-

从“十五”规划开始,我国利用天然气战略发生了较大调整,“十五”规划纲要确定:加快天然气勘察、开发和利用、统筹生产基地、输送管线和用气工程建设引用国外天然气、提高天然气消费比重。随着我国天然气产业的持续发展和资源环境约束的日益加剧,我国气电逐步发展壮大,至2019年底,我国气电装机容量已突破90 GW。预计到2025年“十四五”末会突破150 GW[1]。这是因为天然气联合循环(NGCC)电厂的排放量约为最先进的燃煤电厂的一半,但即使所有的煤炭消耗都被天然气取代,这一削减也仍将不足以达到我国的减排目标[2]。

碳捕集与封存利用(CCUS)已被国际能源机构(IEA)确定为一项可用于实现减排目标的关键技术(IEA,2010年),是实现能源低碳化应用的唯一途径[3-4]。目前,国内尚未有燃气电厂CCUS项目示范,模拟和仿真成为研究气电CCUS集成挑战的最有用工具。

-

在这项工作中,主要设想有:(1)使用经过验证的、大小合理的工程实物模型,对一个集成的NGCC、CO2捕集和压缩装置(PCC)的综合工厂进行评估;(2)通过按系统流程的方法建造工厂产生的投资和运行成本估算,对其综合工厂进行经济分析。NGCC工厂输入设计数据,即机组设计数据参如表1所示,机组主要技术指标如表2所示,排烟参数如表3所示。

项目 数据 环境温度/℃ 28.2 大气压力/kPa(a) 100.4 相对湿度/% 85 电网频率/Hz 50 燃气轮机负荷/% 100 燃料类型 天然气 燃料耗量/(t·h−1) 81.65 燃料入口温度/℃ 25 燃料低位热值,LHV 20℃/(MJ·Nm−3) 36.28 燃气轮机排气温度/℃ 638 燃气轮机排气流量/(t·h−1) 3 428 NOx排放量,在15%O2时/(mg·Nm−3) ≤50 燃气轮机输出功率/MW 453.754 烟囱排烟温度/℃ 86 主蒸汽压力/MPa(a) 16.64 主蒸汽温度/℃ 600 主蒸汽流量/(t·h−1) 473.8 再热蒸汽压力(进口/出口)/MPa(a) 3.408/3.759 再热蒸汽温度(进口/出口)/℃ 600/375 再热蒸汽流量(进口/出口)/(t·h−1) 497.5/457.2 低压蒸汽压力/MPa(a) 0.331 低压蒸汽温度/℃ 264 低压蒸汽流量/(t·h−1) 67.48 凝汽器蒸汽流量/(t·h−1) 580.6 凝汽器压力/kPa(a) 8.8 蒸汽轮机轴端输出功率/MW 228.687 Table 1. Design data of unit

项目 数据 单台机组总发电功率/MW 682.441 机组的年发电利用小时数/h 3 500 单台机组的小时耗气量/(104 Nm3·h−1) 11.14 单台机组的年耗气量/(108 Nm3·h−1) 4.45 计算毛发电气耗率/[Nm3·(kWh)−1] 0.163 单台机组年毛发电量/(108 kWh) 27.3 毛发电热耗/[kJ·(kWh)−1] 5 919 毛发电效率/% 60.82 注:1)保证工况:环境条件为28.2 ℃、100.4 kPa(a)、85%相对湿度; 2)参考机型暂按Ansaldo GT36机型。 Table 2. Technical indexes of unit (single unit)

序号 项目 数据 1 烟囱排烟温度/℃ 86 2 烟气量/(Nm3·h−1) 2 714 286 烟气量/ (m3·h−1) 3 552 853 3 烟气成分(Vol%) O2/% 10.92 N2/% 72.62 CO2/% 4.452 SO2/% 0 H2O/% 11.14 Table 3. Flue exhaust parameters

-

NGCC电厂机岛主要系统有:进气系统、排气系统、天然气系统、油系统、盘车系统、发电机本体及氢油水系统、汽机轴封系统及本体疏水系统等。Ansaldo GT36有别于其他机型设有OTC系统,该系统利用锅炉侧的水冷压气机抽出来的空气,冷却后的空气进入透平叶片,产生的高压蒸汽进入汽水侧做功。该系统实现了能量的梯级利用,进一步提高了联合循环机组的出力及效率。NGCC电厂由安萨尔多Ansaldo GT36燃气轮机和一个带再热的三压级蒸汽循环组成,并带OTC系统。模型对象的输入和设计数据如表1所示。该模型对象结合燃气轮机性能和设计系统能达到的性能参数如表2所示。

-

建立以MEA溶液为基础溶剂的PCC装置模型[5]。

胺化学吸收法碳捕集过程是一个典型的化学过程,可利用化工模拟软件Aspen-Plus进行模拟分析[6],这个模型是由双膜理论支撑的,该理论描述了组分在极小厚度的气膜和液膜上的扩散,并在膜之间的界面上存在相平衡。化学反应也被考虑,并假定在液膜中发生。

根据理论分析,有机乙醇胺溶液MEA与CO2反应生成比较稳定的氨基甲酸盐,在再生过程中需要较多的能量才能分解,导致再生能耗较大[7-8]。同时氨基甲酸盐对设备的腐蚀性较强,又易形成水垢。MEA与CO2的反应式如下:

$$ {\rm{CO}}_{2}+{\rm{HO}}({\rm{CH}}_{2})_{2}{\rm{NH}}_{2}={\rm{HO}}({\rm{CH}}_{2})_{2}{\rm{HNCOO}}^-+{\rm{H}}^+$$ (1) $$ {\rm{HO}}({\rm{CH}}_{2})_{2}{\rm{HNCOO}}^- + {\rm{H}}_{2}{\rm{O}} = {\rm{HO}}({\rm{CH}}_{2})_{2}{\rm{NH}}_{2} + {\rm{HCO}}_{3}^-$$ (2) $$ {\rm{H}}^++{\rm{HO}}({\rm{CH}}_{2})_{2}{\rm{NH}}_{2}={\rm{HOCH}}_{2}{\rm{CH}}_{2}{\rm{NH}}_{3}^+ $$ (3) 因为MEA与CO2反应生成比较稳定的氨基甲酸盐,反应(2)比反应(1)要快得多,反应式可以写为:

$$ \begin{split} {\rm{CO}}_{2}+2{\rm{HO}}({\rm{CH}}_{2})_{2}{\rm{NH}}_{2}+{\rm{H}}_{2}{\rm{O}}=&{\rm{HO}}({\rm{CH}}_{2})_{2}{\rm{HNCOO}}^-+\\&{\rm{HO}}({\rm{CH}}_{2})_{2}{\rm{NH}}_{3}^+ \end{split} $$ (4) 由式(4)可知,MEA吸收CO2的最大容量为0.5(CO2与胺摩尔比)[9]。

电解质相互作用如水解离、碳酸氢盐解离和MEA水解也在液膜中起作用。

PCC装置工艺设计参数、计算模型对象参数和主要设备参数如表4所示。

项目 参数 数据 吸收塔 烟气量/(kg·h−1) 3 678 120 入塔烟气CO2含量(Vol)/% 4.452 出塔烟气CO2含量(Vol)/% 0.445 2 吸收塔个数/个 2 操作温度/℃ 40 操作压力/atm 1 填料/波纹填料 Mellapak 250Y 吸收液-30%MEA溶液/(t·h−1) 4 504 单个塔径/m 18.30 填料层高/m 18 压降/[mmH2O·(m填料)−1] 20 湿润率/[m3·(m·h)−1] 0.043 6 入塔MEA液CO2含量/(molCO2·molMEA−1) 0.233 出塔MEA液CO2含量/(molCO2·molMEA−1) 0.485 捕集效率等级(wt)/% 90 解析塔 解析塔个数/个 1 操作温度/℃ 120 操作压力/atm 1 填料/波纹填料 Mellapak 250Y 蒸汽量/(kg·h−1) 344 360 塔径/m 9.4 填料层高/m 12 压降/(mmH2O·m填料−1) 18 再生所需能量/(kJ·h−1) 8.368×108 解析率/% 81.0 Table 4. Design and operation parameters of PCC plant

-

压缩系统由离心式压缩机、后冷却器和洗涤器组成。CO2压缩装置的尺寸和建模,以适当地考虑压缩捕集的CO2所需的能量需求。参考日本KEPCO/MHI应用程序(IPCC,2005)规定,最终压缩阶段排放压力为110 bar,其中CO2为超临界或致密相,用于高效管道输送。纯CO2在96 bar的压力下变为超临界,并且在所有温度下都保持超临界状态(IPCC,2005)[10],然而更高的110 bar的压力允许存在杂质。在模型中加入分子筛以去除水分,确保最终CO2浓度为99.5%。随着越来越多的CO2被储存在地下,随着储层压力的增加,泵能够将CO2压力提高到175 bar[11]。压缩装置设计和运行数据如表5所示。

项目名称 参数 压缩机的型式 离心式 数量 3 进口压力/MPa(g) 0.03 出口压力/MPa(g) 8~11 单机进气量/(Nm3·h−1) 26 745 进气温度/℃ 40 排气温度/℃ 40~125 压缩机效率范围/% 78~83 后冷器出口温度/℃ 40 压缩机转速/(r·min-1) 6 000 总功率/kW 13 693 Table 5. Design and operation parameters of compression plant

-

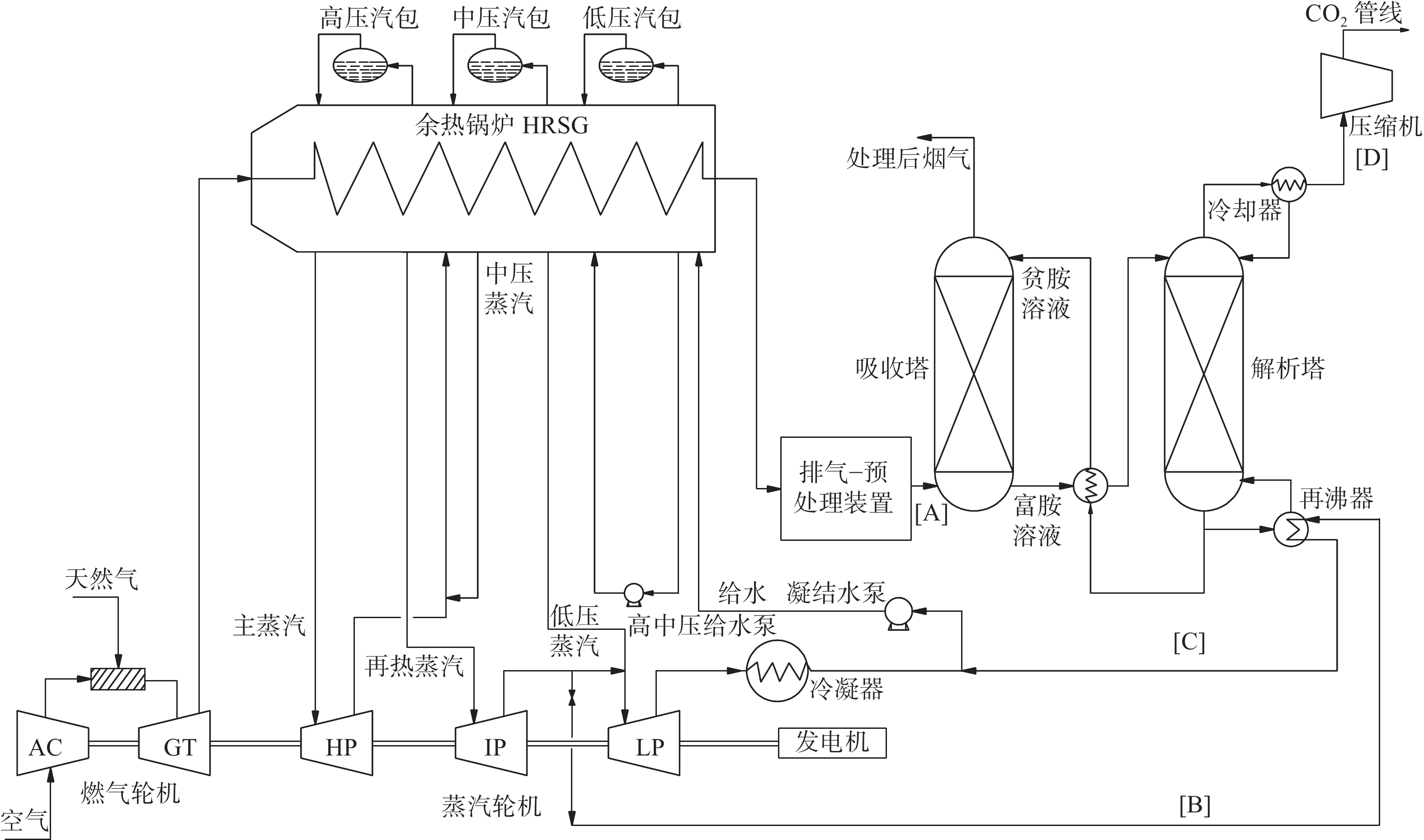

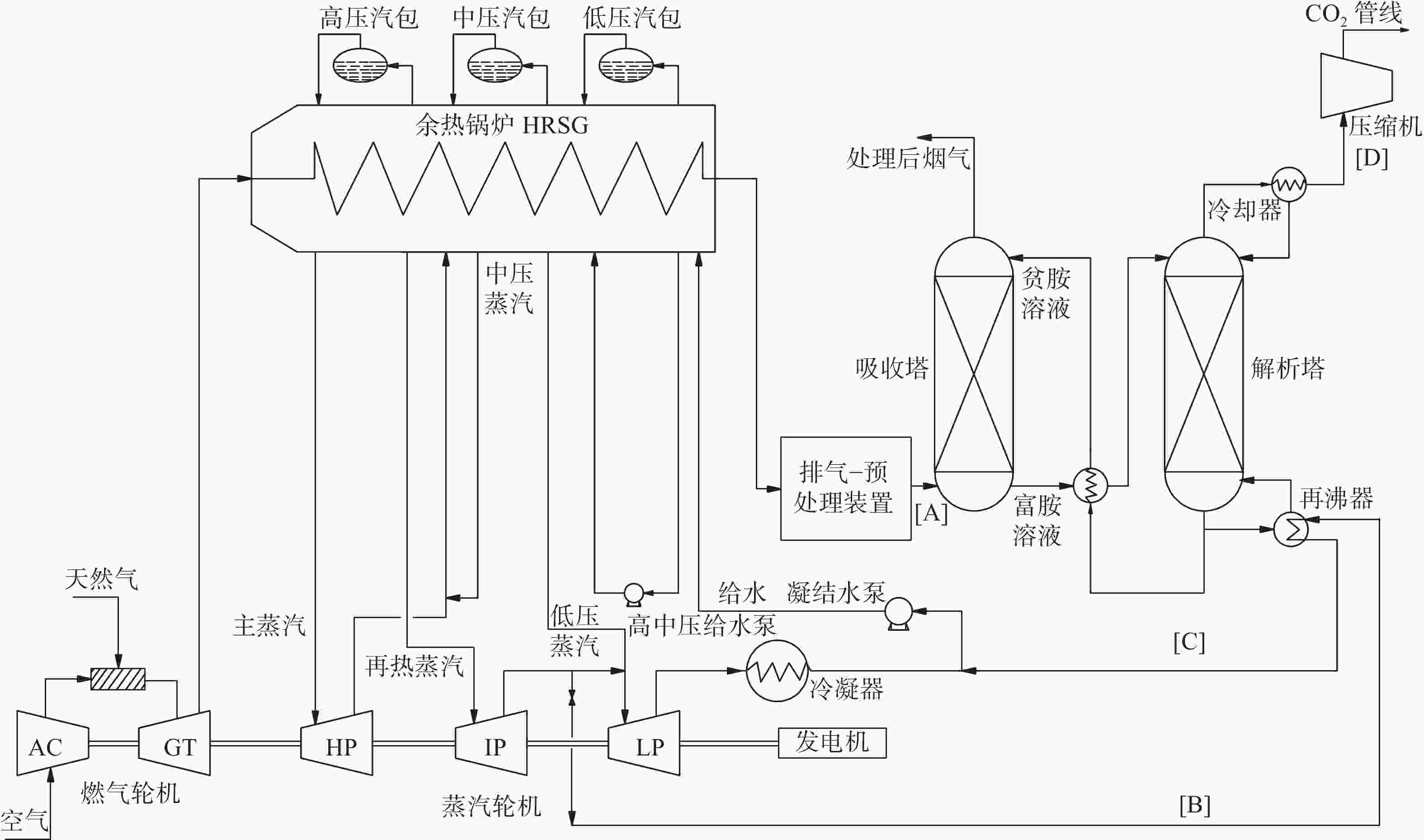

考虑主要有4项流程集成点(图1)。

1) 进入PCC装置的废气。

2) 从NGCC装置抽取到PCC装置再沸器的蒸汽。

3) 从再沸器返回到NGCC装置的冷凝液。

4) 从再生器捕集的CO2进入CO2压缩装置。

废气在进入PCC吸收器之前进行预处理。通过脱硫除尘装置去除SOx气体,通过静电沉淀装置去除NOx气体。利用缓释剂和抗氧化剂来限制MEA的溶剂降解。然后,采用直接接触冷却器(DCC)将气体冷却到40 ℃左右,以便在吸收器中获得有利的吸收条件,并将水从气体中冷凝出来。

蒸汽通过节流阀从中压涡轮和低压涡轮的交叉处获得,从而限制压力损失,然后用于PCC工厂的溶剂再生。再沸器的冷凝液回送到NGCC装置的冷凝器。选择蒸汽压力3.5 bar,温度160 ℃,选择这个参数是假设1个合理的压降和蒸汽凝结在3 bar、饱和温度134 ℃,在这个温度下,在再沸器中可以保持1个适当的最小尺寸,其中溶剂温度被限制在最大120~125 ℃,以避免热降解。1个减温器是用来控制蒸汽抽出的温度,喷射冷凝水,以确保温度保持刚刚超过饱和。在本研究中,我们假设低压涡轮能够处理大流量变化,而效率下降可以忽略不计[12-13]。

CO2在解析器1.0 bar的压力下被捕集,并被送到压缩装置,在那里它被压缩到超临界状态。超临界二氧化碳被送到附近的含盐含水层进行隔离。因此,从朗肯循环中提取的蒸汽,以及气体鼓风机、溶剂泵和二氧化碳压缩机的功率需求,都构成了NGCC电厂额外的负荷。综合的一体化装置的工艺流程和性能如图1和表6所示。

项目 NGCC NGCC+PCC 电厂净出力/MW 682.441 572.916 CO2捕集和压缩PCC的功率损耗/% - 16.05 厂用电率/% 1.95 7.5 总冷却水需水量/(t·h−1) 27 650 41 618 冷却水增加/% - 50.52 燃气轮机净出力/MW 453.754 453.754 排气流量/(kg·h−1) 3 678 120 3 678 120 废气CO2含量/V% 4.452 4.452 排气出口温度/℃ 86 125 蒸汽生成/(kg·s−1) 161.28 165.62 抽汽流量/(kg·s−1) - 111.322 吸收器数量 - 2 吸收器L/G比 - 1.42 总溶剂循环速率/(kg·s−1) - 1 251 蒸汽/CO2/(kJ·kg−1) - 3 916 额外的PCC工厂/MW - 16.15 压缩装置进气率/(kg·s−1) - 59.34 压缩功率需求/MW - 13.69 小时CO2捕集量/(kg·h−1) - 213 628 年CO2捕集量/(t·a−1) - 748 000 蒸汽耗量/CO2捕集量(t·t−1) - 1.876 电耗量/CO2捕集量/(kW·t−1) - 148.48 净比排放量/[kgCO2·(MWh)−1] 385.76 44.92 Table 6. Performance comparison

-

假设1个位于广东省的某燃气工厂的成本,是使用来自中国国内的材料成本和工资率来评估的。间接工程费用,包括工程费用和业主费用,使用工资率和建筑设备租金率。我们做了以下假设:

本研究仅针对CO2的捕集环节,不考虑后续运输、利用或者封存的技术经济性。所有的电力需求,包括设备电机和控制过程元件的电力需求,都是在工厂中产生的,即来自厂用电。循环冷却水来自附近的水体,成本是抽水和冷却塔运行[14-15]。

针对独立的NGCC工厂、NGCC+PCC集成工厂场景,关键评估成本指标[16],如表7所示,表中列举了需要的成本投入项目及数值。

项目 数值 天然气价格/(元·Nm−3) 2.53 MEA价格/(元·t−1) 16 000 电/[元·(MWh)−1] 549.5 蒸汽/(元·t−1) 200 工业水/(元·t−1) 3.15 NGCC测算上网电价/[元·(MWh)−1] 621.5 碳排放交易收益/(元·tCO2−1) 58 机组利用小时/h 3 500 项目经济寿命/a 30 Table 7. Cost input in economic analysis

静态投资成本,不包括建设利息。

电力均等化成本(LCOE),是电厂在整个生命周期内发电的单位成本,包括运行和维护成本。CO2静态成本,计算为[17]:

$$ \begin{split} &\qquad { {\rm{CO}}_2的成本 }=\\&\dfrac{[\mathrm{LCOE}] \;{\rm{with}}\; {\rm{CCS}} - [\mathrm{LCOE}] \;{\rm{without}}\;{\rm{CCS}} }{\left[\mathrm{CO}_2 / \mathrm{MW}\right] \;{\rm{without}}\; \mathrm{CCS} - \left[\mathrm{CO}_2 / \mathrm{MW}\right] \;{\rm{with}} \; \mathrm{CCS}} \end{split} $$ (5) -

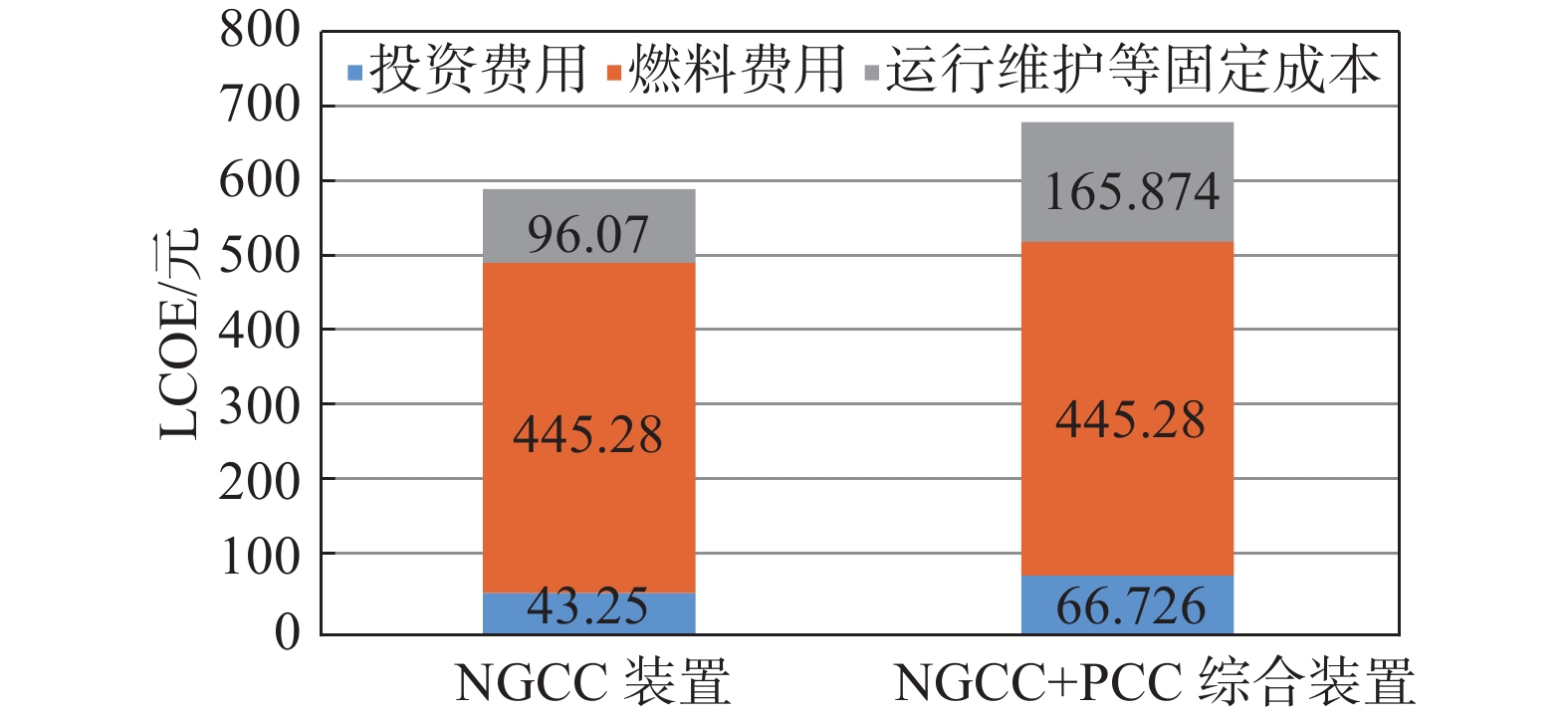

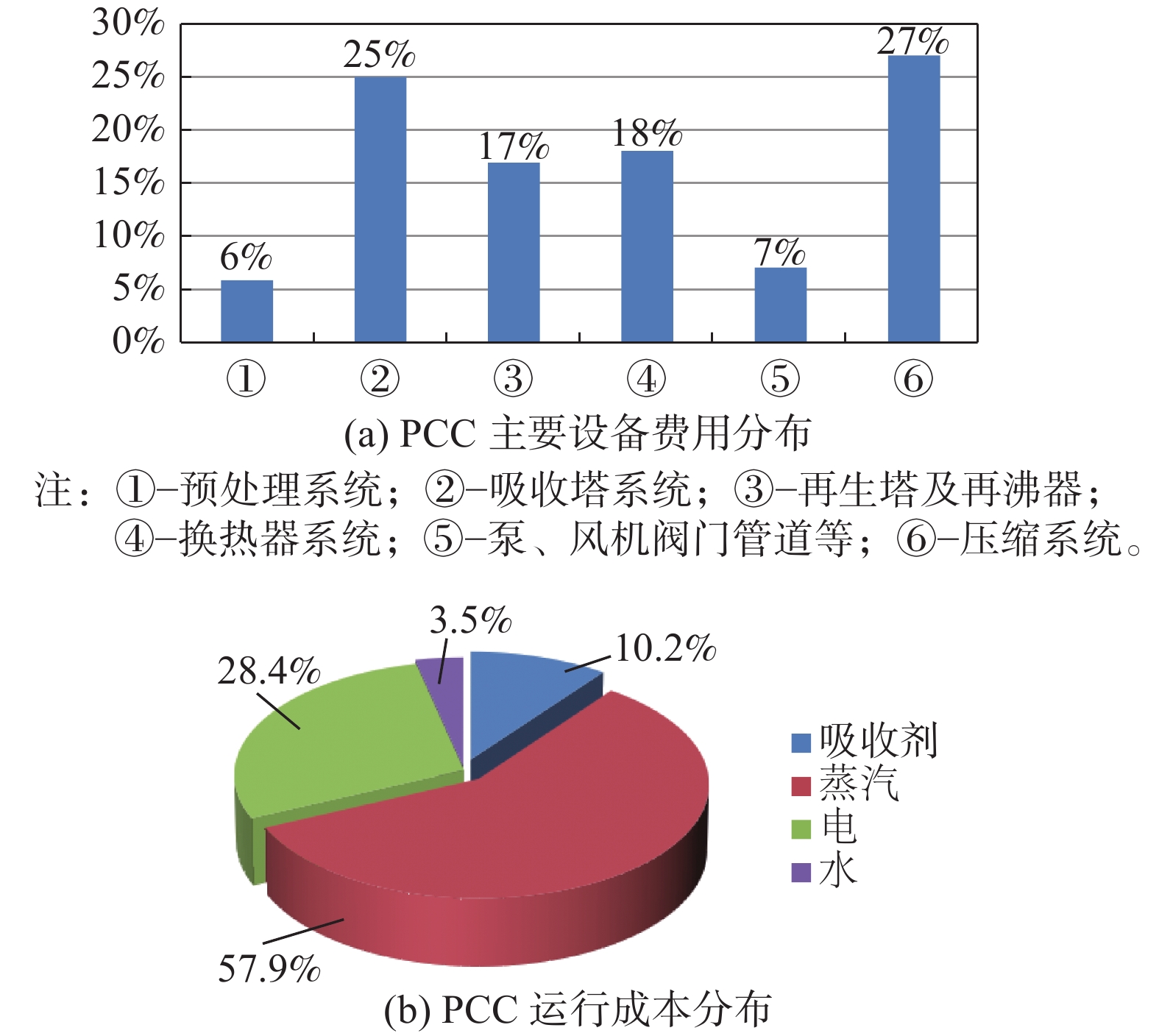

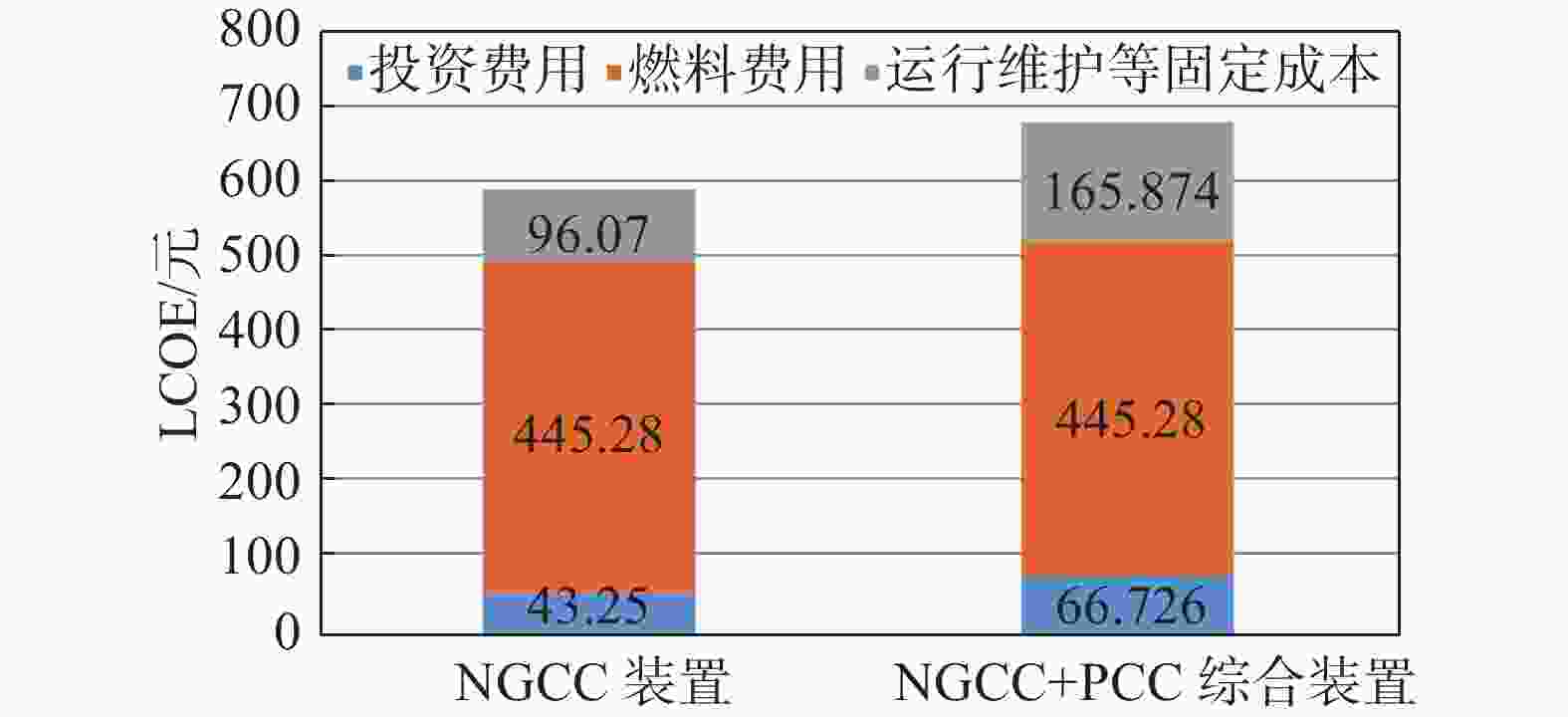

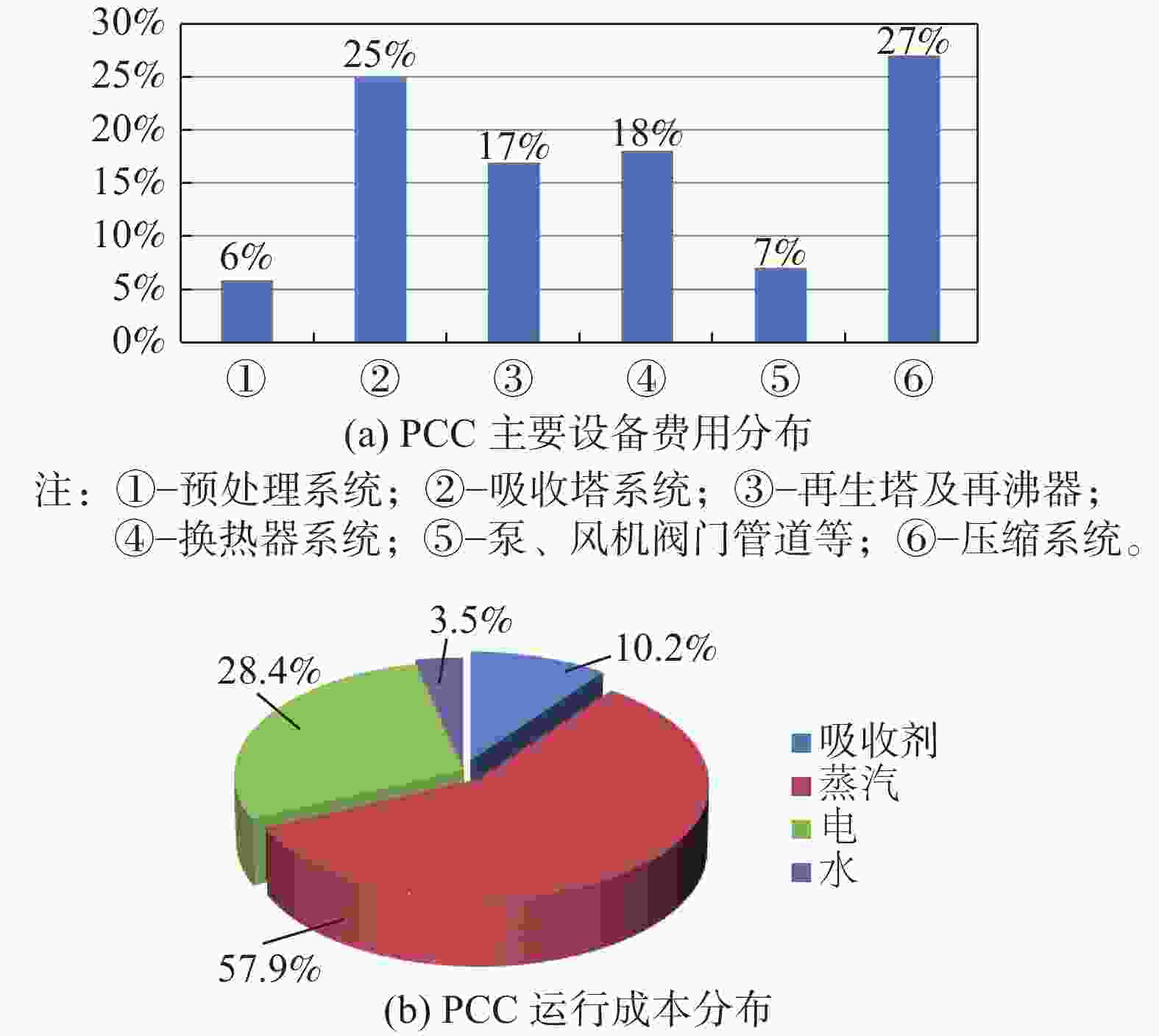

如表8所示,可以看出,与NGCC电厂2 220 元/kW的原始成本相比,NGCC+PCC一体化综合工厂的静态投资成本增加了54.28%。这表明投资成本的显著增加,必须降低投资[18-20],以鼓励NGCC电厂使用CCUS。综合工厂的LCOE比NGCC工厂的LCOE高15.96%。事实上,图2及图3显示[21],最大的LCOE仍然是天然气成本,将PCC工厂和压缩装置集成到NGCC工厂并不会改变LCOE上天然气价格的重要性。由于燃料价格风险受市场影响,不可避免,当燃料价格上涨时,会对项目的收益率造成较大影响。

项目 NGCC NGCC+PCC 静态投资成本/(元·kW−1) 2 220 3 425 静态投资成本增加/% - 54.28 CO2捕集静态投资/(元·CO2−1) - 1 100 CO2捕集运营成本/(元·CO2−1) - 298 LCOE/[元·(MWh)−1] 584.6 677.88 LCOE增加/% - 15.96 CO2扣减收益后运营成本/(元·tCO2−1) - 240 Table 8. Economic performance

据估算,集成工厂静态的CO2捕集与压缩营运成本为扣减碳交易收益后每捕集1 tCO2 240元。然而,如果考虑到CO2的运输和储存成本,这个值将会更大。

-

通过使用Ansaldo公司GT36机型的燃气轮机库的数据以及PCC电厂模型对象,对600 MW等级NGCC电厂、PCC和CO2压缩装置的模拟设计,得知NGCC+PCC综合工厂设计CO2捕集率为90%的水平,使得机组净功率输出下降16.05%,厂用电率增加5.55%,而冷却水需求上升50.52%。

对位于广东省的某燃气电厂进行经济分析时,NGCC+PCC综合工厂静态投资的成本比NGCC电厂高54.28%。另一方面,LCOE预计在综合工厂中增加15.96%,在所有情况下,天然气价格成本是LCOE的最大驱动因素。最后,对综合工厂而言,静态的CO2成本为240元/tCO2。根据目前国内外投运的示范工程,通过不断的技术迭代和改进,预计PCC系统投资和运营成本对比现有模型对象设计会进一步降低。

Economic Evaluation of Post-Combustion CO2 Capture Integration Technology in Natural Gas Combined Cycle Power Plant

doi: 10.16516/j.gedi.issn2095-8676.2023.02.008

- Received Date: 2022-07-07

- Rev Recd Date: 2022-11-08

- Available Online: 2023-03-13

- Publish Date: 2023-03-25

-

Key words:

- natural gas combined cycle (NGCC) /

- post-combustion capture /

- simulation /

- cost analysis /

- carbon capture

Abstract:

| Citation: | ZHANG Zhizhong, CHEN Jiping, TAN Xueqian, YE Daiqi, ZOU Jingcheng. Economic Evaluation of Post-Combustion CO2 Capture Integration Technology in Natural Gas Combined Cycle Power Plant[J]. SOUTHERN ENERGY CONSTRUCTION, 2023, 10(2): 55-61. doi: 10.16516/j.gedi.issn2095-8676.2023.02.008 |

DownLoad:

DownLoad: