-

当今国内燃煤机组面临着电负荷与热负荷矛盾突出的问题,机组供电能力大于求,但供热量需求却一直在增加,与之相关的供热改造的研究逐渐成为大家关注的焦点。对于承担供暖季民生之本的热电联产机组,打破其热电耦合关系是保障机组冬季热源供给的关键[1-2]。

目前燃煤机组供热改造的方式主要为旁路供热改造、增加背压汽轮机、高背压改造、切缸改造等[3-5]。

旁路供热改造一般分为汽轮机高低压旁路联合抽汽供热和低压旁路抽汽供热两种技术方案,联合旁路抽汽是指利用高压旁路将部分主蒸汽减温减压后送至高压缸排汽,经锅炉再热器加热后,从低压旁路(中压缸进口)抽汽对外供热;低压旁路抽汽是利用低压旁路管道,直接引出部分再热蒸汽对外供热。汽轮机旁路供热方案将部分做功蒸汽转化为供热蒸汽,降低了汽轮发电机组的强迫出力水平,提高了汽轮机的供热能力,但由于将高品质热能用于供热,存在一定的热经济损失[6]。

增加背压汽轮机能有效地利用蒸汽的高品位能量做功发电,低位能量用于供热,减少了抽汽通过减压减温供热,节流损失过大的问题,实现了能量梯级利用。增加背压汽轮机的供热方式适用于蒸汽参数等级较高,与用户侧热负荷需求参数不匹配,造成了高品位能量的损失的情况。但其改造投资成本高,回报周期较长[7]。

高背压改造能有效地利用蒸汽的高品位能量做功发电,低位能量用于供热,减少了抽汽通过减压减温供热,节流损失过大的问题,实现了能量梯级利用。而且高背压工况下驱动发电机发电,产生电量并入厂用电系统,能够显著降低厂用电率。但其调峰能力有限,而且需要每年更换2次低压缸转子,运行维护不便[8]。

切缸改造又称“切除低压缸进汽供热技术”,是指在调峰期间,切除低压缸全部进汽用于供热,仅通入少量的冷却蒸汽,使低压缸在高真空条件下“空转”,实现低压缸“零出力”运行,从而降低汽轮发电机组强迫出力水平,增加机组的调峰能力;并且由于排汽全部用于供热,消除了冷源损失,具有良好的供热经济性[9-10],目前该项供热改造技术已在东北区域、华北区域、西北区域的电厂广泛使用[11-12]。但为了将低压缸鼓风所产生的热量带走,需要一直开启排汽缸喷水减温系统,大量蒸汽回流冲刷叶片出汽侧会造成汽蚀,长期运行会导致应力集中,削弱叶片的结构强度[13-14]。

目前各种供热改造方式的效果不同,其应用的场合也不同,针对不同供热需求进行改造才是硬道理[15]。本文通过对某类型300 MW燃煤机组的高背压改造和切缸改造这两种供热改造方式进行模型分析,比较机组改造前后的供热量等数据,总结供热改造的经济效果。对今后相同类型的燃煤机组供热改造具有借鉴意义。

-

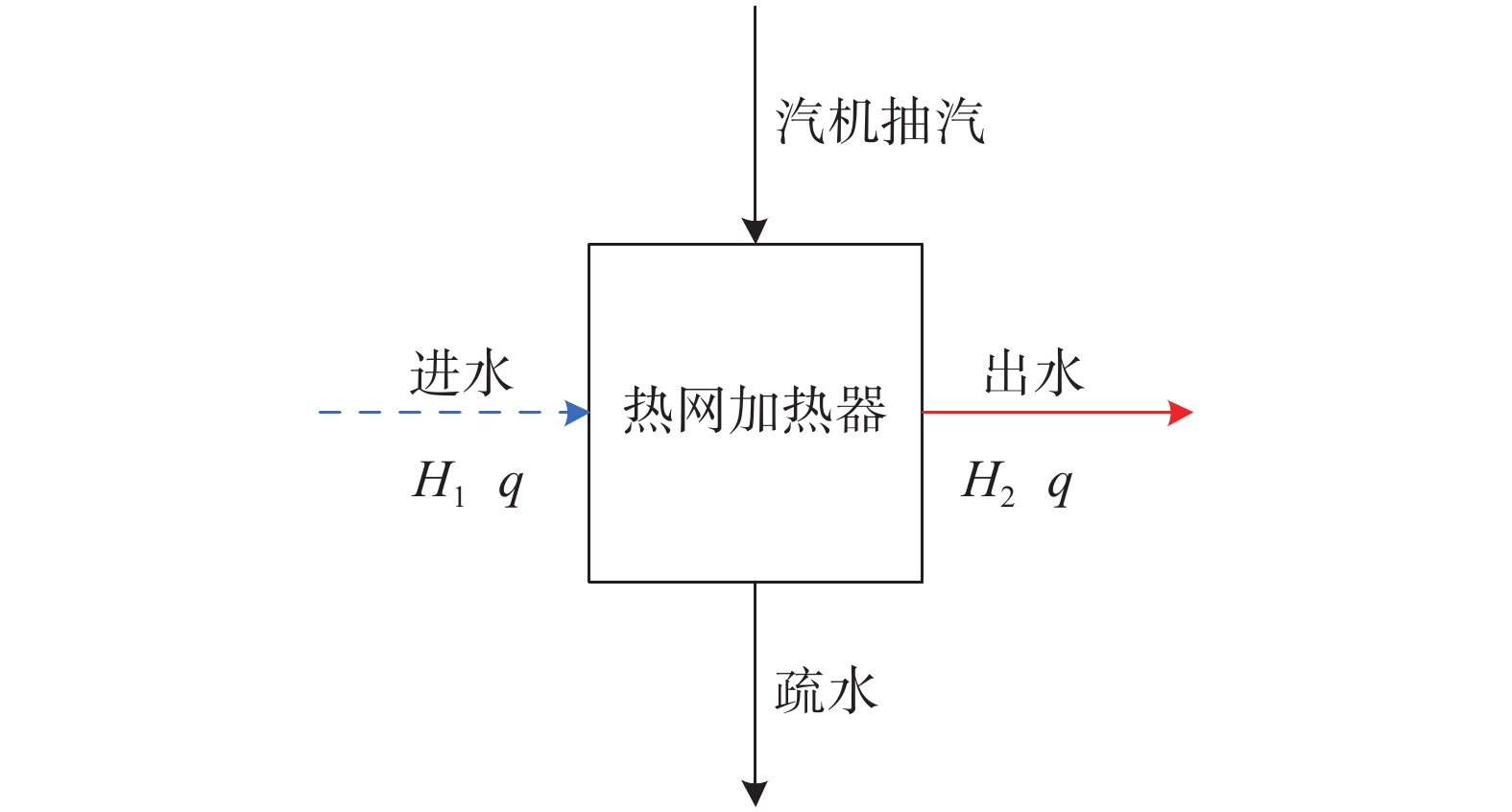

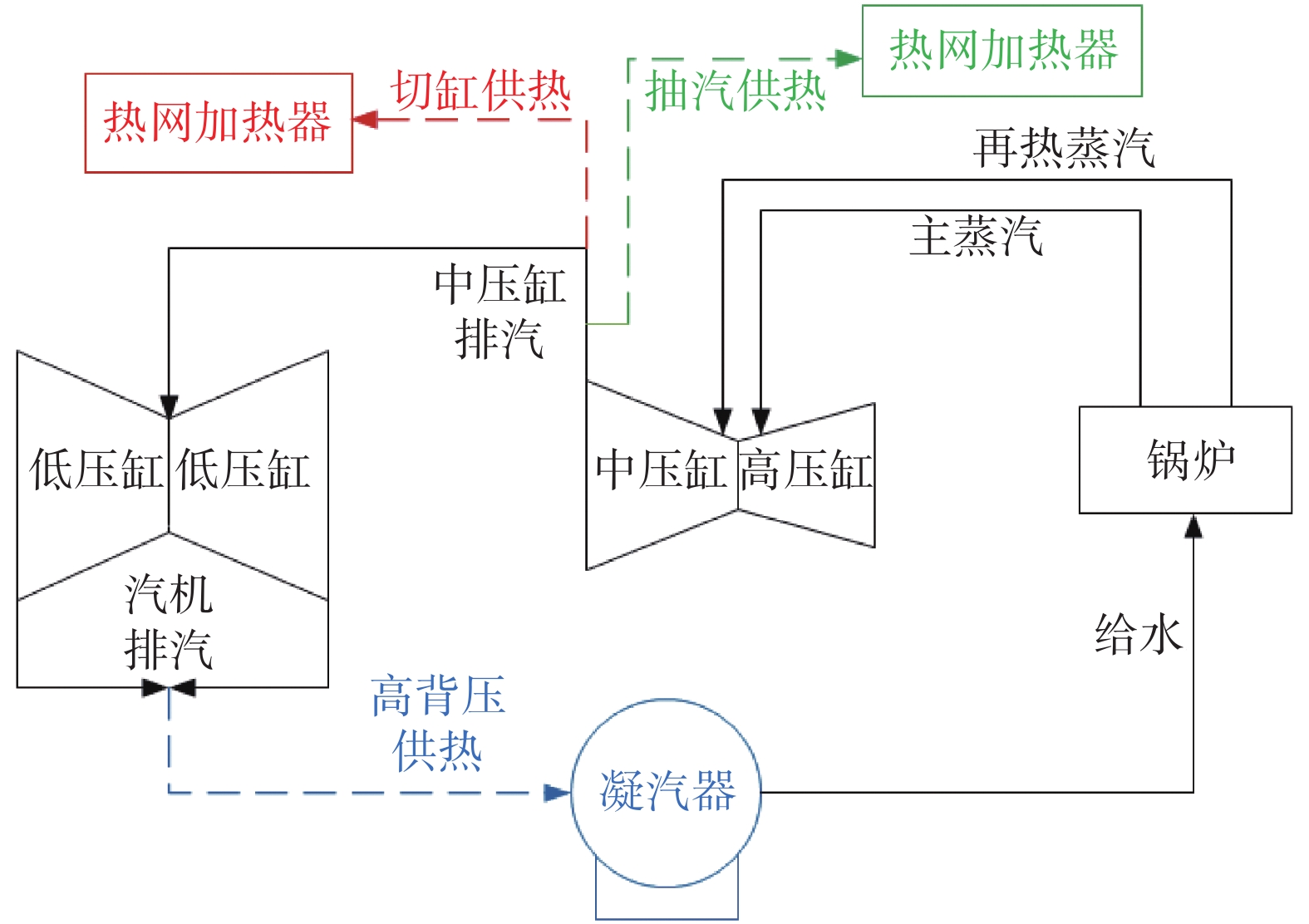

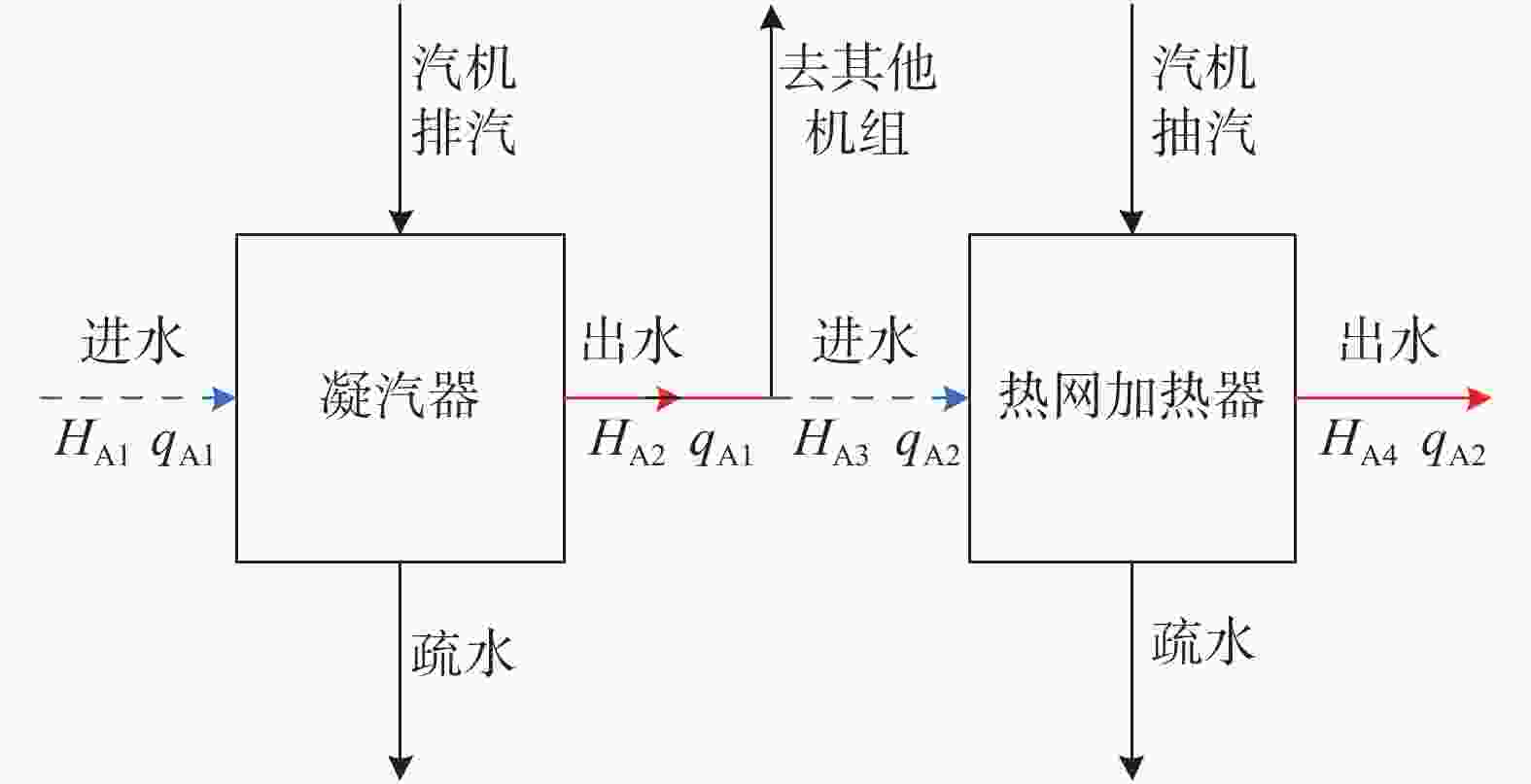

某类型300 MW燃煤机组原设计为单轴、高中压合缸、低压缸双分流、亚临界、一次中间再热、双缸双排汽、抽汽凝汽器式汽轮机。热网加热蒸汽汽源由汽轮机中压缸末级引出。额定采暖工况蒸汽压力为0.4 MPa,蒸汽温度264 ℃,压力调整范围0.25~0.55 MPa。该类型汽轮机组冬季供热热力系统图如图1所示。

-

该机组在供暖期,机组运行方式为以热定电,即首先满足供热要求,根据热负荷的变化来调整机组的发电功率。采暖供热采用二级换热闭式循环系统,在厂内设一级换热站,用汽机抽汽将热网循环水加热,在热用户附近设二级换热站,用高温热网循环水加热二次循环水向用户供热。

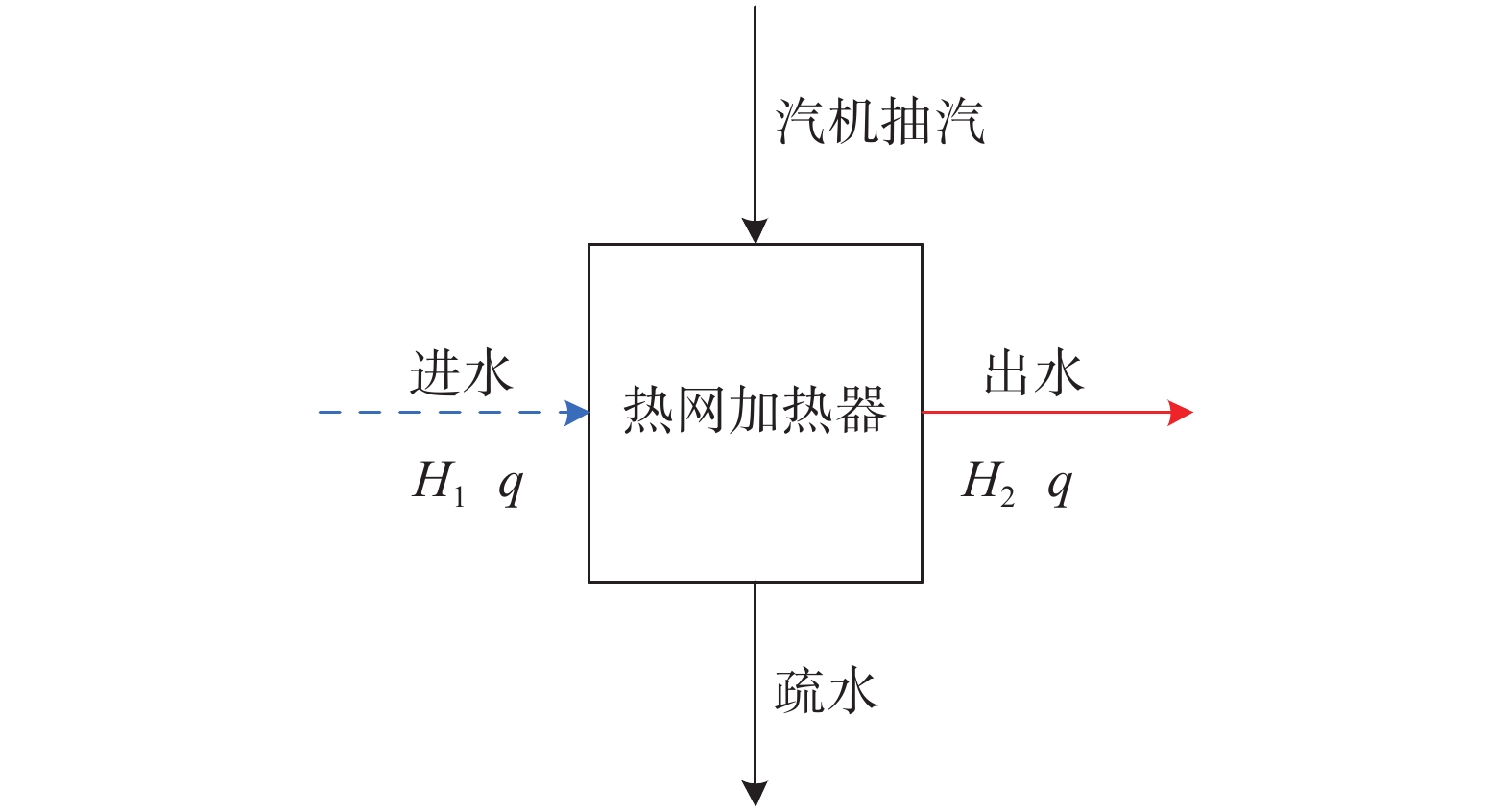

机组抽汽供热模型图如图2所示,机组抽汽供热的汽侧为汽轮机抽汽直接进入热网加热器进行加热,疏水回至凝汽器。水侧为热网回水加热后成为一级热网供水。

供热量计算公式[16]:

$$ Q=\left( {{H}_{2}—{H}_{1}} \right)q1{0}^{3} $$ (1) 式中:

Q ——供热量(kJ/h);

H1 ——进水焓(kJ/kg);

H2 ——出水焓(kJ/kg);

q ——水流量(t/h)。

-

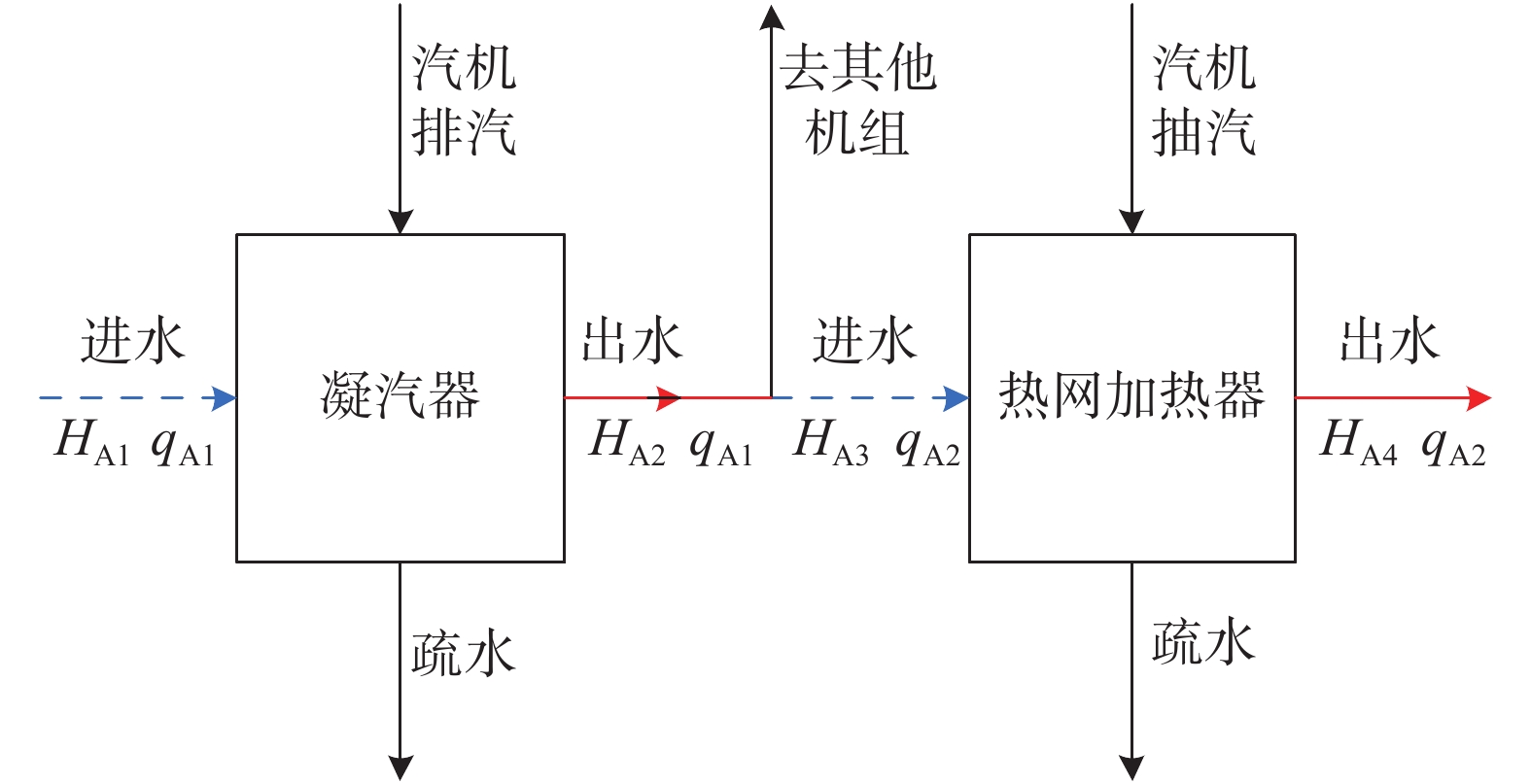

机组高背压供热模型图如图3所示。对该类型燃煤机组进行高背压改造,实现了纯凝工况与供热工况低压缸双背压双转子互换。非供热期机组以抽汽凝汽方式运行,供热期间机组以抽汽凝汽背压方式运行。水网供热采用串联式两级加热系统:即热网循环水回水首先经过机组凝汽器进行第一级加热,吸收低压缸排汽余热,然后再经过机组热网加热器完成第二级加热,高温热水通过水网供水管道送至厂外换热站换热供向热用户。高温热水经热用户换热降温后,通过热网回水管回至机组凝汽器,构成一个水循环系统。

机组高背压供热的热网水加热形式为梯级加热,首先由汽机排汽在凝汽器中进行第一级加热,然后热网水分流一部分去其他机组,另一部分进入热网加热器由汽轮机抽汽进行第二级加热。

供热量计算公式:

$$ Q_{{\rm{A}}}=(H_{{\rm{A}} 2}-H_{{\rm{A}} 1}) q_{{\rm{A}} 1} 10^{3}+(H_{{\rm{A}} 4}-H_{{\rm{A}} 3}) q_{{\rm{A}} 2} 10^{3} $$ (2) 式中:

QA ——高背压方式供热量(kJ/h);

HA1 ——凝汽器进水焓(kJ/kg);

HA2 ——凝汽器出水焓(kJ/kg);

HA3 ——加热器进水焓(kJ/kg);

HA4 ——加热器出水焓(kJ/kg);

qA1 ——凝汽器水流量(t/h);

qA2 ——加热器水流量(t/h)。

-

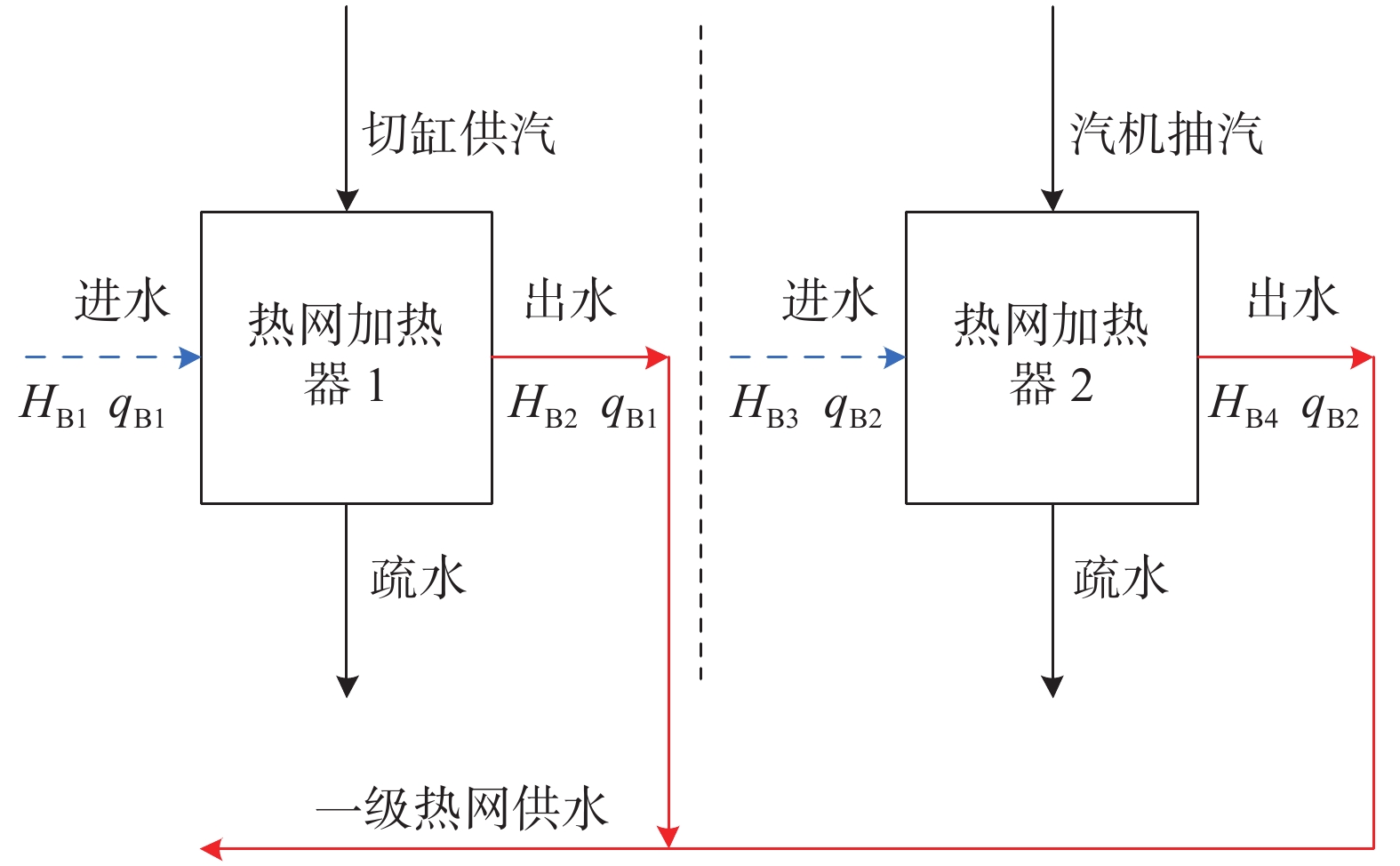

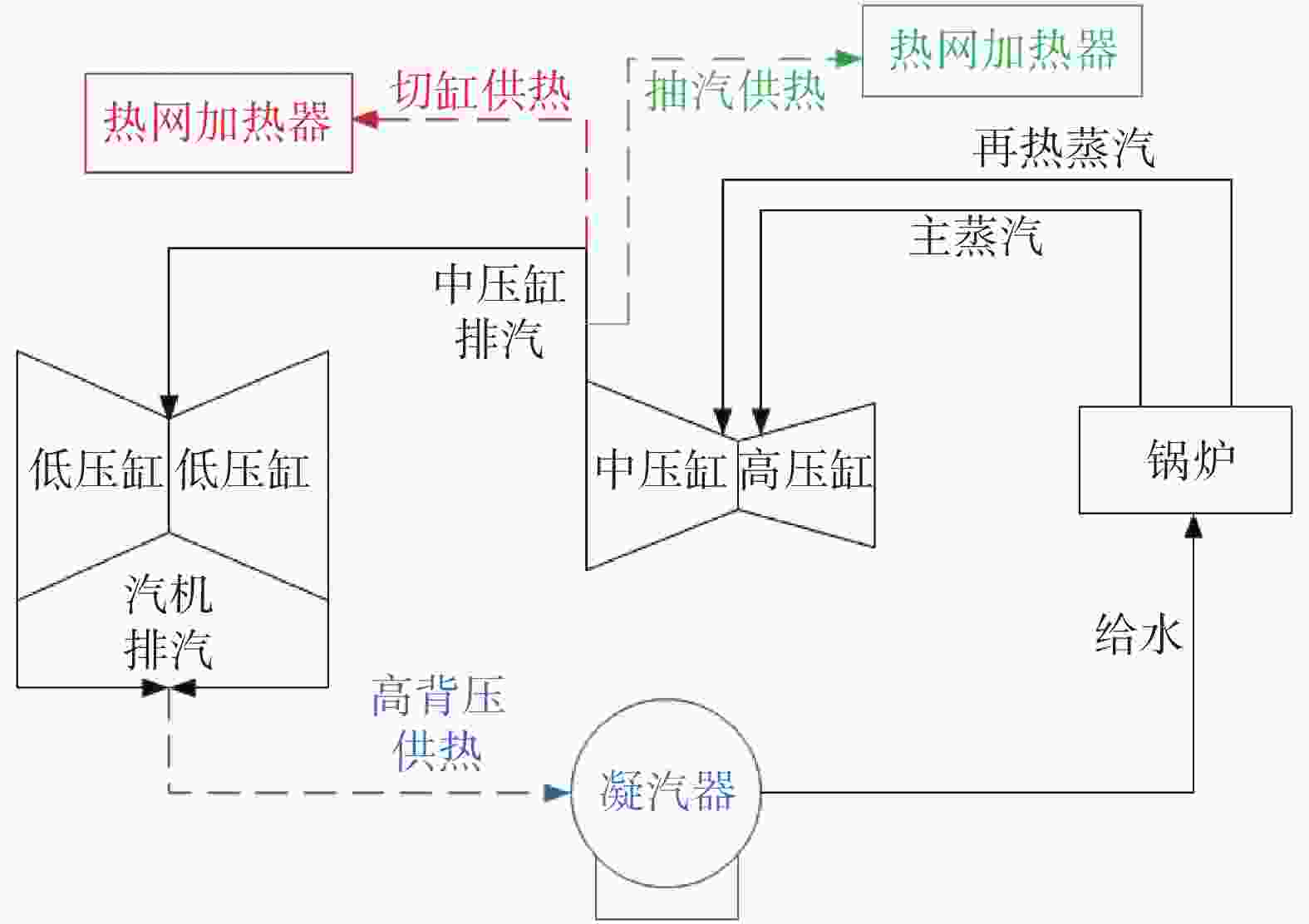

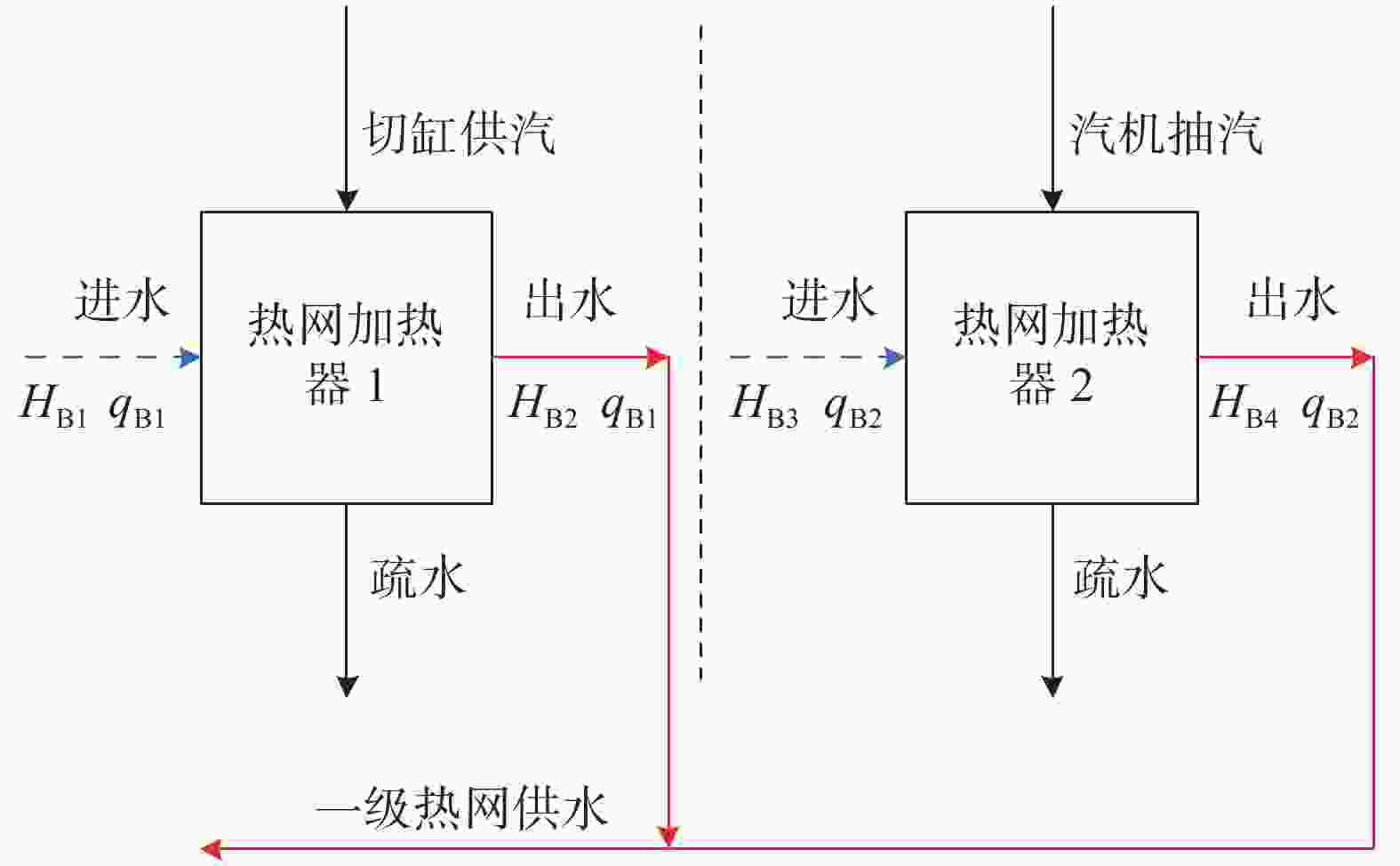

机组切缸供热模型图如图4所示。对该类型燃煤机组进行切缸改造,实现了纯凝工况与供热工况低压缸切除互换。非供热期机组以抽汽凝汽方式运行,供热期间机组以切缸方式运行。供热汽源分为两部分对热网进行加热:其中机组切缸汽源供给大容量热网加热器,直接加热热网回水,高温热水通过水网供水管道送至厂外换热站换热供向热用户。另外机组抽汽与其他机组的小容量热网加热器相连,作为其他机组供热的补充汽源。

机组切缸供热的热网水分别在两个热网加热器中进行加热,其中一个加热器的汽源为切缸供汽,另一个加热器的汽源为汽轮机抽汽,两个热网加热器的出水汇合后作为一级热网供水。

供热量计算公式:

$$Q_{{\rm{B}}}=(H_{{\rm{B}} 2}-H_{{\rm{B}} 1}) q_{{\rm{B}} 1} 10^{3}+(H_{{\rm{B}} 4}-H_{{\rm{B}} 3}) q_{{\rm{B}} 2} 10^{3} $$ (3) 式中:

QB ——切缸方式供热量(kJ/h);

HB1 ——加热器1进水焓(kJ/kg);

HB2 ——加热器1出水焓(kJ/kg);

HB3 ——加热器2进水焓(kJ/kg);

HB4 ——加热器2出水焓(kJ/kg);

qB1 ——加热器1水流量(t/h);

qB2 ——加热器2水流量(t/h)。

-

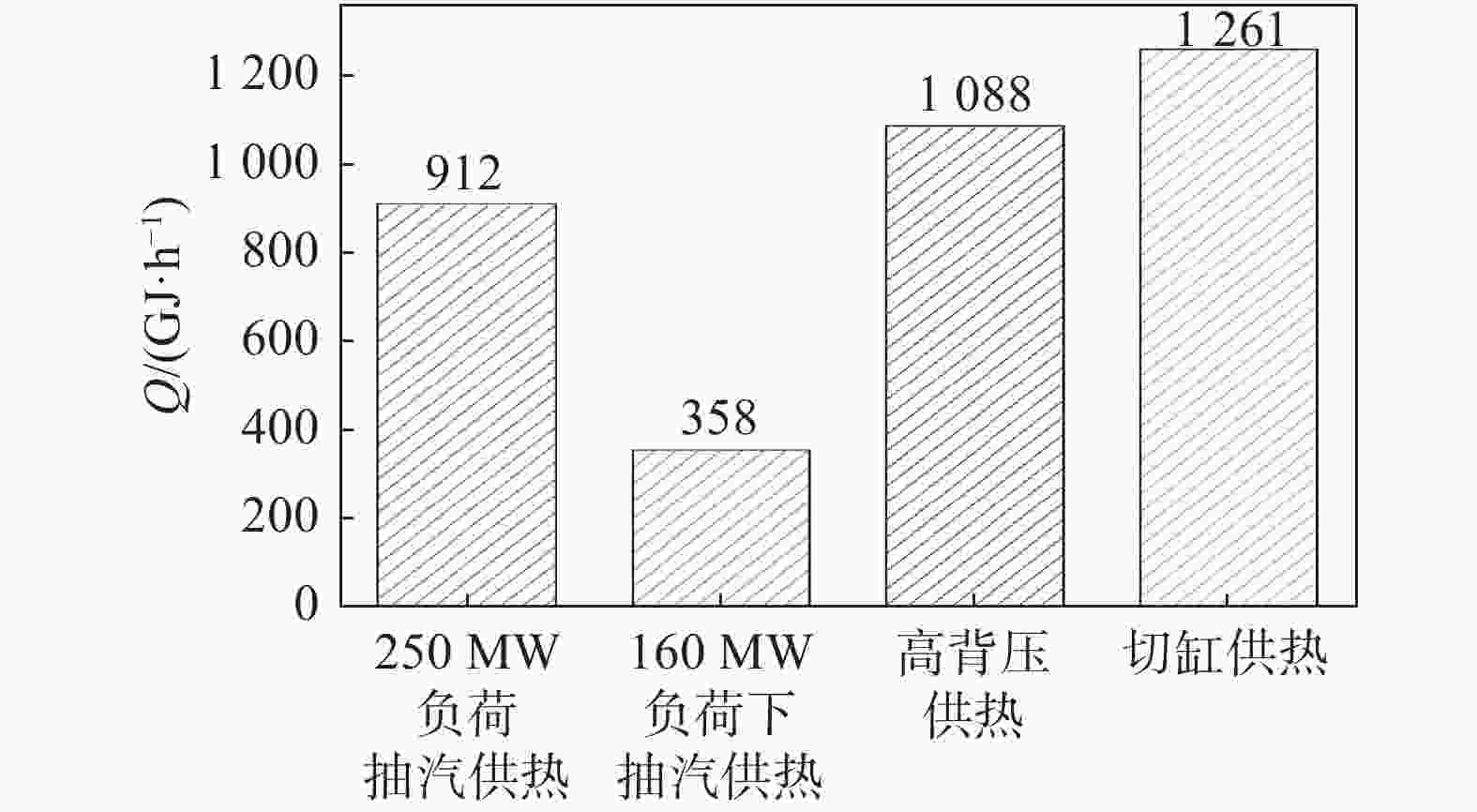

对该类型300 MW燃煤机组供热期试验数据进行收集,并分别对未改造机组抽汽供热、机组高背压改造供热、机组切缸改造供热建立模型进行供热量计算。

-

该类型300 MW燃煤机组出厂为抽凝式供热机组,抽汽进入热网加热器对热网水进行加热。

首先对其额定锅炉蒸发量下最大供热量进行计算,此时由于机组中部分蒸汽抽出进行供热,汽轮机无法达到纯凝工况,能达到的最大负荷为250 MW。此工况下热网加热器进水温度为61 ℃,热网加热器出水温度为91 ℃,水流量为7 253 t/h,压力为1.34 MPa,根据公式(1)计算得出供热量为912 064 750 kJ/h,约为912 GJ/h。

然后取其160 MW负荷时进行供热量计算,此工况下热网加热器进水温度为60 ℃,热网加热器出水温度为90 ℃,水流量为2 850 t/h,压力为1.05 MPa,根据公式(1)计算得出供热量为358 359 000 kJ/h,约为358 GJ/h。

-

该类型300 MW燃煤机组经历了高背压改造,首先汽轮机排汽在凝汽器中加热热网水,然后抽汽进入热网加热器再对热网水进行二次加热。取其160 MW负荷时进行供热量计算。此工况下凝汽器进水温度为49 ℃,凝汽器出水温度为63 ℃,凝汽器水流量为12 270 t/h,压力为0.16 MPa。热网加热器进水温度为63 ℃,热网加热器出水温度为77 ℃,热网加热器水流量为6 310 t/h,压力为1.04 MPa,根据公式(2)计算得出供热量为1 088 486 500 kJ/h,约为1 088 GJ/h。

-

该类型300 MW燃煤机组经历了切缸改造,中压缸排汽直接进入热网加热器1加热热网水,另外机组抽汽进入热网加热器2对其他部分热网水进行加热。该类型300 MW机组供热量如图5所示。取其160 MW负荷时进行供热量计算。此工况下热网加热器1进水温度为42 ℃,热网加热器1出水温度为75 ℃,热网加热器1水流量为6 650 t/h,压力为0.78 MPa。热网加热器2进水温度为65 ℃,热网加热器出水温度为76 ℃,热网加热器水流量为7 450 t/h,压力为1.36 MPa,根据公式(3)计算得出供热量为1 261 113 000 kJ/h,约为1 261 GJ/h。

-

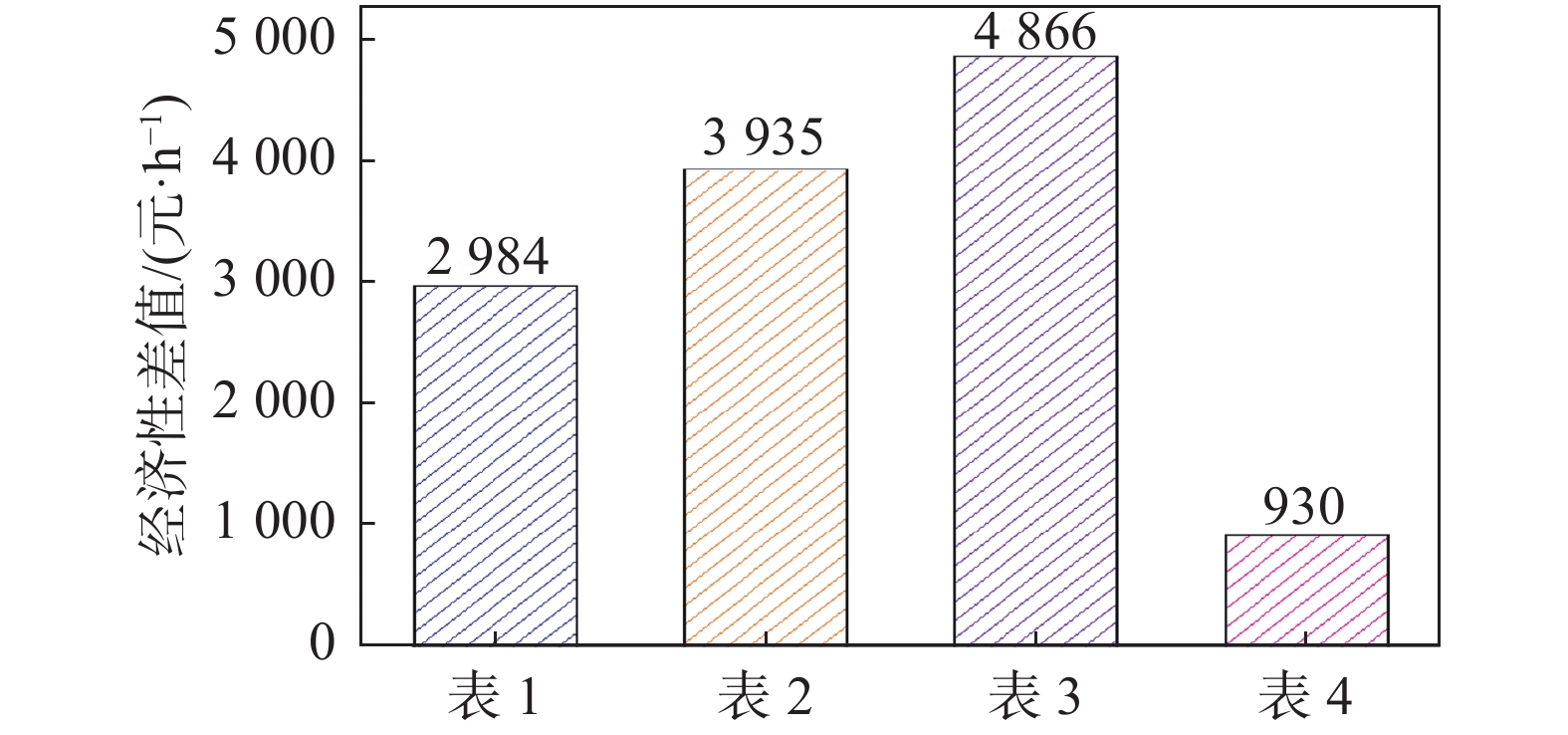

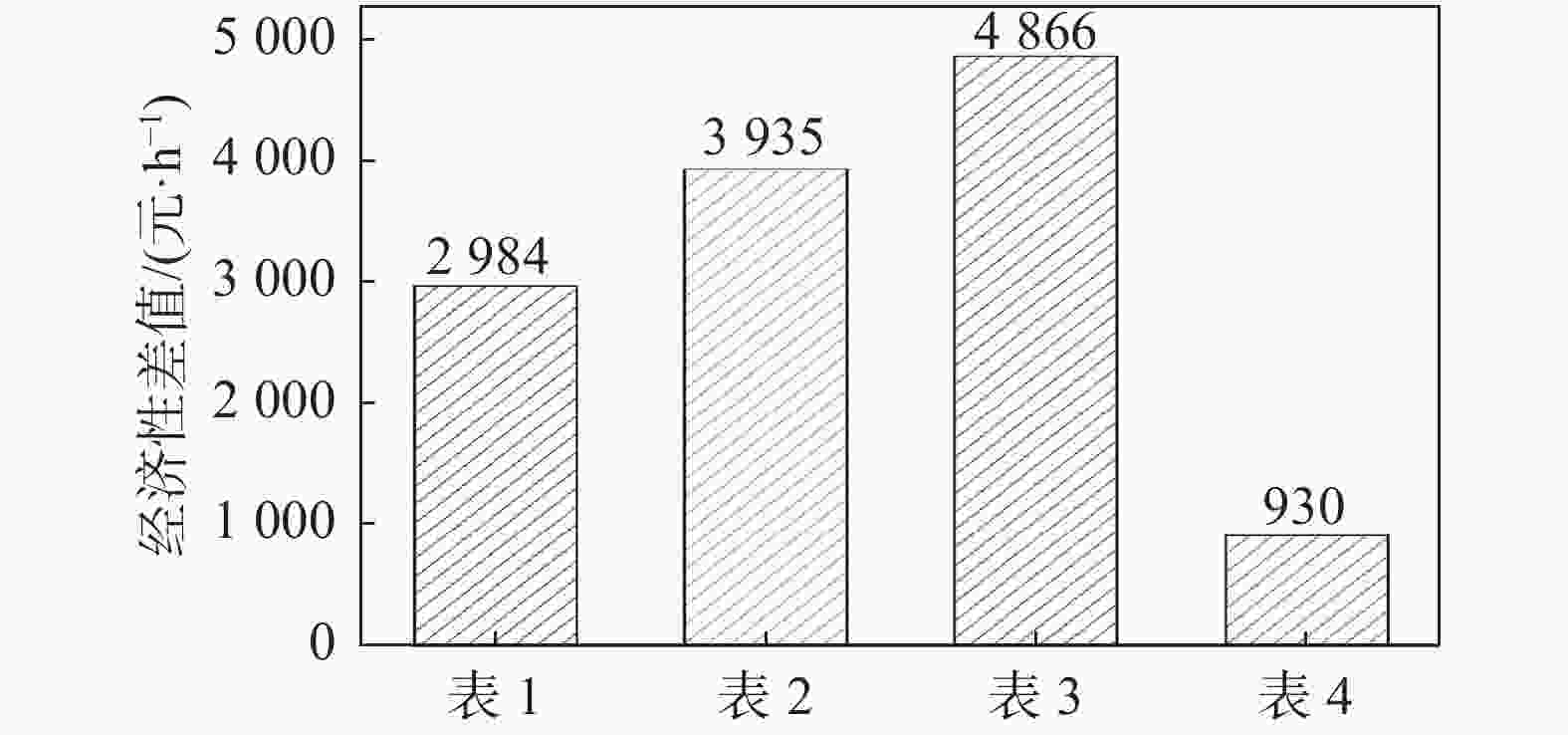

根据三种供热方案计算出的供热量情况以及该地区供热经济性系数,将燃煤机组三种供热方案进行技术经济性比较,具体情况如表1~表4所示。

250 MW负荷下抽

汽供热量/(GJ·h−1)160 MW负荷下抽

汽供热量/(GJ·h−1)供热量差

值/(GJ·h−1)经济性差

值/(元·h−1)912 358 554 2 984 Table 1. Comparison between steam extraction heating under 250 MW load and steam extraction heating under 160 MW load

高背压供热量/

(GJ·h−1)抽汽供热量/

(GJ·h−1)供热量差值/

(GJ·h−1)经济性差值/

(元·h−1)1 088 358 730 3 935 Table 2. Comparison between high back pressure heating and steam extraction heating under 160 MW load

切缸供热量/

(GJ·h−1)抽汽供热量/

(GJ·h−1)供热量差值/

(GJ·h−1)经济性差值/

(元·h−1)1 261 358 903 4 866 Table 3. Comparison between cylinder cutting heating and steam extraction heating under 160 MW load

切缸供热量/

(GJ·h−1)高背压供热量/

(GJ·h−1)供热量差值/

(GJ·h−1)经济性差值/

(元·h−1)1 261 1 088 173 930 Table 4. Comparison between cylinder cutting heating and high back pressure heating

从表1、表2、表3可以看出,该类型300 MW燃煤机组仅靠抽汽进行供热时,受电负荷制约很大,但经历过切缸供热改造或高背压供热改造后,该问题得以解决,在160 MW负荷时,相比改造前的抽汽供热形式,供热能力及经济性都得到大幅提升。从表4可以看出,切缸供热与高背压供热相比较,供热能力及经济性有一定优势,机组的供热期调峰能力也更强,这是因为燃煤机组经过切缸改造后,排汽全部用于供热,消除了冷源损失。供热经济性差值比较图如图6所示。切缸供热还具有切换灵活,汽轮机本体改造范围小,改造费用低,运行维护成本低的优势。

-

1)燃煤机组仅靠抽汽进行供热,其供热量较低,且受电负荷制约很大,高电负荷时供热量为低电负荷时的2~3倍。

2)燃煤机组经过高背压改造后,受电负荷制约情况改善明显,相同电负荷情况下,与仅靠抽汽进行供热的机组相比供热量明显增加。

3)燃煤机组经过切缸改造后,增加了机组的调峰能力,受电负荷制约较小,相同电负荷情况下,供热量与仅靠抽汽进行供热的机组相比大幅增加。

4)机组经过高背压改造、切缸改造后,供热期调峰能力增强,相同电负荷下其供热量增加到原来的3~4倍。

5)燃煤机组经过切缸改造后,排汽全部用于供热,消除了冷源损失,相同电负荷情况下,供热量与高背压改造的机组相比更大,具有良好的供热经济性。

Technical and Economic Study on Heating Transformation Scheme of Coal-Fired Units

doi: 10.16516/j.gedi.issn2095-8676.2022.03.010

- Received Date: 2022-01-18

- Accepted Date: 2022-03-03

- Rev Recd Date: 2022-03-03

- Available Online: 2022-05-30

- Publish Date: 2022-09-25

-

Key words:

- coal-fired unit /

- heating transformation /

- high back pressure transformation /

- cylinder cutting transformation /

- heating capacity

Abstract:

| Citation: | XU Weixuan. Technical and Economic Study on Heating Transformation Scheme of Coal-Fired Units[J]. SOUTHERN ENERGY CONSTRUCTION, 2022, 9(3): 88-93. doi: 10.16516/j.gedi.issn2095-8676.2022.03.010 |

DownLoad:

DownLoad: