-

淡水和能源是人类赖以生存和发展的两大要素,虽然地球表面的72%被水覆盖,但是其中适合人类饮用的仅有0.001%[1]。为了实现人类及自然生态系统的可持续发展,海水淡化成为一项缓解淡水资源短缺问题的绿色可持续发展方案。但是,随着化石能源短缺以及环境污染等问题的日益加剧,反渗透膜法、离子交换法和电渗析法等传统的淡水获取方式不再能够满足人们的需求[2-4]。因此,以绿色清洁的太阳能作为能源驱动实现海水淡化的技术对于缓解全球能源紧缺和减少环境污染具有重要意义。其中,基于光热转换技术进行太阳能驱动的界面蒸发因其高效率和零能耗受到越来越广泛的关注。

太阳能驱动界面蒸发技术的核心是光热转换材料,目前常用的光热材料可以分为纳米金属颗粒、半导体材料、碳基材料和有机聚合物4大类。其中,纳米金属颗粒能够在光照下产生表面等离子共振效应[5-6];半导体材料能够在光照后产生价带电子向导带的跃迁,从而产生空穴,被激发的电子返回价带的过程中会通过光子的形式辐射弛豫或非辐射释放能量从而产生热能[7];碳基材料的光热转换主要是基于π-π体系、p-π体系和p-p体系的共轭效应[8];有机聚合物中大多也存在共轭体系,能够通过共轭效应实现可见光和红外光向热能的转换[9-10]。但是,纳米金属颗粒价格昂贵,热稳定性较差;碳基材料制备和功能化的条件较为严苛;有机聚合物合成步骤繁琐、稳定性差。因此,无机半导体材料成为最有前景大规模应用的光热转换材料。

目前被用作光热转换的半导体材料有MoS2[11-12]、Cu7S4[13]等硫化物,Fe3O4[14]、Ti2O3[15]等氧化物,Ti3C2[16-17]等碳化物,以及Al-Al2O3[18]等金属-非金属复合体系。其中,Magnéli相亚氧化钛不仅具有二氧化钛来源广泛、无毒无害的优点,还具有相较于二氧化钛更窄的带隙[19],但是目前关于Magnéli相亚氧化钛的报道相对较少,Magnéli相是是亚化学计量的氧化钛,化学式为TinO2n-1(4≤n≤10),通常被称为Magnéli-TiOx相,其中Ti4O7具有最佳的室温导电性以及优异的光吸收性能。

Ti4O7的制备一般是在还原性气氛或惰性气氛如H2[20-22]、CO[23]或Ar[24]中还原TiO2,或者通过固态单质C、Ti、Al、Mg还原TiO2来得到[25]。但是,通过还原性气体还原TiO2不仅具有更高的风险,而且工艺的可重复性也较差。由于文章选用静电纺丝工艺制备的TiO2纤维膜生坯,其中由于聚合物助纺剂的存在,在惰性气氛中煅烧后会产生大量的C单质。因此,文章利用这些原位生成的C单质对TiO2纤维膜进行还原,不仅简化了生产步骤,而且有利于提升材料对太阳光的吸收能力。

-

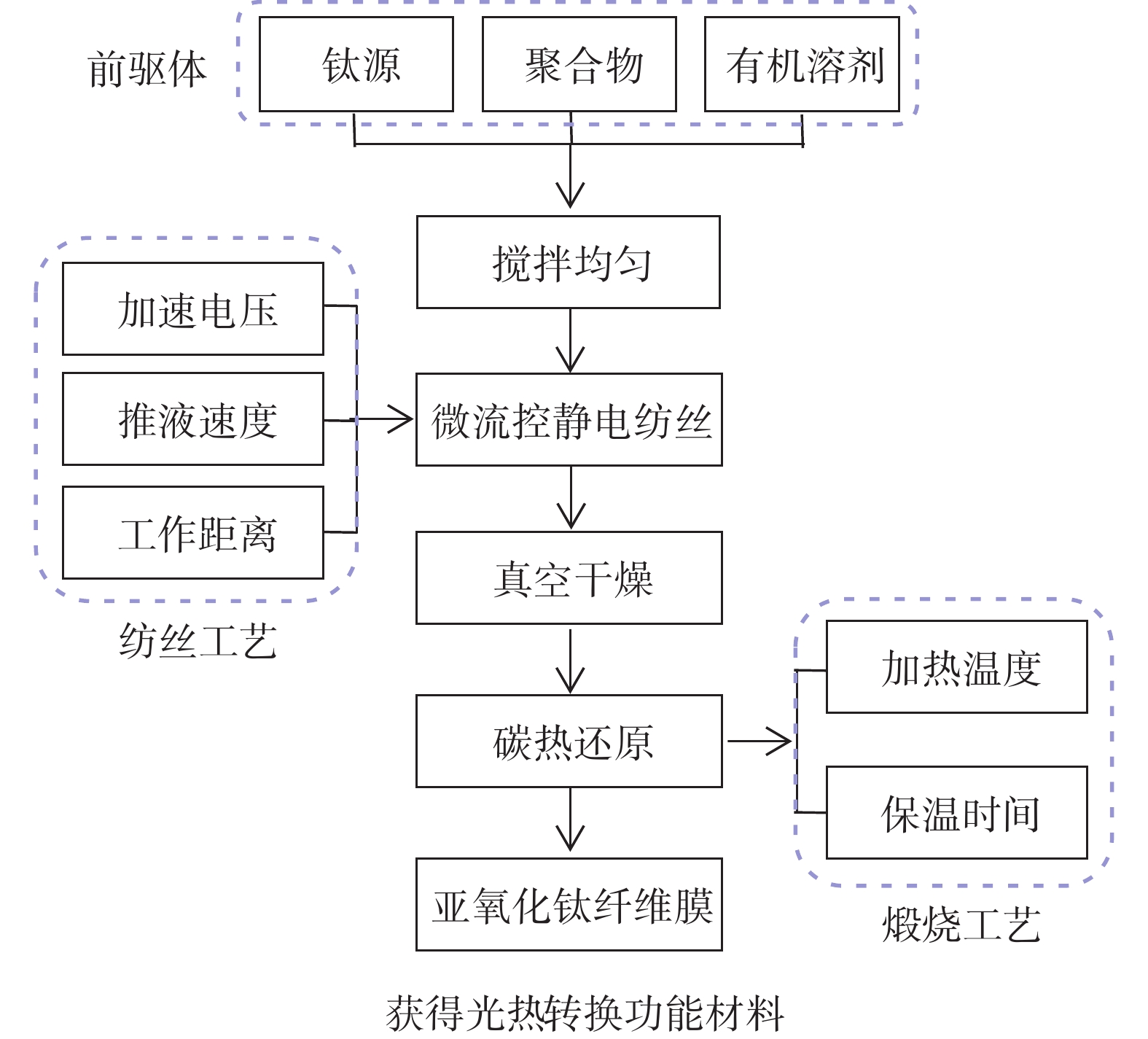

静电纺丝工艺具有设备简单、操作方便及成膜效果好等优点,是目前制备柔性纳米陶瓷纤维膜的主要工艺之一。文章以聚乙烯吡咯烷酮(PVP)为助纺剂,以无水乙醇为溶剂,以钛酸四丁酯为有机钛源。首先,将PVP和无水乙醇混合后以400 r/min的转速搅拌2 h,形成质量分数为7%的均匀溶液,称为溶液A;然后,将10 mL钛酸四丁酯溶液缓慢滴入由20 mL无水乙醇和10 mL冰醋酸组成的混合溶液中,同样以400 r/min的转速搅拌2 h,称为B溶液。其中,冰醋酸主要起到延缓钛酸四丁酯水解的作用。随后,取20 mL溶液A和15 mL溶液B混合均匀后得到C@TiO2纤维膜的纺丝液。通过静电纺丝设备将纺丝液制备成C@TiO2纤维膜生坯,进行真空干燥后在氩气气氛的真空管式炉中进行原位碳热还原,从而得到所需的C@Ti4O7光热转换材料,其制备流程如图1所示。

-

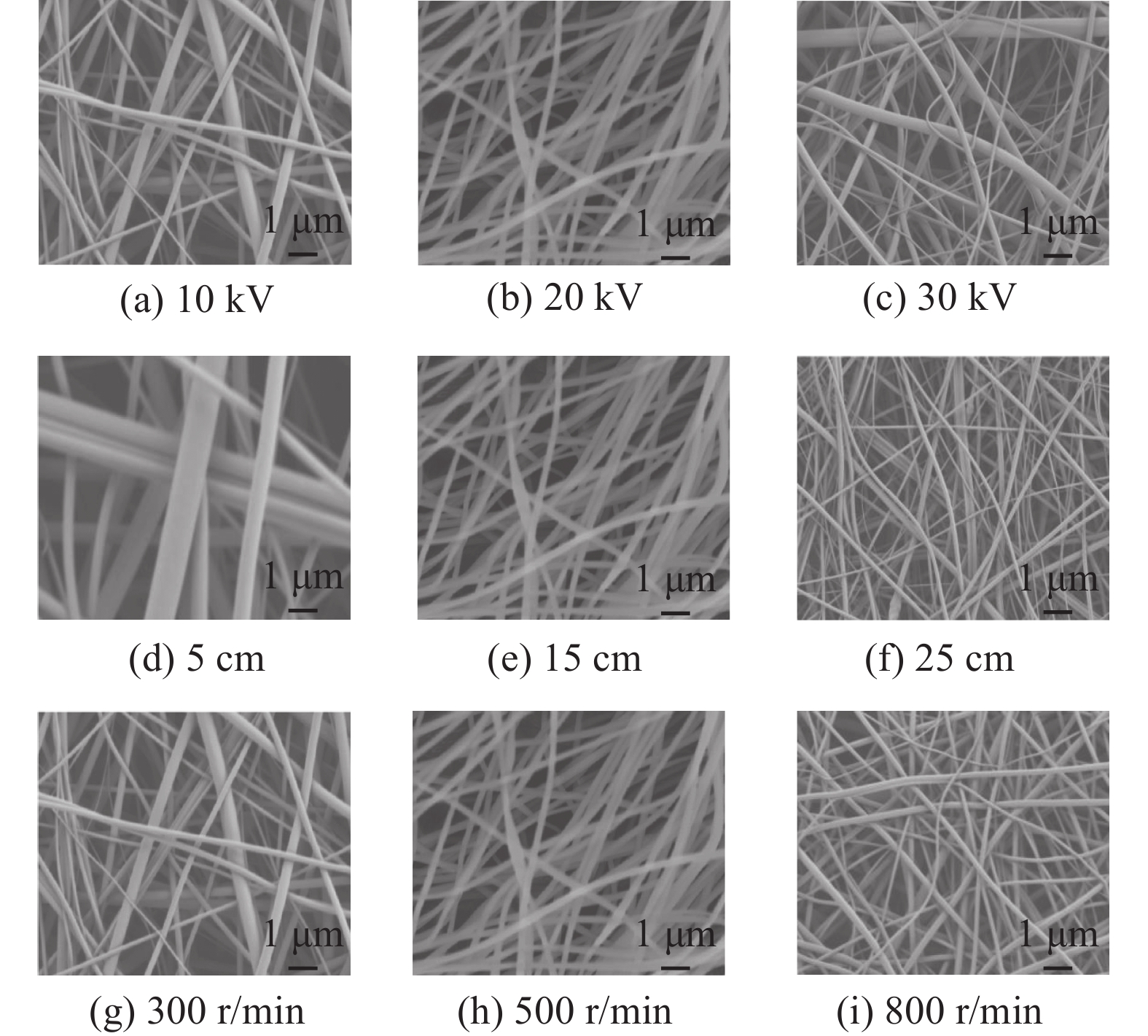

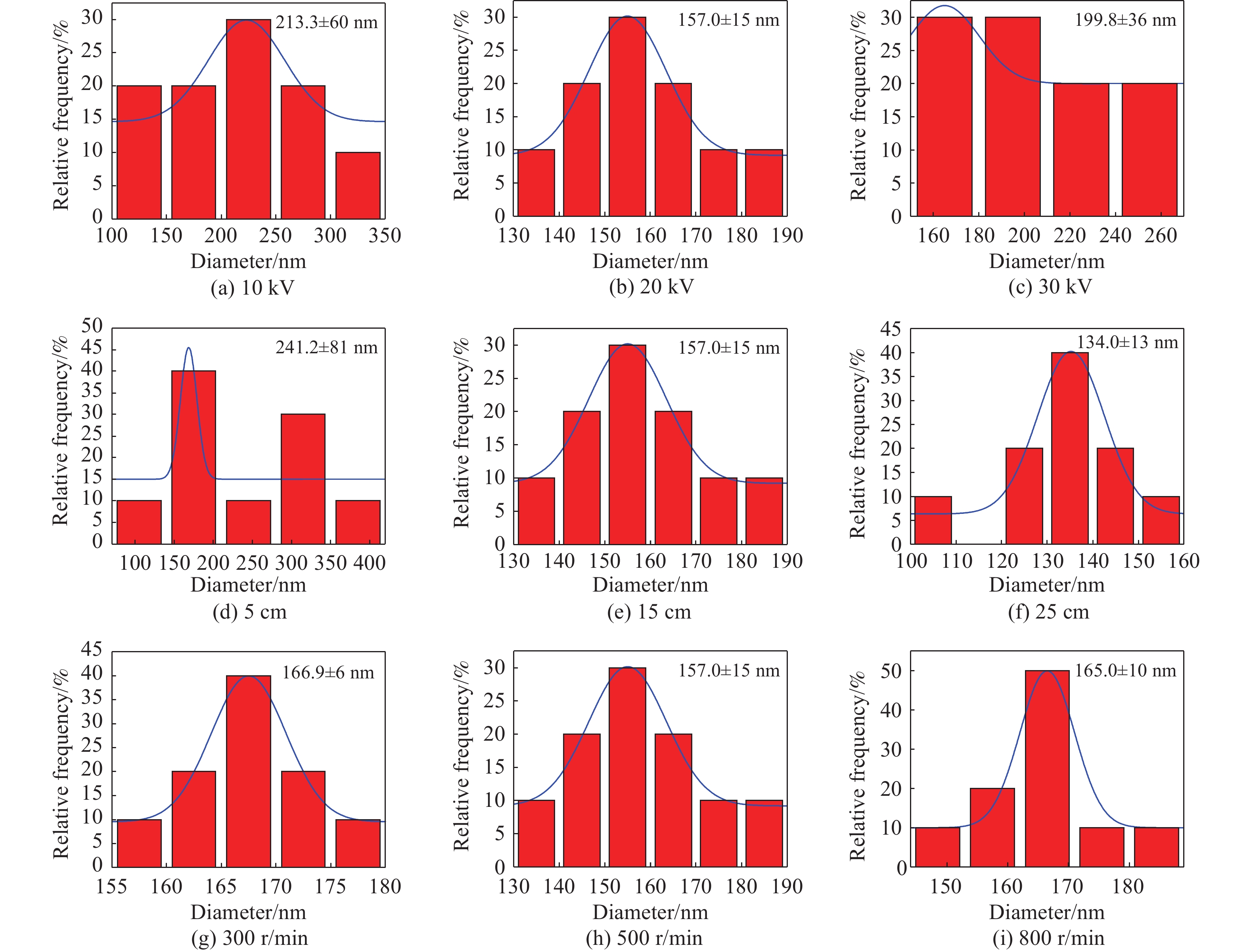

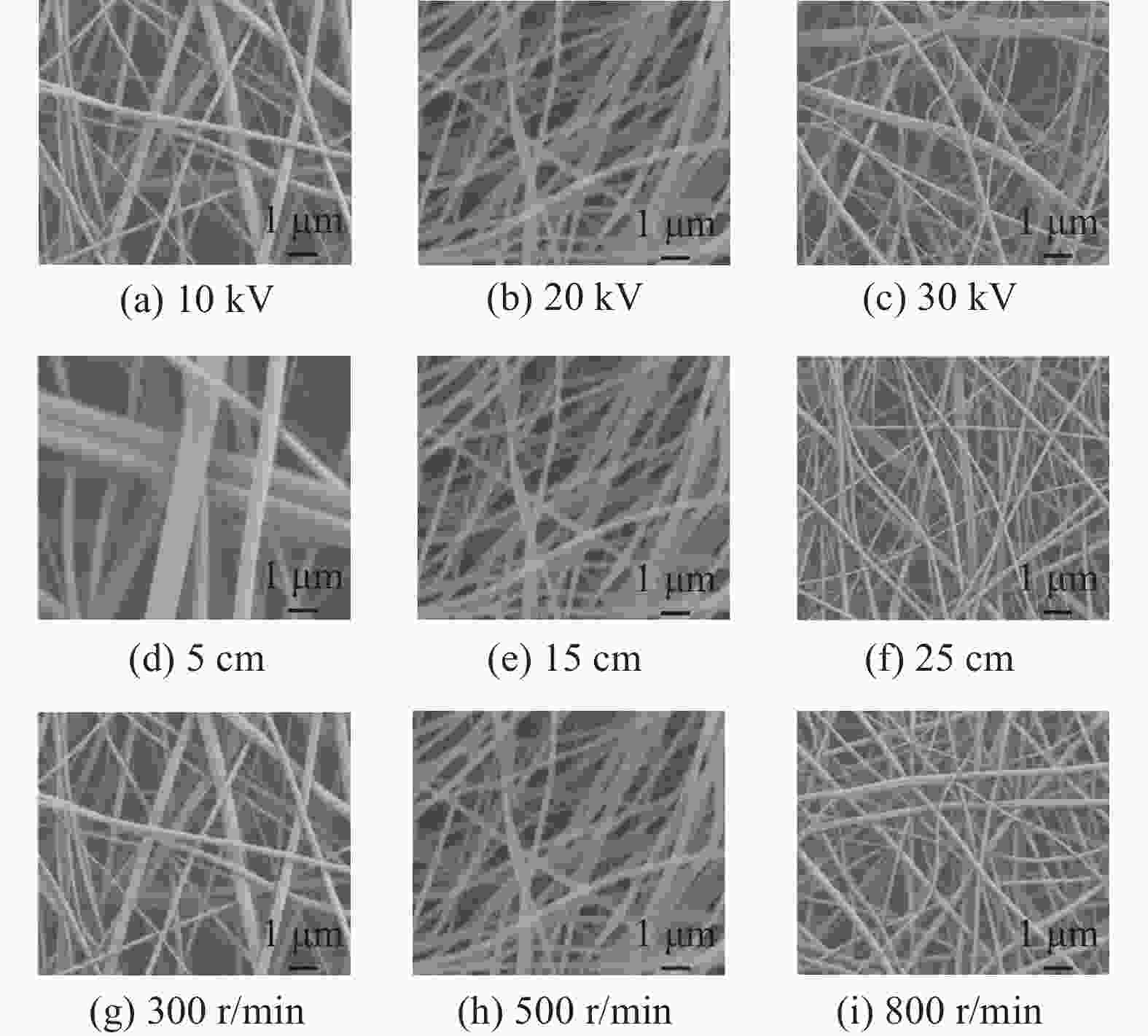

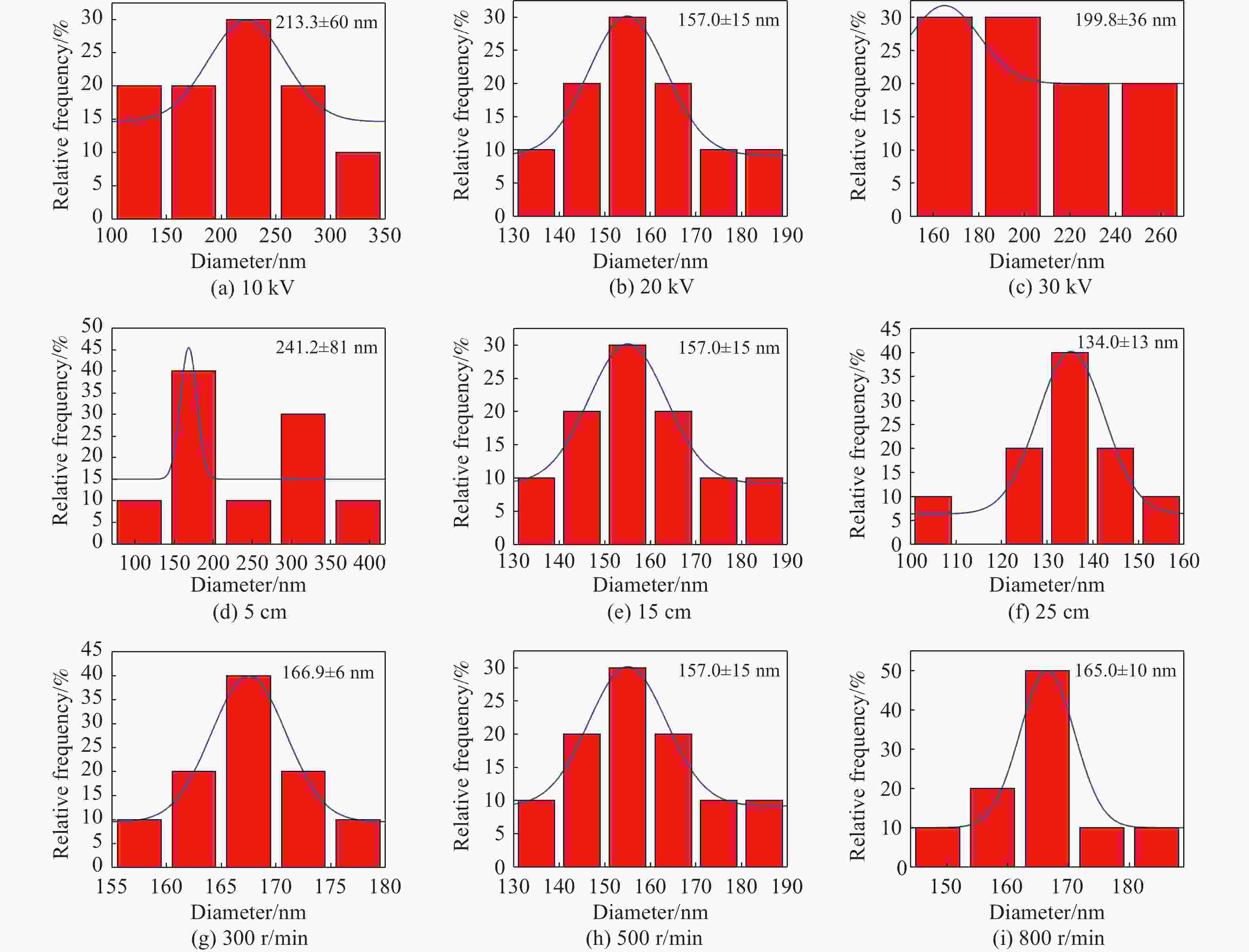

在静电纺丝过程中,加速电压、接收距离和辊筒转速等参数均会对纤维形貌造成明显影响。如图2所示,随着电压由10 kV升高至30 kV,纤维直径逐渐减小,但是当电压过高时,纤维直径的不均匀程度明显增加。接收距离也会对纤维形貌及成丝速度造成很明显的影响,在固定电压为20 kV(正压为15 kV,负压为−5 kV)的条件下,当接收距离为5 cm时,有一部分有机溶剂不能充分挥发,接收到的纤维直径较大并且出现较多并丝的现象;当接收距离为15 cm时,形成的纤维较为光滑,溶剂的挥发较为充分,纤维的直径分布相对均匀;当接收距离为25 cm时,纤维由于过度拉伸而直径缩小,接收效率降低且直径均匀程度降低。另外,纤维直径也会受到辊筒转速的影响,滚筒转速越高,纤维的直径拉伸得越细长,但是辊筒转速也不宜过高,否则容易导致纤维颈缩和断裂。

如图3所示,对不同工艺条件下所得到的纤维直径分布进行高斯拟合。加速电压过高、接收距离过近或过远都会使得直径分布不均匀。当纺丝加速电压为20 kV,接收距离为15 cm,滚筒转速为500 r/min时,纤维直径分布符合正态分布,平均直径为(157±15) nm。

-

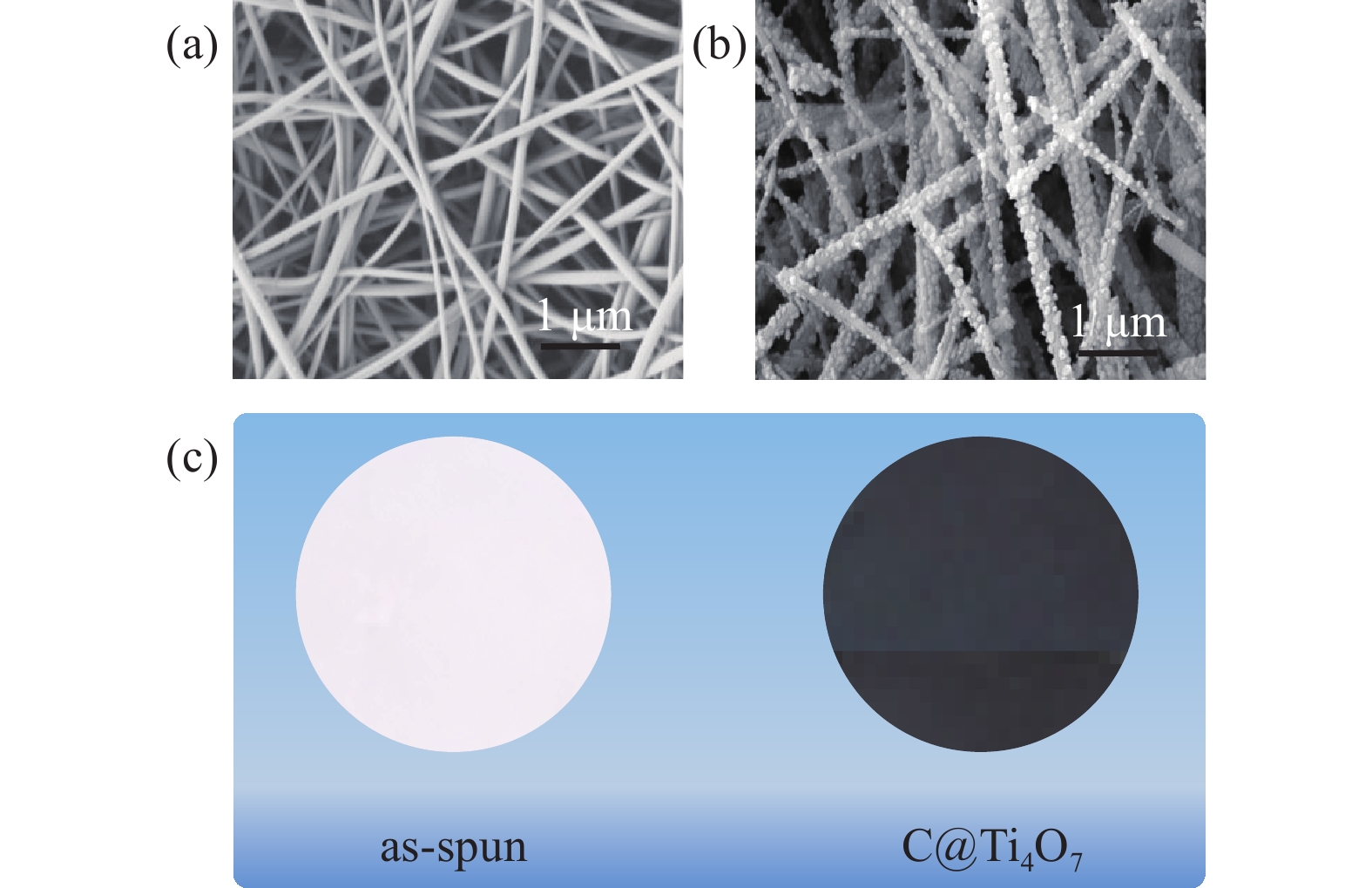

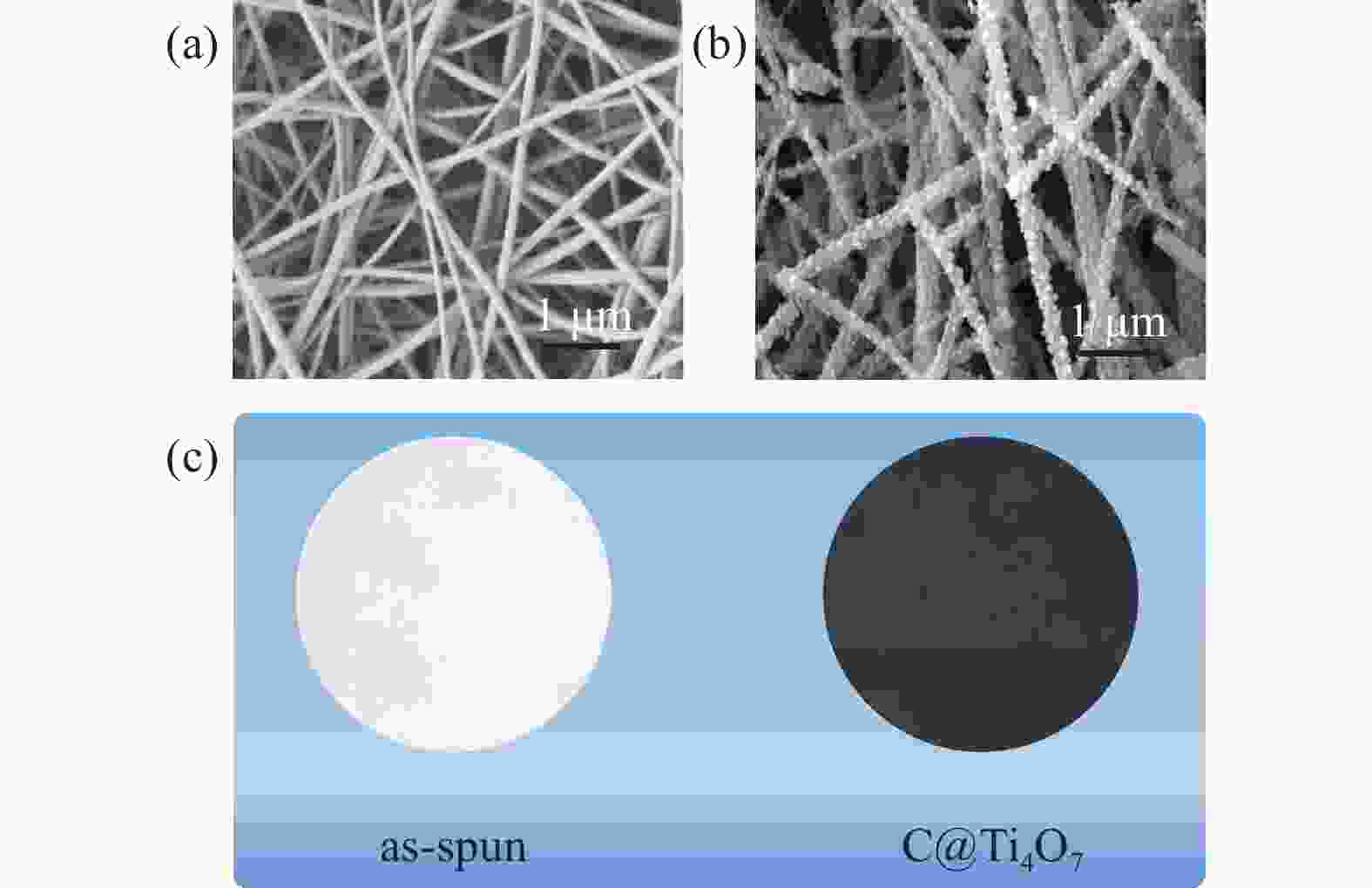

如图4(a)所示,初纺纤维表面光滑且直径分布较为均匀。根据之前的研究工作,纤维膜的煅烧温度设定为800 ℃,保温时间为2 h的条件下能够获得主要物相为Ti4O7的碳基陶瓷纤维[26]。在800 ℃于氩气气氛中进行高温煅烧后,纤维表面出现大量Ti4O7颗粒,这些Ti4O7颗粒是由纤维内部的TiO2经碳热还原而得到的,发生的化学反应方程如式(1)所示,煅烧前后的纤维微观形貌如图4(b)所示。

$$ 4 \mathrm{TiO}_2+\mathrm{C}=\mathrm{Ti}_4 \mathrm{O}_7+\mathrm{CO}(\mathrm{g}) $$ (1) 纤维膜在煅烧前后的宏观形貌如图4(c)所示,初纺纤维膜生坯为白色,经过高温碳热还原之后,纤维膜表面呈现深黑色。

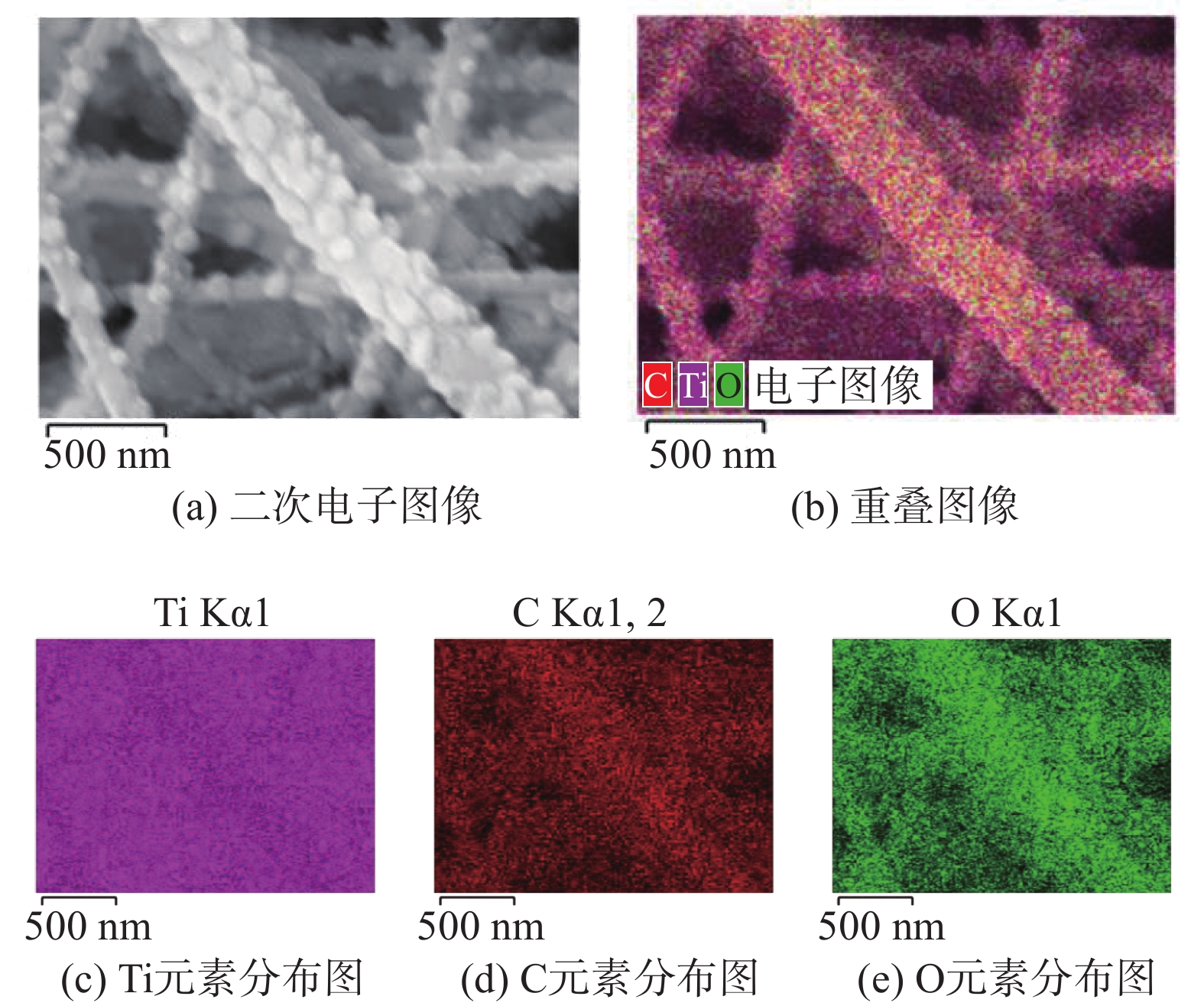

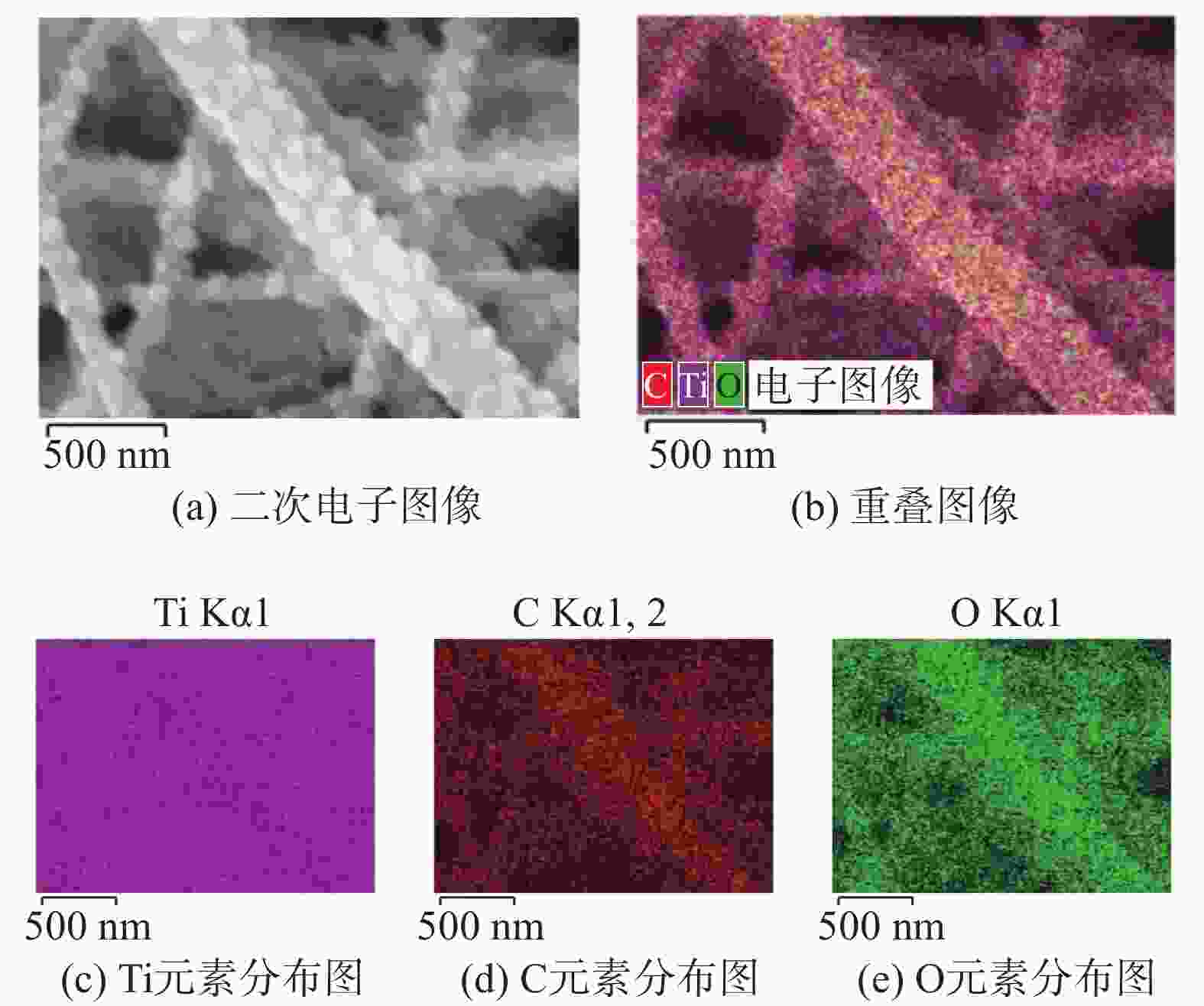

如图5所示,通过能谱仪(EDS)对在800 ℃还原2 h后得到的纤维膜进行了成分分析。纤维膜主要由Ti、C和O 3种元素组成,其中,C元素在整个纤维膜内部均匀分布,纤维膜表面的颗粒主要由Ti和O元素组成。

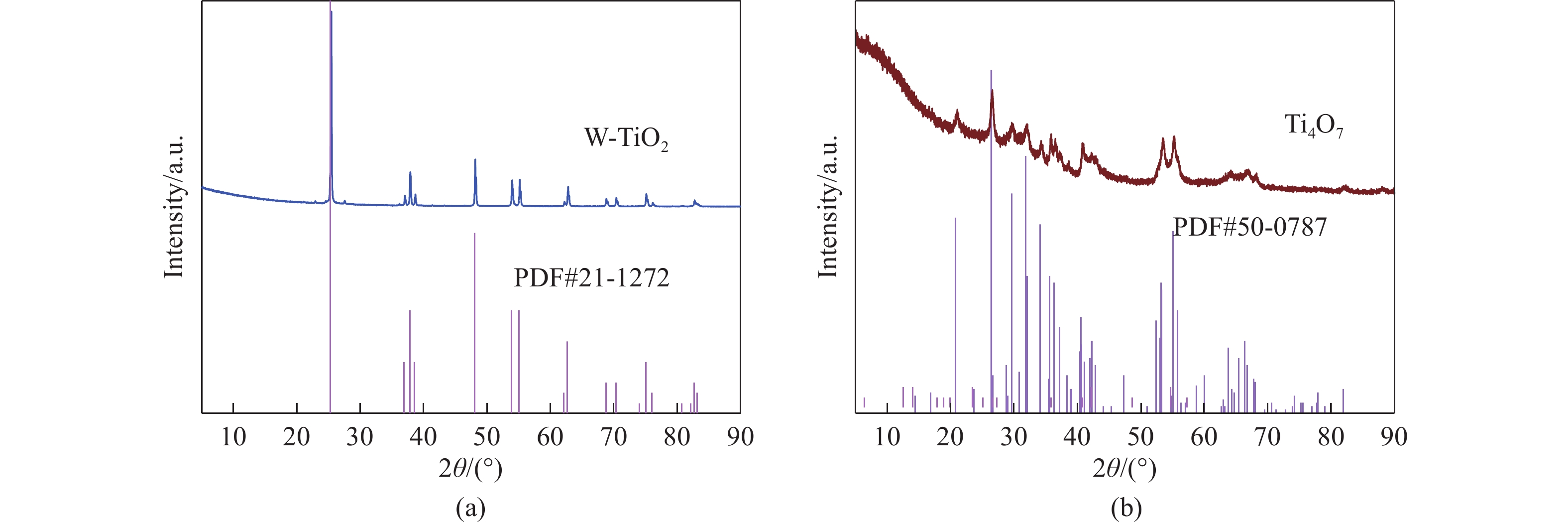

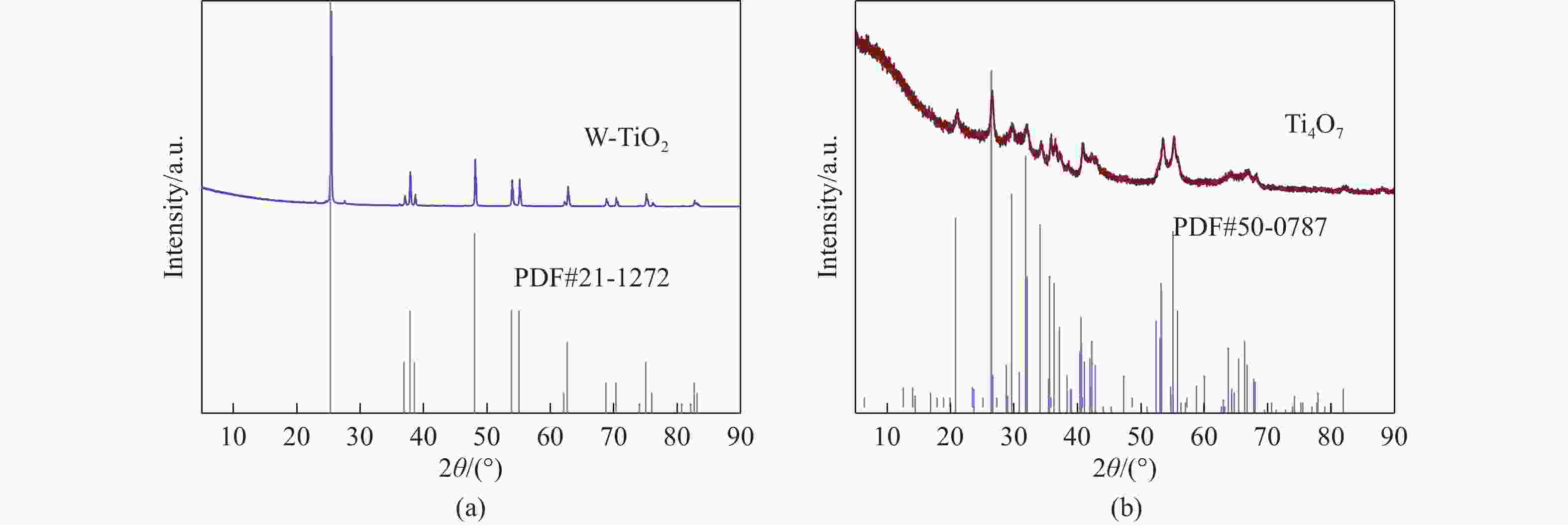

作为对比,同时在空气气氛中于800 ℃煅烧2 h得到了不含C元素的白色TiO2纤维膜,记作W-TiO2。W-TiO2和C@Ti4O7的物相组成如图6所示。其中,纤维膜中的物相主要为金红石相TiO2,其X射线衍射(XRD)图谱与标准图谱PDF #21-1272相对应。而C@Ti4O7纤维膜中的物相主要为Ti4O7,其X射线衍射(XRD)图谱与标准图谱PDF #50-0787相对应,其中C的峰被掩盖。

-

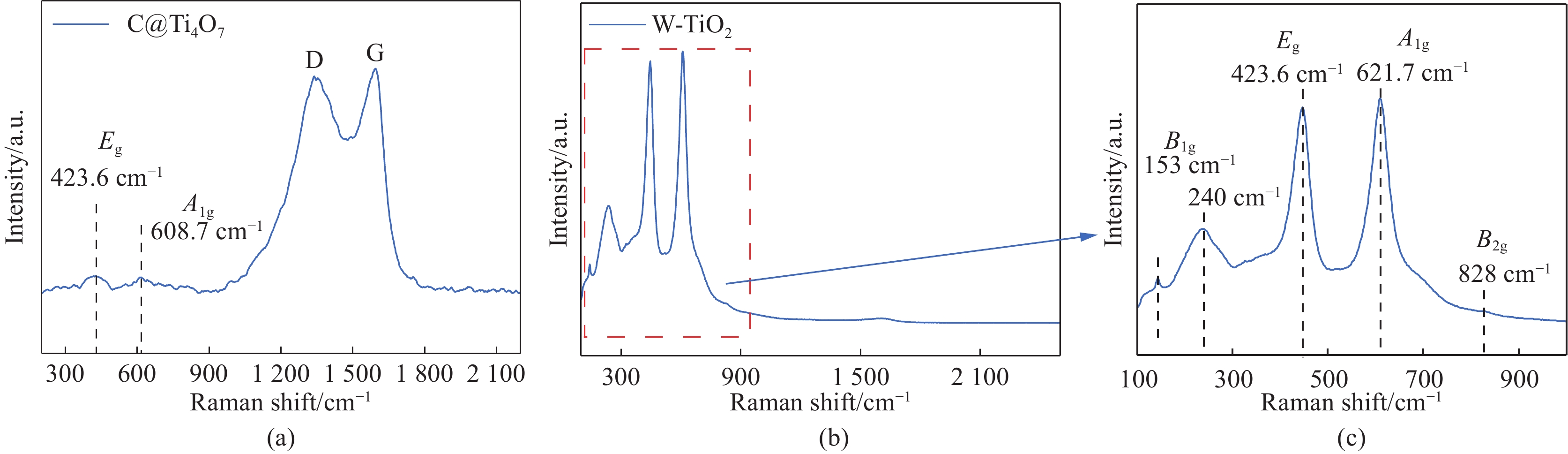

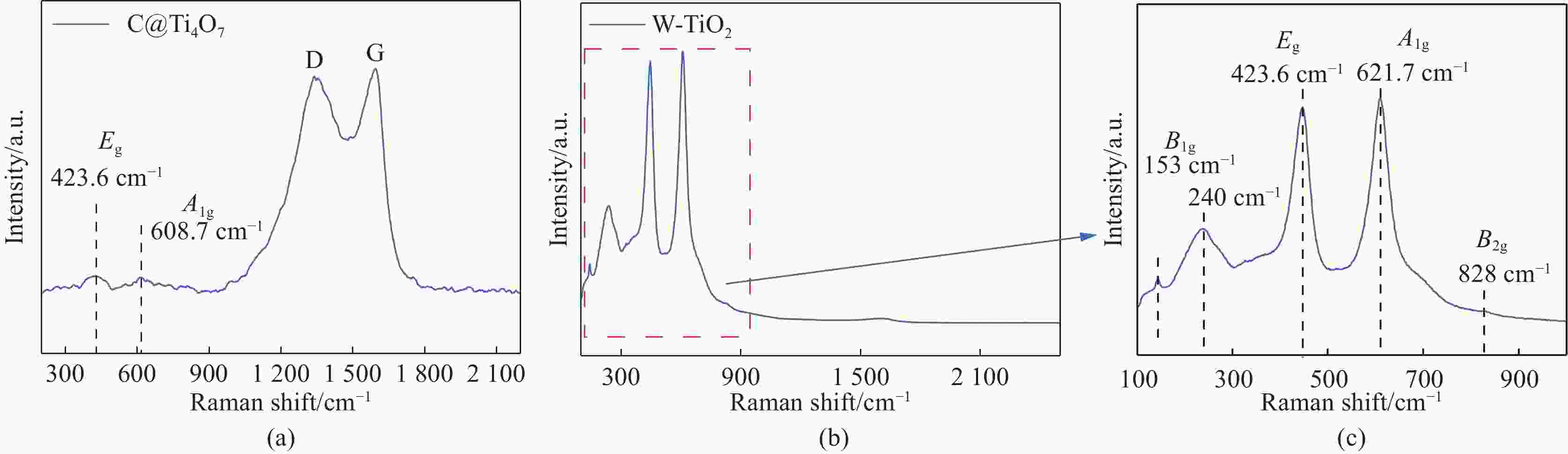

如图7所示,在C@Ti4O7纤维膜的拉曼图谱中出现了明显的D带(1326 cm−1)和G带(1582 cm−1),说明纤维膜内部的C除了参与碳热还原反应,还有残余的C起到了原位碳元素掺杂的作用。而在空气气氛下煅烧得到的W-TiO2纤维膜的拉曼测试结果中并未出现D带和G带,只出现了TiO2所对应的峰谱。

-

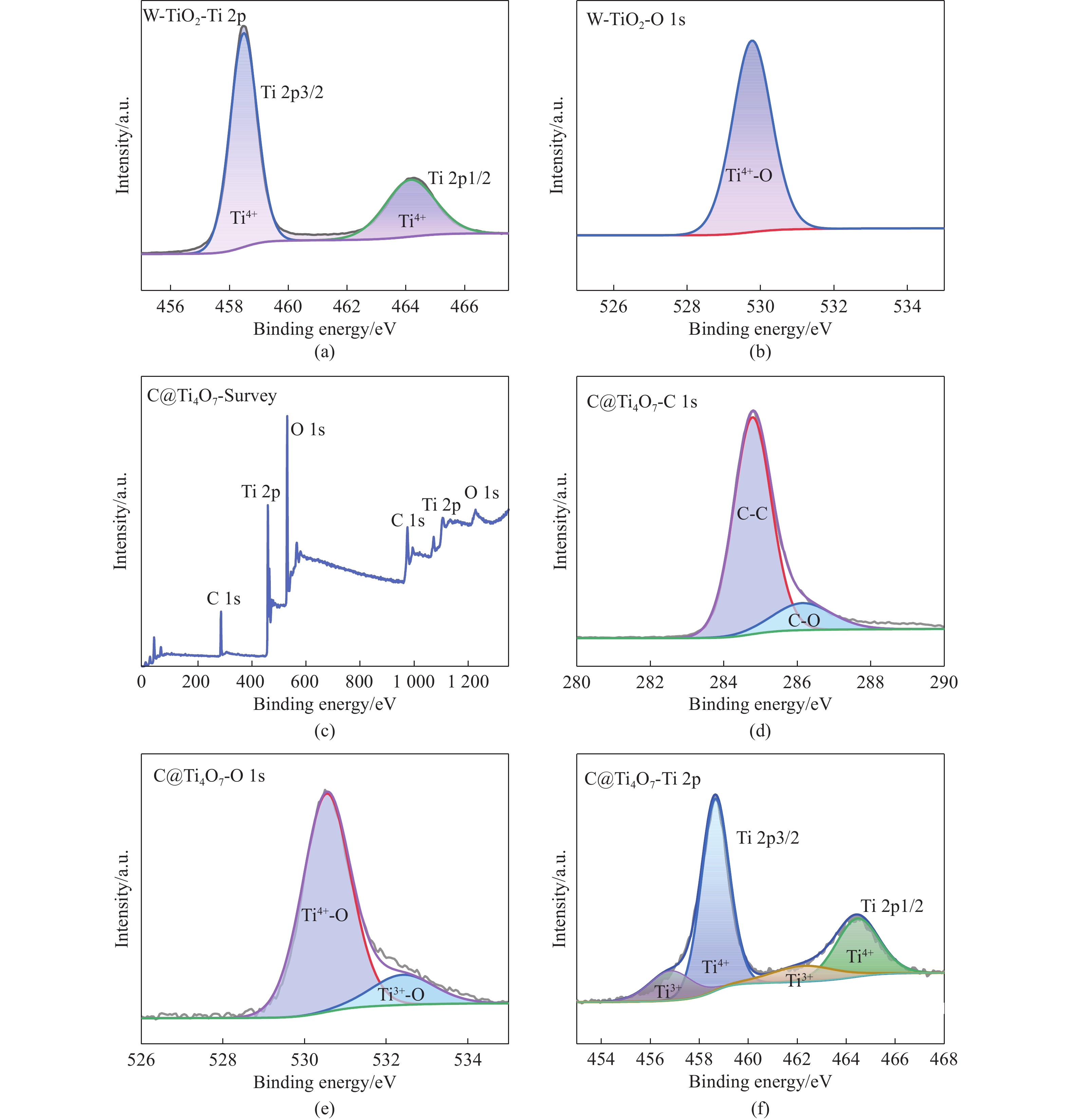

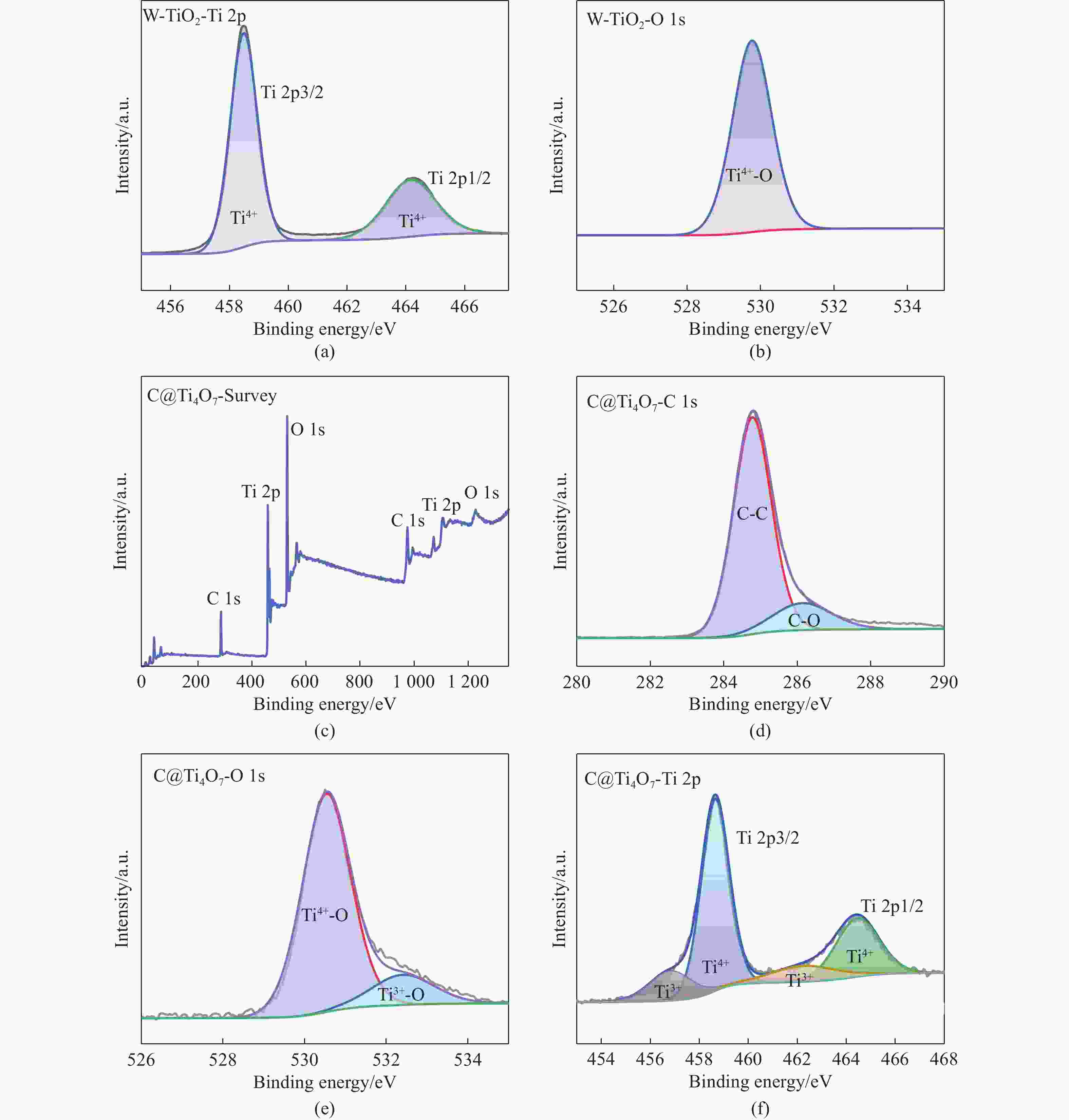

根据Ti的氧化程度不同,Ti可能会出现Ti2+、Ti3+和Ti4+ 3种不同的价态,为了确认W-TiO2和C@Ti4O7纤维膜中Ti元素的价态,对两种纤维膜样品进行了X射线光电子能谱(XPS)分析。由于电子的自旋-轨道耦合,Ti 2p能级分解为Ti 2p1/2和Ti 2p3/2两个能级,如图8所示,在W—TiO2纤维膜对应的Ti的标准XPS图谱中,Ti只有Ti4+价态,分别对应的结合能为459.0 eV和464.8 eV。在C@Ti4O7纤维膜对应的高分辨率XPS全谱图中能够明显看出C 1s、Ti 2p和O 1s所对应的谱峰,其中C 1s轨道的主峰位于284.8 eV,对应于C—C的结合能,而位于286.1 eV处的另一个峰与C—O的结合能一致。O 1s轨道的XPS谱图在结合能为529.5 eV处出现了带有一个肩峰的强峰,归属于Ti-O晶格中的O2-。C@Ti4O7纤维膜对应的Ti标准XPS图谱中,在结合能为457.6 eV和462.8 eV出现了明显的Ti 2p3/2和Ti 2p1/2轨道的特征峰,证明了C@Ti4O7纤维膜中Ti3+的存在[27]。这些Ti3+的3d轨道会由于John-Teller效应的存在而分裂成费米能级以下1 eV的带隙态和费米能级2.5 eV的激发态,Ti3+的跃迁通过局域的d→d跃迁即可实现带隙态到激发态的跃迁,使得材料的吸收光谱大大扩展,从而提高光热转换效率[28]。

-

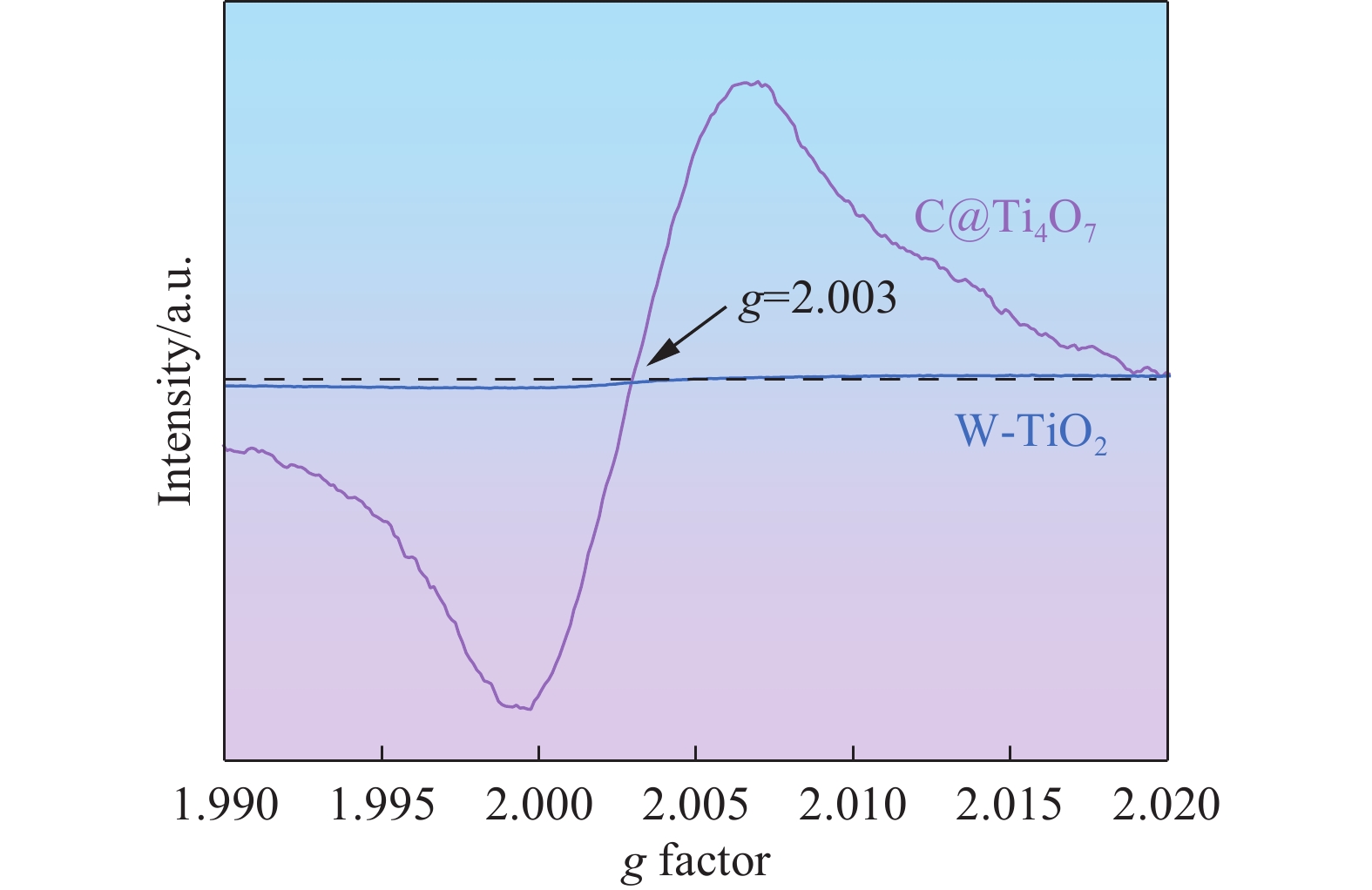

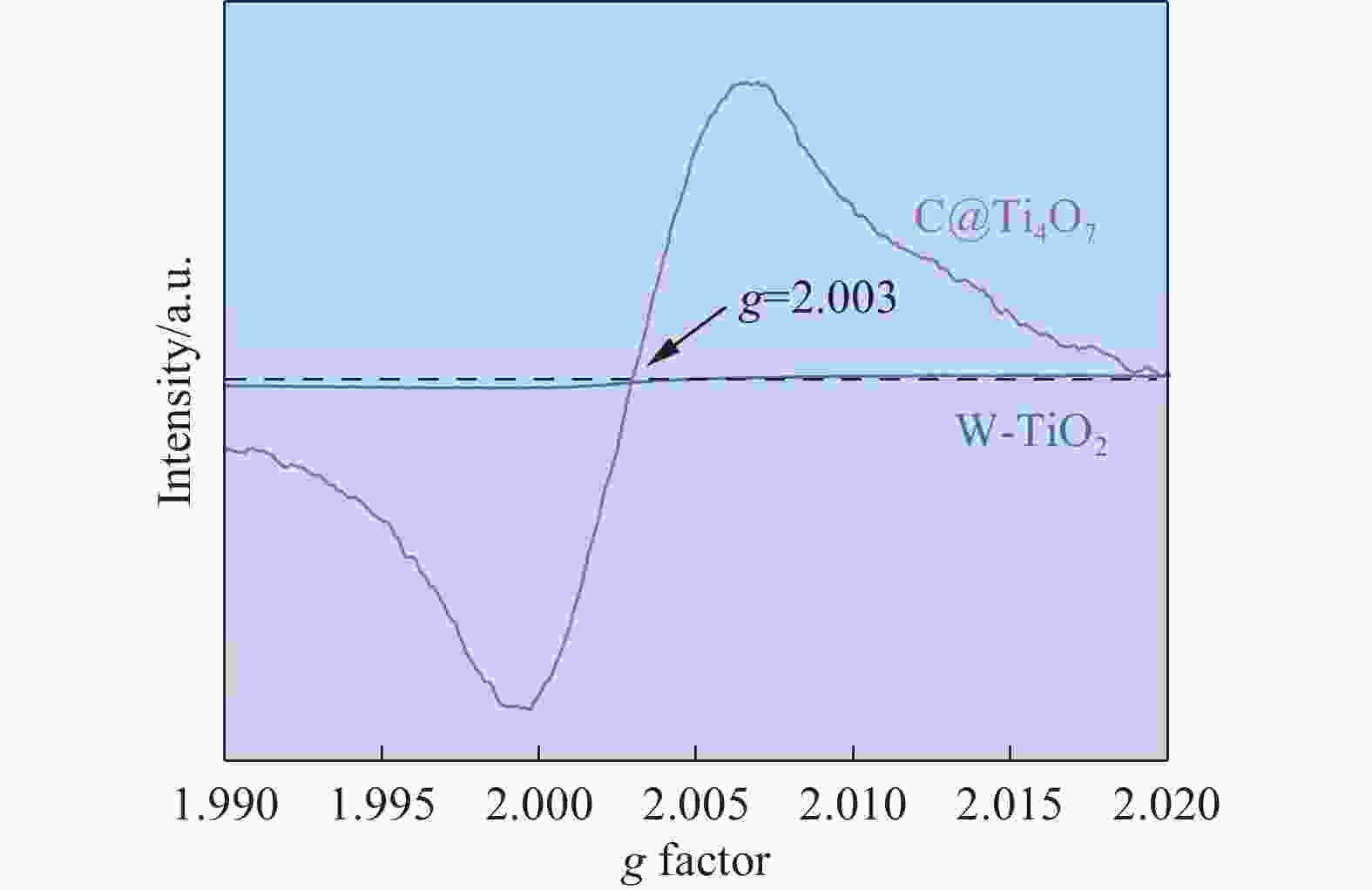

氧空位的存在对材料的吸光特性具有重要影响,文章采用电子顺磁共振(EPR)光谱对纤维膜内部的氧空位进行了检测。由于顺磁样品在合适的磁场下会在特定频率上吸收电磁辐射,从而能够提供材料表面的未配对电子的指纹信息。如图9所示,峰值中心对应磁场的g因子的值为2.003,证明了C@Ti4O7纤维膜中存在大量的氧空位,这些氧空位可以增加电子密度,降低电子与原子核之间的距离,从而进一步降低C@Ti4O7的带隙宽度,而W-TiO2纤维膜中几乎不存在氧空位。

-

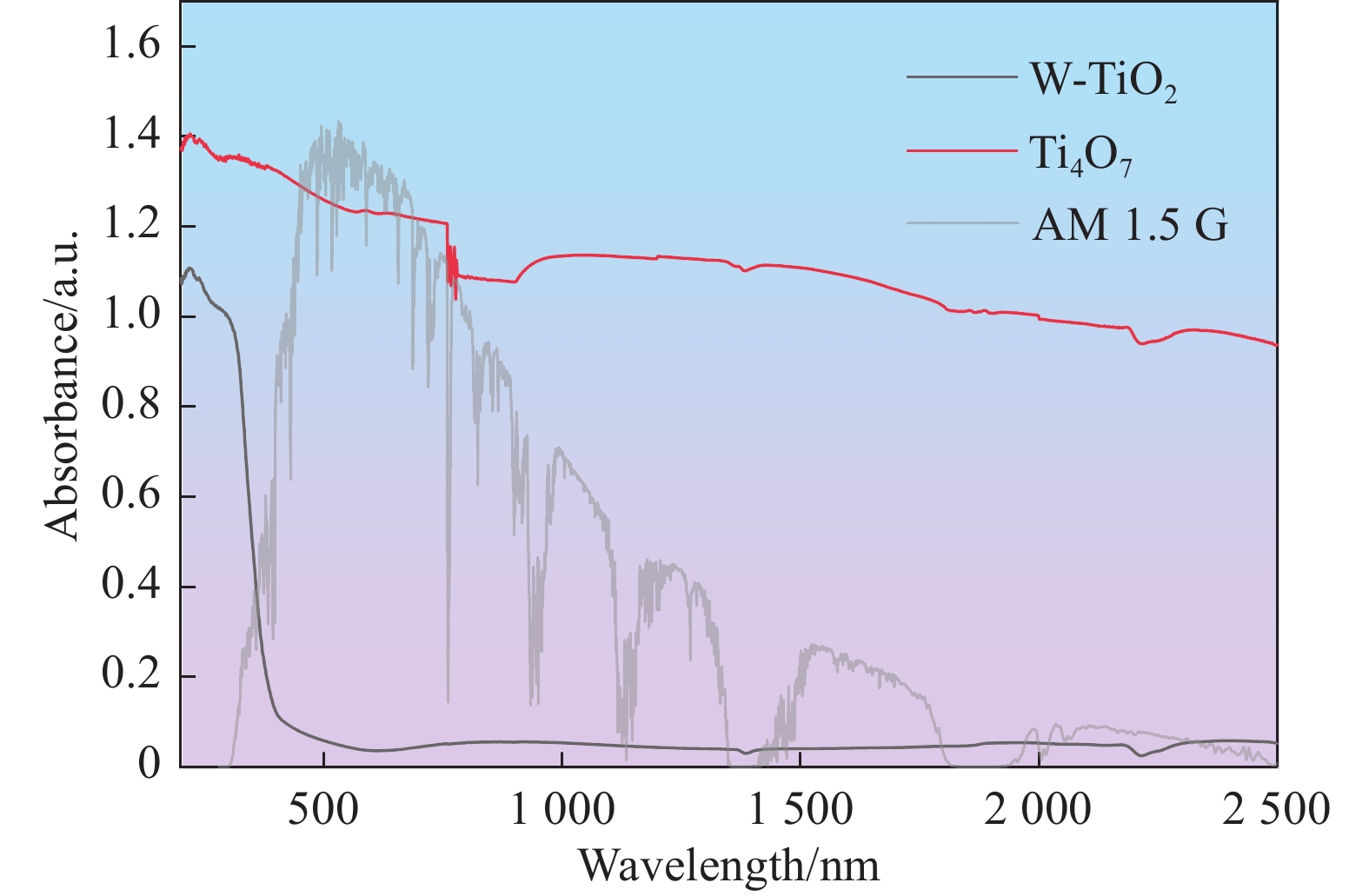

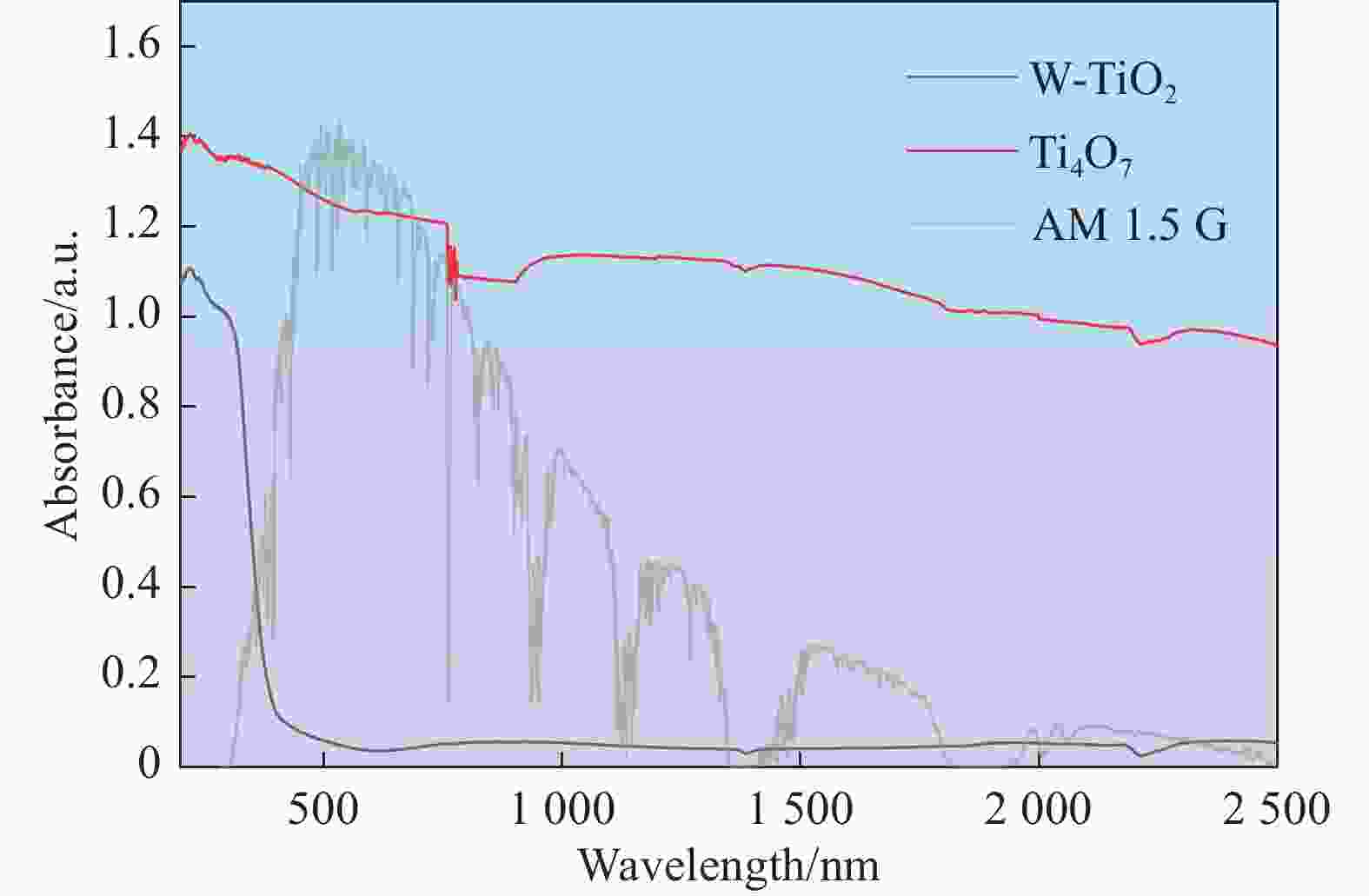

能够辐射至地面的太阳光的波长主要分布在200~2500 nm,因此,文章主要通过紫外-可见分光光度仪(UV-Vis-NIR)对样品在200~2500 nm范围内的光吸收性能进行分析。由图10可以看出,W-TiO2纤维膜仅对200~400 nm的紫外光具有较为明显的吸收能力,对可见光和近红外光的吸收能力很弱,而C@Ti4O7纤维膜在全光谱内对太阳光均有优异的吸收能力。

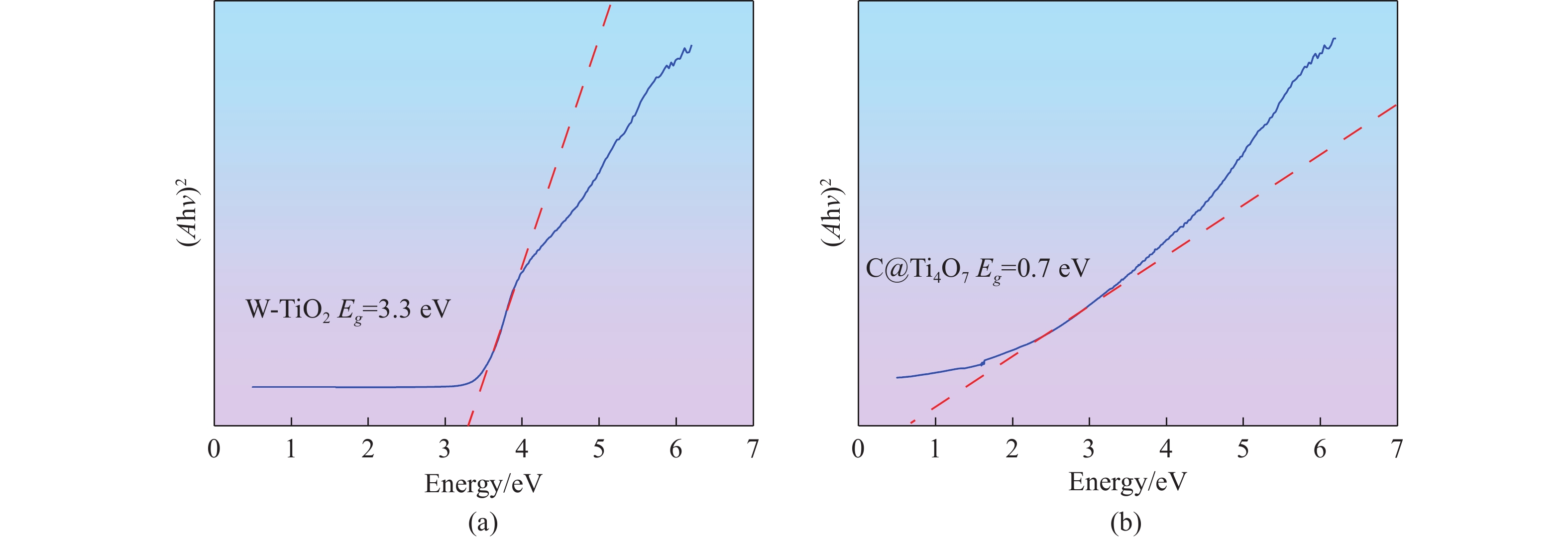

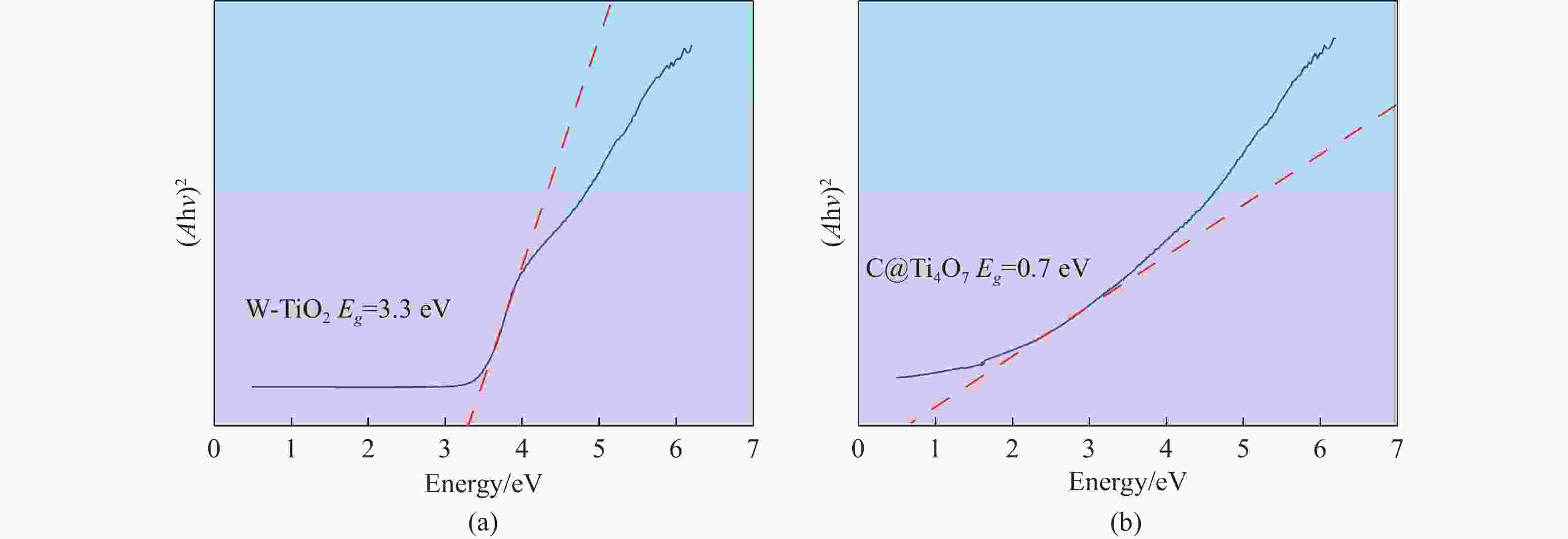

由于半导体材料对太阳光的吸收主要依靠价带-导带跃迁,带隙在很大程度上影响了半导体材料对可见光的吸收能力,带隙越小,其光吸收能力越强。W-TiO2和C@Ti4O7的带隙Eg计算如式(2)所示:

$$ (\alpha \mathrm{h} v)^{1 / 2}=A\left(\mathrm{h} v-E_g\right) $$ (2) 式中:

α ——吸光度指数;

h ——普朗克常数,4.14×10 −15 (eV·s);

ν ——光频率(s−1);

A ——常数。

W-TiO2和C@Ti4O7纤维膜的Tauc图如图11所示,其中W-TiO2的带隙为3.3 eV,而C@Ti4O7的带隙仅为0.7 eV,远低于W-TiO2,进一步证明了C@Ti4O7纤维膜具有更强的光吸收能力。

-

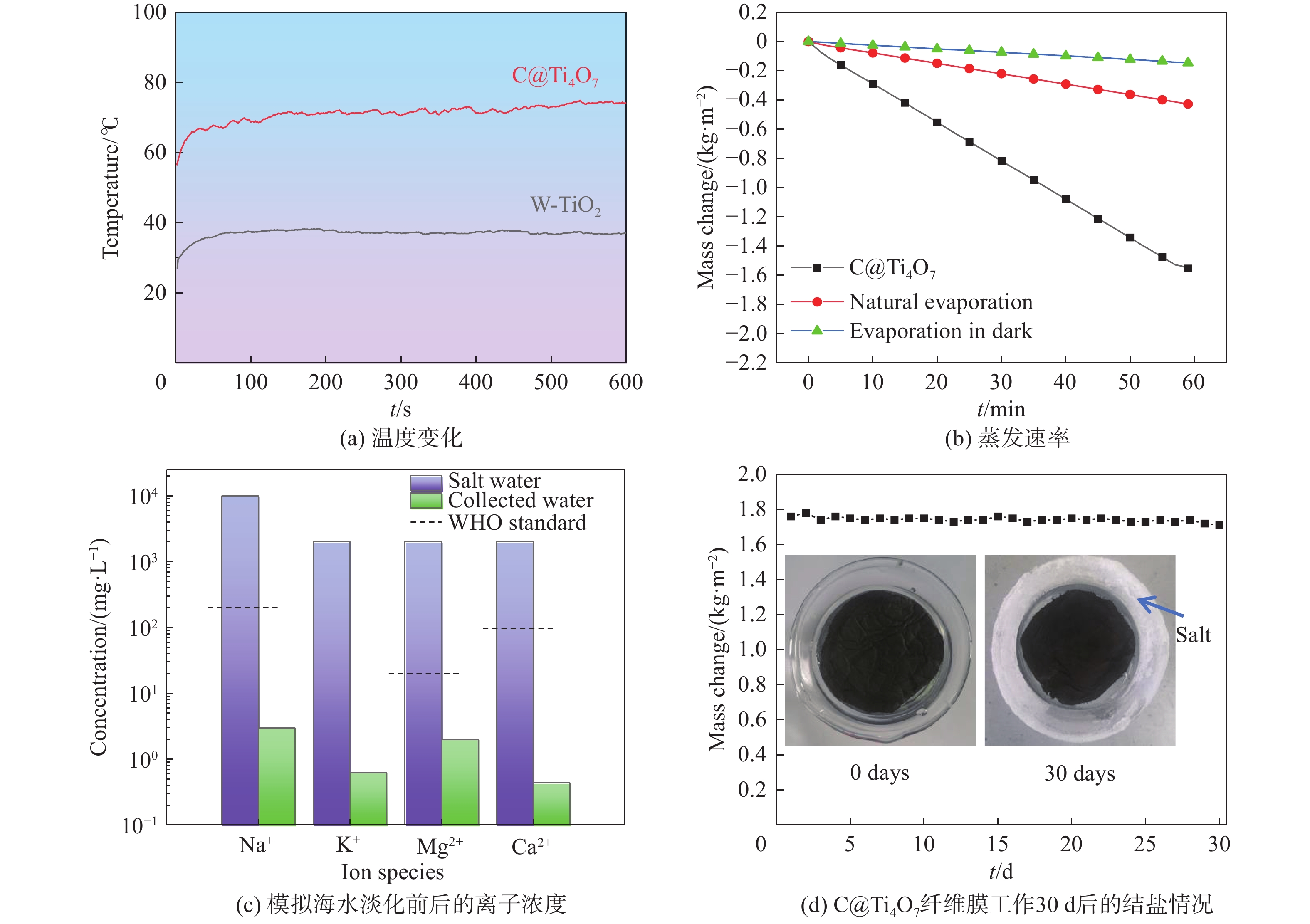

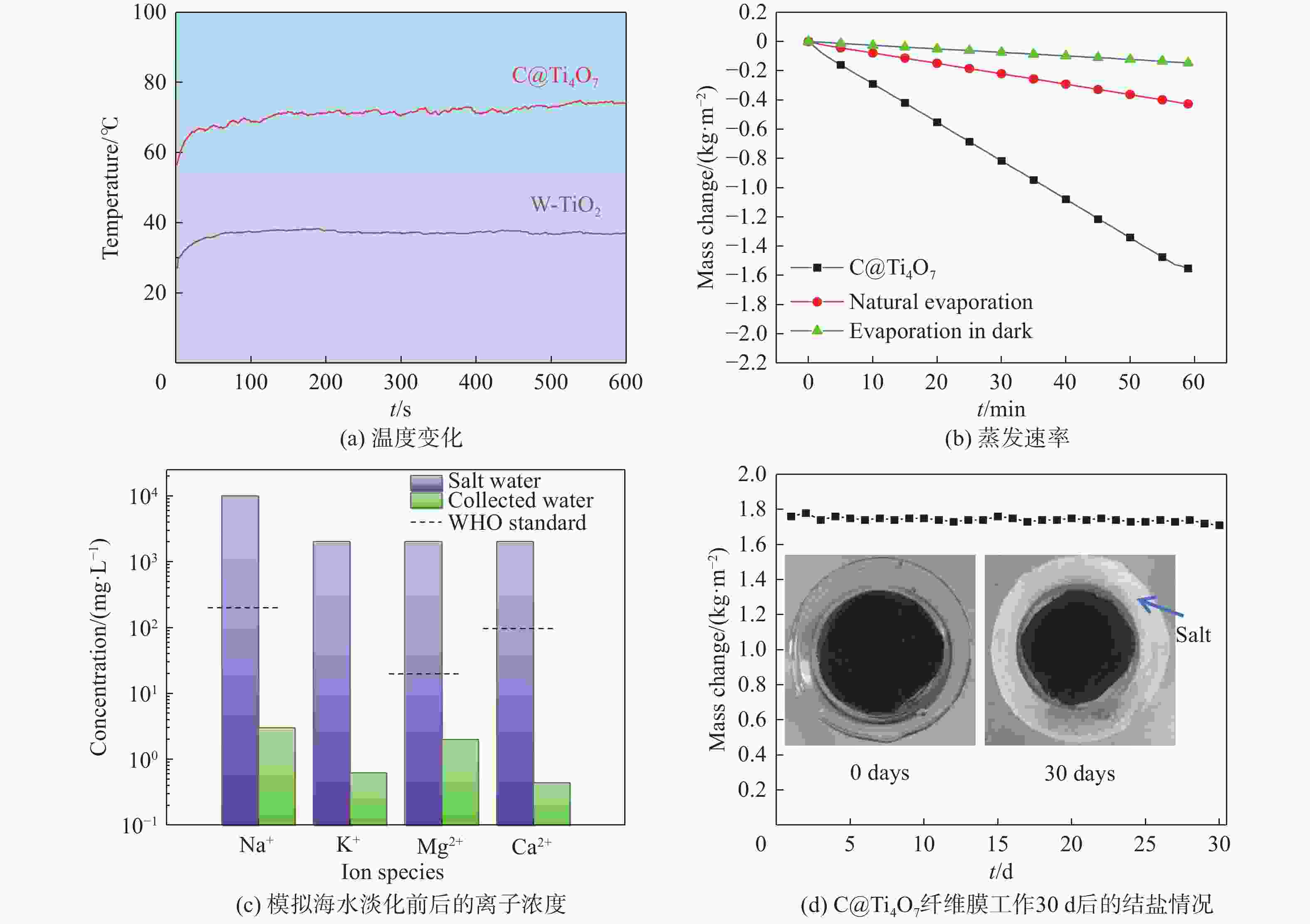

通过太阳光模拟器对W-TiO2和C@Ti4O7纤维膜表面进行照射,采用高精度接触式热电偶测温仪对其表面温度变化进行监测。如图12(a)所示,W-TiO2纤维膜在1 kW/m2的光强照射下,其表面温度最高约为38.3 ℃,而C@Ti4O7纤维膜在相同的光照强度下能够达到74.55 ℃。为了测试纤维膜的海水淡化能力,通过将10000 mg/L NaCl、500 mg/L KCl、500 mg/L MgCl2、500 mg/L CaCl2混合均匀配置了模拟海水。为了计算其蒸发速率,采用万分之一精度的天平对其在太阳光模拟器下的质量变化进行了实时监测,如图12(b)所示,模拟海水在黑暗环境中的蒸发速率约为0.15 kg/(m2·h),自然蒸发速率约为0.42 kg/(m2·h),而漂浮C@Ti4O7纤维膜的水体的蒸发速率达到1.55 kg/(m2·h),相较于之前报道过的黑色氧化钛膜材料在界面水蒸发中能够达到的蒸发速率提高了33.62%[29-30]。C@Ti4O7纤维膜蒸发器能够达到如此高的蒸发速率不仅得益于其优异的光热转换能力,而且与其优异的亲水性有较大关系,由于C@Ti4O7纤维膜是通过静电纺丝工艺和高温煅烧得到的金属氧化物陶瓷,其表面存在大量的羟基(-OH),这些-OH带来的亲水特性使其能够通过毛细作用将水分源源不断地传输至蒸发器表面[31]。在蒸发冷凝后,收集到的水能够达到世界卫生组织(WHO)对饮用水的标准,如图12(c)所示,模拟海水中4种主要离子浓度在蒸发后下降约4个数量级。如图12(d)所示,C@Ti4O7纤维膜在工作30 d后仍未结盐。

C@Ti4O7纤维膜的光热转换效率η可通过式(3)进行计算:

$$ \eta=\dot{m} h_{{\mathrm{L V}}} / \mathrm{I} $$ (3) 式中:

ṁ ——蒸发水量的质量通量[ṁ=mlight−mdark,kg/(m2·h)];

hLV——水在气-液界面处相变总焓(温度升高导致的显热和相变导致的潜热);

I ——直射太阳光标准强度,3600 kJ/(m2·h)。

其中,hLV可通过式(4)进行计算:

$$ h_{{\mathrm{L V}}}=\lambda+\mathrm{C} {\mathit{\Delta }}T $$ (4) 式中:

λ ——水的相变潜热,2257.2 kJ/kg;

C ——水的比热容常数,4.19 J/(g·K);

ΔT ——水蒸气温度与环境温度之间的差值(K)。

通过以上计算可得,碳基陶瓷C@Ti4O7纤维膜的光热转换效率η高达90.68%。

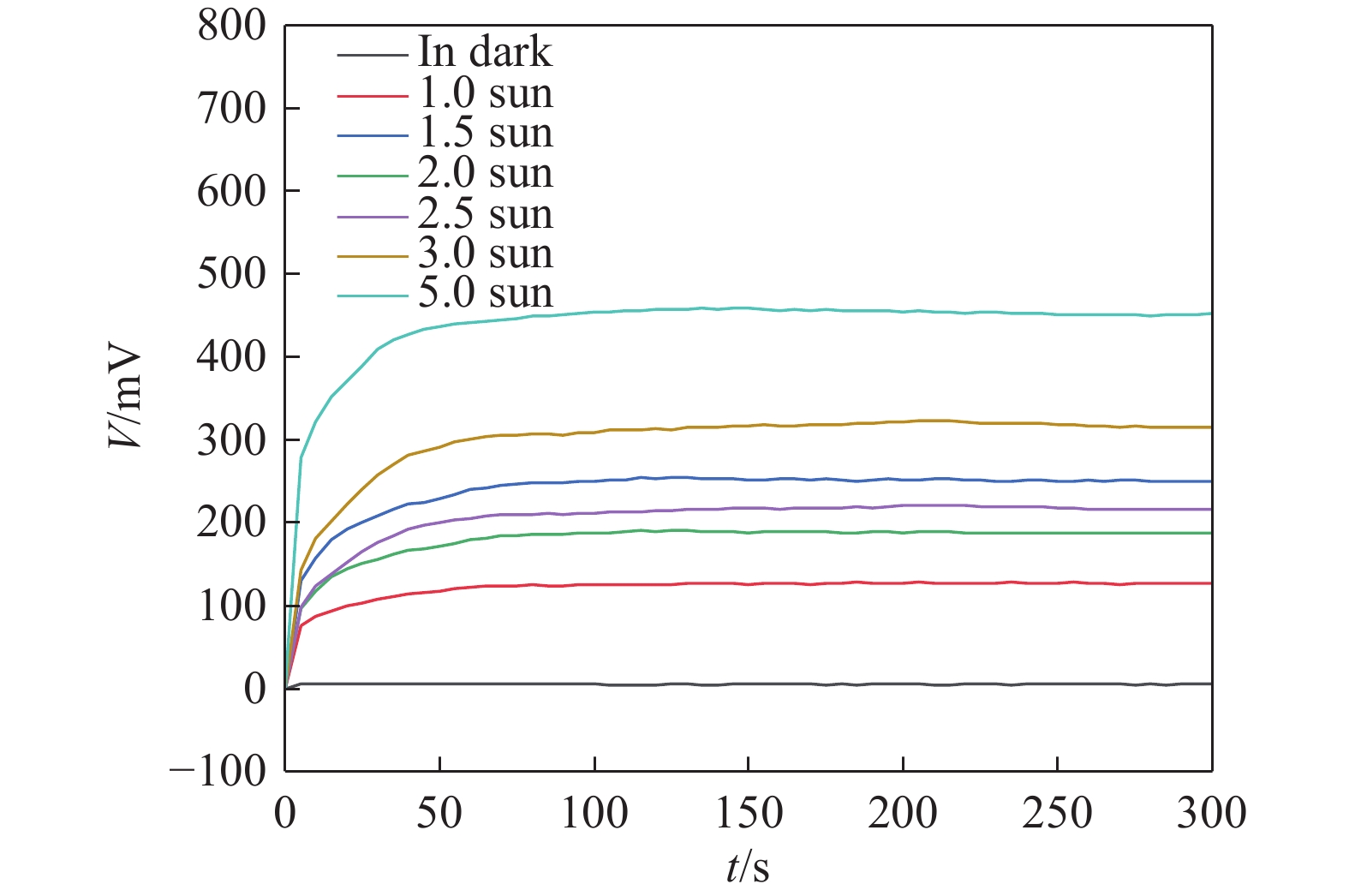

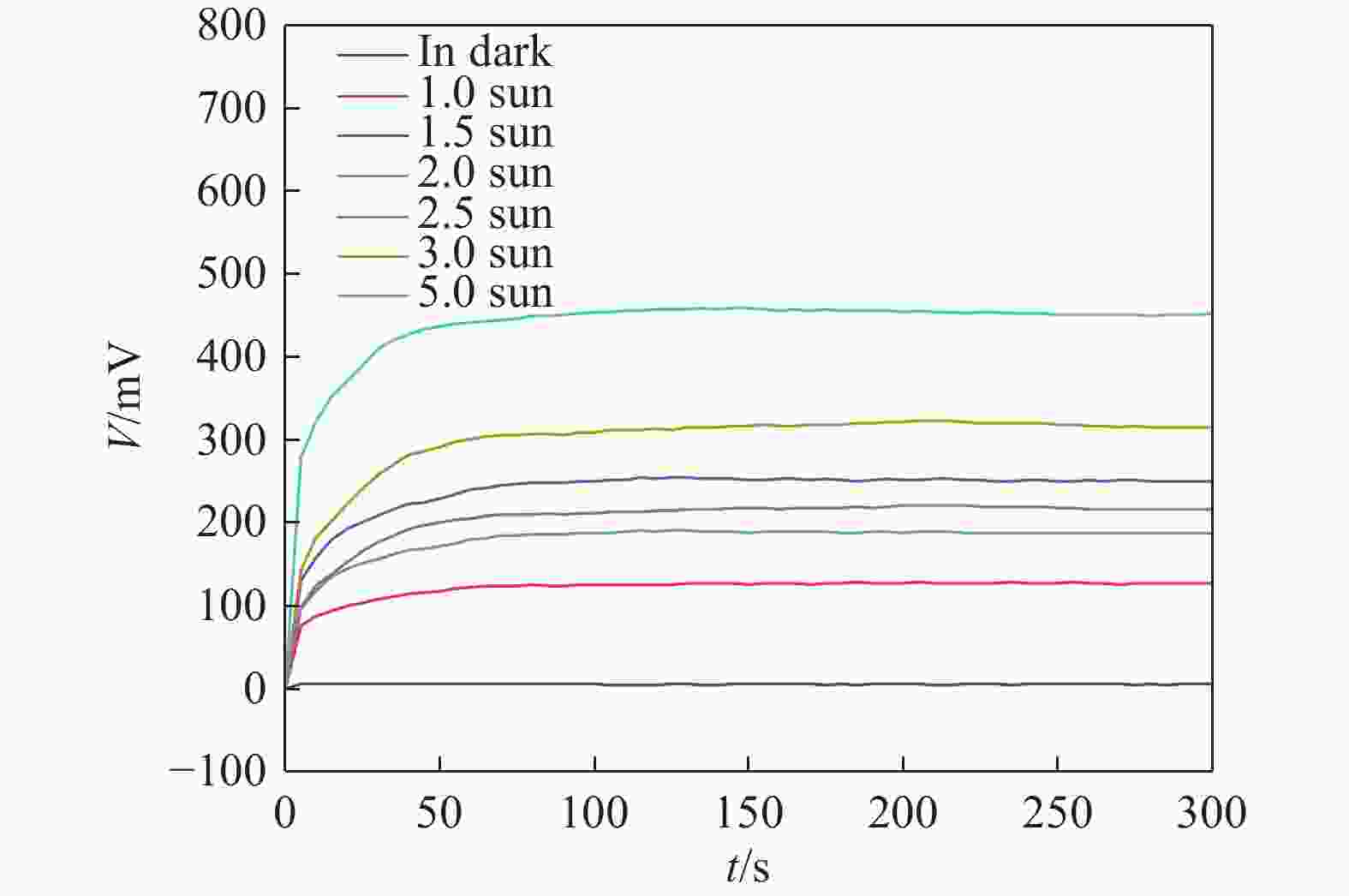

另外,该蒸发器在工作过程中会由于水伏效应而产生一定量的电信号,能够同时实现太阳能向热能和电能的转换,为微纳电子系统的绿色能量供应提供了新的思路。当碳基陶瓷纤维C@Ti4O7与Na+接触时,Na+会吸引纤维表面的电子,在液滴和纤维之间产生赝电容,当蒸汽通过纤维膜时会导致纤维内部的电子-空穴移动并重新排布,促使纤维表面的离子运动而诱导电信号的产生。文章通过电化学工作站对不同光强照射下的开路电压随时间的变化进行了监测,C@Ti4O7蒸发器在不同光照强度下产生的电信号如图13所示,当光照强度为5 kW/m2时,蒸发器在工作过程中能够产生高达460 mV的电信号。

-

文章结合静电纺丝工艺与原位碳热还原工艺制备了具有全光谱吸收能力的C@Ti4O7纤维膜,可在NaCl质量分数为10%的模拟海水中连续工作30 d且表面不结盐,主要结论如下:

1)在静电纺丝制备纤维膜生坯的过程中,纺丝加速电压为20 kV,接收距离为15 cm,辊筒转速为500 r/min时能够得到直径尺寸均匀的纤维膜,纤维的平均直径为(157±15) nm。

2)C元素掺杂、Ti3+掺杂以及氧空位缺陷能够降低C@Ti4O7的带隙宽度至0.7 eV,使其对全光谱内的太阳光具有更强的吸收能力。

3)C@Ti4O7在1 kW/m2的太阳光照射下能够达到74.55 ℃,作为太阳能驱动界面蒸发器的光热材料能够使海水的蒸发速率达到1.55 kg/(m2·h),其光热转换效率高达90.68%。当光照强度为5 kW/m2时,蒸发器能够产生高达460 mV的电信号。

Full-Spectrum Carbon-Based Ceramic Fibers and Their Application in Seawater Desalination

doi: 10.16516/j.ceec.2024.2.20

- Received Date: 2023-06-03

- Rev Recd Date: 2023-06-14

- Available Online: 2024-03-22

- Publish Date: 2024-03-26

-

Key words:

- interfacial evaporation /

- photothermal conversion /

- Ti4O7 /

- seawater desalination /

- hydroelectric power generation

Abstract:

| Citation: | QIU Xiaopan, XI Yulin, ZHU Jingshuai. Full-Spectrum carbon-based ceramic fibers and their application in seawater desalination [J]. Southern energy construction, 2024, 11(2): 198-207 doi: 10.16516/j.ceec.2024.2.20 |

DownLoad:

DownLoad: