-

在全球范围内的能源消费中,化石能源的消费占80%以上。其中煤炭、天然气和石油分别为30.0%、23.7%和32.6%,而风能、地热能和太阳能等新能源仅占总能源消费的13.7%[1]。世界范围内煤炭、化石等燃料的燃烧,排放出大量的二氧化碳气体,致使温室效应日益严重,从而引起国际上广泛的关注[2]。在发电领域中,火力发电技术以燃煤为主,排放大量的二氧化碳[3]。此外还产生氮氧化物、硫化物、烟尘等污染物。为解决化石燃料燃烧所引发的环境问题,哥本哈根会议[4]和巴黎气候大会[5]均进一步确定了控制温室气体排放的战略目标。

整体煤气化联合循环(Integrated Gasification Combined Cycle, IGCC)是将煤气化技术和燃气–蒸汽联合循环有机结合成一体的新型发电系统。IGCC系统不仅可以降低环境污染,还可以方便地进行CO2捕集,因此具有二氧化碳排放量低、发电效率高等优点[6]。为实现能源的高效利用和二氧化碳减排的目标,世界上多个国家开始对IGCC发电场站进行研究与实践。世界上第一座IGCC示范电厂[7]于1994年在荷兰建成,之后中国[8]、美国[9]、日本[10]等国家相继建成IGCC示范电站。随着IGCC技术的不断发展与改进,装机容量逐渐上升。据调查现有的装机容量情况为:中国GreenGen的IGCC发电站为265 MW[11],美国Kemper IGCC发电站为524 MW[12],日本Nakoso IGCC发电站为250 MW[13]。

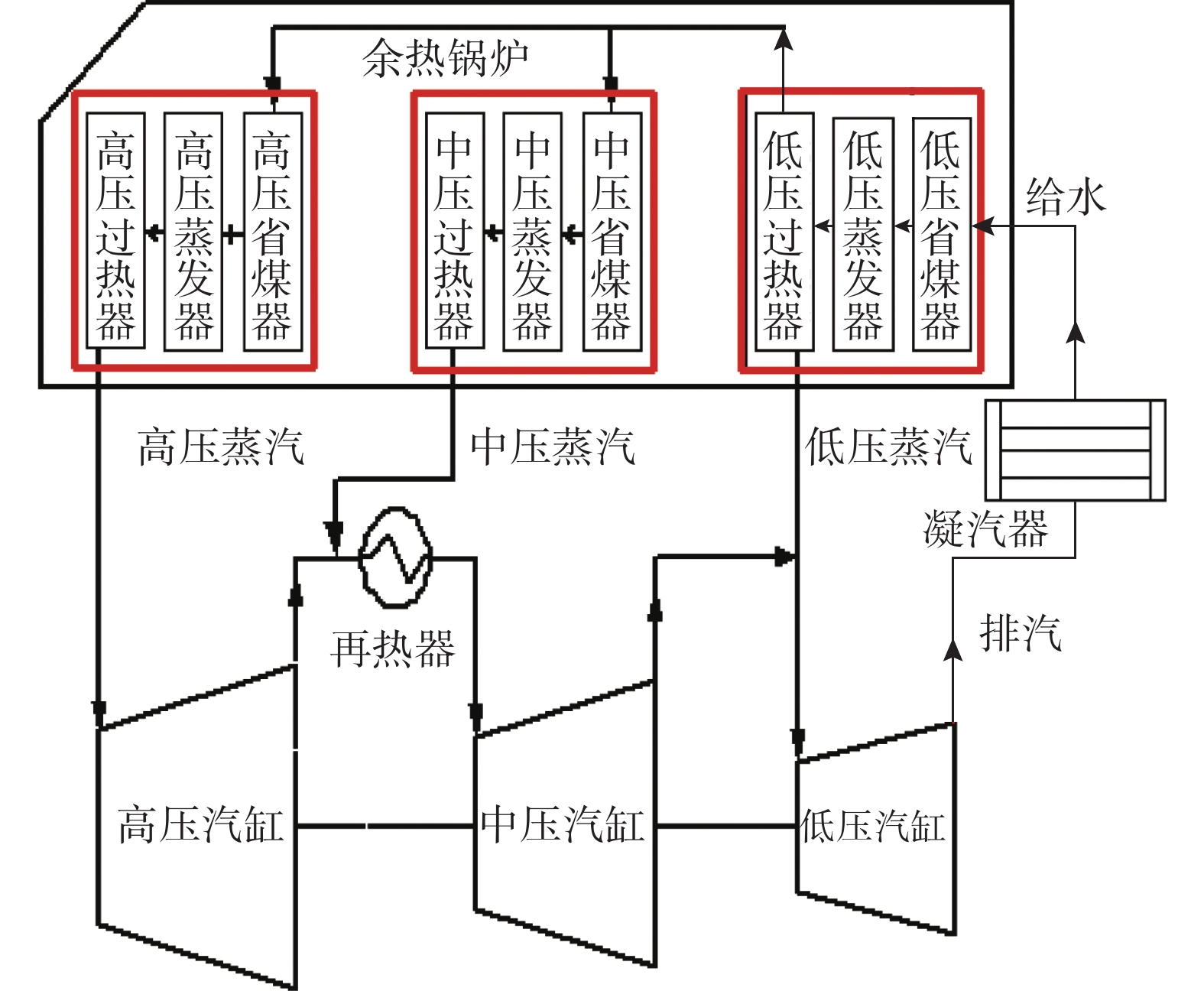

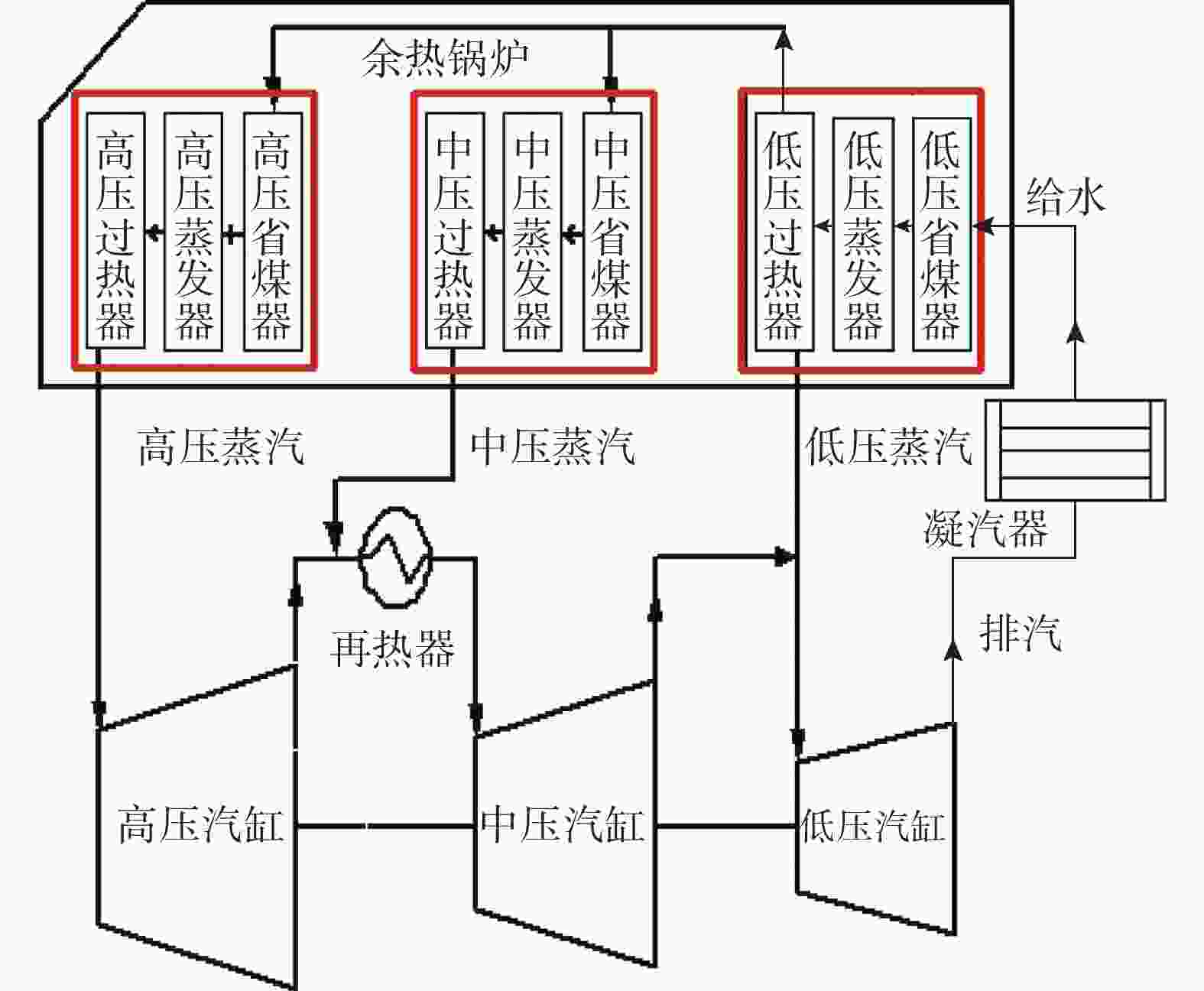

IGCC发电站主要包括气化岛、空分岛和动力岛三部分。其中动力岛(燃气–蒸汽联合循环)是该系统的研究重点[14]。IGCC联合循环系统中,主要包括燃气轮机、余热锅炉和蒸汽轮机[15]。本文主要侧重联合循环的底循环中的蒸汽轮机。工况的改变会使系统的效率发生很大的变化。当大气温度升高到一定值时,压气机的压缩比将有所下降,则会导致压缩机效率降低。同时,节点温差也是影响系统效率的因素之一,节点温差是蒸发器出口烟气温度与蒸发器内汽水温度之差,节点温差越小,能回收更多的热量,余热锅炉的效率就越高,但是会增加锅炉换热面积,进而增加烟气流动的阻力,增加了燃气轮机排气的背压,减少了燃汽轮机的出力,这将导致联合循环整体效率的下降。即使机组的转速和燃气初温保持恒定A. Ganjehkaviri等[16]提出了具有双压余热蒸汽发生器的联合循环电厂的热力学模型,研究了蒸汽轮机出口蒸汽干度对输出功率的影响。结果表明,蒸汽干度为88%的系统在经济、效率和环境方面是实际可靠的。Yousef S.H. Najjar等[17]通过建立模型来模拟不同负荷下蒸汽轮机的性能及效率对高压汽轮机、低压汽轮机等蒸汽循环部件进行评估,分析了各部件的劣化率及其对蒸汽轮机发电功率和热效率的影响。Mansur Aliyu等[18]通过设计数据对三压联合循环电厂进行热力学分析,通过研究运行参数对汽轮机输出功率和效率的影响,发现低压汽轮机出口处的过热压力、再热压力和蒸汽质量显著影响汽轮机的输出功率和效率。A. Ganjehkaviri等在文献[16]中分析汽轮机出口蒸汽质量对输出功率的影响,提出了能量效率和㶲效率两个评价指标,针对不同工况下的运行结果进行比较分析,为系统的优化和能源的有效利用提供指导。

结合当前对联合循环系统的研究现状,本文以IGCC系统为背景,针对底循环进行建模计算。分析蒸汽流量、给水温度、过热蒸汽温度和再热蒸汽温度对蒸汽轮机的输出功率、蒸汽的吸热负荷和系统热效率的影响,得到各变量变化时系统的运行曲线。结合分析结论,给出给水温度、给水流量、过热蒸汽温度和再热蒸汽温度的取值依据,使系统总输出功率和热效率达到较高水平,从而达到优化蒸汽轮机系统运行的目的。

-

本文主要考虑高压、中压和低压过热蒸汽的参数与机组输出功率的影响关系,忽略一些次要的因素,具体假设条件如下所示:

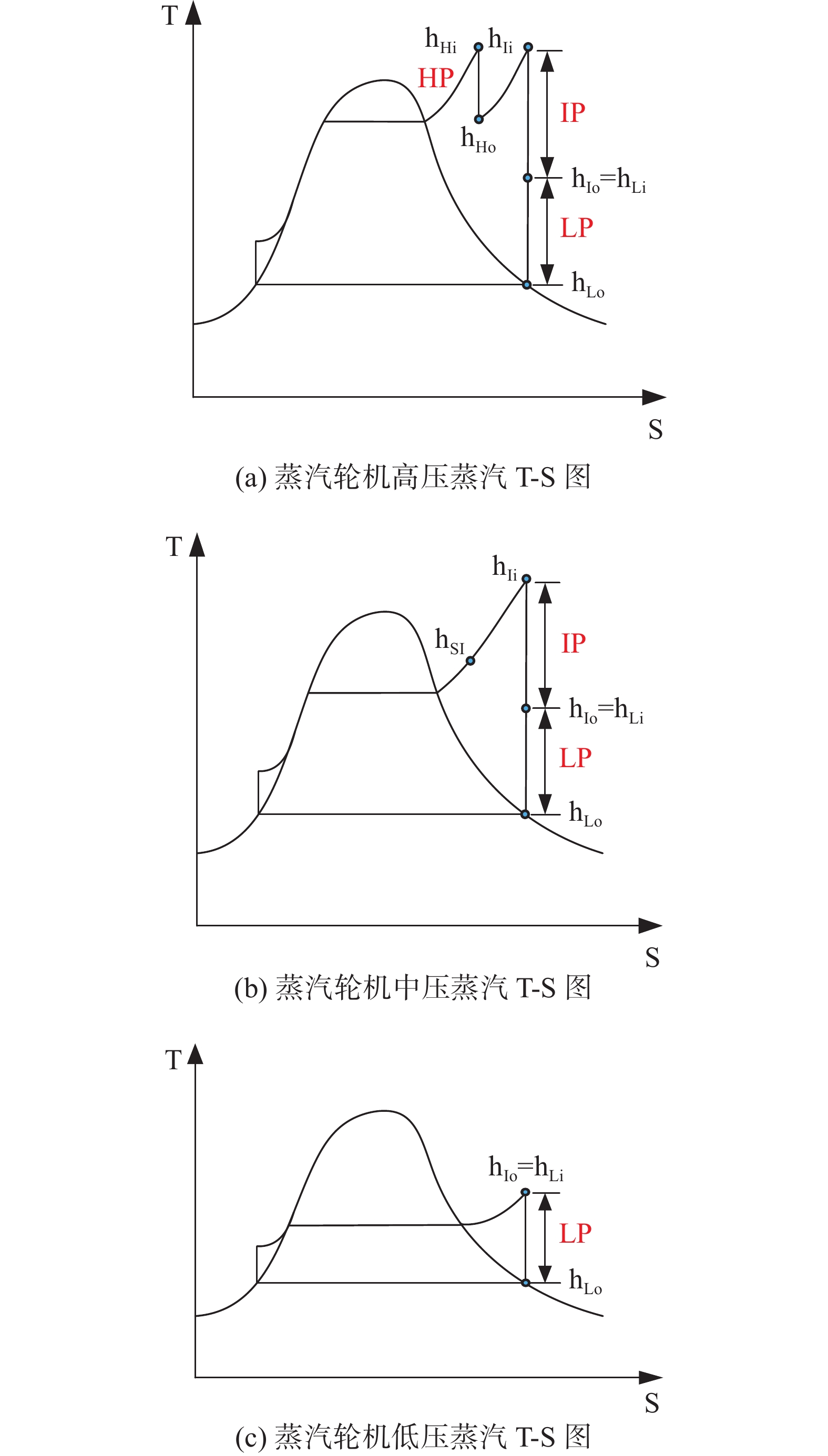

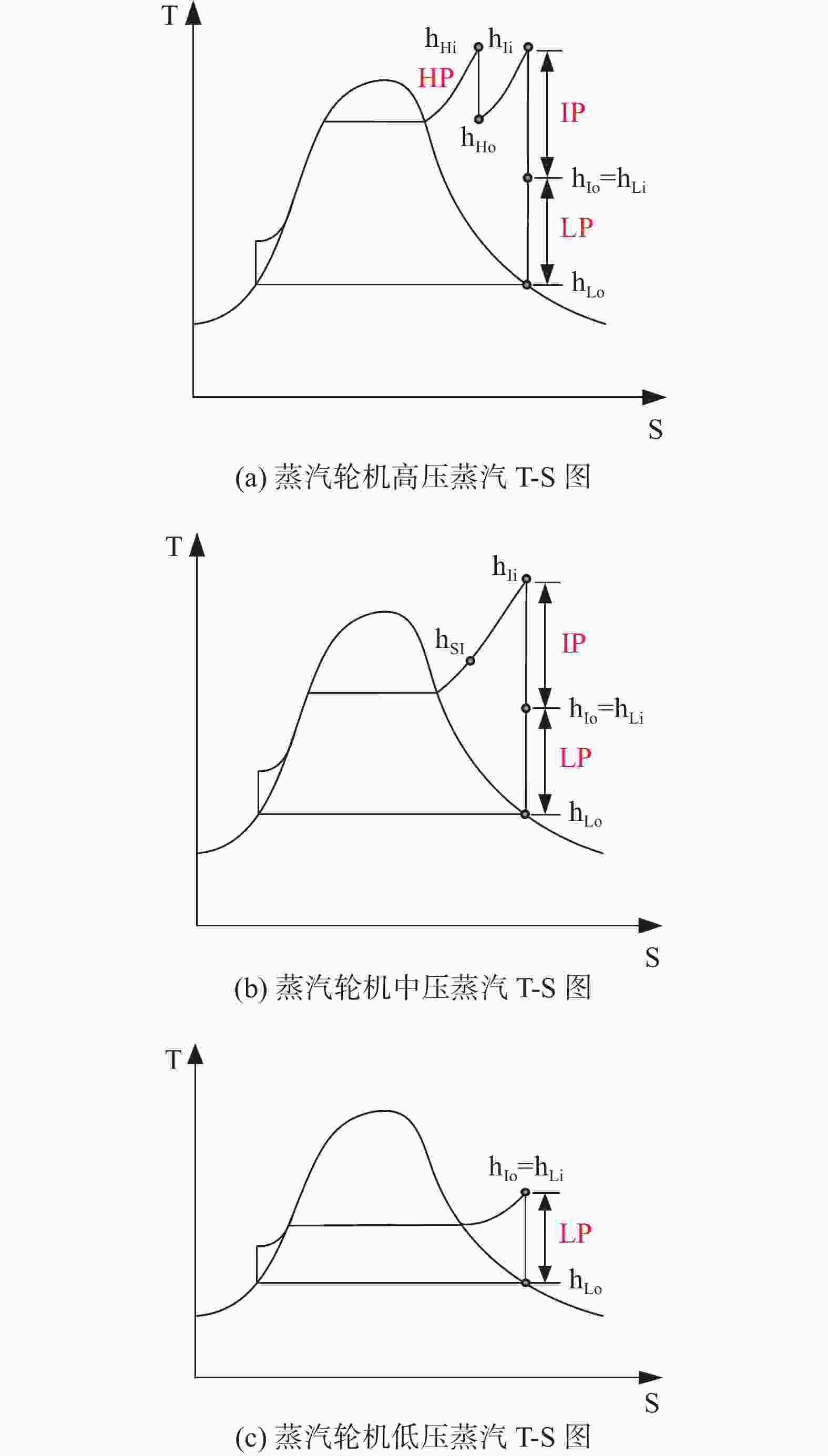

1)余热锅炉生产的高压过热蒸汽直接进入高压汽轮机中等熵膨胀做功,不考虑该过程中的能量损失,即hSH=hHi。

2)中压过热蒸汽的压力、再热器运行压力和高压汽轮机排汽压力三者相同,高压汽轮机排汽与中压过热蒸汽在再热器中混合,加热为再热蒸汽,其中tSI<tHo<tIi,即hSI<hHo<hIi。

3)再热蒸汽直接进入中压汽轮机中等熵膨胀做功,中压汽缸排汽的压力与低压过热蒸汽相同,一并混合后进入低压汽轮机中膨胀做功,其中hIo=hLi。

4)低压汽轮机排汽状态为背压5 kPa下的饱和蒸汽。

5)不考虑蒸汽进入各级压力汽缸时的温差,认为温度不变。

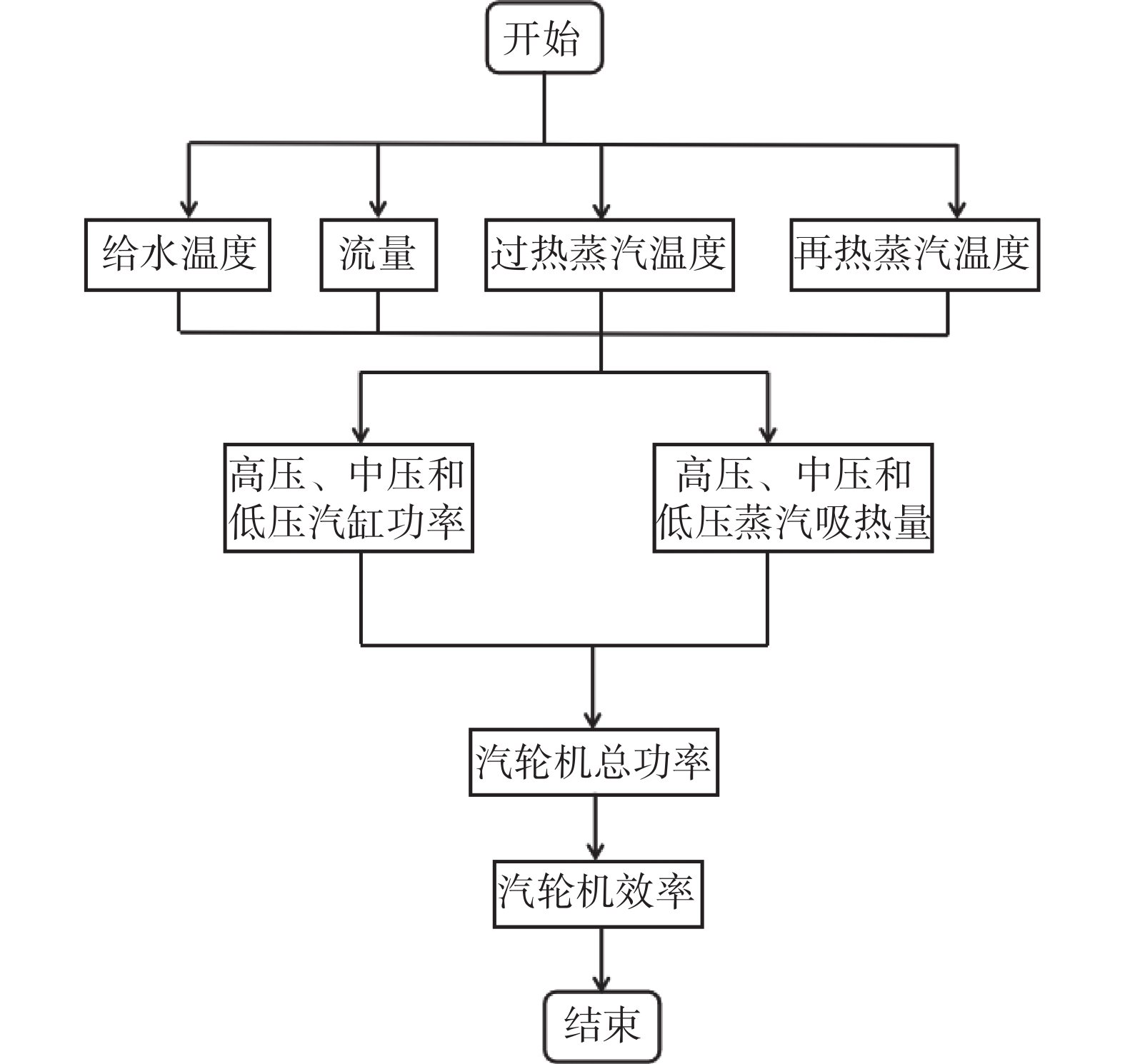

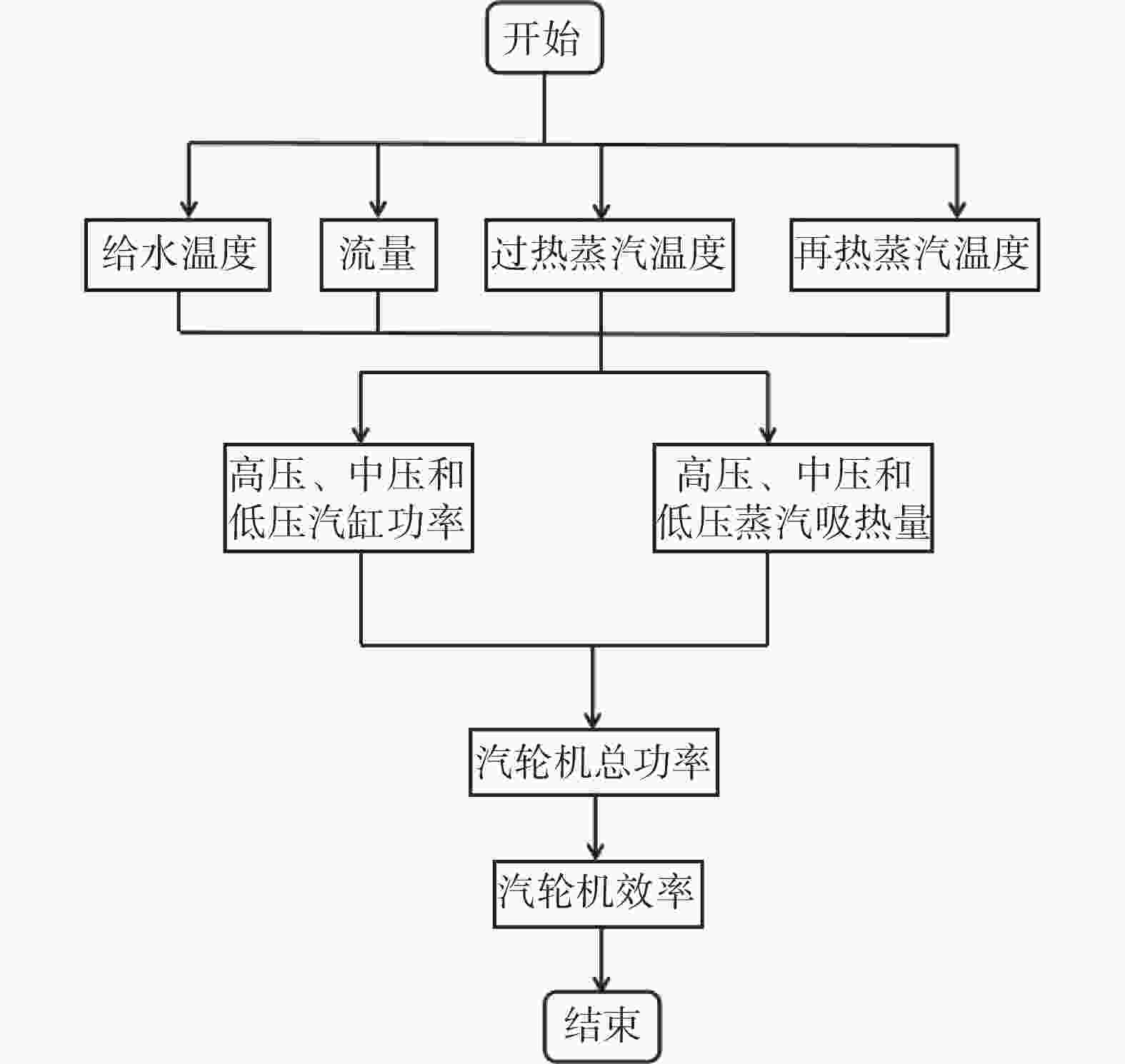

由式(1)~式(12)可计算出中高低压蒸汽吸热量QH、QI和QL;高中低压汽轮机输出功率WH、WI和WL;底循环总输出功率P。依据图3所示的建模逻辑运行图,将高中低压蒸汽流量、给水温度、和再热蒸汽温度约束定为变量,结合上述公式在MATLAB中编写计算代码,分析当各变量取值变化时对总输出功率、效率以及相应评价指标的影响。

-

余热锅炉与蒸汽轮机系统所构成的底循环部分存在能量平衡关系,高压、中压和低压蒸汽进入该底循环时,余热锅炉与蒸汽轮机的能量平衡关系如下:

$$ \begin{split} &Q = {m_H}({h_{Hi}} - {h_W}) + {m_H}({h_{Ii}} - {h_{Ho}}) + {m_I}({h_{SI}} - {h_W}) +\\& {m_I}({h_{Ii}} - {h_{SI}}) + {m_L}({h_{Li}} - {h_W}) \end{split} $$ (1) 式中:

Q ——余热锅炉换热量(MW);

i、o ——汽轮机进出口;

W、S ——水和蒸汽;

H、I、L ——高压、中压和低压;

mH、mI、mL——高中低压蒸汽的流量(kg/s);

hW ——锅炉给水焓值(kJ/kg);

hHi ——高压蒸汽轮机入口处蒸汽焓值(kJ/kg);

hHo ——高压蒸汽轮机排汽焓值(kJ/kg);

hSI ——中压过热蒸汽焓值(kJ/kg);

hIi ——中压蒸汽轮机入口处蒸汽焓值(kJ/kg);

hLi ——低压蒸汽轮机入口处蒸汽焓值(kJ/kg)。

高中低压蒸汽吸热负荷量计算式为:

$$ {Q_H} = {m_H}({h_{Hi}} - {h_W}) + {m_H}({h_{Ii}} - {h_{Ho}}) $$ (2) $$ {Q_I} = {m_I}({h_{SI}} - {h_W}) + {m_I}({h_{Ii}} - {h_{SI}}) $$ (3) $$ {Q_L} = {m_L}({h_{Li}} - {h_W}) $$ (4) -

高中低压蒸汽轮机的理论输出功率计算式为:

$$ {W_{H1}} = {m_H}({h_{Hi}} - {h_{Ho}}) $$ (5) $$ {W_{I1}} = ({m_H} + {m_I})({h_{Ii}} - {h_{Io}}) $$ (6) $$ {W_{L1}} = ({m_H} + {m_I} + {m_L})({h_{Li}} - {h_{Lo}}) $$ (7) 式中:

WH1、WI1、WL1——高中低压蒸汽轮机的理论输出功率(MW);

hIo ——中压蒸汽轮机排汽焓值(kJ/kg);

hLo ——低压蒸汽轮机排汽焓值(kJ/kg)。

高压、中压和低压蒸汽轮机的实际输出功率计算式为:

$$ {W_H} = {W_{H1}}\eta H $$ (8) $$ {W_I} = {W_{I1}}\eta I $$ (9) $$ {W_L} = {W_{L1}}\eta L $$ (10) 式中:

ηH、ηI、ηL ——高中低压蒸汽轮机的相对内效率。

蒸汽轮机总输出功率计算式为:

$$ P = {W_H} + {W_I} + {W_L} $$ (11) 底循环热效率计算式为:

$$ \eta = \frac{P}{Q} \times 100{\text{% }} $$ (12) -

结合华能天津IGCC示范电站中所使用的三压再热联合循环汽轮机的主要运行参数[20],本文中所用参数如表1所示。其中,高压、中压和低压过热蒸汽以及再热蒸汽的焓值通过基于IAPWS IF-97标准的水与蒸汽热力学性质的计算软件和插值法求得。

项目 入口温度/℃ 入口压力/MPa 出口温度/℃ 出口压力/MPa 入口焓值/[kJ·(kg)−1] 出口焓值/[kJ·(kg)−1] 质量流量/(kg·s−1) 高压汽缸 520 9.2 383.5 4.0 3 435 3 064 55 中压汽缸 520 4.0 240 0.586 3 492 2 936 123 低压汽缸 240 0.586 101 0.105 2 936 2 678 129 Table 1. IGCC combined cycle steam turbine operating parameters

-

本文将表1中的数据作为参考工况。参考工况下系统运行结果如表2所示。

给水温度/℃ 35 低压蒸汽吸热/MW 16.7 再热蒸汽温度/℃ 520 总吸热负荷/MW 442.3 高压蒸汽流量/(kg·s−1) 55 高压汽缸功率/MW 12.4 中压蒸汽流量/(kg·s−1) 68 中压汽缸功率/MW 63.5 低压蒸汽流量/(kg·s−1) 6 低压汽缸功率/MW 29.6 高压蒸汽吸热/MW 198.2 总输出功率/MW 105.5 中压蒸汽吸热/MW 227.4 汽轮机热效率/% 23.86 Table 2. Refer to the operating parameters of the bottom circulation system under the working conditions

-

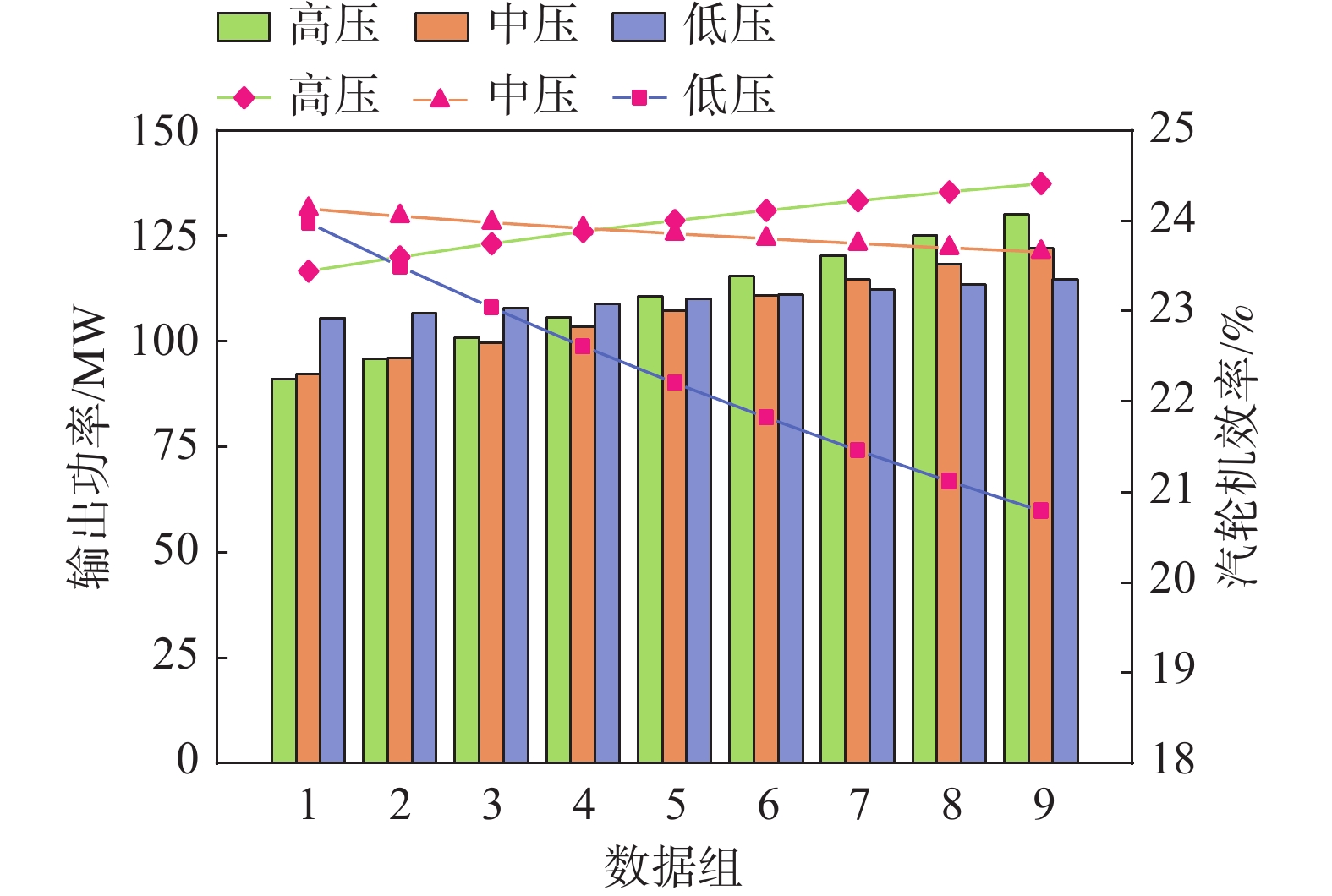

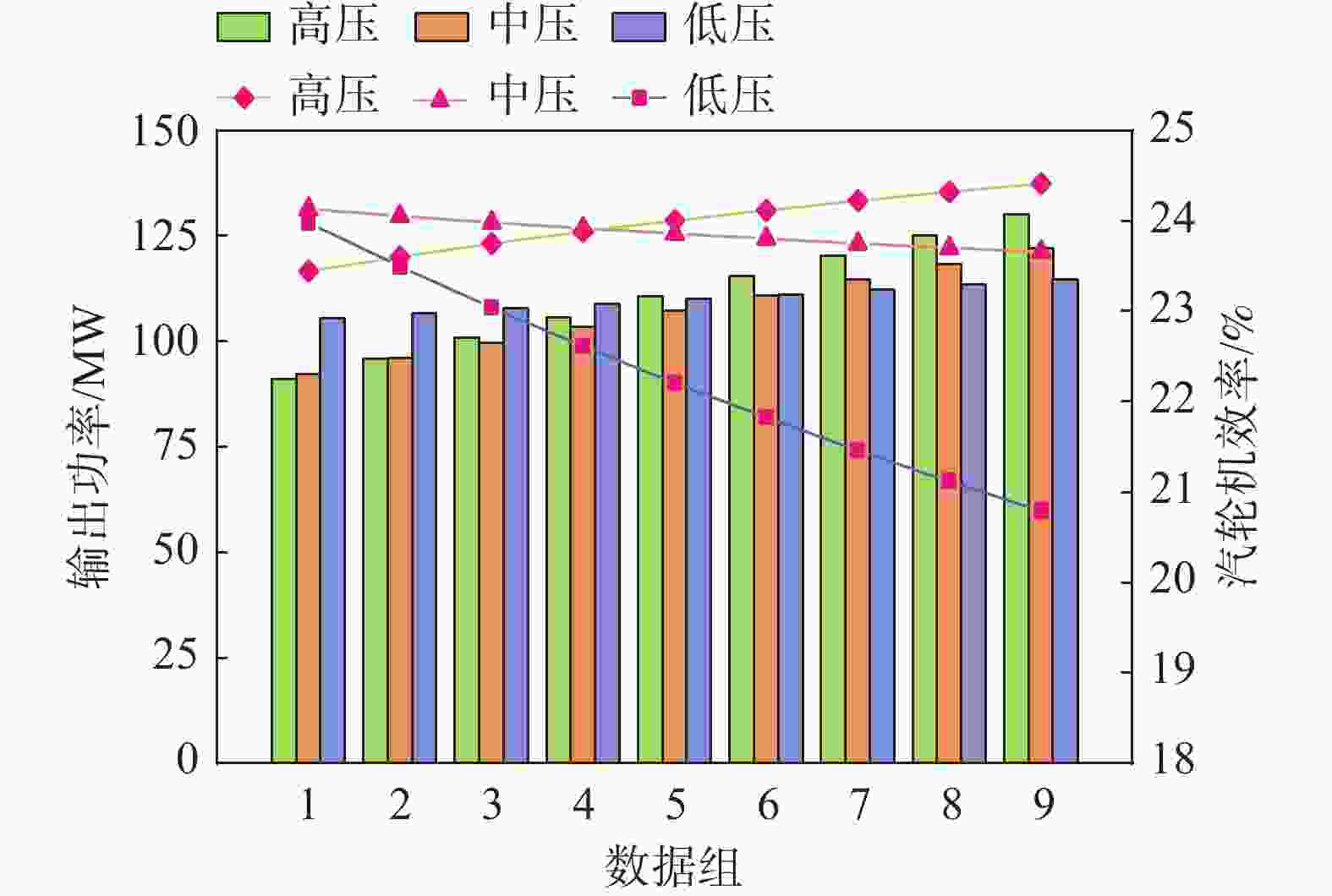

高压、中压和低压蒸汽流量均以5 kg/s的增量逐步增加,每个变量连续取9个值,组成9组数据进行分析,如表3、图4所示,且图4右侧纵轴为整个蒸汽轮机的热效率。从图中可以观察到输出功率随流量的增加均增大,但高压蒸汽流量的变化对总输出功率的影响最大,低压蒸汽流量的变化次之,中压蒸汽流量的变化对总输出功率的影响最小。蒸汽轮机的热效率随着高压蒸汽流量的增加而升高,随着中压和低压蒸汽流量的增加而降低。中压蒸汽流量增加时,热效率降低幅度很小,趋于平缓稳定;低压蒸汽流量增加时,热效率从23.98%降低至20.79%,对热效率的影响较大。对于中压蒸汽流量的取值,不仅要考虑热效率,还要考虑输出功率。在热效率降低相对不大的情况下,可折中考虑中压蒸汽流量值来保证一定的输出功率。

数据/(kg·s−1) 1 2 3 4 5 6 7 8 9 高压 40 45 50 55 60 65 70 75 80 中压 50 55 60 65 70 75 80 85 90 低压 5 10 15 20 25 30 35 40 45 Table 3. Variable working conditions 9 sets of data parameters

通过上述对蒸汽流量变化的分析,增加高压蒸汽流量,减小低压蒸汽流量,折中取值中压蒸汽流量,可以充分利用回收的热能,在具有较高热效率前提下,使蒸汽轮机输出更高的功率。

-

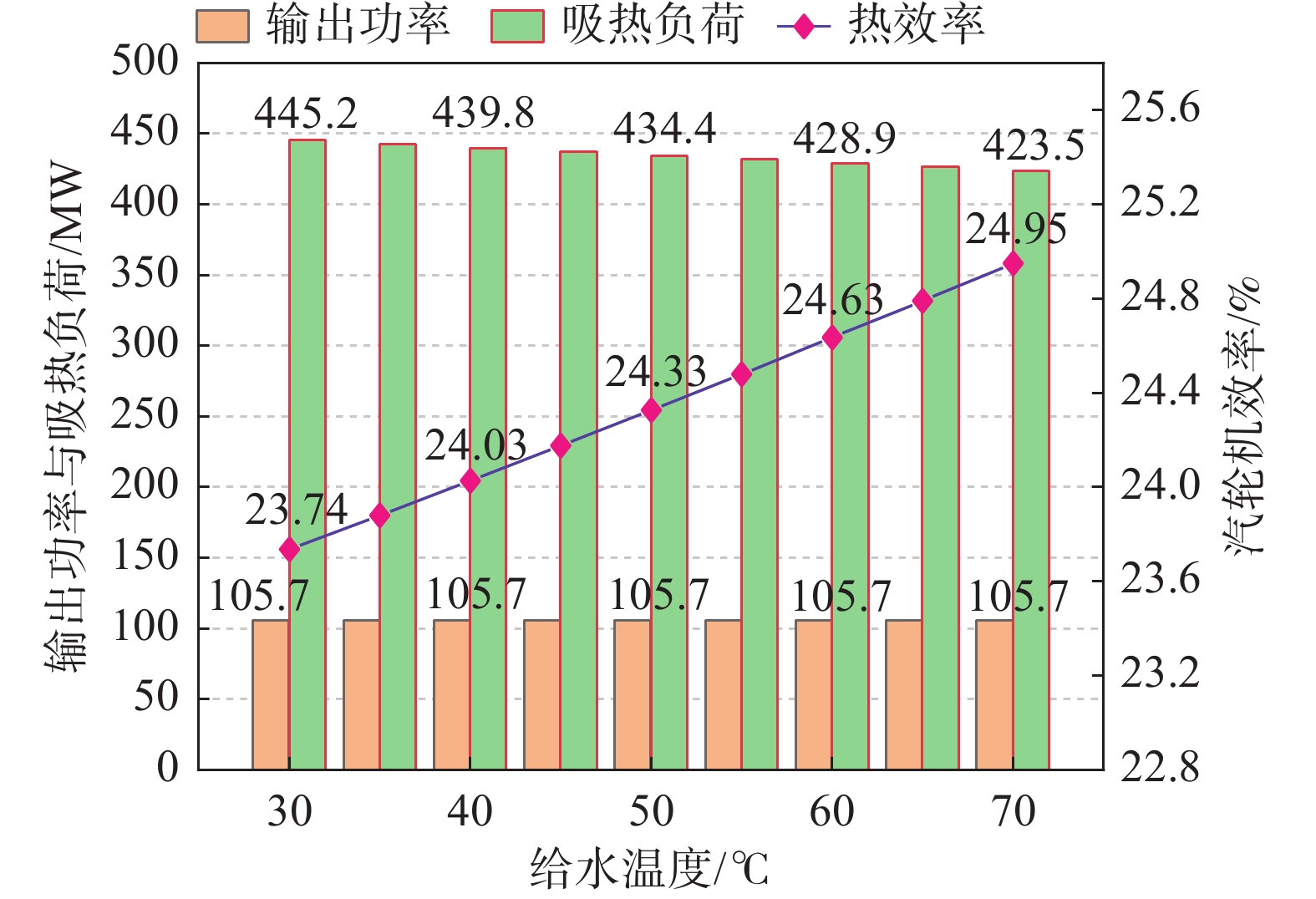

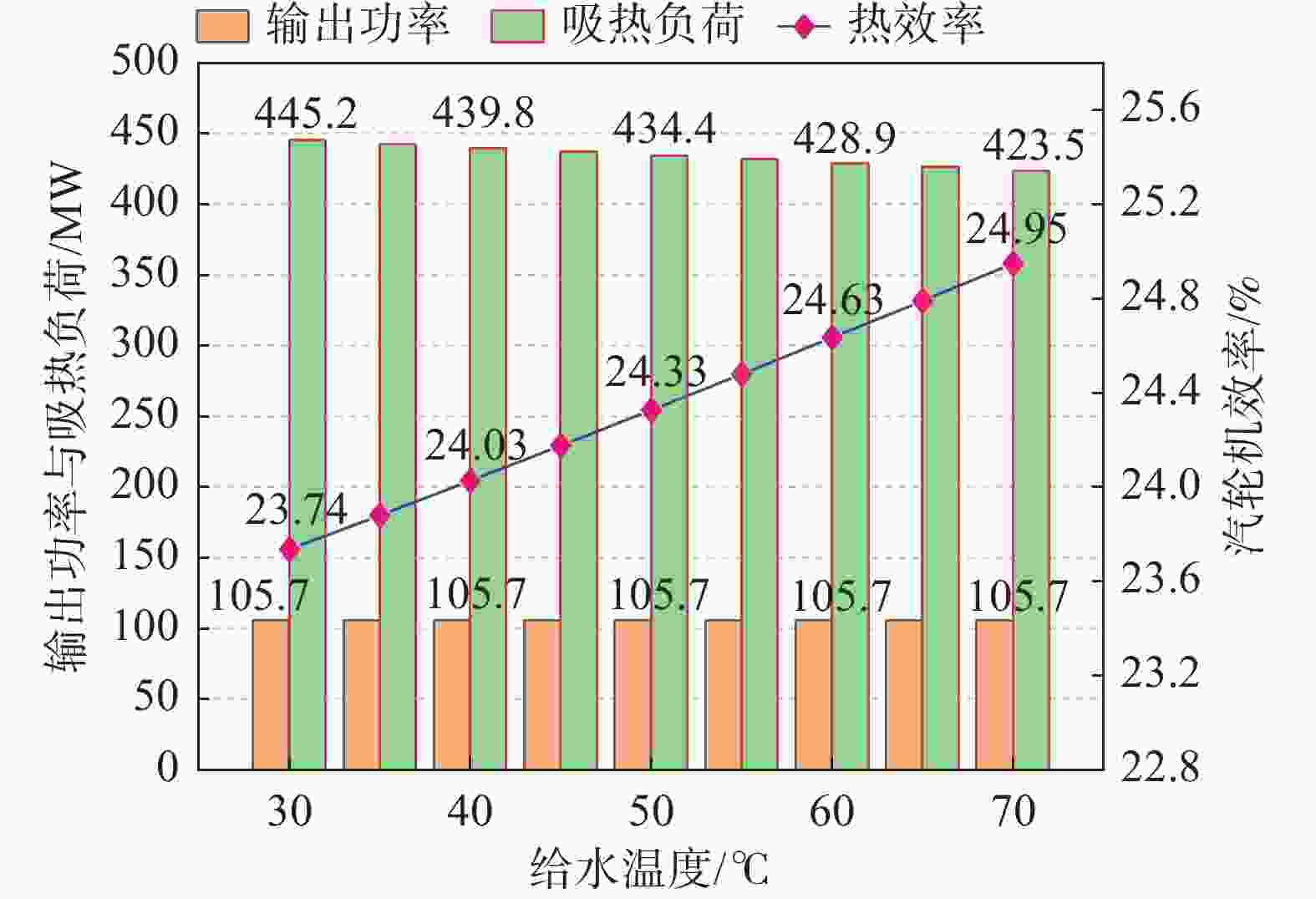

低压汽轮机排汽的能量很低,会经过凝汽器后冷凝成凝结水,泵入余热锅炉中作为给水进行余热锅炉的汽水循环。凝汽器提供的负荷变化时会影响给水温度,当给水温度变化时,系统的运行特性如图5所示。

输出功率不随给水温度发生变化,而蒸汽吸热负荷会随着给水温度的升高而降低。这是因为余热锅炉出口蒸汽的参数是确定的,当其他变量不变的情况下,给水温度只影响从该温度升高至余热锅炉出口蒸汽温度这个过程所吸收的热量,而不影响做功量。根据图5可以看出蒸汽轮机的热效率从23.74%升高至24.95%,所以给水温度越高,输出相同的功率所需要吸收的热负荷就越小,越有利于减少热能的消耗。

-

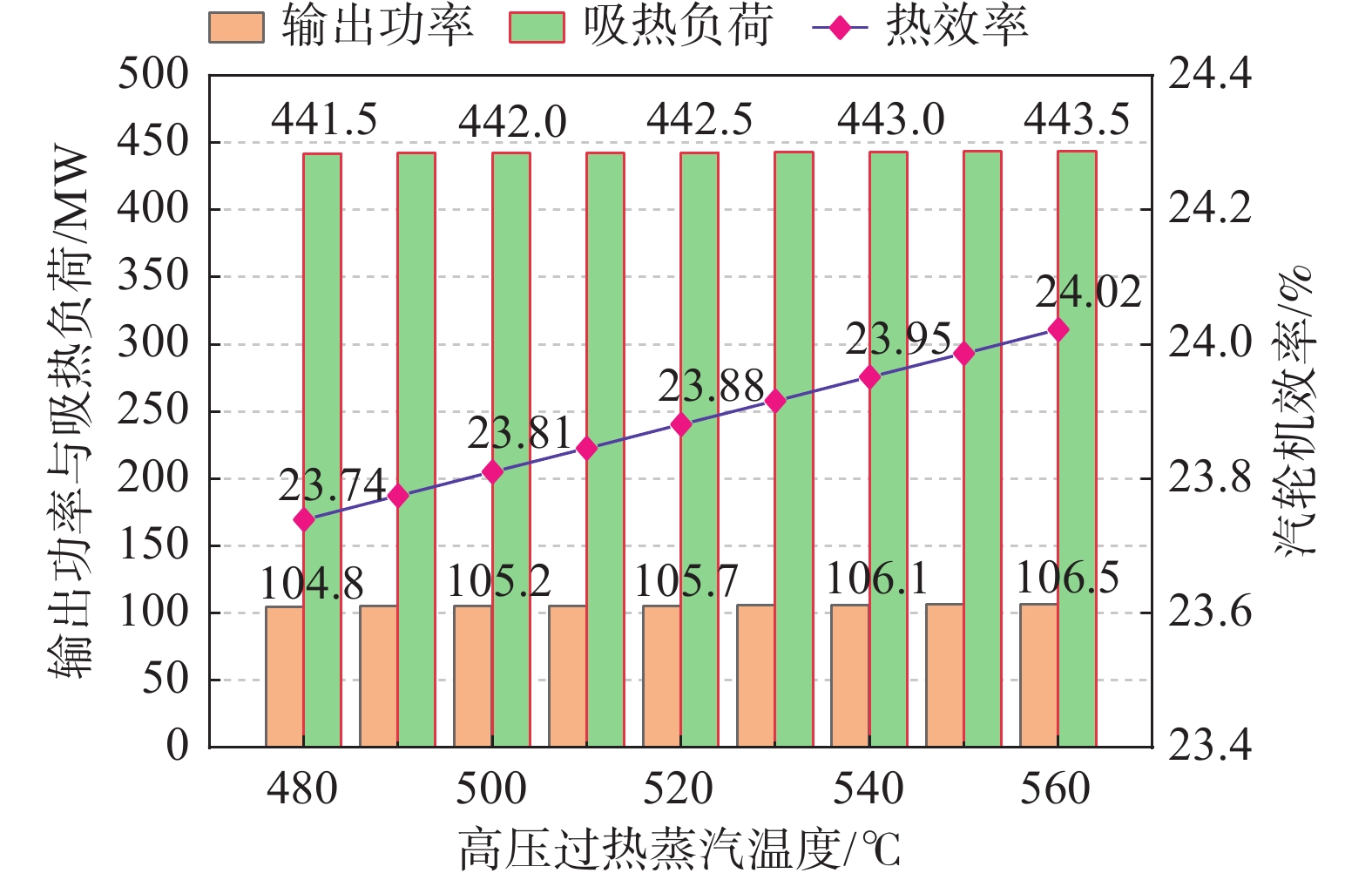

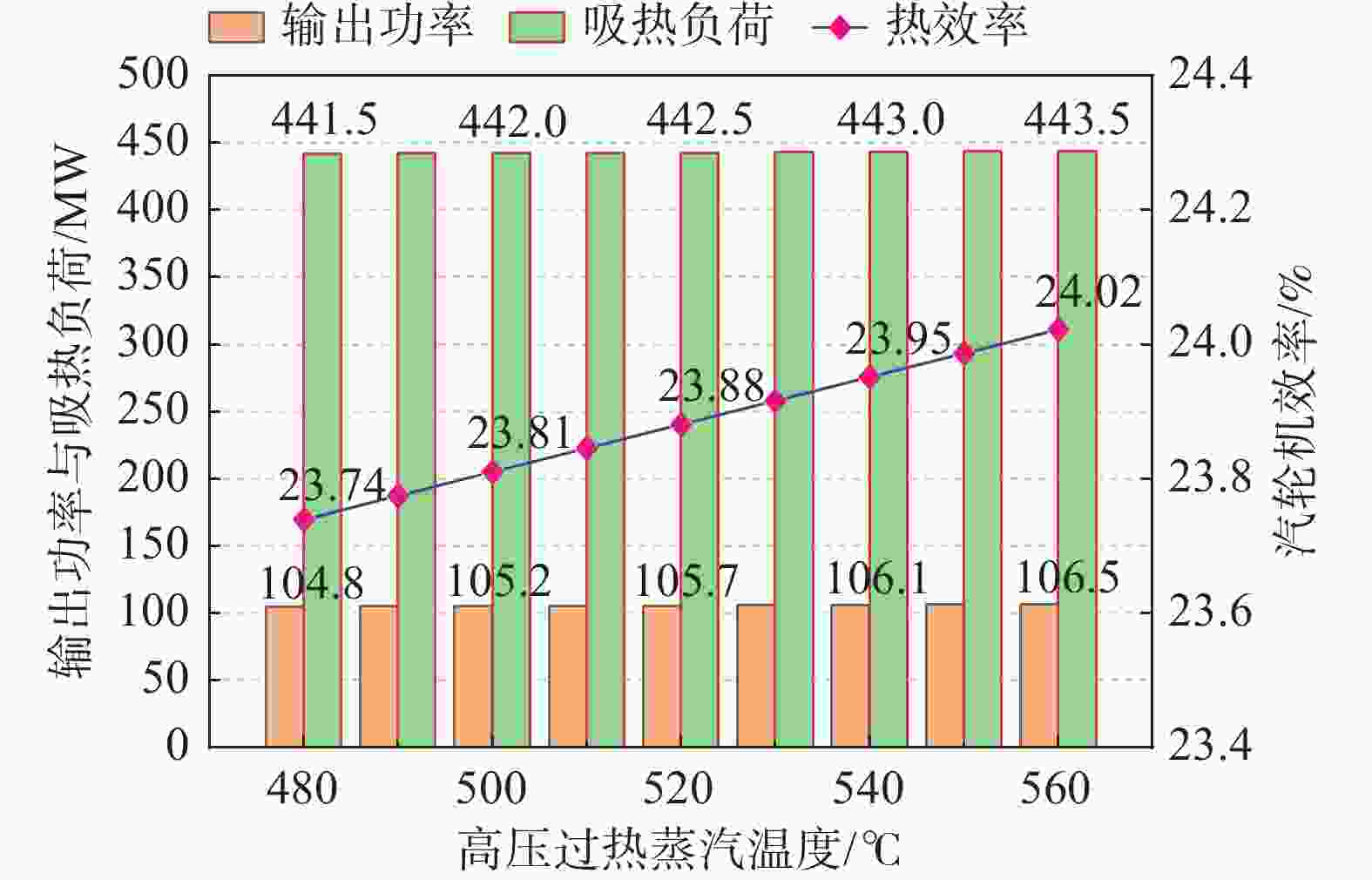

三压再热余热锅炉中分别设置有高压、中压和低压过热器,用于生产高压、中压和低压过热蒸汽进入汽轮机中做功。这里研究讨论了当高压过热蒸汽温度发生变化时,对总的输出功率和吸热负荷的影响,以及对热效率的影响,结果如图6所示。

由图6可以看出总的输出功率、吸热负荷和热效率随高压过热蒸汽温度升高而增大,但是增幅极小,可见高压过热蒸汽温度变化对系统的影响很小。这是因为高压过热蒸汽在9.2 MPa下饱和蒸汽温度为305 ℃,随着定压加热使温度上升为过热蒸汽后,其焓值的增量随温度变化很小,所以输出功率和吸热负荷的增量均很小。

由图6可以看出热效率是逐步上升的,所以高压过热蒸汽温度可以适当选高一些,在吸收相同热负荷的情况下,输出功率会相对增大。

-

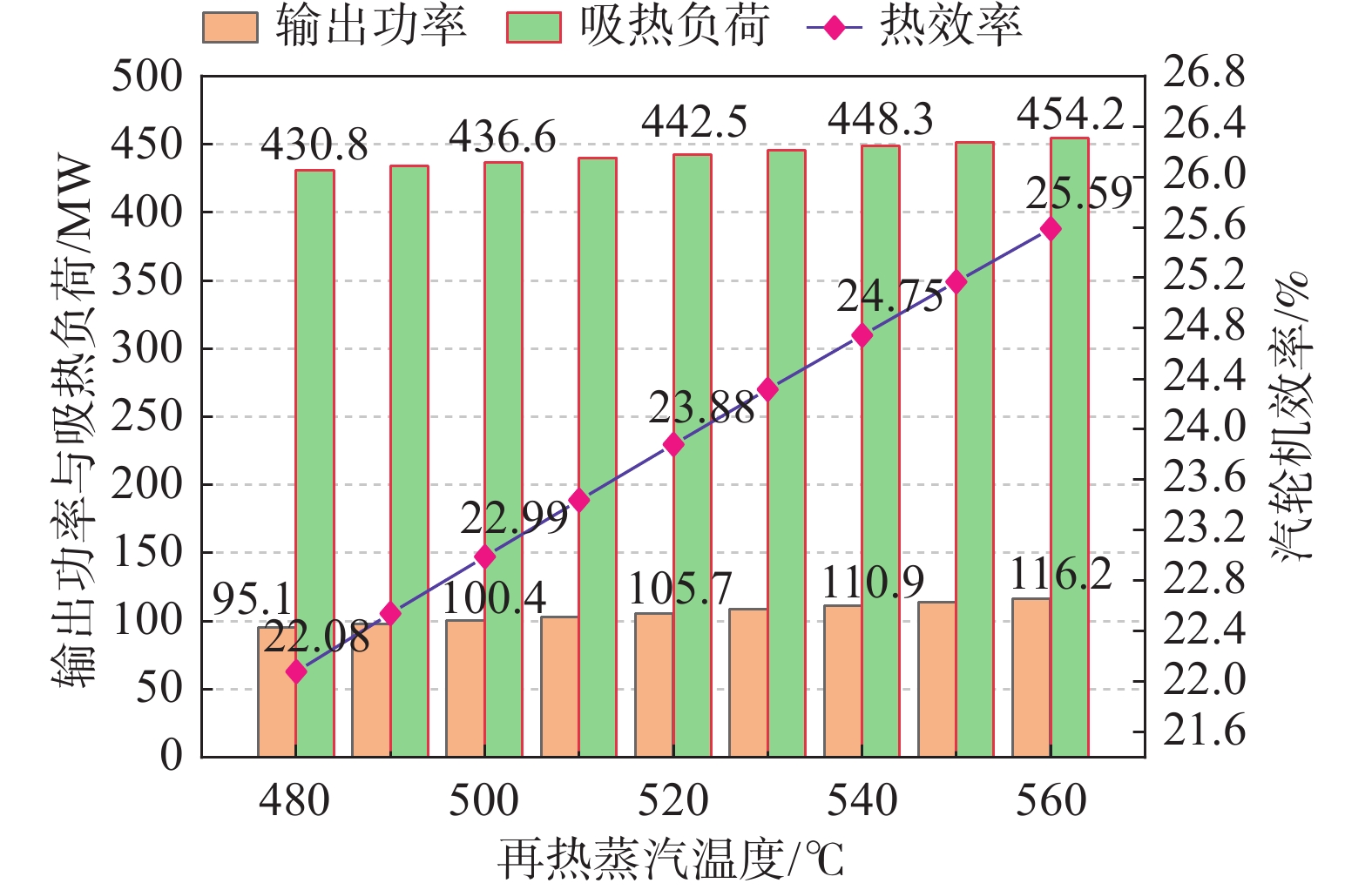

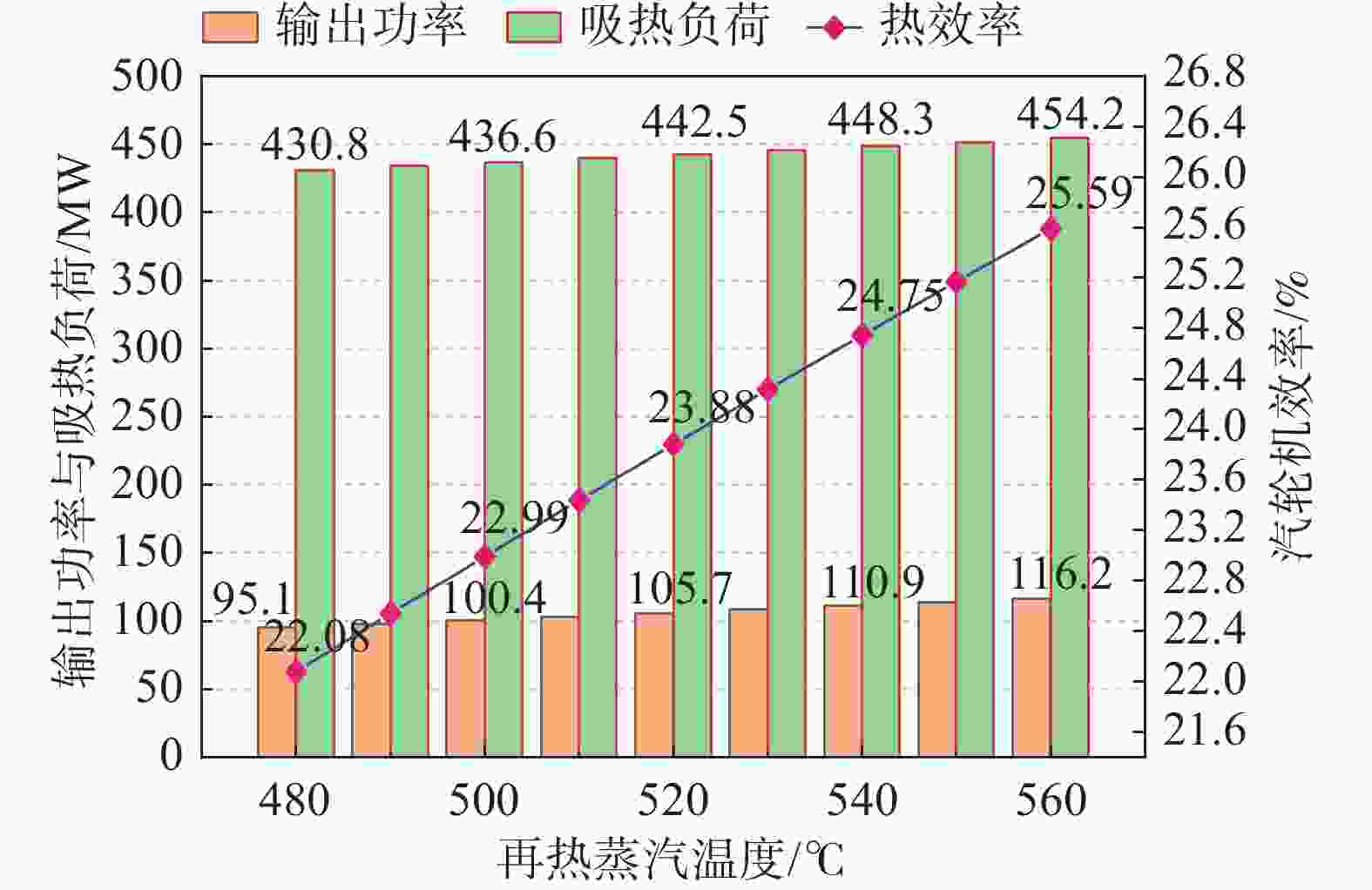

高压汽缸排汽与中压过热蒸汽混合后,由再热器加热成参数更高的再热蒸汽,这里主要研究当再热蒸汽温度变化时对总输出功率、吸热负荷和热效率的影响。

如图7所示,总输出功率和吸热负荷随再热蒸汽温度增加幅度较小,而热效率的增加幅度较大,从22.08%升高至25.59%。由此可知,当再热蒸汽温度大幅度增加时,输出功率和吸热负荷虽然不会大幅度增加,但是仍然处于增加的趋势,且热效率增加趋势明显。故再热蒸汽温度可以适当取得高一些。

-

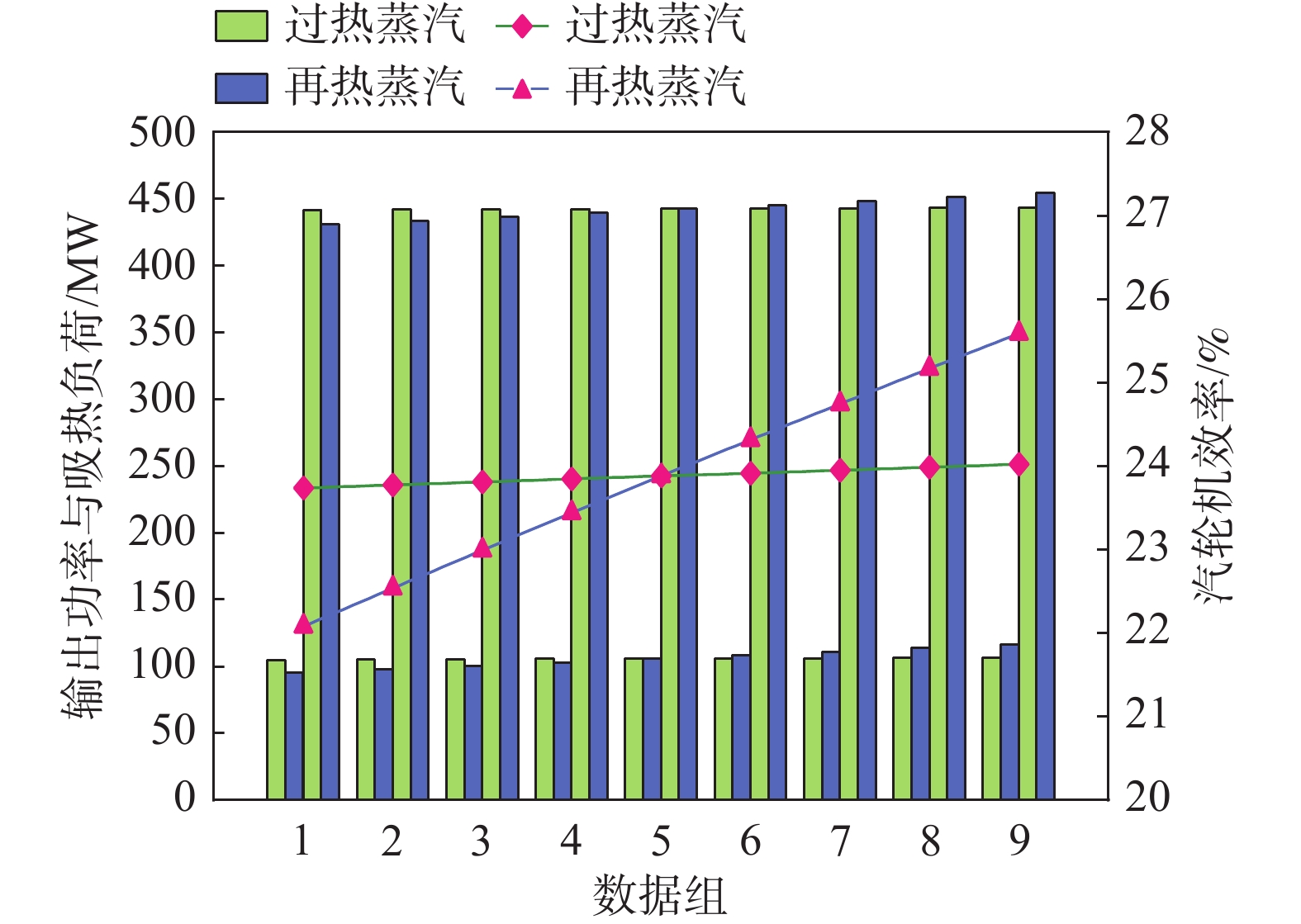

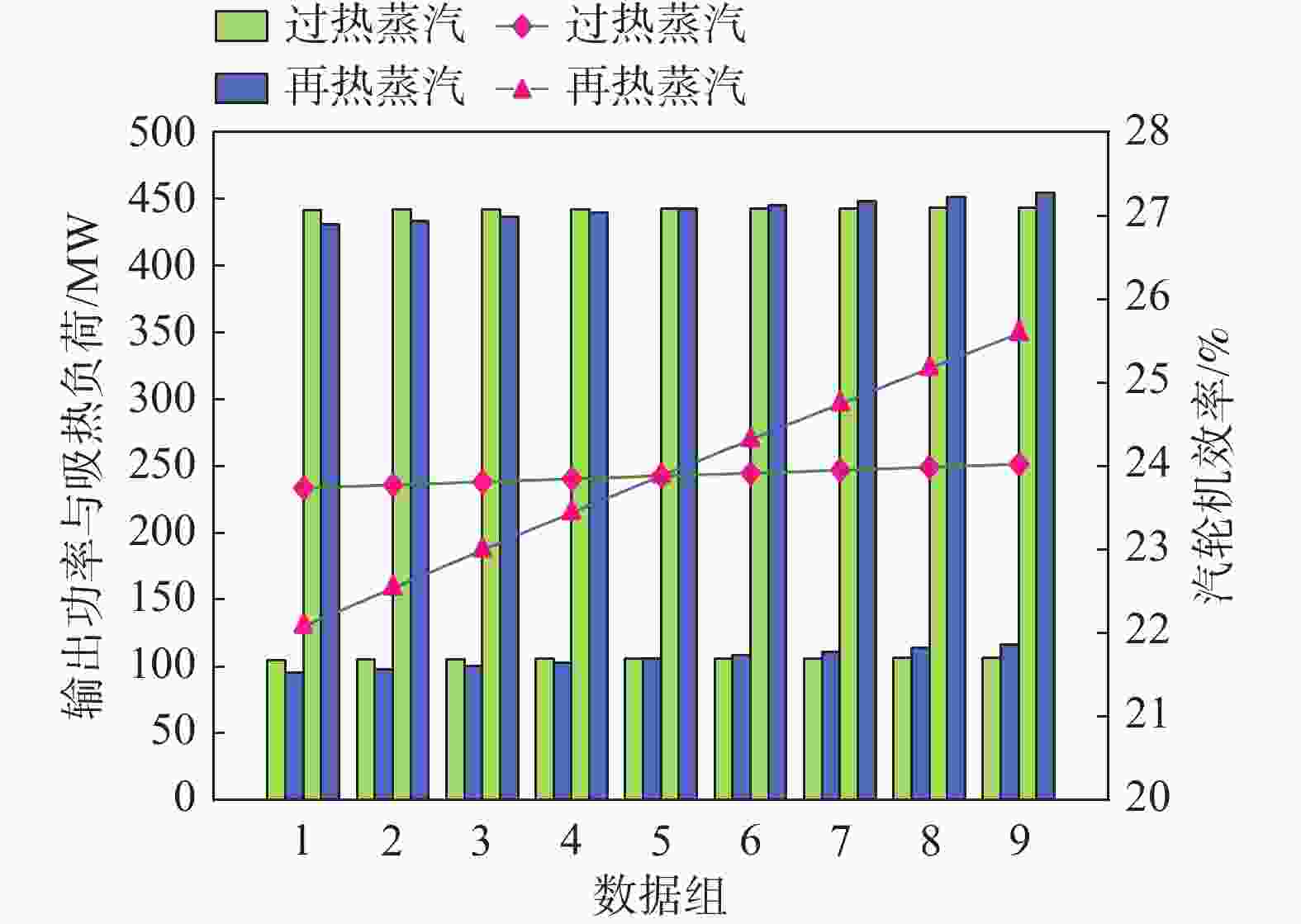

高压过热蒸汽温度和再热蒸汽温度均以10 ℃的增量逐步增加,每个变量连续取9个值,即图中数据组1-9分别为:480 ℃、490 ℃、500 ℃、510 ℃、520 ℃、530 ℃、540 ℃、550 ℃、560 ℃。由其组成数据组分析,如图8所示。

图中可以直观地看出高压过热蒸汽温度变化对输出功率和吸热负荷的影响不大,热效率也趋于平缓;再热蒸汽温度增加会使输出功率和吸热负荷以一定增幅变大,热效率明显升高。这是因为高压过热蒸汽的焓值随温度升高的增量很小,所以对输出功率的影响不大。虽然再热蒸汽的焓值随温度升高的增量也很小,但是再热蒸汽的流量是高压汽缸排汽与中压过热蒸汽的加和,因此对输出功率的影响较大一些。

基于上述分析,高压过热蒸汽温度和再热蒸汽温度越高,蒸汽轮机的热效率就越高。在吸收相同热负荷的情况下,能够输出更高的功率。但是由于输出功率和吸热负荷随这两个变量变化的幅度很小,所以在设定高压过热蒸汽和再热蒸汽温度时,要考虑高参数蒸汽对设备的影响。在不增加设备成本、不会对设备运行造成破坏的前体下,可以适当提高高压过热蒸汽和再热蒸汽的温度。

-

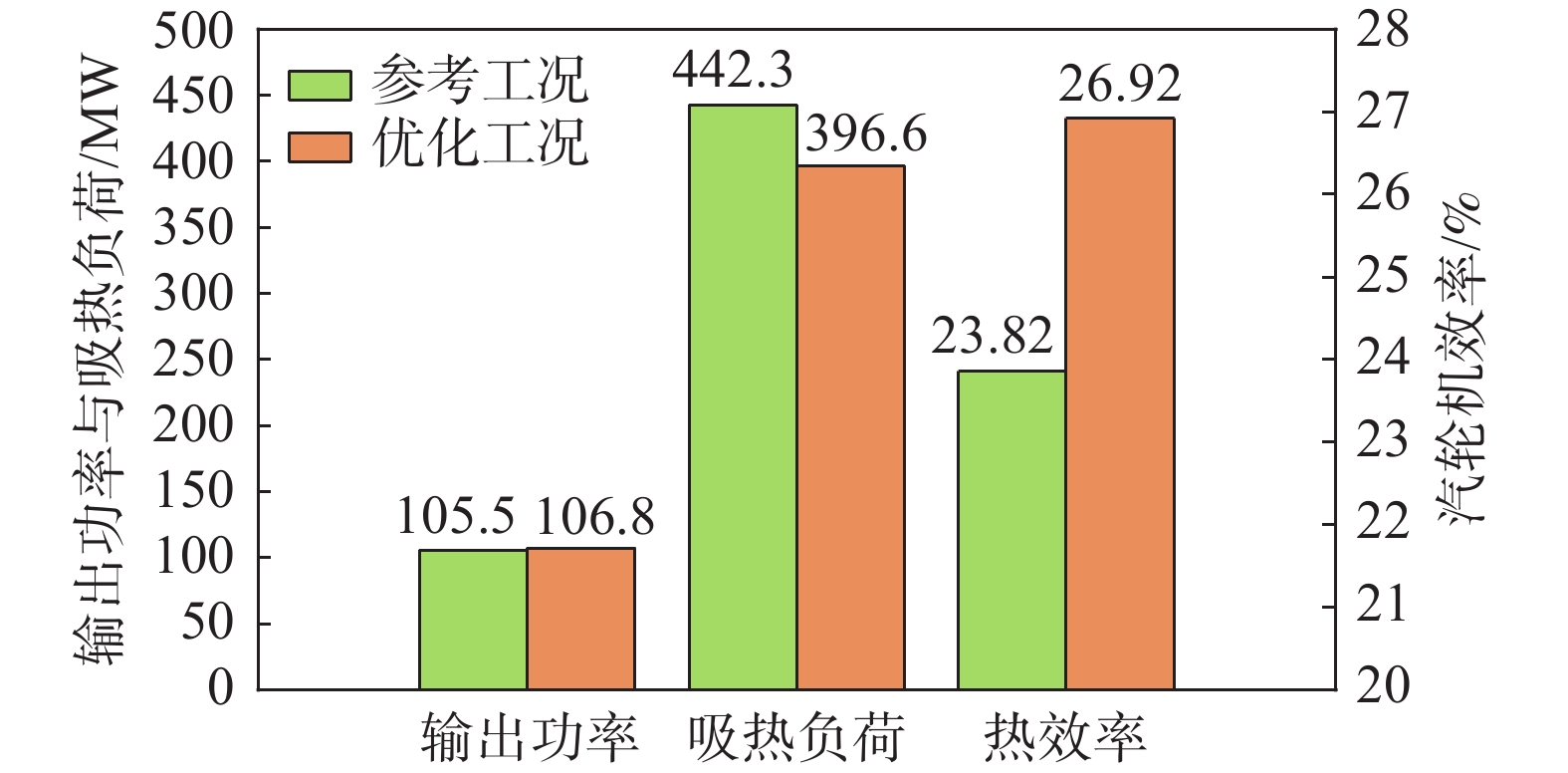

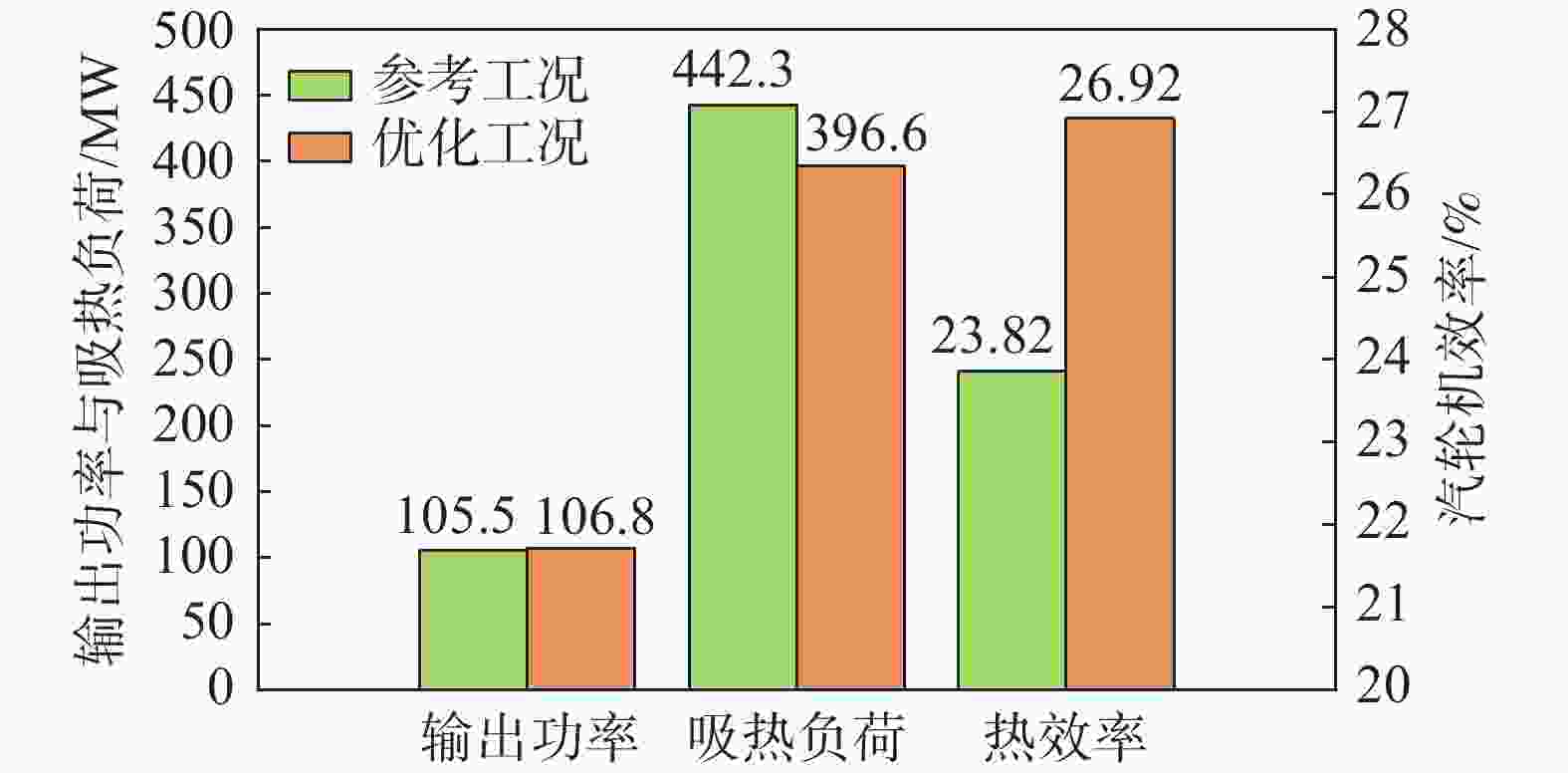

根据上述对蒸汽流量、给水温度、高压过热蒸汽温度和再热蒸汽温度这四个变量的分析,得到了各变量对蒸汽轮机输出功率和运行热效率的影响情况。将优化工况与参考工况的运行特性进行对比,如图9所示。

如图9所示,在输出功率基本不变的情况下,优化工况的吸热负荷比参考工况减小了45.7 kW,而热效率由23.82%变成26.92%。这是由于提高了高压蒸汽流量和给水温度,降低了中压蒸汽流量。这大大降低了吸热负荷,并保持了较高的输出功率,从而使得蒸汽轮机的热效率升高。通过对运行参数的合理取值,可以在一定范围内保持较高的热效率,在输出一定功率的情况下减少对热能的输入,有利于能源的节约与高效利用。

-

本文运用MATLAB进行计算代码的编写与运算,将计算结果用origin绘制成柱状图和点线图进行分析研究。当每个变量发生变化时,分析其对蒸汽轮机总输出功率、热效率和蒸汽总吸热负荷的影响,具体结论如下:

1) 增加高压蒸汽流量,减小低压蒸汽流量,折中取值中压蒸汽流量,可以充分利用回收的热能,在具有较高热效率前提下,使蒸汽轮机输出更高的功率。

2) 给水温度升高时,输出功率不随给水温度发生变化,而蒸汽吸热负荷会随着给水温度的升高而降低。较大给水温度可以减少热能的输入。

3) 高压过热蒸汽和再热蒸汽温度升高,蒸汽轮机的热效率就越高,但输出功率和吸热负荷变化幅度很小。在不增加设备成本和不会对影响设备正常运行的情况下,可以适当提高高压过热蒸汽和再热蒸汽的温度。

Steady-State Operation Characteristics of 100 MW Class Steam Turbine System

doi: 10.16516/j.gedi.issn2095-8676.2022.03.013

- Received Date: 2022-05-31

- Accepted Date: 2022-07-13

- Rev Recd Date: 2022-07-13

- Available Online: 2022-09-26

- Publish Date: 2022-09-25

-

Key words:

- IGCC /

- bottom circulation /

- steam turbine /

- variable condition /

- thermal efficiency

Abstract:

| Citation: | JIANG Lin, YANG Haoran, GUO Ziyan, LIU Shuang, ZHANG Jieyu, HUANG Zhanping, ZHOU Xing. Steady-State Operation Characteristics of 100 MW Class Steam Turbine System[J]. SOUTHERN ENERGY CONSTRUCTION, 2022, 9(3): 111-118. doi: 10.16516/j.gedi.issn2095-8676.2022.03.013 |

DownLoad:

DownLoad: