-

新时代对电网技术的发展提出了新的要求[1-2]。未来随着国家“一带一路”倡议的推动,越来越多的中国企业会参与到国际输电线路工程建设业务中[3-4],海外不同国家和地区要求采用的铁塔结构设计标准不尽相同[5-6]。在“一带一路”沿线国家中,多数国家在进行输电线路铁塔结构设计时采用欧洲标准[7]。在准确理解中国标准与欧洲标准不同的基础上进行铁塔设计可以有效规避由于国内外工程设计规范不同引起的设计质量问题[8-10]。对格构式角钢铁塔来说,受压杆件破坏形式通常为屈曲失稳破坏[11-13],而杆件的稳定承载力大小又取决于杆件长细比取值,故本文采用中国标准与欧洲标准对比的方式,分析计算了中国标准《架空输电线路杆塔结构设计技术规程》(DL/T 5486—2020)[14] (取代DL/T 5154—2012[15],以下简称中国标准)及欧洲标准EN—50341—2012[16] (以下简称欧洲标准)在铁塔交叉斜材长细比计算方法中的差别。主材及单斜材的长细比取值[17-19],可参考相关文献进行计算。

-

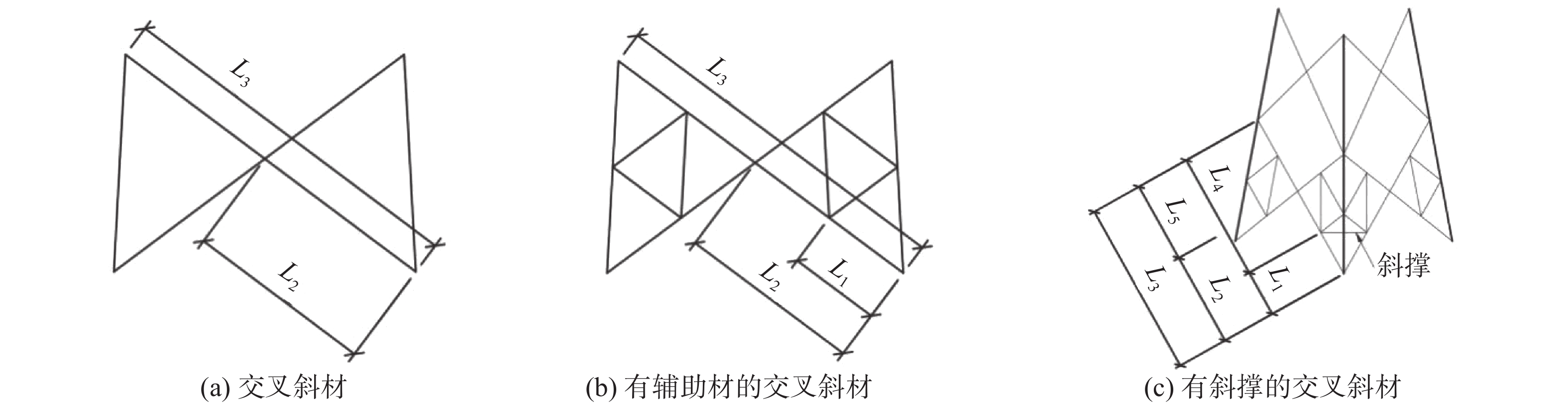

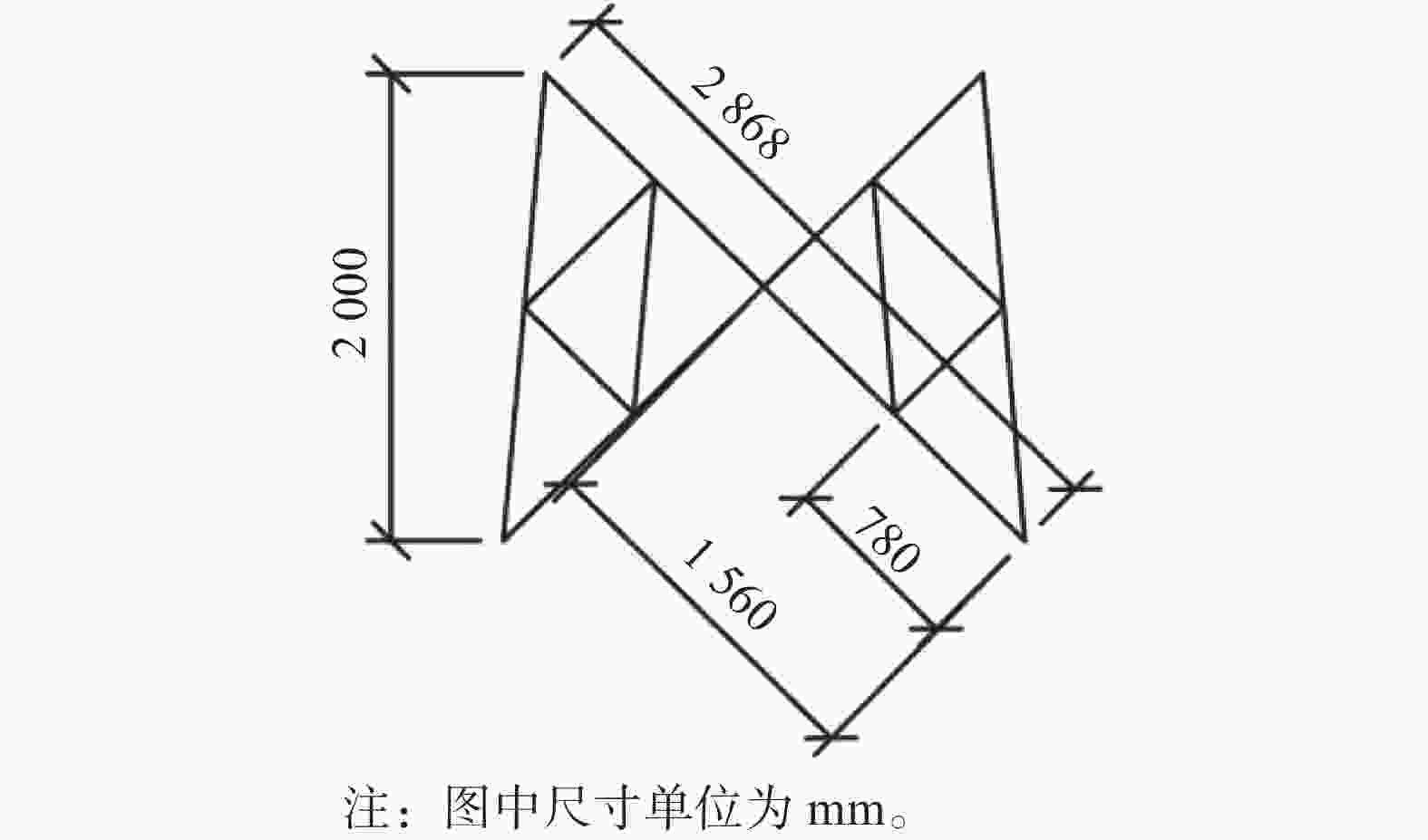

在计算交叉斜材长细比时,对斜材的不同布置型式,中国标准和欧洲标准计算方法差异较大。现以图1所示典型铁塔交叉斜材布置型式为例,比较中国标准和欧标标准杆件长细比计算方法。

-

交叉斜材布置型式如图1(a)所示时,根据中国标准中表6.1.8-2的规定,交叉斜材的长细比计算方法如下:

1)当两根斜材为一拉一压且拉杆内力大于或等于20%压杆内力时:

$$ \lambda =\dfrac{{L}_{2}}{{r}_{y0}}$$ (1) 式中:

$ \lambda $ ——构件长细比;${L}_{2}$ ——杆件计算长度,如图1(a)所示;${r}_{y0}$ ——杆件最小轴方向回转半径。2)当两根斜材为一拉一压且拉杆内力小于20%压杆内力或两根斜材同时受压时:

$$ \lambda=\dfrac{KL_{3}}{{r_{x}}}$$ (2) 式中:

${L}_{3}$ ——杆件计算长度(m),如图1(a)所示;$r_x$ ——杆件平行轴方向回转半径(m);K——交叉斜材计算长度修正系数,按下式计算 确定:

两根斜材一拉一压时:

$$ K = \sqrt {({{L}_{2}}/{{L}_{3}}) \cdot ({\rm{1 - 3}}{{N_0}}/4N)} \geqslant {0.5} $$ (3) 两根斜材同时受压时:

$$ K=\sqrt{0.5(1+N_0/N)}$$ (4) 式中:

N ——所计算杆的内力(kN),取绝对值;

${N}_{0}$ ——相交另一杆的内力(kN),取绝对值,两根斜材同时受压时,取N0≤N。 -

当交叉斜材采用与1.1.1节同样的布置型式,如图1(a)所示,根据欧洲标准规定,交叉斜材的长细比计算方法如下:

1)当两根斜材为一拉一压且拉杆内力大于2/3压杆内力时:

应计算L2长度沿最小轴方向的长细比,即:

$$ \lambda=\dfrac{{L_2}}{{r_{y0}}} $$ (5) 2)当两根斜材为一拉一压且拉杆内力不大于2/3压杆内力或两根斜材同时受压时:

首先应使用式(5)计算L2长度沿最小轴方向的长细比。

当两杆同时受压时,还应验算两杆的受压稳定承载力之和大于或等于两杆所受内力的代数和。计算稳定承载力时,计算长度取L3,回转半径取平行轴。长细比可取值为:

$$ \lambda=\dfrac{{L}_{3}}{{r}_{x}}$$ (6) -

1)中国标准和欧洲标准确定杆件计算长度方法不同。中国标准分类方式为两根斜材为一拉一压且拉杆内力大于或等于20%压杆内力与两根斜材为一拉一压且拉杆内力小于20%压杆内力或两根斜材同时受压,计算长度与拉杆内力与压杆内力的相对大小关系有关。

欧洲标准为当两根斜材为一拉一压且拉杆内力大于2/3压杆内力时,可仅计算L2长度沿最小轴的长细比;否则还需验算两杆受压稳定承载力。

2)当斜材同压时,中国标准采用交叉斜材计算长度修正系数K的方法来修正两根斜材的共同作用对受压构件稳定承载力的影响;欧洲标准采用验算两杆的受压稳定承载力之和不小于两杆内力代数和的方法来保证构件的稳定承载力满足要求。

-

有辅助材的交叉斜材布置型式如图1(b)所示时,根据中国标准中表6.1.8-2的规定,交叉斜材的长细比计算方法如下:

1)当两根斜材为一拉一压且拉杆内力大于或等于20%压杆内力时:

$$ \lambda=\dfrac{1.1{L_2}}{{r}_{x}}$$ (7) 2)当两根斜材为一拉一压且拉杆内力小于20%压杆内力或两根斜材同时受压时:

$$ \lambda=\dfrac{KL_{3}}{{r}_{x}}$$ (8) -

1)交叉斜材之间无斜撑连接情况:

当有辅助材的交叉斜材采用与1.2.1节中同样的布置型式,如图1(b)所示时,根据欧洲标准规定,当拉、压力相同时,首先应计算L1长度沿最小轴方向的长细比,即:

$$ \lambda=\dfrac{{L_1}}{{r}_{y0}}$$ (9) 式中:

L1——杆件计算长度,如图1(b)所示。

还需计算L2长度沿平行轴方向的长细比,即:

$$ \lambda=\dfrac{{L_2}}{{r}_{x}} $$ (10) 当两根斜材拉力与压力不同或同时受压时,需进一步验算两杆的受压稳定承载力之和不小于两杆内力的代数和。计算稳定承载力时,沿平行轴方向计算长度取L3。长细比可取值为:

$$ \lambda=\dfrac{{L_3}}{{r}_{x}} $$ (11) 2)交叉斜材之间有斜撑连接情况:

如图1(c)所示,在交叉斜材正侧面加设斜向支撑,根据欧洲标准规定,此交叉斜材系统应分别验算以下5种情况:

1)计算L1长度沿最小轴的长细比,即:

$$ \lambda=\dfrac{{L_1}}{{r}_{y0}}$$ (12) 2)计算L5长度沿平行轴的长细比,即:

$$ \lambda=\dfrac{{L_5}}{{r}_{x}}$$ (13) 式中:

L5——杆件计算长度,如图1(c)所示。

3)由于有斜撑的连接,还需验算L4长度内两杆的受压稳定承载力之和大于或等于两杆所受荷载的代数和。计算稳定承载力时,计算长度取L4,回转半径取平行轴。长细比可取值为:

$$ \lambda=\dfrac{{L_4}}{{r}_{x}}$$ (14) 式中:

L4——杆件计算长度,如图1(c)所示。

4)验算由斜撑连接的两杆(在相邻的正侧面中)的受压稳定承载力之和大于或等于两杆所受荷载的代数和。计算稳定承载力时,计算长度取L2,回转半径取平行轴。长细比可取值为:

$$ \lambda=\dfrac{{L_2}}{{r}_{x}}$$ (15) 5)验算交叉斜材中四根杆件(在相邻的正侧面中)的受压稳定承载力之和大于或等于四杆内力的代数和。计算稳定承载力时,计算长度取L3,回转半径取平行轴。长细比可取值为:

$$ \lambda=\dfrac{{L_3}}{{r}_{x}}$$ (16) -

除1.1.3节中所列中国标准与欧洲标准计算长细比的主要区别外,还应注意:

1)欧洲标准中,考虑了斜撑对交叉斜材稳定计算的影响。在斜撑与斜材交点处,由于斜撑的存在,该节点可提供平面内及平面外约束,因此,验算两杆的受压稳定承载力之和大于或等于两杆所受荷载的代数和时,计算长度由没有斜撑时的L3变为有斜撑时的L4。由于布置了斜撑,由斜撑连接的两杆之间的相互作用有所增强,需验算两杆之间以及由斜撑连接的交叉斜材四根杆件的稳定承载力。在中国标准表6.1.8-2中,未明确列出有斜撑连接的布置型式和有斜撑连接时交叉斜材长细比的计算方法。

2)欧洲标准中,需考虑L1长度沿最小轴的长细比;对有辅助材的交叉斜材,中国标准未考虑此计算长度。这是因为中国国内铁塔一般采用等肢角钢,其rx/ryo≤2,当辅助材布置在L2段的中点时,L1段沿最小轴的长细比小于L2段沿平行轴的长细比,对杆件长细比一般不起控制作用。国外部分铁塔采用不等肢角钢,对不等肢角钢构件,L1段最小轴长细比可能会控制整个杆件的长细比,因此需严格验算。

3)当两根斜材一拉一压时,中国标准L2计算长度取1.1的增大系数,即L0=1.1 L2;欧洲标准并没有考虑此项影响,其计算长度仍为L2。这是由于中国标准计算条件为拉杆内力不小于20%压杆内力,欧洲标准为拉杆内力不小于66.7%压杆内力;中国标准中拉杆可能不能为压杆提供有效约束,因此乘以1.1的增大系数。

-

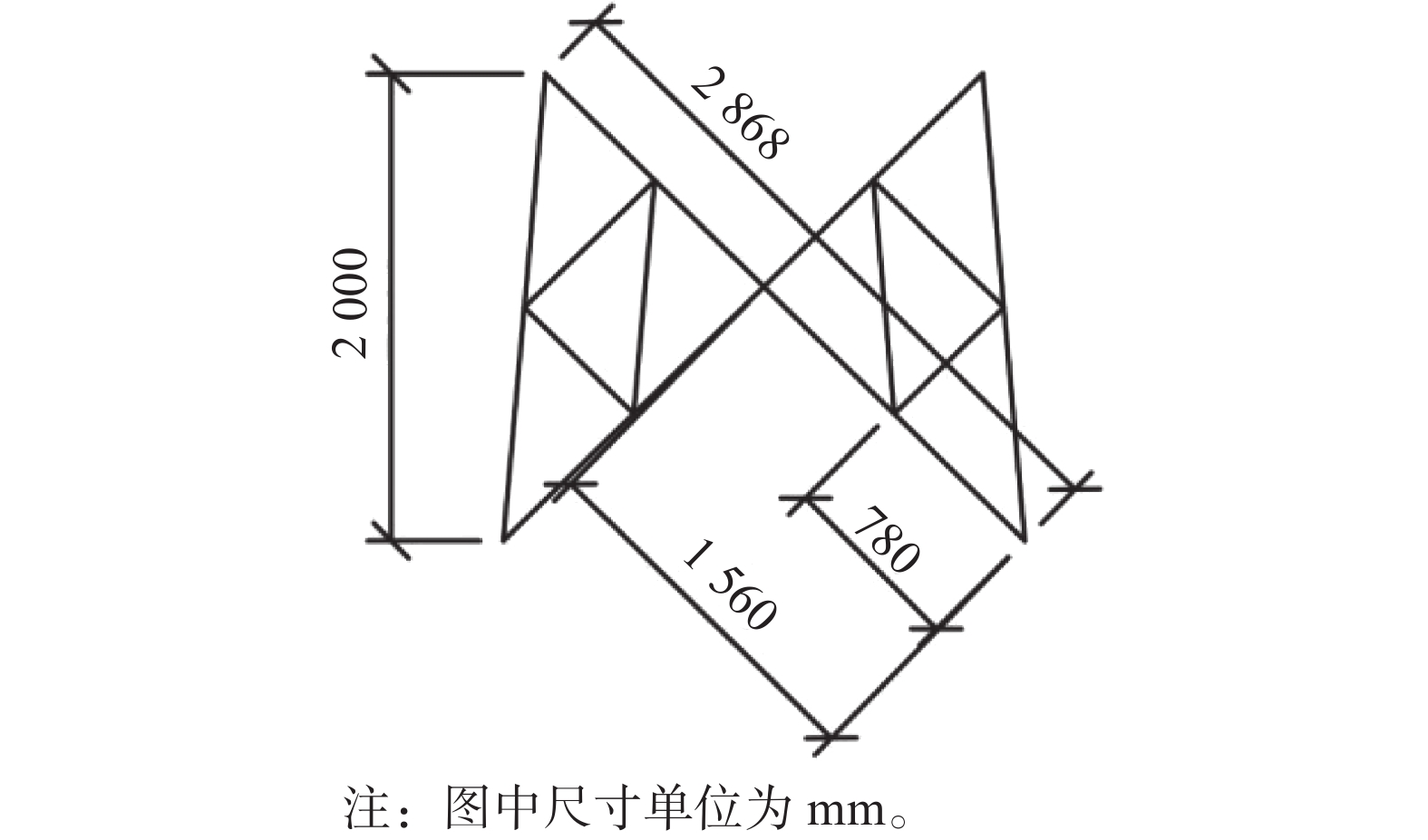

本文以工程中常见的有辅助材的交叉斜材布置型式为例,对比了中国标准和欧洲标准长细比计算的不同。铁塔斜材布置型式及杆件尺寸如图2所示,L1=780 mm,L2=1 560 mm,L3=2 868 mm,钢材强度为Q235,计算斜材长细比及杆件规格。

-

假设交叉材同时受压力作用,内力大小为:

N=−30 kN,

$N_0$ =−30 kN(符号命名规则为:拉力为正,压力为负),计算如下:1)欧洲标准

经试算,取杆件截面为L56×3(虽然在输电线路铁塔构件中较少采用该规格角钢,为了说明因中国标准和欧洲标准长细比计算结果的差异导致构件选材的不同,本文采用该规格角钢进行计算比较)。同压时,杆件控制长细比为:

$$ \lambda = \dfrac{{{L_2}}}{{{{r}_{x}}}} = \dfrac{{{156}}}{{{1.75}}}={89.14} $$ 根据欧标受压杆件稳定承载力计算方法,可得杆件稳定承载力为53.3 kN。

因为两根斜材同时受压,还需验算两根杆件的受压稳定承载力之和是否大于或等于两杆所受荷载的代数和。此时:

$$\lambda =\dfrac{{L_3}}{{r}_{x}}=\dfrac{286.8}{1.75}=163.89 $$ 按照欧标计算方法,杆件稳定承载力为26.0 kN。此时,不满足两杆的受压稳定承载力之和大于或等于两杆所受荷载的代数和,需要加大截面。

调整杆件规格为L56×4:

$$ \lambda =\dfrac{{L_3}}{{r}_{x}}=\dfrac{286.8}{1.73}=165.78 $$ 在此长细比下,根据欧标受压杆件稳定承载力计算方法,得杆件稳定承载力为34.4 kN。两根杆件稳定承载力之和大于所受力代数和,满足要求。

2)中国标准

当N=−30 kN,

$N_0$ =−30 kN时:$$ K=\sqrt{0.5(1+{N_0}/N)}=1 $$ 计算长度为:

$$ {L_0}=K{L_3}=2\;868\;{\rm{mm}} $$ 取杆件截面为L56×4:

$$ \lambda=\dfrac{KL_3}{{r}_{x}}=\dfrac{286.8}{1.73}=165.78 $$ 根据国标受压杆件稳定承载力计算方法,得杆件稳定承载力为31.47 kN。

从以上两种标准的计算结果来看,虽然计算方法不同,但杆件控制长细比相同,且该规格该长细比下国标稳定承载力略小于欧标稳定承载力。

-

铁塔斜材布置型式及杆件尺寸与2.1节设计条件相同,当内力大小分别为:N=−30 kN,

$N_0$ =−15 kN,计算过程如下所示:1)欧洲标准

经试算,取杆件截面为L56×3,此时杆件控制长细比为:

$$ \lambda=\dfrac{{L_2}}{{r}_{x}}=\dfrac{156}{1.75}=89.14 $$ 根据欧标受压杆件稳定承载力计算方法,可得杆件稳定承载力为53.3 kN。

因为两根斜材同时受压,还需验算两杆的受压稳定承载力之和大于或等于两杆所受荷载的代数和。此时:

$$ \lambda=\dfrac{{L}_{3}}{{r}_{x}}=\dfrac{286.8}{1.75}=163.89 $$ 在此长细比下,根据欧标受压杆件稳定承载力计算方法,得杆件稳定承载力为26.0 kN。取杆件截面为L56×3,满足要求。

2)中国标准

当N=−30 kN,

$N_0$ =−15 kN时:$$ K=\sqrt{0.5(1+{N_0}/N)=0.866} $$ 计算长度为:

$$ {L_0}={KL_3}=2\;484{\rm{mm}} $$ 取杆件截面为L56×3:

$$ \lambda=\dfrac{KL_3}{r_{x}}=\dfrac{248.4}{1.75}=141.94 $$ 在此长细比下,根据中国标准受压杆件稳定承载力计算方法,得杆件稳定承载力为25.81 kN<30 kN,不满足要求。

取杆件截面为L56×4:

$$ \lambda=\dfrac{KL_3}{{r}_{x}}=\dfrac{248.4}{1.73}=143.58 $$ 在此长细比下,根据中国标准受压杆件稳定承载力计算方法,得杆件稳定承载力为33.42 kN > 30 kN,满足要求。

对比同压时在不同内力条件下的欧标计算结果可以发现,当N=−30 kN,

${N}_{\text{0}}$ =−30 kN时,是由L3段对应的长细比控制整个杆件的稳定承载力,即由L2段对应的长细比计算出的杆件规格并不满足两杆的受压稳定承载力之和大于等于两杆所受荷载的代数和的要求;当N=−30 kN,${N}_{\text{0}}$ =−15 kN时,由于两杆所受荷载变小,是由L2段对应的长细比控制整个杆件的稳定承载力的,因此,后者的选材较小。当两杆同压且两杆内力大小不同时,欧洲标准、中国标准的计算结果差异较大。欧洲标准计算结果中,当杆件规格为L56×3时,虽然L3长度对应的杆件受压稳定承载力为26 kN,从单根杆件来看,小于压力较大杆件所受内力30 kN,但欧洲标准认为两根杆件的受压稳定承载力之和大于或等于两杆所受荷载的代数和,两根交叉斜材组成的系统即满足受压稳定承载力要求,因此该规格角钢满足要求。中国标准需验算交叉斜材两根杆件各自的受压稳定承载力。

从选材结果来看,按欧标计算杆件截面取L56×3满足承载力要求,按国标计算需取L56×4才能满足。可见在 两杆同压且压力不等的情况下,欧标稳定承载力大于国标稳定承载力。

-

铁塔斜材布置型式及杆件尺寸与2.1节设计条件相同,当内力大小为:N=−30 kN,

$N_0$ =30 kN(一拉一压),计算过程如下所示:1)欧洲标准

取杆件截面为L56×3,此时杆件控制长细比为:

$$ \lambda=\dfrac{{L_2}}{{r}_{x}}=\dfrac{156}{1.75}=89.14 $$ 根据欧标受压杆件稳定承载力计算方法,可得杆件稳定承载力为53.3 kN,满足要求。

2)中国标准

经试算,取杆件截面为L56×3,此时杆件控制长细比为:

$$ \lambda=\dfrac{1.1L_2}{{r}_{x}}=\dfrac{171.6}{1.75}=98.06 $$ 在此长细比下,根据中国标准受压杆件稳定承载力计算方法,得杆件稳定承载力为38.26 kN > 30 kN,满足要求。

从以上两种标准的计算结果来看,中国标准L2计算长度取1.1的增大系数,即L0=1.1L2;欧洲标准并没有考虑此项影响,其计算长度仍为L2,因此中国标准长细比计算结果为欧洲标准的1.1倍,且国标稳定承载力小于欧标稳定承载力。

-

以上3种情况国标、欧标承载力计算结果如表1所示:

工况 国标承载力 欧标承载力 两杆同压且压力相等 31.47 kN 34.4 kN 两杆同压且压力不等 L56×4 L56×3 两杆一拉一压 38.26 kN 53.3 kN 注:两杆同压且压力不等时按国标、欧标计算选材不同。 Table 1. Comparison of calculated buckling strength obtained according to Chinese standard and European standard

从表1可以看出,在图2所示铁塔斜材布置型式及杆件尺寸下,以上3种情况时国标稳定承载力计算结果均小于欧标稳定承载力计算结果。

-

1) 在计算交叉斜材同压时,中国标准采用交叉斜材计算长度修正系数K来修正两根斜材的共同作用对受压构件稳定承载力的影响;欧洲标准采用验算两杆的受压稳定承载力之和大于或等于两杆所受荷载代数和的方法来保证构件的稳定承载力满足结构要求。

2) 对于有辅助材的交叉斜材布置型式,当两根斜材一拉一压时,中国标准L2计算长度取1.1的增大系数,即L0=1.1 L2;欧洲标准并没有考虑此项影响,其计算长度仍为L2。这是由于中国标准计算条件为拉杆内力不小于20%压杆内力,欧洲标准为拉杆内力不小于66.7%压杆内力;中国标准中拉杆可能不能为压杆提供有效约束,因此乘以1.1的增大系数。

3) 欧洲标准中,对于有辅助材的交叉斜材,考虑了斜撑对交叉斜材稳定性的影响。在斜撑与斜材交点处,斜撑可以提供平面内与平面外约束。因为布置了斜撑,由斜撑连接的两杆之间的相互作用有所增强,需验算两杆之间以及由斜撑连接的交叉斜材4根杆件的稳定承载力。在中国标准中,未对此作特殊说明。

4) 从计算实例可以看出,在有辅助材的交叉斜材布置型式时,两杆同压且压力相等、两杆同压且压力不等、两杆一拉一压这3种情况下国标稳定承载力计算结果均小于欧标稳定承载力。

Comparative Analysis of Slenderness Ratio Calculation Methods of Cross Bracings for Towers Between China and EU Overhead Transmission Line Standards

doi: 10.16516/j.gedi.issn2095-8676.2023.02.017

- Received Date: 2022-05-18

- Rev Recd Date: 2022-12-03

- Available Online: 2023-03-13

- Publish Date: 2023-03-25

-

Key words:

- overhead transmission line /

- angle steel member /

- cross bracings /

- slenderness ratio /

- buckling strength /

- China and EU standards /

- standard comparison

Abstract:

| Citation: | SUN Molin, ZHUANG Zhixiang, GUO Hongliang, HOU Wei. Comparative Analysis of Slenderness Ratio Calculation Methods of Cross Bracings for Towers Between China and EU Overhead Transmission Line Standards[J]. SOUTHERN ENERGY CONSTRUCTION, 2023, 10(2): 129-135. doi: 10.16516/j.gedi.issn2095-8676.2023.02.017 |

DownLoad:

DownLoad: