-

温室效应的紧迫性已成为全球协作控制碳排放的共同话题。为此,中国政府提出了“碳达峰、碳中和”战略规划[1]。“双碳”政策的提出大大增强了对新能源发电并网的需求,同时这将深化中国能源结构的改革。现有新能源(光伏、风电之类)存在间歇性的特点,对电网有冲击,因此提高机组的灵活性运行能力是一种必然的选择。燃煤机组的灵活性改造分为机组灵活性和燃料多样性[2]。机组灵活性要求系统各组件的调节深度和响应速度。燃料多样性要求煤质的差异性和掺烧生物质等易燃固体燃料。

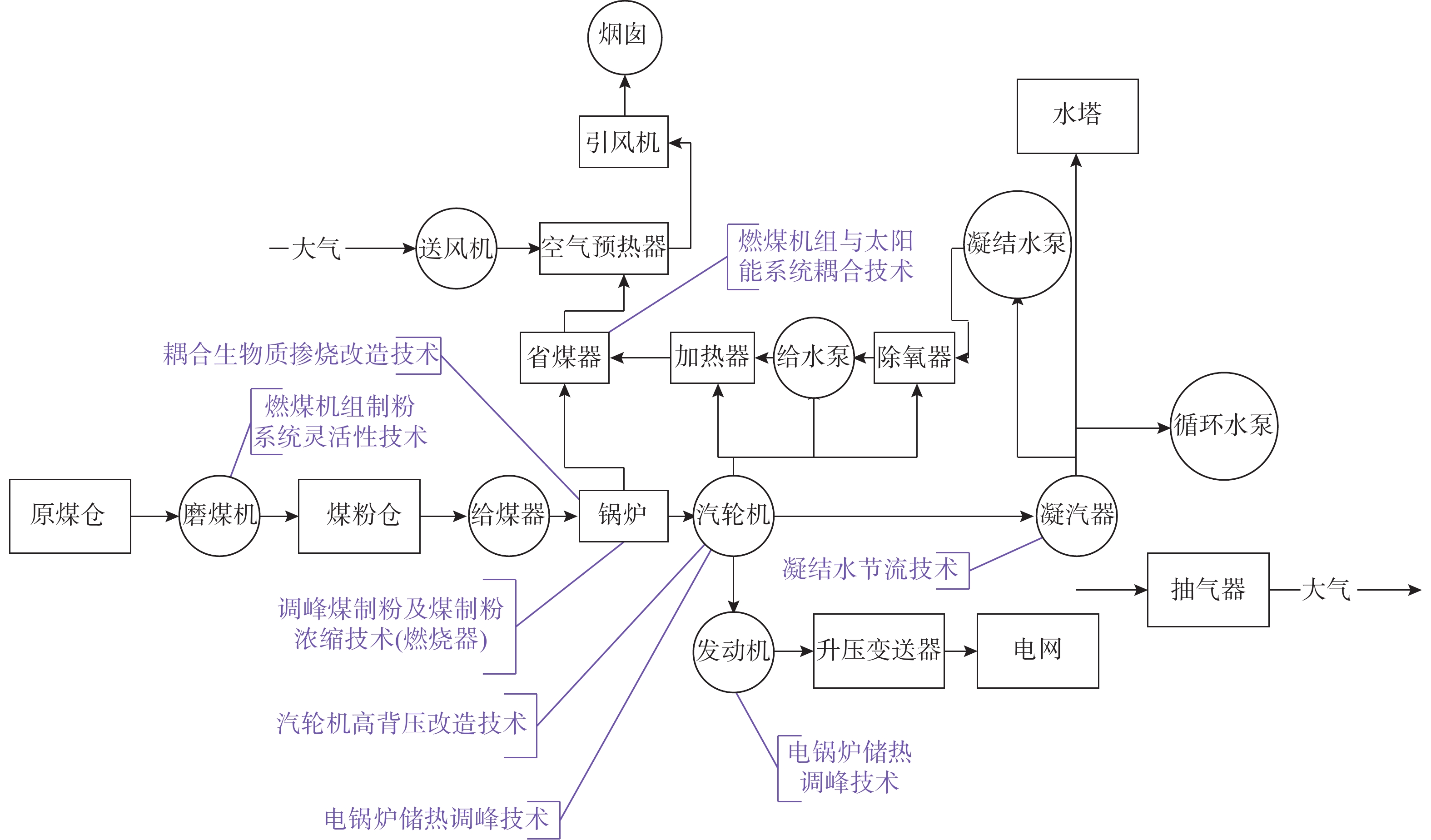

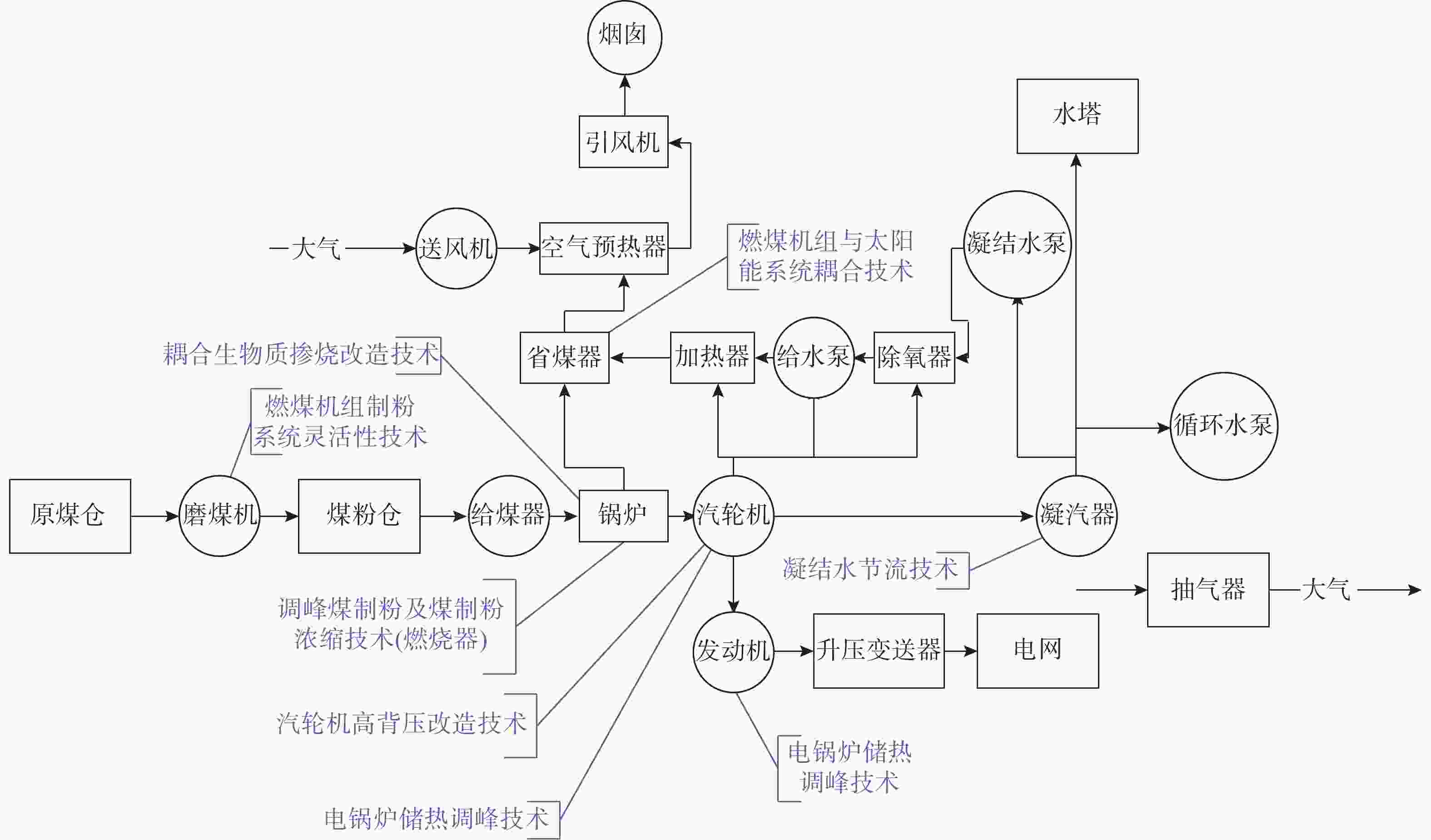

燃煤机组的灵活性改造技术包括:凝结水节流技术[3]、燃煤机组制粉系统灵活性改造技术[4]、风电-抽凝机组耦合系统[5]、汽轮机高背压改造调节技术[6]等。钟祎勍等[3]对凝结水节流技术进行了研究尝试,该技术通过降低节流损失实现了提效目标,同时挖掘了除氧器及低加部分的储能潜力,进而增强机组的调频能力。增设调峰煤制粉以及煤粉浓缩等技术,证实了燃煤机组制粉系统灵活性改造的必要性。在灵活性改造中,通过降低主蒸汽调节阀节流损失、充分利用除氧器及低压加热系统中部分储能、增设调峰煤制粉以及煤粉浓缩等方法来解决我国燃煤机组能耗高、灵活调节能力不足等问题。李建强等[4]对600 MW燃煤机组制粉系统和配风方式进行优化,得出在优化后工况的净单位发电量明显提升,通过降低制粉能耗,在保证稳燃的同时有效提高了锅炉效率。张翼等[5]以350 MW抽凝机组为研究对象,利用Ebsilon软件构件抽凝机组仿真模型对消纳风电容量、主蒸汽消耗量和热负荷扩大比例等参数进行计算,得出增设蓄热电锅炉和电热泵与储热罐耦合后,消纳风电能力得到明显提高。储能方式的“削峰填谷”、用电侧的“灵活负荷”对提高热电联产系统消纳风电有显著的效果。

Cheng等[7]以300 MW亚临界热电联产机组高背压供热特性进行研究,机组背压由5~14 kPa提升至34~54 kPa后,机组最大供热能力提高了80 MW,达到460 MW,实现了扩大热电比,提高机组负荷灵活性调节的目的。在后续的灵活性改造中,为了更大程度地增强机组灵活性,提高机组背压是一项可以考虑的切入点。戈志华等[6]建立300 MW等级高背压供热机组热力系统模型,分析抽汽参数变化对低压加热器附加单耗的影响,优化后机组的发电功率增加507 kW,提高了低压缸的通流效率,有效提高热源的供热能力。

综上所述,多种灵活性改造技术已经成为当下燃煤火电机组结构优化的重要方向。本文将结合燃煤发电机组灵活改造技术分类、灵活性改造的评价参数、燃煤发电机组的发展方向及相关建议等3个方面进行系统性地介绍和讨论,明确灵活性改造技术的特点和评价参数,为后续的实际相关灵活性改造提供参考。

-

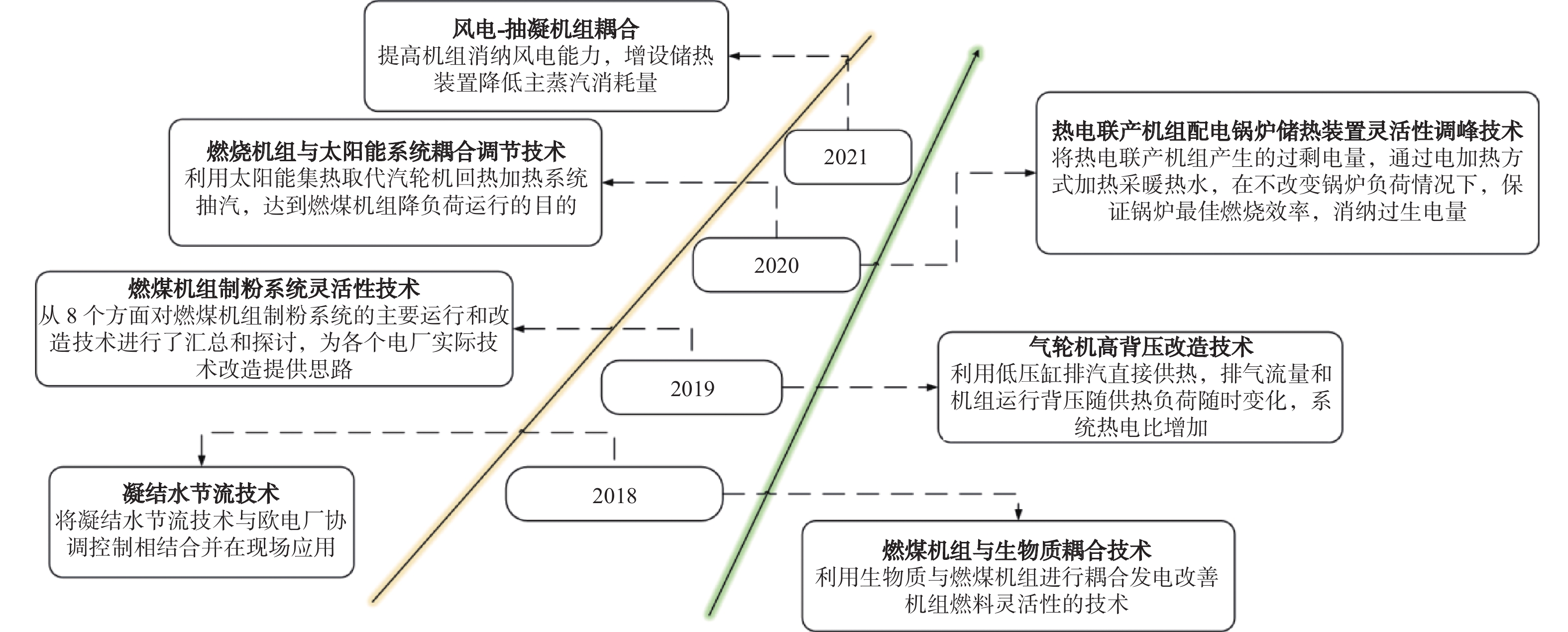

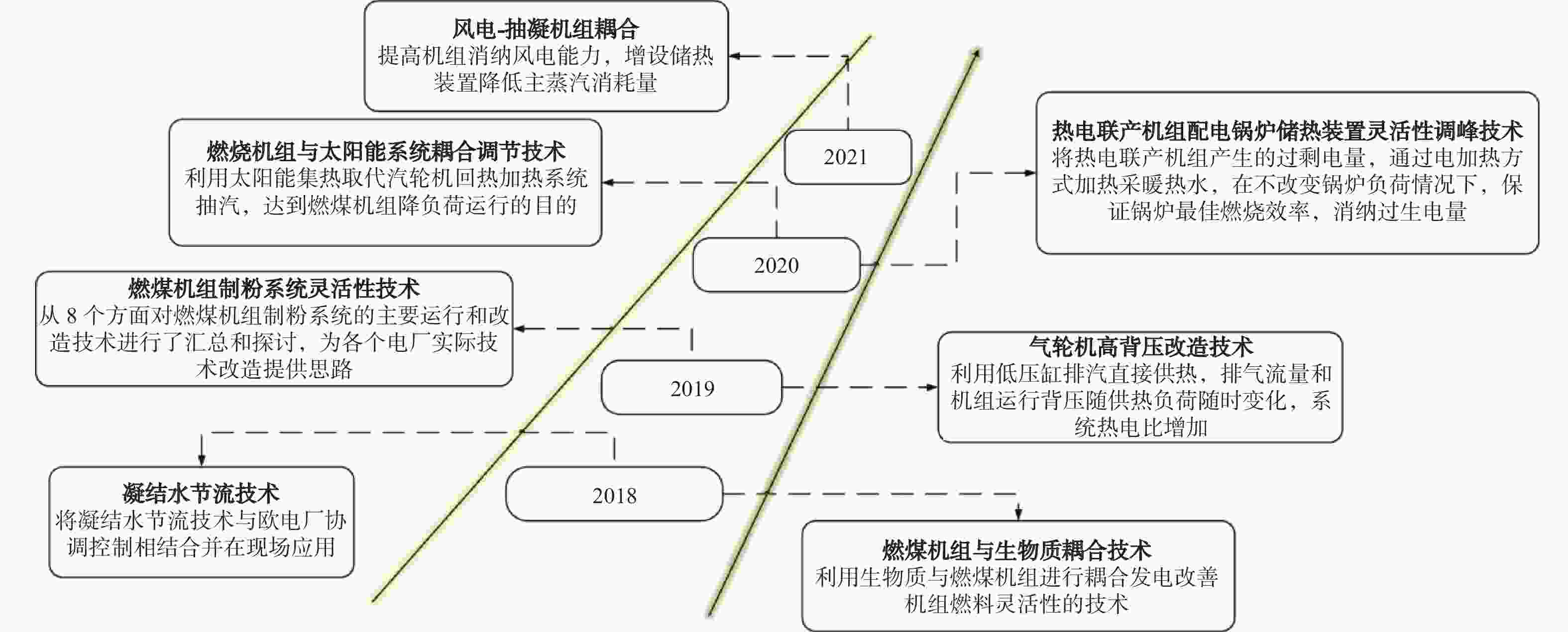

在国家政策推动和调峰激励机制[8]引导下,燃煤发电机组灵活性改造技术越来越丰富,除上述提到的技术外,还包括以下技术:燃煤锅炉耦合生物质混烧改造技术和冷凝法烟气回收技术[9]、燃煤机组与太阳能系统耦合调节技术[6]、热电联产机组配电锅炉储热装置灵活性调峰技术[6]、风电-抽凝机组耦合系统等。部分灵活性改造技术如图1所示。

上述燃煤机组的灵活性改造技术已取得了一定的成效。王一坤等[10]以某330 MW机组配套20 MW生物质气化耦合发电项目为研究对象,发现生物质的良好着火特性可以降低机组不投油最低稳燃负荷,提高机组灵活性。於震跃[11-12]发现槽式太阳能替代汽轮机三级高压抽汽的耦合方案可将300 MW燃煤机煤耗由287.53 g/(kWh)降低到254.29 g/(kWh);陈天佑等[13-14]发现,添加储热水装置也可提高燃煤机组调峰容量,调峰容量约提高2.5倍;郭丰慧等[15]发现,增设储热式电锅炉能够取得较好的风电消纳效果,可将风电消纳率由原来的98.72%增加到99.12%,并且相比于设置普通电锅炉的消纳弃风方案具有更好的灵活性。

-

现有的评价参数主要包括:发电机组自身用电率[16]、供电效率[17]、机组调峰能力[3]、CO2排放因子[18]、锅炉热效率[19]、机组发电标准煤耗率[20]等。其中主要的评价参数如表1所示。

评价参数 计算公式 机组功率/MW 参考文献 公式中各个参数的物理意义 评价参数变化 供电效率 $\eta =\dfrac{ {P}_{{\rm{e}}} }{ {BQ}_{{\rm{net}},{\rm{ar}}} }$ 600 [17] Pe为机组发电功率;B为燃煤消耗量;Qnet,ar为燃料的收到基低位发热量 当供热系统增加了背压

式汽轮发电机时,供电

效率提高了1.10%。$ {\mathrm{C}\mathrm{O}}_{2} $排放因子 ${EF}_{ { {\rm{CO} } }_{2.{\rm{y} } } }=\\\dfrac{\gamma \times {\rm{OR}}\times H\times {{\rm{Mol}}}_{ { {\rm{co} } }_{2} }/{{\rm{Mol}}}_{ {\rm{c} } } }{ {\eta }_{ {\rm{y} } } }$ 600/300 [21] γ为煤的含碳量;OR为煤的氧化率;H为电的低热值;${ {\rm{Mol} } }_{ { {\rm{co} } }_{2} } $为CO2的摩尔质量;Molc为碳的摩尔质量;ηy为发电机组热效率 当运行操作发生深度循

环变化时,CO2排放因子

参数增加了11.3%。锅炉热效率 ${\eta }_{{\rm{g}}}$=100−(${q_2}+{q_3}+{q_4}$+${q_5}$+${q_6}$+qoth−qex) 300 [22] q2为排烟热损失,q3为可燃气体不完全燃烧热损失,q4为固体不完全燃烧损失,q5为锅炉散热损失,q6为灰渣物理热损失;qoth为其他热损失;qex为外来热量与燃料低位发热量的百分比 当燃煤机组中生物质气

掺烧量为10000~50000 m3/h时,锅炉热效率

下降了0.2%~1.39%。机组发电

标准煤耗率${b}_{{\rm{g}}}=HR/(29.308\times \dfrac{ {\eta_{{\rm{bo}}} } }{100}$×$\dfrac{ {\eta _{{\rm{pi}}} } }{100}$) 660 [20] HR为汽轮机设计热耗率;ηbo为锅炉燃料效率;ηpi为管道效率 在旁路烟气比为25%工

况下,当能级平衡节点温度由70℃变化到130℃时,机

组发电标准煤耗率参数

降低了2.24 g/kWh。Table 1. Main evaluation parameters of existing units for flexibility modification

发电机组自身用电率、供电效率、机组调峰能力是从电量方面进行机组灵活性评价的。许啸[16]发现在供热系统中增加背压式汽轮发电机组可以实现供热蒸汽能量的梯级利用,同时降低厂用电率;李沁伦[17]发现采用集成抽汽式空气加热器(SAH)型烟气余热利用系统可以使整个系统的供电效率提高1.10%。钟祎勍等[3]发现将凝结水节流技术用于燃煤发电机组调峰,可以将机组平均调节性能综合指标提高约10%,煤耗降低约0.93 g/(kWh),显著提高了机组的调峰能力和经济性。

CO2排放因子从排放出的污染物方面进行评价。Yu等[18]在对600 MW和300 MW两个典型煤电机组进行深度循环操作和常规操作的结果中发现:深度循环运行和满负荷运行时相比,CO2排放因子增加11.3%,由于深度和频繁的循环而导致更多的污染物排放,另外灵活性操作还将产生额外的成本。

锅炉热效率和机组发电标准煤耗率是从温度以及热经济性等方面进行的评价。王一坤[19]发现当燃煤机组中生物质气掺烧量为104~5×104 m3/h时,锅炉热效率下降0.2%~1.39%;陈珣等[20-21]对燃煤发电机组展开了烟气余热梯级利用系统的研究,结果发现,在旁路烟气比例25%的相同工况下,将排烟温度由130 ℃降低到70 ℃时,标煤耗可降低2.24 g/(kWh);郭璞维等[22]研究发现低温省煤器与暖风器联合运行可以使得排烟温度从122~160 ℃降到100 ℃,实现更好的节煤及降低㶲损失。

-

在众多燃煤发电机组灵活性改造技术之中,较为典型的是:凝结水节流技术、燃煤机组耦合生物质混烧改造技术、燃煤机组制粉系统灵活性技术、汽轮机高背压改造技术、燃煤机组与太阳能系统耦合调节技术、热电联产机组配电锅炉储热装置灵活性调峰技术、风电-抽凝机组耦合系统7种技术。

它们的原理、特征及应用对象各不相同。凝结水节流技术具有很高的安全性。燃煤机组耦合生物质混烧是利用生物质气的良好着火特性,降低燃煤机组最低稳燃负荷,提高机组适应燃料的灵活性。汽轮机高背压改造技术重点在于提高了系统的热电比。热电联产机组配电锅炉储热装置,利用在机组低负荷运行时将电量转化为热能进行储存,减少热电联产机组进网电量。

储能是将产生的不同形式的能量通过不同的方式储存起来,便于后续利用的技术。虽然目前可再生能源利用占比逐渐增加,但由于气候等自然因素影响,利用太阳能、风能等可再生能源调节燃煤机组负荷灵活性的技术比较少。耦合可再生能源进行燃煤机组的调节仍是值得深入研究的内容。目前,主要采用电网调度优化或从电厂侧进行调节来减少燃煤机组发电比例,实现机组运行负荷的灵活性调节。近年来,人类社会能源需求增加,风电等可再生能源发电自身的波动性和间歇性增加了灵活调节的必要性[23]。与此同时,扩大新能源电力的消纳能力也是提高经济竞争力的重要途径[24]。储能技术还可以通过调峰起到削风填谷的作用,消纳可再生能源,吸收过剩的电力,减少“弃风弃光”现象,推动能源低碳转型。储能技术是可通过装置或物理介质将能量储存起来以便以后需要时利用的技术,它的出现有利于实现供电侧的灵活性改造。通过提高新能源消纳能力,挖掘火电机组调峰潜力,进而提升中国火电运行灵活性。现阶段,风电具有间歇性、随机性和与电负荷相反的峰谷特性,导致风电高峰期调峰困难,弃风现象严重,因而设计新能源多形式的嵌入以及多储热的协同调控具有重要的意义。

图2梳理了近年来火电厂燃煤发电机组灵活性改造发展路径。

-

在“双碳”背景下,燃煤火电机组的灵活性改造是适应新能源电力安全嵌入的保障。本文综述了现有的各种火电机组灵活性改造技术,主要包括:凝结水节流技术、燃煤机组耦合生物质混烧改造技术、燃煤机组制粉系统灵活性技术、汽轮机高背压改造技术、燃煤机组与太阳能系统耦合调节技术、热电联产机组配电锅炉储热装置灵活性调峰技术、风电—抽凝机组耦合系统等。在此基础上,从发电机组自身用电率、供电效率、机组调峰能力、污染物排放量、CO2排放因子、锅炉热效率、机组发电标准煤耗率、工质最大温度偏差和平均标准煤耗率差值等评价参数对上述技术进行了对比。最后,提出燃煤机组的发展方向,原有机组的结构改进、新能源多形式的嵌入以及多储热的协同调控设计将是后续发展的主要方向。

Research Progress on Flexibility Modification of Coal-Fired Generating Units

doi: 10.16516/j.gedi.issn2095-8676.2023.02.007

- Received Date: 2022-02-14

- Rev Recd Date: 2022-04-21

- Available Online: 2023-03-13

- Publish Date: 2023-03-25

-

Key words:

- coal-fired units /

- flexibility modification /

- technology classification /

- evaluation parameter /

- technical prospect

Abstract:

| Citation: | ZHANG Shaoqiang, SUN Chenyang, YU Luohang, FAN Xiaomei, PAN Dujuan, WEI Shuzhou, ZHOU Xing. Research Progress on Flexibility Modification of Coal-Fired Generating Units[J]. SOUTHERN ENERGY CONSTRUCTION, 2023, 10(2): 48-54. doi: 10.16516/j.gedi.issn2095-8676.2023.02.007 |

DownLoad:

DownLoad: