-

当前,世界能源发展的主流趋势正在发生重大转变,正逐步走向摒弃核电和摒弃水电的道路,例如欧洲的核心国德国已宣布2020年弃核,其它欧洲国家已炸掉到期水电站;从2010年开始,中国已经超过美国成为世界第一大能源消费国,未来,随着中国经济的快速发展,对能源的消耗还会大幅增加,中国能源发展趋势也在发生转变,重点提高现有能源的利用率,逐步提高新兴能源与可再生能源在电网中所占比重,有计划的发展核电,逐步限制火电的发展[1,2,3]。

风电是中国唯一已经被大规模开发利用的可再生能源。2010年底,我国风电装机总容量达到44.733 GW,超过美国成为世界第一,风电并网容量也达到了29.56 GW,十二五末总装机容量达到100 GW。随着并网容量的增加,2010年的弃风总量已超过2.0×109度电,尤其是进入2011年后,风电基地的弃风量在急剧增加。未来几年,其风量还会增加,一些风电基地的风机脱网事故频繁发生,所有这些问题已经对风电场和电网的安全运行带来了严重影响,已经到了非解决不可的时候了[4-5]。

归根结底,中国风电场的风电波动性强,稳定性差,电网调峰能力和吸纳能力低是产生上述问题的根源。根据国外的经验,有效解决该问题的办法:通过对风电的大规模储存,提高其并网的稳定性、可控性及电网的安全性。

目前为止,关于风电储存的方法很多:压缩空气储能、抽水蓄能、电磁储能、飞轮储能、超级电容储能、超临界压缩空气储能、充电电池储能等,但是能够进行大规模风电储存的成熟技术只有两种:一种是抽水蓄能技术,另一种是压缩空气储能(CAES)技术[6-7]。

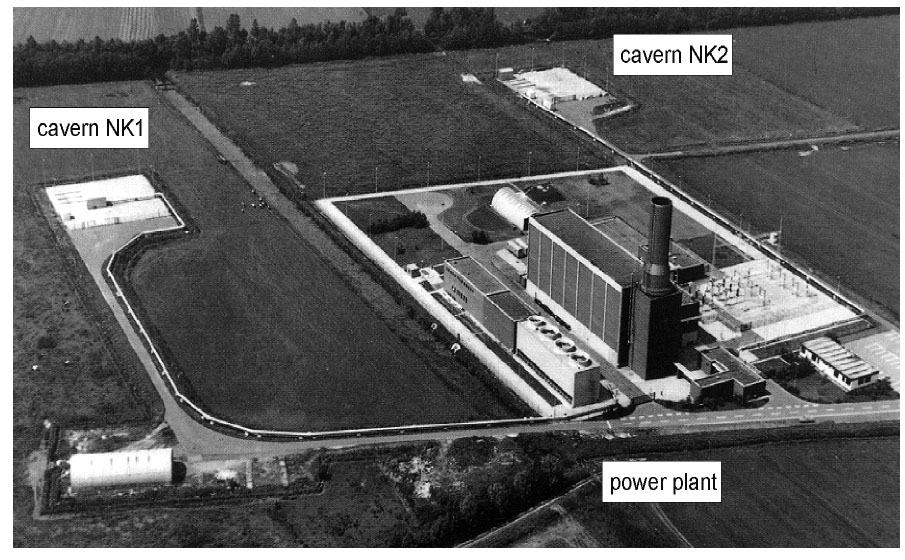

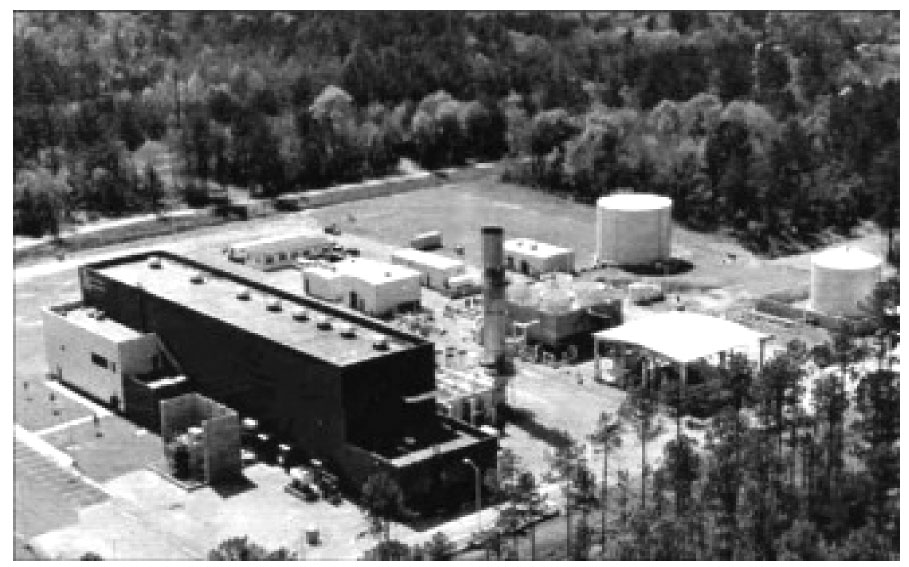

由于中国广大的西部地区普遍干旱缺水,无法采用抽水蓄能技术,因此,压缩空气储能技术成为中国西部地区,对风电进行大规模储存唯一可以采用的技术。德国在上世纪七八十年代就已经建立了压缩空气储能电站的示范工程[8,9,10]。今天仍在安全运行。目前,在运行的电站有美国的阿拉巴马州项目和德国的Huntorf项目,如图1和图2所示[11-12]。

尽管压缩空气储能技术已有很多报道和一些研究文献[13-16],到目前为止,现有技术条件下可以实施的压缩空气储能技术,必须解决两个技术问题:储能过程中,压缩过程中空气的冷却问题;发电过程中,气体透平进口空气的加热问题。在中国西部地区,是火力发电和风力发电最富裕的地区,当地干旱缺水、高风沙,采用传统的水冷技术和空冷技术冷却压缩过程被限制使用,天然气作为宝贵资源通过管道输送到中国东部地区,也被限制使用。因此,要想在中国西部使用压缩空气储能技术,必须解决上述压缩过程中的冷却问题和发电过程中的加热问题[17]。为此,本文提出一种适用于中国西部地区特点的压缩空气储能技术方案,并对储能过程和发电过程进行热力学分析,研究多变指数、储气最高压力及透平进口温度对该储能系统的影响规律[18]。

HTML

-

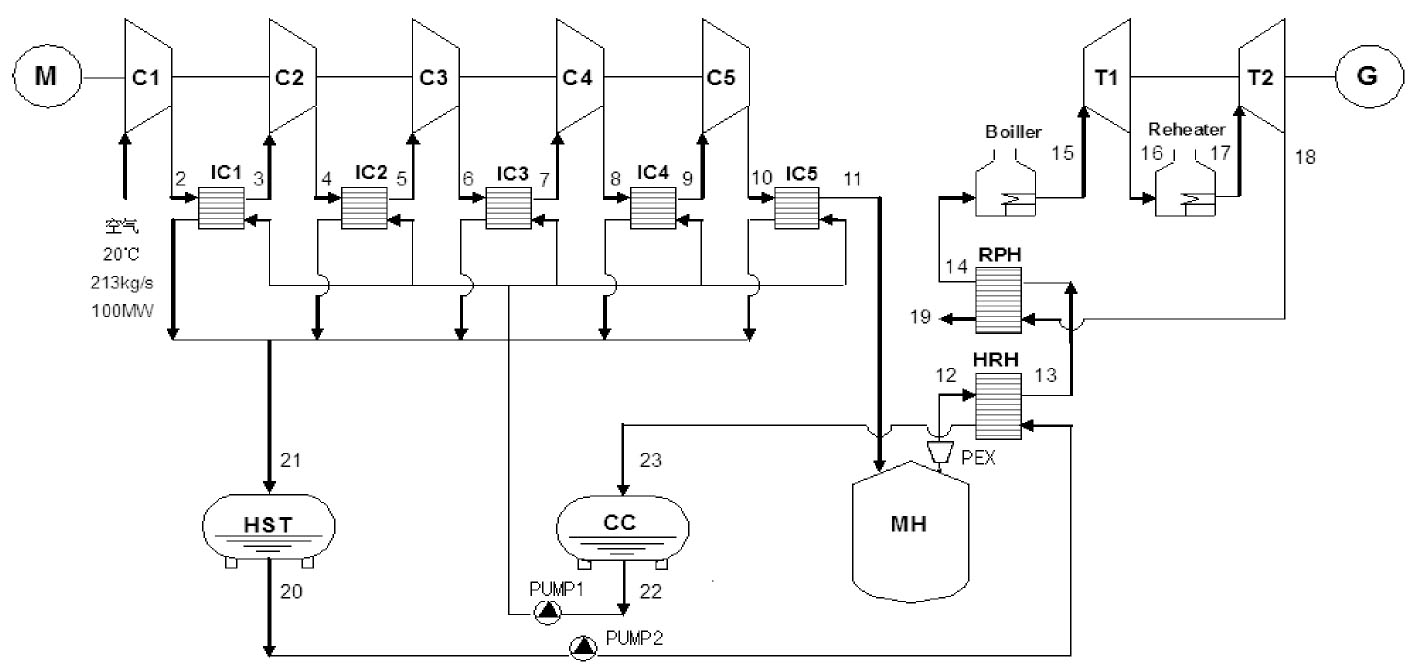

本文提出的压缩空气储能系统的原理简图,如图3所示,该系统中,冷却水采用闭式循环,冷却水所带热量以热能形式被储存在如图3所示的HST容器中。在发电过程中,HST容器中的热水用来预热气体透平膨胀机进气,被冷却的水被储存在如图所示的容器CC中,待压缩机工作时,再作为冷却水使用。该系统可以在干旱缺水地区正常使用。此外,该系统还有一个特点,压缩机采用有独立电机驱动的多级压缩机机组;气体膨胀透平采用是高低压透平组成的串级系统,共用一个电机。这样可以使气体膨胀透平进口温度达到所需温度,采用同德国Huntorf项目中的压缩空气储能技术中一样的回热技术和燃烧加热技术。燃料可以采用化石类燃料,也可以采用天然气加热[19]。

该压缩空气储能系统与德国Huntorf项目和美国阿拉巴马州项目中所采用的储能系统的最大区别在于最大限度地减低系统对外界排放热量中所含的有效能量,回收了压缩机压缩过程中放出的热量。

-

在研究压缩空气储能过程中,空气被视为理想气体,储气容器为绝热容器,相对水泵耗功很少计算时可不计。

-

对于绝热压缩过程,单位质量耗功为:

((1)) 式中:k—绝热指数;ε—压比,

由于中间冷却器的作用,各级压缩后的气体,再冷却至T0,冷却过程对外放热:

((2)) 设高压储气室体积为Vh,根据理想气体的状态方程,可得到:

((3)) 压缩过程总耗功:

((4)) 式中:pi为高压储气室初始压力,ph为终了压力总对外放热量为:

((5)) -

预膨胀损失:

((6)) 式中:ε1为压比,

则温度变化为:

((7)) 设高压储气室体积为Vh,根据理想气体的状态方程,可得到:

((8)) 膨胀总损失:

((9)) 预热器温升:T13=T12+ΔT。其中:ΔT为经预热器,吸热而使气体温度增加的量,该值取决于预热器效果,其范围可有后面确定。

在预热器中单位质量吸热:

((10)) 总吸热:

((11)) 有Qh必定小于Qc,可以得出ΔT的取值范围,设间冷器回收热量利用率为λ,则:

((12)) 回热器温升:

((13)) 其中ΔT1必定小于末级透平排气温度与大气环境的差值,同时取决于回热器效果。在回热器中单位质量吸热:

((15)) 总吸热:

((16)) 燃烧室单位质量吸热:

((17)) 其中T15视为已知的某一定值(800~1 000 K),则总吸热:

((18)) 透平1单位质量对外做功:

((19)) 其中εt1为一定值,则总对外做功:

((20)) 其中T17视为已知的某一定值(800~1 000 K)。再加热器吸热:

((21)) 透平2对外做功:

((22)) 其中εt2为一定值。

电耗:

((23)) 热耗:

((24)) 总效率:

((25)) -

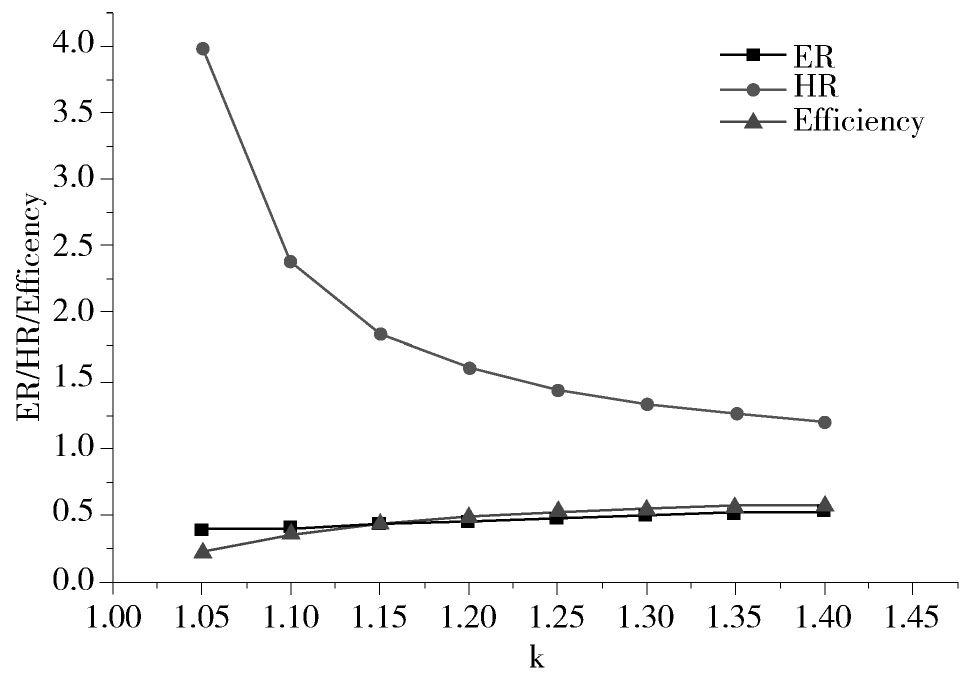

在设计工况下,高压储气室体积1.2×105 m3,高压储气室内高压空气压力为8.0 MPa,在进气为p0=0.1 MPa,T0=303 K的环境工况下,得出如图4所示压缩空气储能系统的热耗、电耗、效率随多变指数的变化曲线。从图4中可以看出,压缩空气储能系统的电耗随多变指数的升高基本保持不变,压缩空气储能的能量效率都随多变指数的升高而增加,而压缩空气储能系统的热耗随多变指数的升高而大幅减小。这是因为随着多变指数的升高,压缩空气储能系统内的压缩机组的耗功量和空气透平的做功量均有所升高,但是由于在系统计算过程中忽略了压缩机组和空气透平的各项运行损失,因此压缩机组耗功量和空气透平做功量的提升幅度基本保持一致,系统的电耗基本保持不变,同时系统所需的加热量也保持不变,在空气透平做功量升高的情况下,系统的热耗大幅降低,而系统的能量效率有所升高。

-

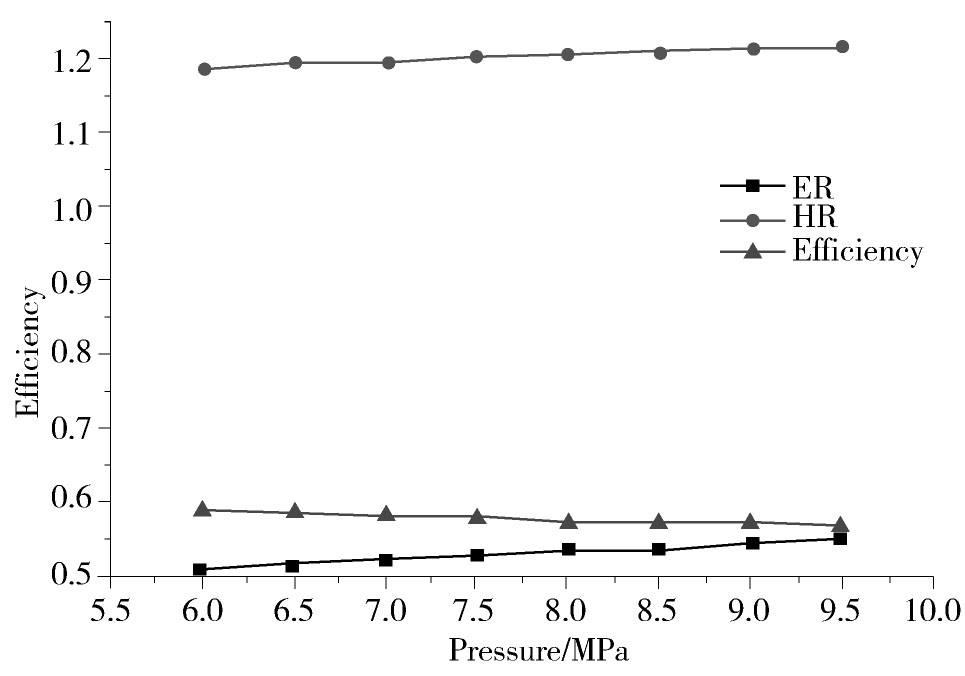

在设计工况下,高压储气室体积为1.2×105 m3,多变指数k=1.4,在进气为ρ0=0.1 MPa,T0=303 K的环境工况下,得到压缩空气储能系统的热耗、电耗、效率随压缩空气储能系统高压储气室内压力的变化情况,结果如图5所示。从图5中可以看出,压缩空气储能系统的电耗和热耗都随压缩空气储能系统高压储气室内压力的变大而增加,而系统的能量效率随压缩空气储能系统高压储气室内压力变大而减小。这是因为随着储能系统中高压储气室内空气压力的升高,压缩空气储能系统中的压缩机组需要消耗更多电能来使进入高压储气室的空气压力升高,因此储能系统的电耗升高,而在高压储气室体积不变的条件和高压储气室内空气温度保持与环境一致的假设下,随着高压储气室内空气压力的升高,高压储气室内空气质量增多,系统需要消耗更多能量使得进入透平的空气达到预设温度,因此系统的热耗也升高。虽然高压储气室内空气压力升高使得系统的做功能力升高,但是系统的做功能力升高幅度小于系统消耗能量的升高幅度,因此系统的能量效率降低。

-

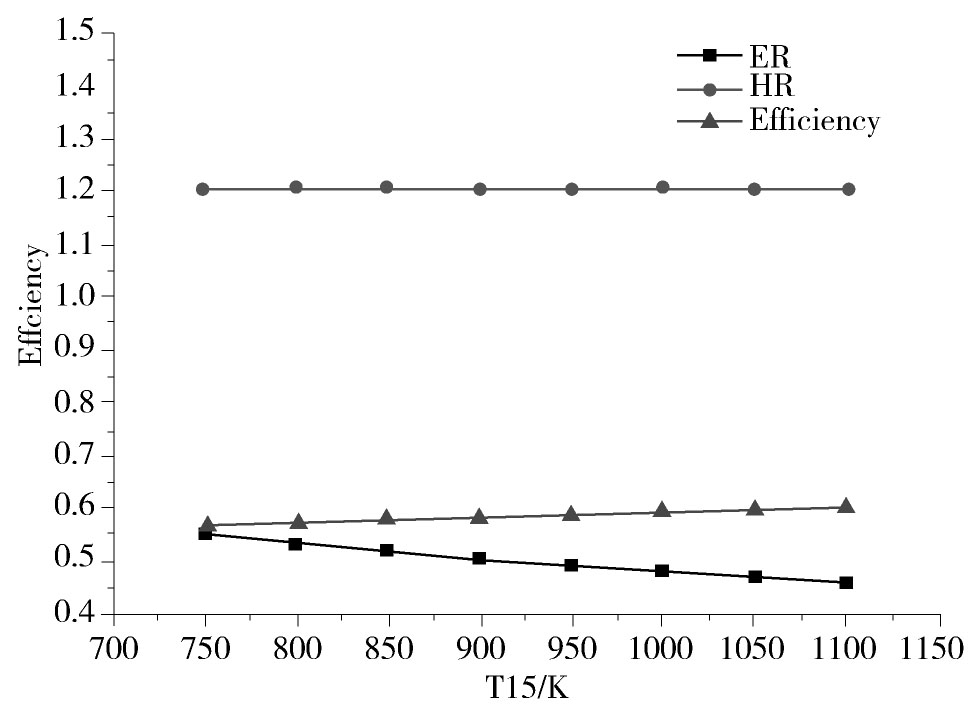

在设计工况下,高压储气室体积为1.2×105 m3,高压储气室内高压空气压力8 MPa,多变指数k=1.4,在进气为p0=0.1 MPa,T0=303 K时,图6为压缩空气储能系统的热耗、电耗、效率随高压气体透平进气温度变化曲线。由图6得出系统的电耗和热耗都随高压气体透平进气温度的升高而下降,而系统的能量效率随高压气体透平进气温度的升高而升高。这是因为在高压气体透平进气压力不变的前提下,随着高压气体透平进气温度的升高,气体透平的对外做功能力升高,而压缩机组消耗电能不变,因此系统的电耗降低。尽管高压气体透平进气温度的升高需要消耗更多能量来加热高压空气,但是系统消耗能量的升幅小于系统做功能力的升幅,因此压缩空气储能系统的热耗以及能量效率随高压气体透平进气温度的升高而升高。

2.1 储能过程的热力学分析

2.2 发电过程的热力学分析

2.3 多变压缩过程指数对系统能量装换效率的影响

2.4 储能终了最高压力对系统能量转换效率的影响

2.5 高压气体透平进气温度对系统能量装换效率的影响

-

提出了一种适合于中国西部地区的具有闭式水储热和水回热系统的压缩空气储能技术方案;热力学分析结果表明:系统的能量转换效率随着储气压力增加而增大、随着气体透平进气温度的升高而增大、随着压缩过程指数的减小而增大。研究结果对在中国开展和大规模推广应用压缩空气储能技术具有重要的指导意义。

DownLoad:

DownLoad: