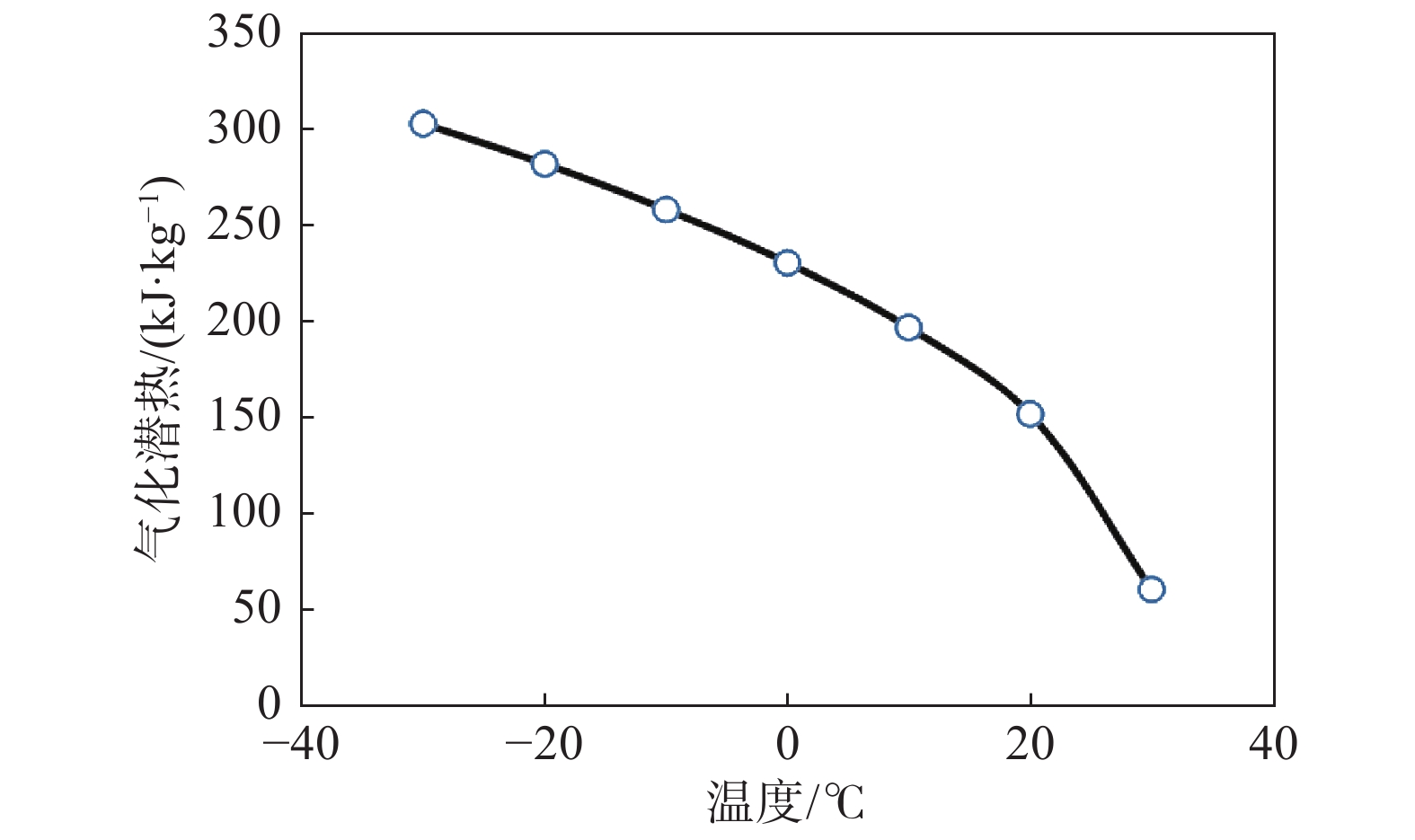

当前LCES系统受到释能过程膨胀机出口的亚临界CO2有效冷凝问题的限制[20]。如何提升液化效率是增强LCES系统性能的关键。图4为二氧化碳相变潜热随饱和温度的变化情况。随着饱和压力的降低,相变温度降低,相变潜热逐渐增加,在1.38 MPa时已达到305 kJ/kg,若直接采用低温低压法,即在系统膨胀发电阶段同时开启制冷机组将膨胀机出口处的CO2进行冷却液化,将带来极大的电力消耗,严重降低LCES系统的循环效率且难以满足电力系统调峰需求。因此,需要针对LCES系统自身特点探索更为高效的低压CO2液化方案。许多学者对此展开了研究,主要方式及其特点如表2所示。

液化方式 优点 缺点 使用混合储能工质 换热性能好,热损失小,液化能耗低 筛选体系不成熟,对设备要求高 CO2自冷凝 不需要额外冷源 系统结构复杂,运行压力过高,实践应用难 采用液态天然气 液化效率高,系统结构简单 依赖特殊场景,成本高 蓄冷液化 蓄冷液化与储释能环节匹配,能量利用率高,

运行压力较低,实践性强技术尚不成熟,需要构建显热和潜热分级蓄冷,结构较复杂 Table 2. Comparison of low-pressure CO2 liquefaction methods for LCES system

-

有学者发现将CO2与其他有机工质混合是解决亚临界CO2冷凝问题的有效方法[21]。混合工质具有更高的临界温度和更低的临界压力,从而减少液化能耗,提升系统安全性和运行效率。此外,混合工质具有温度滑移特性,可实现换热过程良好的温度匹配,降低换热损失[22]。

刘旭等人[23]提出了一种新型的基于二氧化碳混合物的液体储能系统(LMES),如图5所示。储能过程,释能工质储罐中的液态工质经过节流阀调节压力后进入蒸发器吸收环境水的热量气化,再经回热器进一步加热后进入压缩机。释能过程膨胀机出口CO2进入冷凝器直接被环境水冷却液化后储存在释能工质储罐中。文章分别选用有机工质R32和R161与CO2混合,热力学分析显示两种混合工质对应的冷却温度分别为42 ℃和45 ℃,系统循环效率为57.65%和50.54%。

但当前混合工质特性随组分变化规律尚不清晰,尚无标准化的工质筛选体系。且大多仍采用传统氟利昂工质与CO2混合。在未来探究更多自然工质组合,深入研究其特性变化规律及其在储能系统中的应用可能是解决LCES系统工质液化储存难题的一大方向。

-

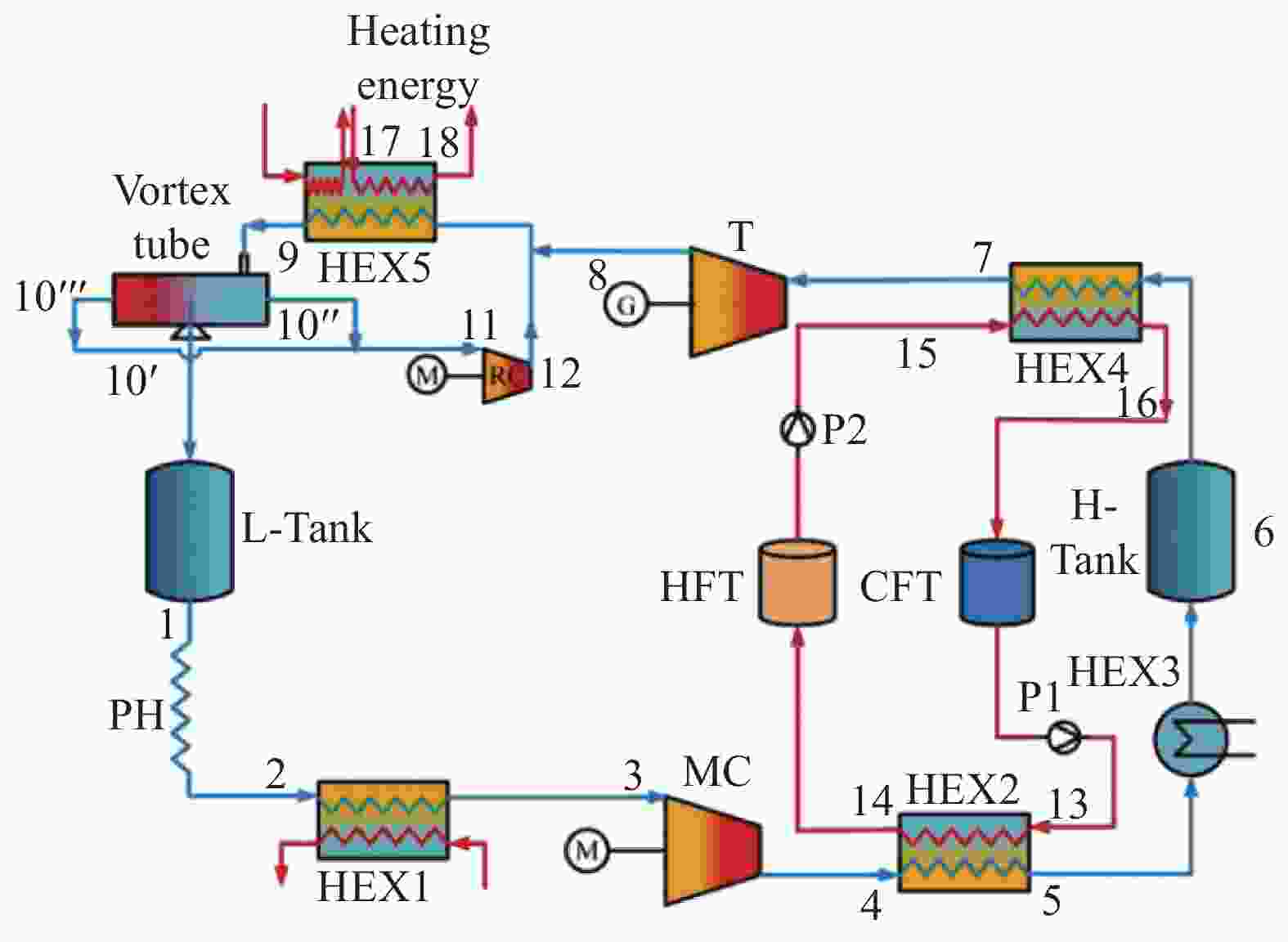

Zhao等人[24]提出一种采用涡旋管实现二氧化碳自冷凝的LCES系统,如图6所示。储能过程CO2被压缩至30 MPa,经环境水冷却液化。释能过程CO2膨胀至约6 MPa,进入涡旋管分成三股流,饱和液体、饱和蒸汽和过热蒸汽。饱和液体直接储存在低压LCO2储罐中,而另外两股液体流混合并重新压缩到涡轮机出口压力。冷却后再次进入涡旋管,实现自冷凝。设计条件下系统循环效率、㶲效率和储能密度分别为53.45%、61.83%和5.43 kWh/m3。

Figure 6. Schematic diagram of the LMES system using vortex tube for carbon dioxide self-condensation

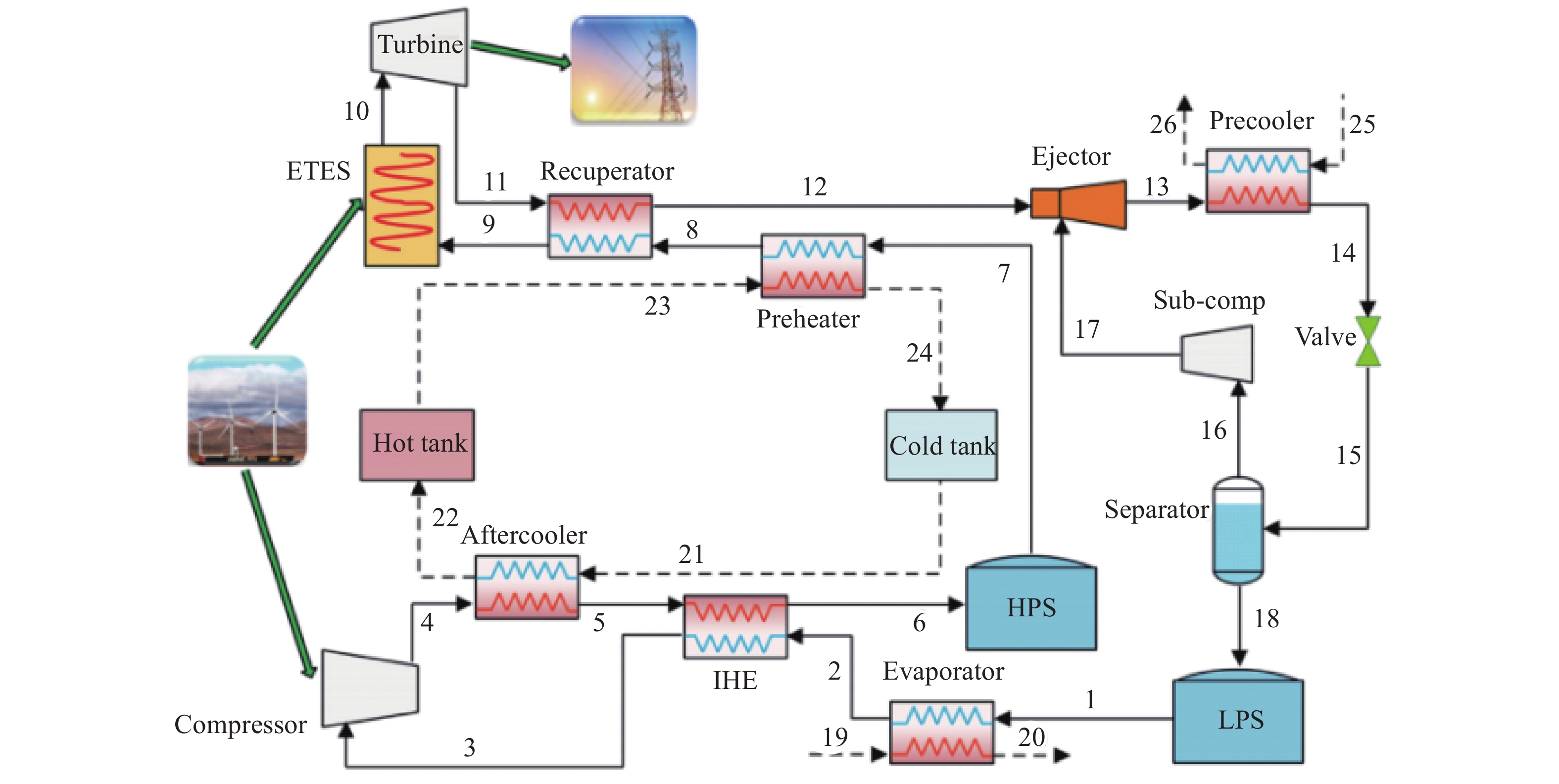

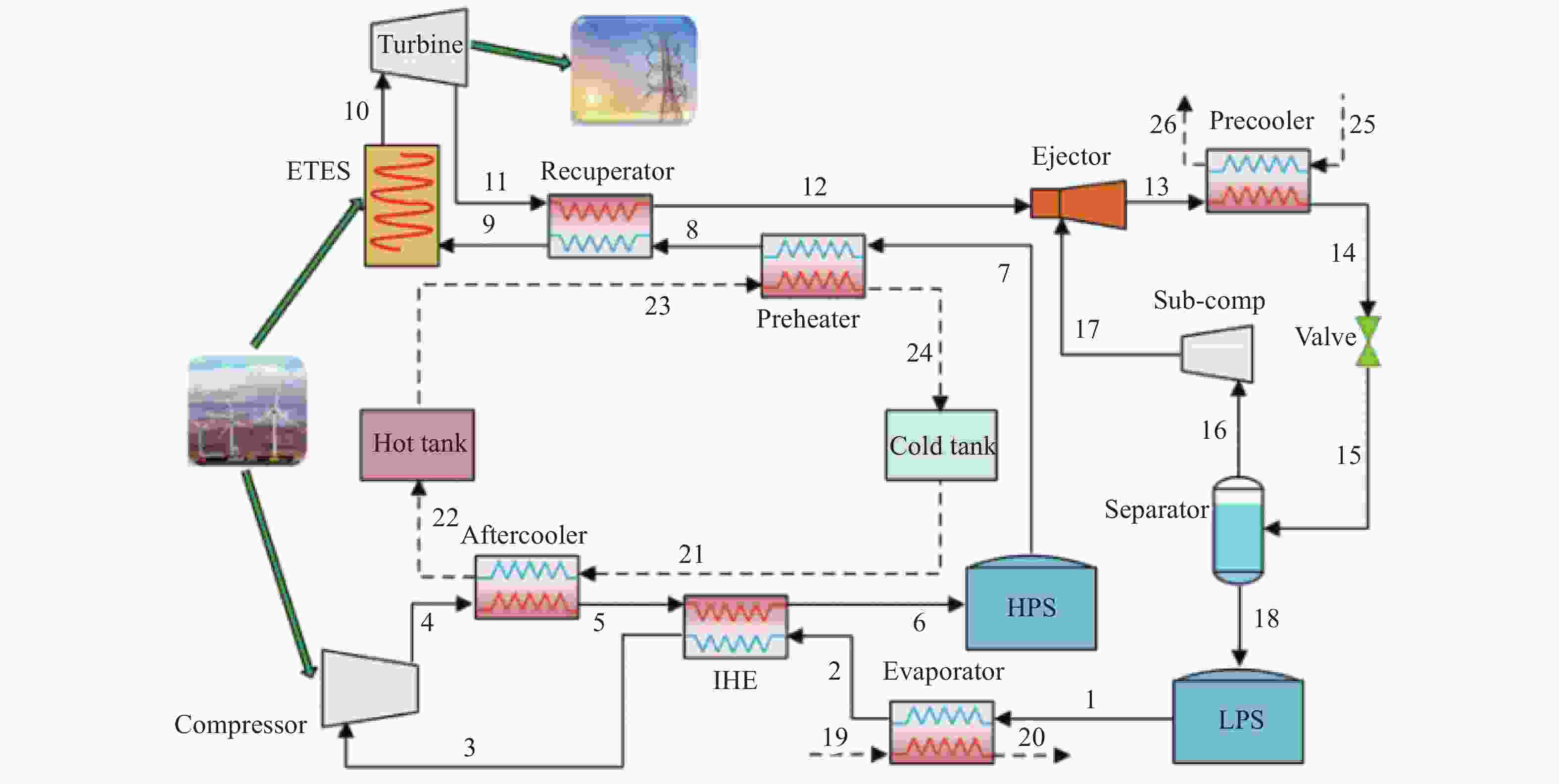

Liu等人[25]提出一种与跨临界布雷顿循环、电热能蓄能和喷射器冷凝循环相结合的新型LCES系统,如图7所示。储能时CO2被压缩至约25 MPa,冷却液化后进入高压储罐中储存。释能过程膨胀机出口CO2先经换热器释放部分热量后进入喷射器,同时副压缩机出口的二次流也进入喷射器,经历混合和扩散。出口处CO2流体利用环境水冷却再通过节流阀降压变成气液两相流,其中饱和液体进入低压储罐中,饱和蒸汽再依次进入副压缩机和喷射器二次流通道。喷射器背压约为8 MPa,该方式不需要外部冷源。

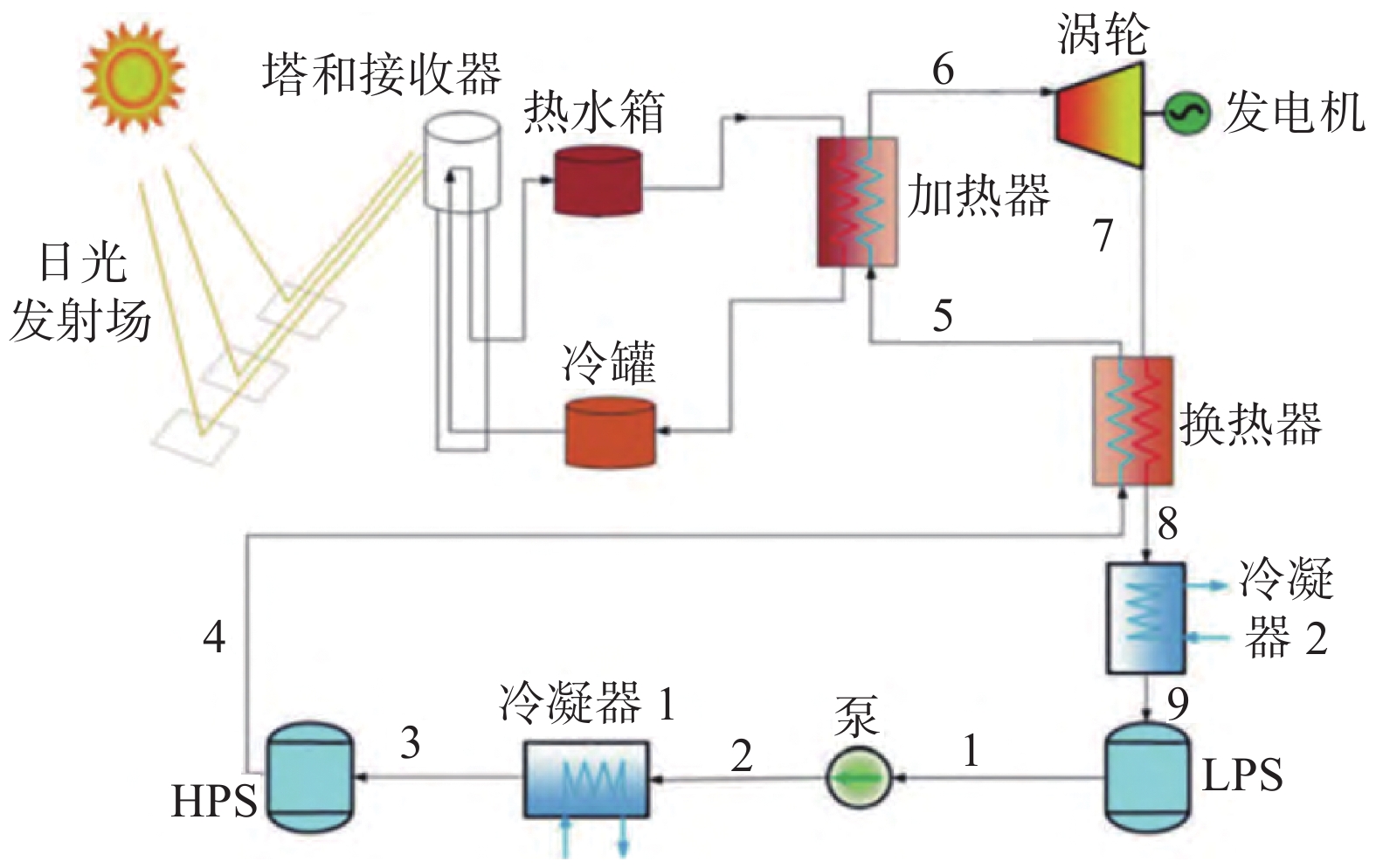

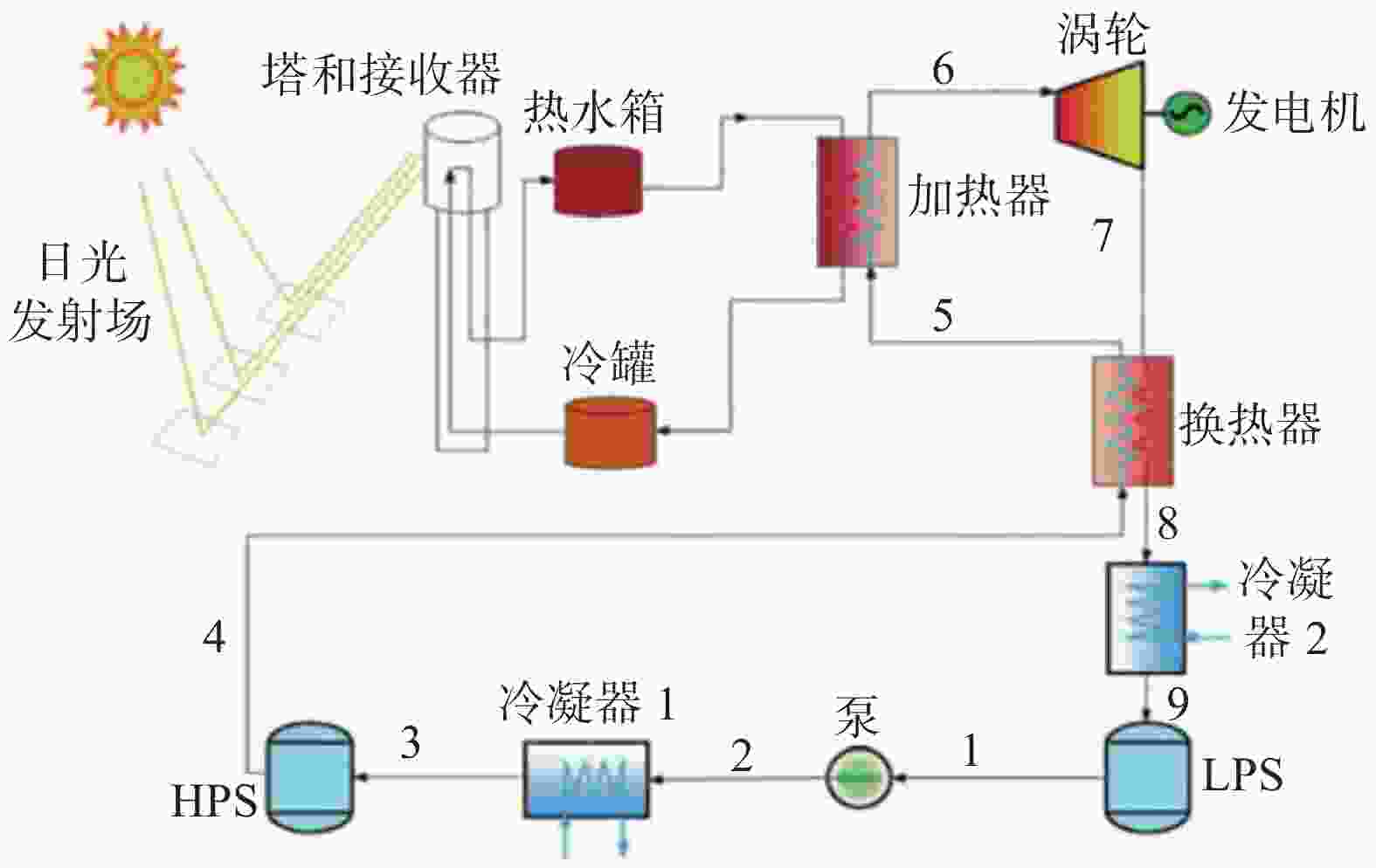

Xu等人[26]提出一种结合太阳能补热的LCES系统,如图8所示。储能过程利用泵将LCO2从6 MPa升压至25 MPa,经冷凝器降温后储存在高压储罐中,释能过程高压LCO2经过回热器吸收膨胀机出口处CO2热量,再利用太阳能进一步加热后进入膨胀机。膨胀后的LCO2经过回热器和冷凝器后液化,进入低压罐储存。设计条件下循环效率、㶲效率和储能密度分别为45.35%、67.20%和18.06 kWh/m3。

还有学者提出利用环境冷水直接实现低压侧CO2的冷凝,系统运行压力范围是6~22 MPa[27]。然而,无论是采用涡旋管或喷射器实现自冷凝,还是直接利用环境冷水,系统运行压力都过高,存在安全隐患。且构造复杂成本较高,难以大规模应用。

-

常压下液态天然气(Liquid Natural Gas,LNG)的沸点为−162 ℃,蕴藏大量冷能,被广泛用来液化气体[28]。吴毅等人[29]提出了一种以LNG为冷源的超临界二氧化碳(SCO2)-跨临界二氧化碳(TCO2)冷电联供系统,采用TCO2循环作为底循环对再压缩式SCO2循环进行余热回收,并采用LNG为冷源。给定条件下系统热效率为54.47%。

Bao等人[30]提出了一种组合液体二氧化碳储能和两级冷凝有机兰金循环(LCES-TCORC)系统,以解决低压CO2冷凝难题和部分LNG发电冷能浪费问题。储能时LCO2先经泵升压再进入加热器气化后进入压缩机,释能时膨胀机出口CO2被LNG冷却液化后进入低压储罐。出口天然气可以供给用户。多目标优化结果表明,采用混合工质的系统具有更高的循环效率和㶲效率,分别为375.49%和81.09%。

但是LNG的温度约为−162 ℃,而低压侧CO2液化温度约为−40 ℃,大温差换热造成了LNG冷㶲的严重损失,一般可以考虑结合兰金循环、数据中心冷却等其他单元以提升系统整体效能。且LNG利用依赖外部环境,其长途运输成本过高,因此经济性较低、灵活性较差。

-

对于LCES系统,膨胀机出口的CO2冷却液化,压缩机进口前的CO2又需要吸热气化,因此采用高效蓄冷器无疑是一种有效途径。该方式原理简单,运行压力不需要太高,且不需要额外冷源,释能阶段利用蓄冷材料吸收CO2的热量使其液化,储能阶段释放热量加热CO2使其气化。实际应用中可根据CO2相变温度设计多级蓄冷以减小换热温差,降低㶲损,提升系统性能。

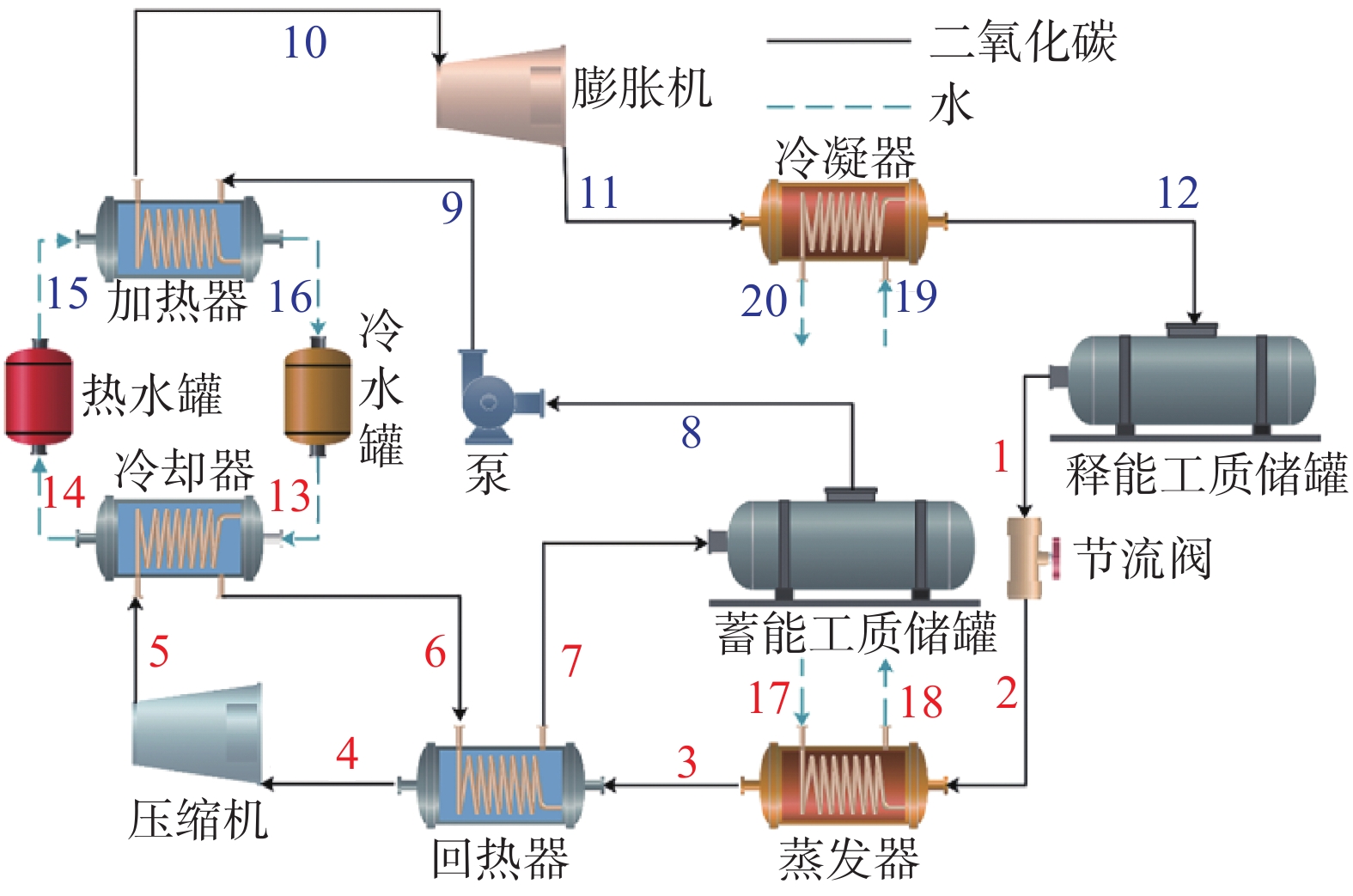

Wang等人[31]提出一种LCES方案,如图9所示。压缩机出口CO2采用冷凝器液化后储存在高压储罐中,膨胀机出口的CO2先被冷凝器冷却至环境温度,然后进入蓄冷器液化后储存在低压储罐中,循环效率约56.64%。文中提出可采用结晶水合盐和充满小卵石的蓄冷装置共同实现,但是并未进行详细介绍。

万玉珂等人[32]提出了一种新型液态存储跨临界CES系统。压缩后的CO2被冷却液化后存储在高压储罐中,膨胀后的CO2则依次通过冷却器和蓄冷器液化后存储在低压储罐中。多目标优化结果表明最优循环效率和能量密度分别为58.79%和17.85 kWh/m3,相应两侧的储存压力分别为23.98 MPa和1.6 MPa。

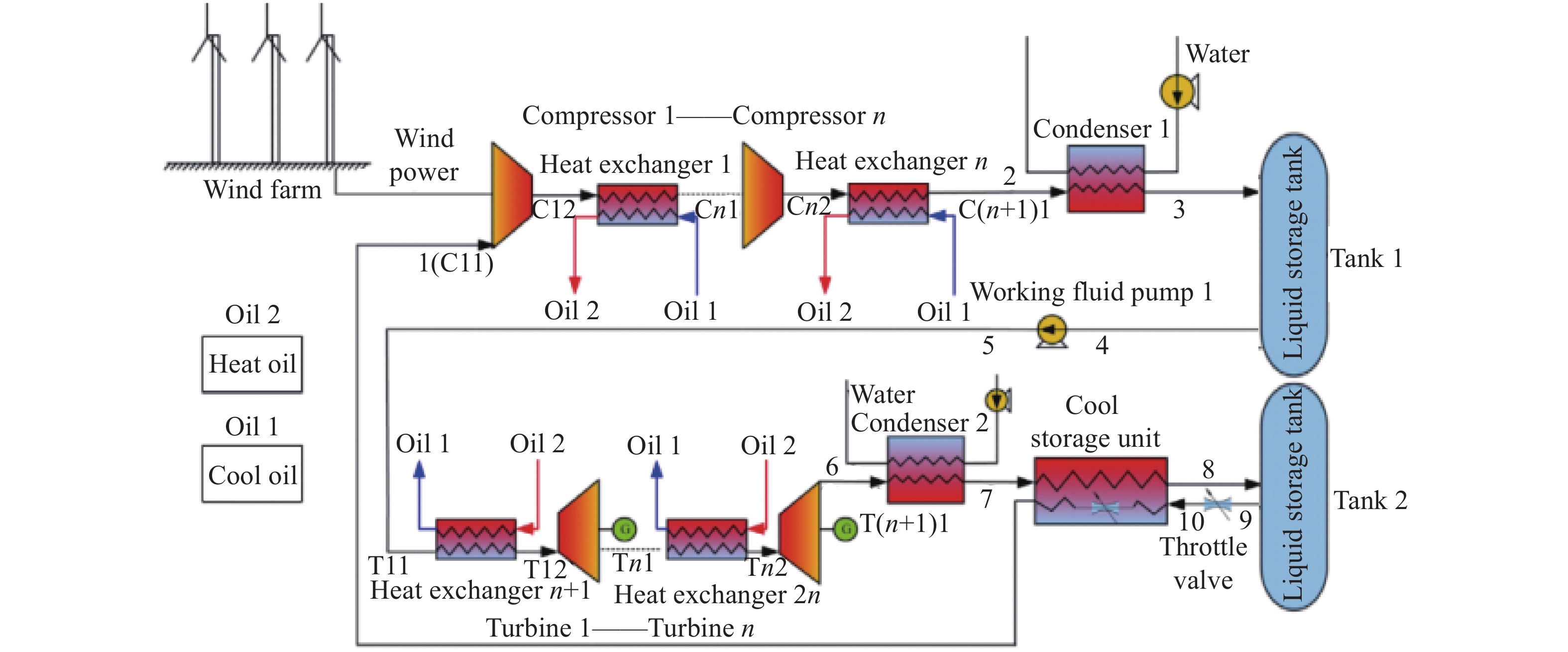

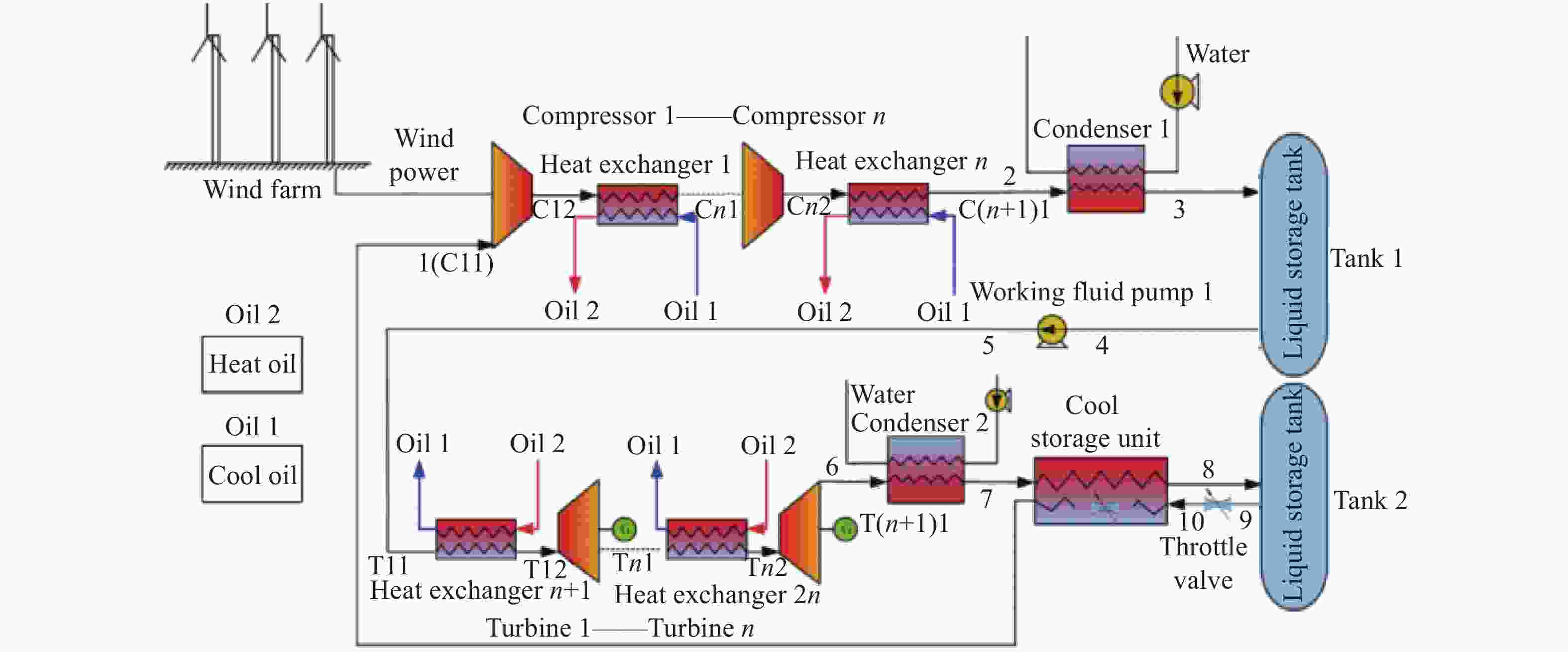

Sun等人[33]提出一种新型低压LCES系统。膨胀机出口CO2显热用液体甲醇储存,潜热储存在相变蓄冷器中。典型条件下循环效率和能量密度分别为51.45%和22.21 kWh/m3。但文章并未构建出详细的相变蓄冷单元,而是建模为一个直接热交换器。Zhang等人[34]提出了一种新型的具有低温蓄热性能的CES方法,如图10所示。压缩机出口处CO2先经过换热器被冷却成液态,冷量来自于高压储罐出口的经过泵升压的LCO2,再经过液体膨胀机降压后进入气液分离器,气相重新进入压缩机,液相进入储罐。膨胀机出口CO2经过换热器冷却液化后储存在低压储罐中,冷量来自于低压储罐出口的经过膨胀机降压的气液两相CO2。分析表明基本工况下循环效率为41.4%,储能密度为15 kWh/m3。该系统直接利用两股工质之间热量交换,实现双侧液相存储,忽略CO2冷能存储释放过程。

可见,当前针对使用蓄冷器实现低压侧CO2液化的研究较多,但大多将其直接简化为CO2换热器,且仿真模拟和实验验证都存在较大空白。其中关键难点在于寻找适配相变温度的蓄冷材料并验证实际蓄冷液化效果。

-

当前主流物理蓄冷方式包括显热蓄冷和潜热蓄冷。显热蓄冷是指利用蓄冷介质的显热实现冷能存储和释放。液相工质要求其凝固点较低,沸点较高,在整个换热温区内不发生相变,比热容较大。固相蓄冷一般采用填充床结构,填充小石子或者鹅卵石,具有不受运行温度限制、运行压力接近环境压力、可直接或间接耦合热源等优势。以上方式都已广泛应用于压缩气体储能、太阳能蓄热、废热回收等系统中[35-37]。

潜热蓄冷又称为相变蓄冷,具有储能密度大、蓄冷温区范围宽、放冷时近似恒温等优点,可显著减小用量,削弱斜温层效应,减少冷能损失[38-39],在蓄冷空调[40]、冷链运输[41]等场景中应用广泛。针对LCES系统,关键在于选择适配低压侧CO2相变温度(约−40 ℃)的相变材料。当前有学者提出质量分数为36%的氯化铜溶液相变温度为−40 ℃[42]。还有学者制备出相变温度为−43 ℃的复合相变材料,测试结果显示该材料潜热大,过冷度小,充放冷循环性能好[43]。

相变材料潜热大用量小,换热过程近似保持恒温,换热损失小,是未来的重点发展方向。在实际应用中,采用固相或液相工质吸收显热和相变材料吸收潜热的两级蓄冷方案,更为合理高效。但目前针对应用于LCES系统的相变蓄冷材料研究较少,相变蓄冷过程的传热传质特性、相界面的移动规律和两相输运特性尚不清晰,更缺乏实验验证。因此,寻找或制备匹配CO2相变温度的相变材料,研究传热传质规律及动态变化特性,降低冷㶲损失提升蓄冷效率,并进一步构建基于显热+潜热分级蓄冷的液化流程,研究关键参数对蓄冷单元以及LCES系统性能的影响,实现系统循环效率、储能密度、投资成本的多目标优化是未来LCES技术发展的关键方向。

-

“双碳”目标下可再生能源规模化利用已成为大势所趋,而储能是解决可再生能源开发和大规模并网挑战的重要途径。在众多的储能技术中,二氧化碳储能技术因其独特优势迎来了快速发展。但当前较成熟的CES技术多依赖于天然储气室或超大体积气囊,这限制了储能密度的进一步提高,同时增加了投资成本。因此以双侧液相存储的液态二氧化碳储能技术成为研究热点,但目前尚无针对LCES系统液化单元的充分研究,如何实现低压(约1 MPa)CO2高效液化仍然是限制该技术发展的瓶颈。

文章首先介绍了LCES系统的运行原理和关键评价指标,指出实现CO2液相存储对于提升储能密度的重要性。然后重点介绍了实现系统低压侧CO2液化存储的常见手段,包括采用混合储能工质、CO2自冷凝、利用LNG冷能和采用蓄冷器。其中蓄冷液化最具优势,关键在于寻找合适蓄冷介质,进而构建基于显热+潜热分级吸收的蓄冷液化流程,并研究关键参数对蓄冷单元以及LCES系统性能的影响,实现循环效率、储能密度、投资成本的多目标优化。

Research Progress of Liquid Carbon Dioxide Energy Storage System Based on Different Liquefaction Methods

doi: 10.16516/j.ceec.2024.2.10

- Received Date: 2023-04-09

- Rev Recd Date: 2023-05-11

- Available Online: 2023-12-27

- Publish Date: 2024-03-26

-

Key words:

- carbon dioxide energy storage (CES) /

- carbon dioxide liquefaction /

- phase change cold storage /

- research status /

- development prospect

Abstract:

| Citation: | ZHENG Pingyang, HAO Jiahao, CHANG Hong, et al. Research progress of liquid carbon dioxide energy storage system based on different liquefaction methods [J]. Southern energy construction, 2024, 11(2): 102-111 doi: 10.16516/j.ceec.2024.2.10 |

DownLoad:

DownLoad: