-

双碳“战略”下,构建以新能源为主体的新型电力系统已大势所趋,风电因技术成熟、潜力巨大呈现迅速发展的态势,在新能源领域占据主导地位[1-2]。然而,复杂的设备结构和恶劣的运行环境不仅加剧风机故障,给风机的检修维护带来诸多不便,更引发系统失稳、经济受损等现象。从长远考虑,风电的检修维护问题亟待解决[3-5]。

目前风机检修体系为“故障检修为主、状态检修和计划检修为辅”[6-7]。故障检修又称事后检修,是发生在设备故障后的被动检修。受限于检修资源的可及性、快速恢复运行的必要性,检修事项往往流于表面,仅适用于重要性低的机组[8]。状态检修以多源异质数据监测、故障诊断为基础,评估机组运行状态和剩余寿命。在实际应用中,受恶劣天气、监测设备性能、多部件层级式耦合的影响,机组状态特征提取困难,监测数据呈现波动剧烈、灵敏不足等特点,易引起故障定位错误、检修过剩等问题[9-10]。计划检修站在全生命周期视角,统筹考虑机组劣化过程和历史故障规律,提前规划检修事项,被认为是最经济、最可行的检修方式[11-12]。目前,计划检修的研究聚焦在检修策略的制定,苏青等[13]引入有效年龄的概念,充分考虑检修次数、检修程度对机组故障演化的影响,求解风机部件的顺序维修。逯红霞等[14]基于故障有向图理论,推演风机维护阈值函数,以最小化维护成本为目标优化检修周期。符杨等[15]同样以维护成本为优化目标,综合考虑天气、设备劣化对检修策略的影响。符杨等[16]借助Copula函数进行多部件联合风险评估,以此为纽带构建双层优化模型,探寻兼顾经济性和安全性的检修策略。IRAWAN C A等[17]考虑检修资源的可及性,构建风电场检修优化模型。王东[18]将风电机组建模为串联系统,利用马尔可夫链和威尔分布描述机组寿命进程,优化检修策略。

上述研究主要存在2个方面的问题:(1)现有研究局限于对风机内部故障演化规律的探讨,外界影响因子等对检修策略的综合影响还有待研究。作为经济调度的前提,风机的检修应在挖掘自身运行特性、气象因素的影响上,系统地实现与其他常规机组的检修协同;(2)检修维护过程忽视了低碳运行这一现实需求,对模型的优化目标考虑不充分。风机的检修引发常规机组出力增加、启停频繁等一系列现象,造成不必要的资源浪费,合理的检修计划应促使调度过程中各类资源实现多能互补。

鉴于此,本文计及多属性气象因子(降雨量、风速、雷电危险度)对检修容量的影响,基于连续隐马尔可夫(Continuous Hidden Markov Model,CHMM)理论构建风电场检修容量跟踪模型,预估契合运行环境的检修容量。并以此为决策依据,构建风水火联合低碳检修优化模型,在兼顾系统低碳性、经济性目标的同时,实现风电与水火电的协同检修优化。IEEE30节点系统算例表明,本文所提模型的降本效益与低碳特性显著,能为风水火的联合检修维护提供有效指导。

-

相较于水火电机组,风机的运行环境较为恶劣。大量调研表明[19-21],气象因素成为机组故障与检修的重要诱因,其中降雨量、风速、雷电危险度占据主导地位。本节以风电场为研究对象,以降雨量、风速、雷电危险度为多属性气象因子,引入CHMM理论,跟踪求解多属性气象因子波动下的风电场检修容量。

-

CHMM经马尔可夫发展而来,它以两个关联的马尔可夫随机过程表征隐状态序列(不可观测)与观测序列的联系[22-23]。其中,马尔科夫链描述隐状态的变化,随机过程则描述两序列映射关系的概率分布,观测序列的概率密度函数通常以高斯混合模型表示[24]。

风电场检修容量无法直接观测得到,但可以通过分析多属性气象因子(降雨量、风速、雷电危险度)的时变过程来间接获得,且多属性气象因子与检修容量之间存在复杂的统计关系。据此,本文将风电场检修容量跟踪问题映射为CHMM。隐状态序列(以天为时间尺度,下同)为检修容量的连续时变过程,观测序列为时变过程内获取的多属性气象因子数值。

风电场检修容量的CHMM由一个五元组

$\lambda = (N,M,{\boldsymbol{\pi}} ,A,B)$ 描述[25],具体如下。1)隐状态数目N。记隐状态集合

$S = \left\{ {{s_1},{s_2}, \cdots {s_N}} \right\}$ ,观测序列$Q = \left\{ {{q_1},{q_2}, \cdots ,{q_T}} \right\}$ ,则t时刻所处状态${q_t} \in S$ 。本文认为风电场检修事项中,每个状态为特定检修容量区间。根据历史检修数据、恶劣天气设定标准等进行风电场检修容量的区间划分[26-28],设定5种隐状态,即N=5,其定义如表1所示。状态 检修容量 物理含义 1 $(0.00 \sim 0.50){P_{\max ,w} }$ 少部分机组需要检修 2 $(0.50 \sim 0.75){P_{\max ,w} }$ — 3 $(0.75 \sim 0.90){P_{\max ,w} }$ 大部分机组需要检修 4 $(0.90 \sim 0.95){P_{\max ,w} }$ — 5 $(0.95 \sim 1.00){P_{\max ,w} }$ 几乎所有的机组需要检修 Table 1. Physical meaning of each hidden state

2)观测值数目M:每个隐状态对应的高斯混合数。记观测值集合

$V = \left\{ {{v_1},{v_2}, \cdots {v_M}} \right\}$ ,则t时刻观测值${o_t} \in V$ ,观测序列$O = \left\{ {{o_1},{o_2}, \cdots ,{o_T}} \right\}$ 。本文以相互关联的降雨量序列、风速序列、雷电危险度序列作为观测序列,采用3个高斯分布的线性组合无限逼近,即M=3。3)初始状态概率矩阵

${\boldsymbol{\pi}}$ 。${\boldsymbol{\pi}}$ 表示初始t=1时的概率矩阵,${\boldsymbol{\pi}} = \left\{ {{{\boldsymbol{\pi}} _i}} \right\}$ ,其中${{ {π}} _i}$ 描述状态${q_1}$ 为${S_i}$ 的概率,即:$$ {{\boldsymbol{\pi}}_i}= P({q_1} = {S_ i})1 \leqslant i \leqslant N $$ (1) 4)状态转移概率矩阵

${\boldsymbol{A}}$ 。${\boldsymbol{A}}$ 描述从状态${S_i}$ (t时刻)转移到状态${S_j}$ (t+1时刻)的概率,即${\boldsymbol{A}} = {({a_{ij}})_{N \times N}}$ :$$ {a_{ij}} = P({q_{t + 1}} = {S_ j}\left| {{q_t} = {S_i}} \right.),{\text{ 1}} \leqslant i,j \leqslant N $$ (2) 5)观测概率矩阵

${\boldsymbol{B}}$ 。CHMM采用高斯混合模型拟合各隐状态对应的观测值的概率密度函数,即:$$ {b_j}({o_t}) = \displaystyle \sum\limits_{m = 1}^M {{w_{j,m}}{b_{j,m}}({o_t}) = } \displaystyle \sum\limits_{m = 1}^M {{w_{j,m}}G\left( {{o_t},{\mu _{j,m}},{\displaystyle \sum\limits_{j,m}}} \right)} $$ (3) 式中:

M ——高斯分量个数;

${w_{j,m}}$ 、${\mu _{j,m}}$ 、${\sum _{j,m}}$ ——状态${S_j}$ 下第m个高斯分布的权值、均值向量、方差矩阵;$G({o_t},{\mu _{j,m}},{\sum _{j,m}})$ ——混合高斯概率密度函数。状态j下的第m个高斯分布$ {b_{j,m}}({o_t}) $ 为:$$ \begin{split} &{b_{j,m}}({o_t}) = G({o_t},{\mu _{j,m}},{\displaystyle \sum\limits_{ j,m}})= \\& \dfrac{1}{{\sqrt {{{(2{\boldsymbol{\pi}})}^D}\left| {{\displaystyle \sum\limits _{j,m}}} \right|} }}\exp ( - \dfrac{1}{2}{\left( {{o_t} - {\mu _{j,m}}} \right)^T}{\displaystyle \sum\limits_{j,m}}^{ - 1}({o_t} - {\mu _{j,m}})) \end{split} $$ (4) 权重

${w_{j,m}}$ 受以下约束限制:$$ {w_{j,m}} > 0,\displaystyle \sum\limits_{m = 1}^M {{w_{j,m}} = 1,1 \leqslant j \leqslant N,1 \leqslant m \leqslant {M_j}} $$ (5) 鉴于五元组各参数联系紧密,参数

${\boldsymbol{B}}$ 可等效为:${\boldsymbol{B}} \to \left( {w,\mu ,\displaystyle \sum\limits } \right)$ ,五元组$\lambda $ 可等效为:$\lambda \to \left( {{\boldsymbol{\pi}} ,{\boldsymbol{A}},w,\mu ,\displaystyle \sum\limits } \right)$ 。 -

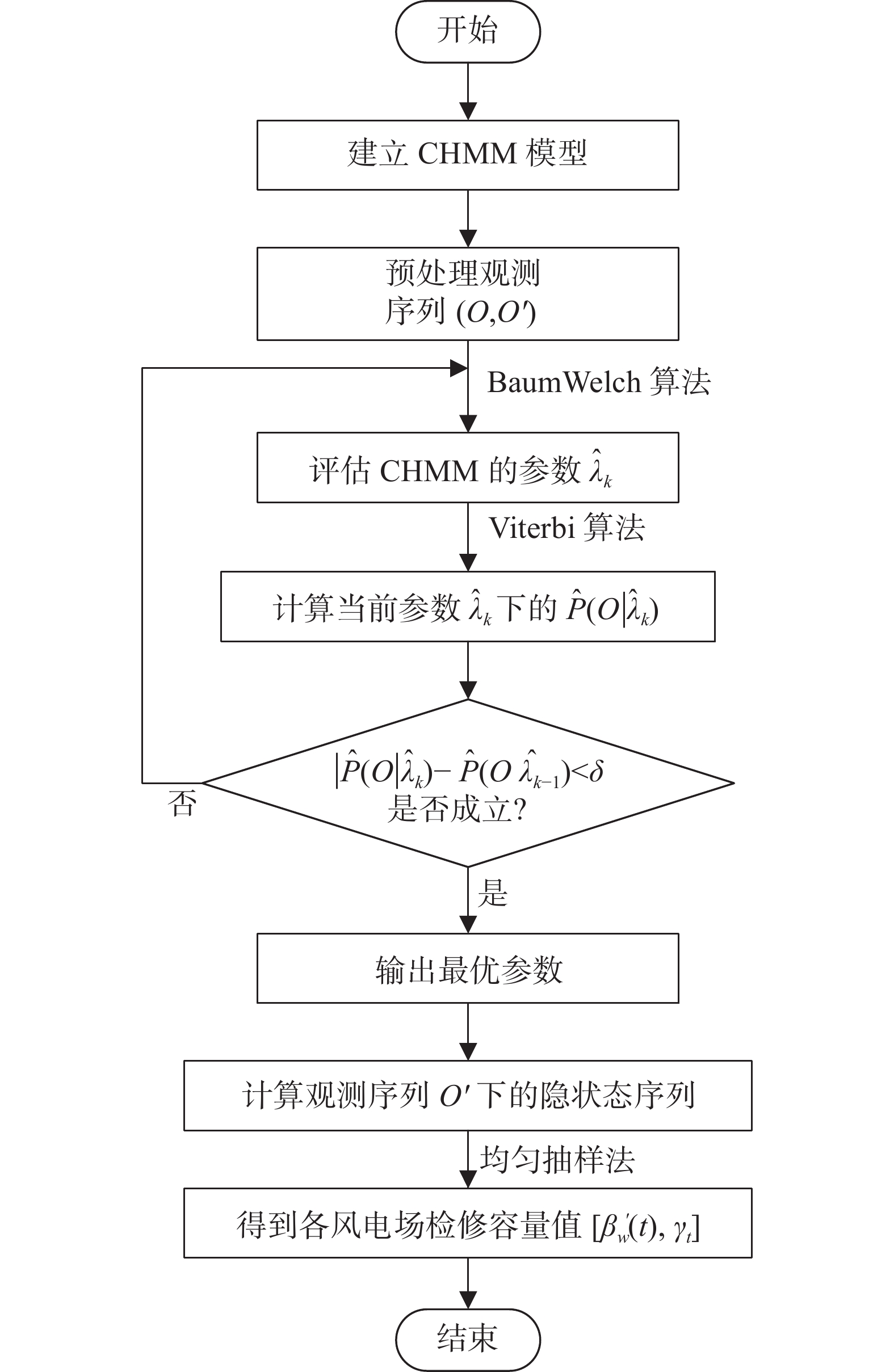

CHMM的训练本质是参数学习问题,即通过循环迭代求解最优参数

$\lambda = \left( {{\boldsymbol{\pi}} ,{\boldsymbol{A}},w,\mu ,\displaystyle \sum\limits } \right)$ ,使得$P(O\left| \lambda \right.)$ 最大。本文以历史观测序列$O$ 为训练数据,估计最优参数$\lambda $ 步骤如下:1)基于

$O$ ,采用Baum-Welch算法评估参数(第k次循环时求解)。2)采用Viterbi算法计算参数

${\hat \lambda _\kappa }$ 下的$\hat P(O{\left| {\hat \lambda } \right._k})$ 。3)判断收敛条件

$\left| {\hat P(O{{\left| {\hat \lambda } \right.}_k}) - \hat P(O{{\left| {\hat \lambda } \right.}_{k - 1}})} \right| < \delta $ ($\delta $ 为设定阈值)是否成立;若成立,将当前求解的${\hat \lambda _\kappa }$ 作为最优参数$\lambda $ ;若不成立,重复前两步,直至收敛。 -

风电场检修容量的确定可视为解码问题,即在给定观测序列

$O'$ 和最优参数$\lambda $ (1.2节得到)的基础上,采用Viterbi算法求解最贴合观测序列时变特性的隐状态序列。其核心思想如下:假定在最优参数和观测序列下,

${q_t}$ 描述$ P({q_t} = {S_i}\left| {O',\lambda } \right.) $ 达最大时的t时刻状态,${q_{1:T}}$ 描述$P({q_T} = {S_i}\left| {O',\lambda } \right.)$ 达最大时的状态序列,即:$$ {q_t} = \arg \mathop {\max }\limits_{1 \leqslant i \leqslant N} [P({q_t} = {S_i}\left| {O',\lambda } \right.)] $$ (6) $$ {q_{1:T}} = \arg \mathop {\max }\limits_{1 \leqslant i \leqslant N} [P({q_T} = {S_i}\left| {O',\lambda } \right.)] $$ (7) $$ P({q_T} = {S_i}\left| {O',\lambda } \right.) = \dfrac{{P(O',{q_T} = {S_i}\left| \lambda \right.)}}{{P(O'\left| \lambda \right.)}} $$ (8) 求解隐状态序列

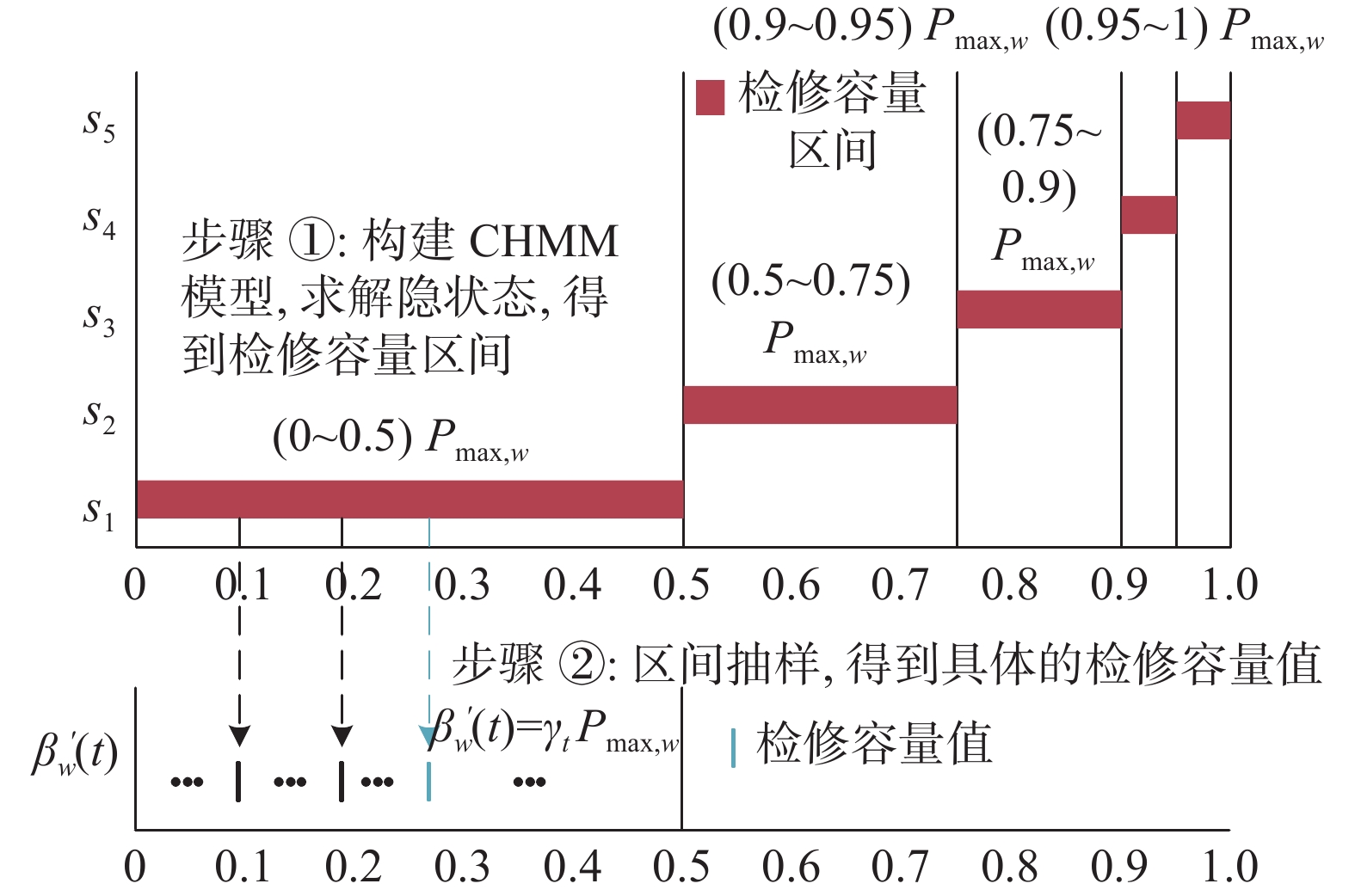

$Q'$ 即得到了风电场的日检修容量区间,依据风电场的运行特点与历史检修维护数据[29-30],求解此区间内的日检修容量值$ {\beta '_w}(t) $ 。即日检修容量值的确定分两步进行:(1)计及多属性气象因子构建CHMM模型,求解式(7)、式(8)得到隐状态(即风电场待检修的容量区间);(2)依据风电场的检修特性等,从式(7)、式(8)求解的容量区间内选取具体的检修容量值。两步骤的逻辑关系如图1所示,具体公式表述如下:$$ {\beta '_w}(t) = {\gamma _t}{P_{\max ,w}} $$ (9) 式中:

$ {\gamma _t} $ ——t时刻隐状态所系区间内的随机系数(抽样法得到),描述风电场检修容量占比,假定t时刻隐状态为${s_1}$ ,则${\gamma _{_t}} \in \left( {0 \sim 0.5} \right)$ ;$ {P_{\max ,w}} $ ——风电场w的最大出力。 -

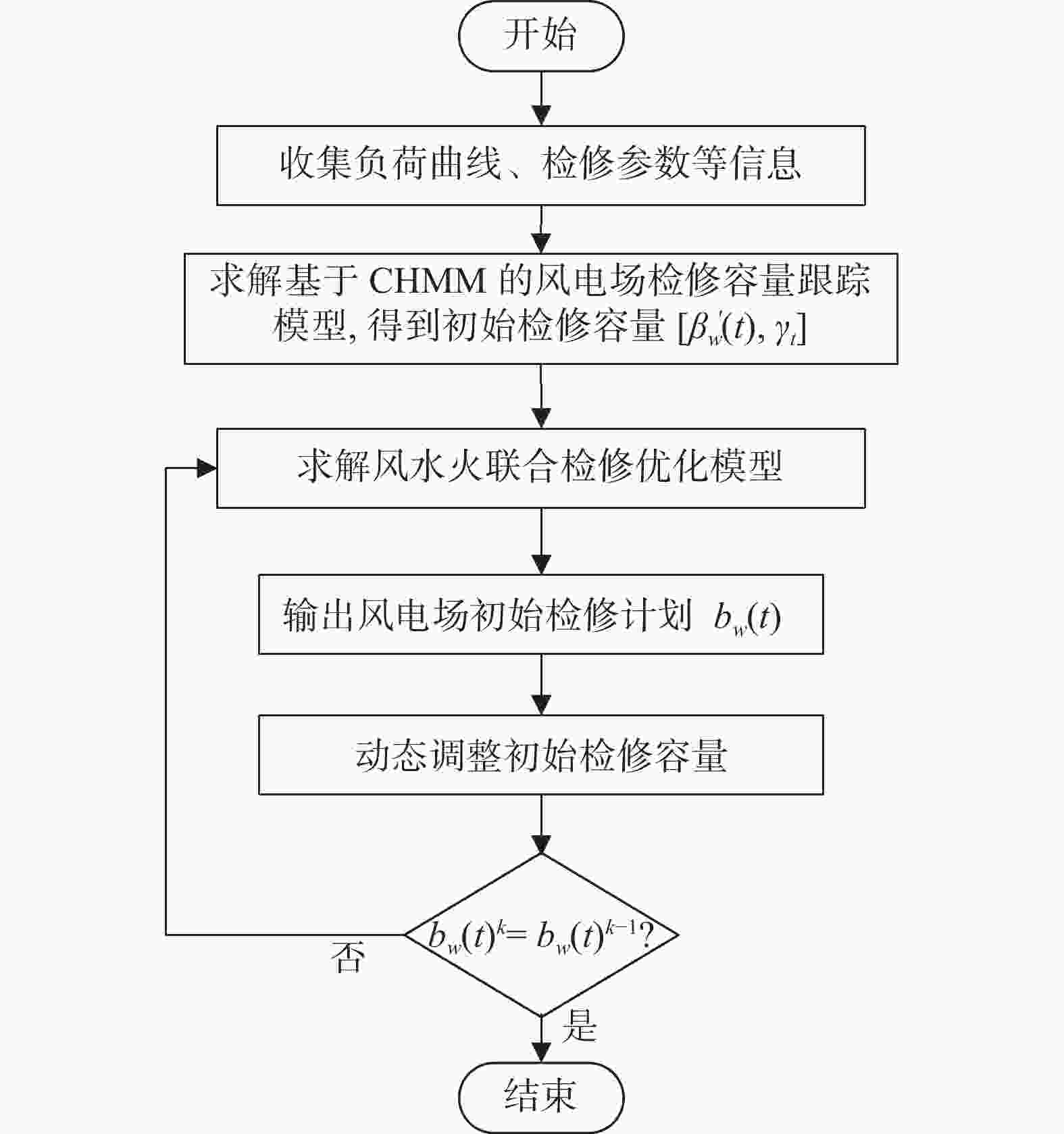

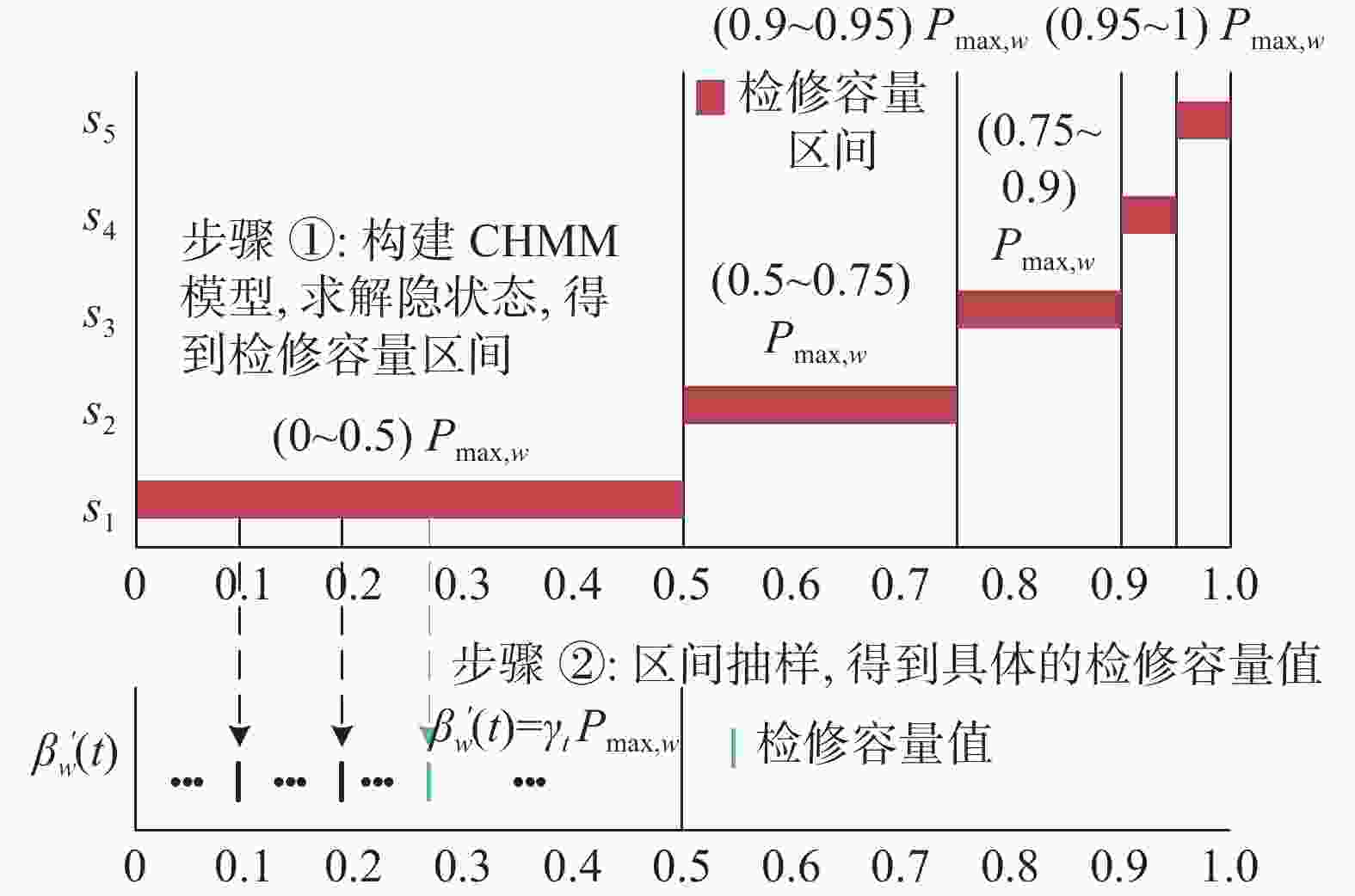

基于CHMM的风电场检修容量跟踪模型的整体流程如图2所示。

-

依据风机检修维护存在极易受外界因素影响、故障频繁、即坏即检等特点,基于简化模型的原则,设定如下假设:

1)考虑到同一地区下各风机类似的系统特性和外部气象特性,风电与水火电机组共同参与检修优化。

2)为确保多属性气象因子的时效性和精准性,根据天气预报分类原则,以月度为检修规划周期,以天为时间尺度。

3)通常风机检修维护周期较短,参考文献,本文设定风机检修工期为3 d。

4)在检修工期内,某一风电场检修容量值须为固定值,本文取检修区间内的最小值,具体见式(17)。

-

本文在构建模型时以最小化经济损失、助力电力系统低碳运行为目标,统筹考虑机组检修成本、运行成本、碳排放成本等目标。以下采用各子目标(成本)加权求和的方式构建种优化目标,其中各项权值系数可以体系对该项成本值的惩罚强度[31-33]。

构建总优化目标:

$$ \min F = \min ({\varpi _1}{F_1} + {\varpi _2}{F_2} + {\varpi _3}{F_3}) $$ (10) 机组检修成本

$ {F_1} $ 表示为:$$ {F_1} = \sum\limits_{t = 1}^T {\sum\limits_{i = 1}^Z {{C_{jx,Z,t}}{P_{\max ,i}}{a_i}(t)} } + \sum\limits_{t = 1}^T {\sum\limits_{w = 1}^W {{C_{jx,w,t}}{\beta _w}(t)} } $$ (11) 机组运行成本

$ {F_2} $ 表示为:$$ {F_2} = \sum\limits_{t = 1}^T {\sum\limits_{i = 1}^{Th} {[{c_{0,i}}{P_i}{{(t)}^2} + {c_{1,i}}{P_i}(t) + {c_{2,i}}(1 - {a_i}(t)]} } $$ (12) 碳排放成本

$ {F_3} $ 表示为:$$ {F_3} = \lambda \sum\limits_{t = 1}^T {\sum\limits_{i = 1}^{T_{\rm{h}}} {{P_i}(t){\delta _t}} } $$ (13) 式中:

T ——检修时段(本文以月为检修周期,T=30);

i ——机组编号;

Z ——水火电机组总数,Z=Th+Tm(Th、Tm分别为火电机组数目、水电机组数目);

W ——风电场总数;

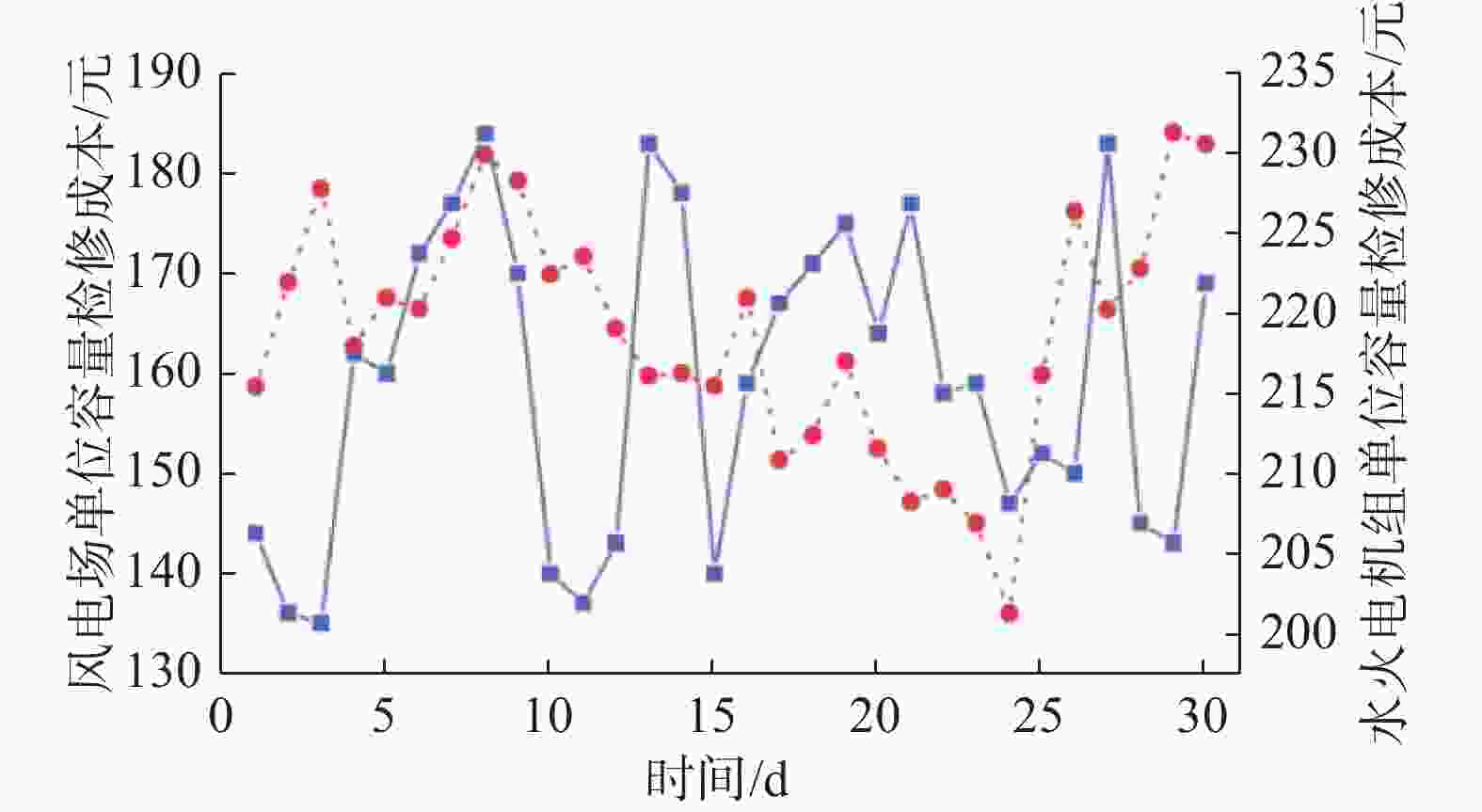

$ {C_{jx,Z,t}} $ 、$ {C_{jx,w,t}} $ ——单位容量水火电机组、风机的检修费用,受实际情况下人力物力资源的限制,该项费用月内随时间变化,人力物力资源缺乏时,其值较高;$ {P_{\max ,i}} $ ——水火电机组的最大出力;$ {a_i}(t) $ ——机组i的检修0~1变量,$ {a_i}(t) = 1 $ 表示t时刻机组i处于检修状态,$ {a_i}(t) = 0 $ 表示t时刻机组i处于非检修状态;$ {\beta _w}(t) $ ——风电场w的检修连续变量,$ {\beta _w}(t) $ 值反映风电场中实际需要检修的容量值;$ {P_i}(t) $ ——火电机组i在t时刻的出力;$ {c_{0,i}} $ 、$ {c_{1,i}} $ 、$ {c_{2,i}} $ ——火电机组的煤耗系数。 根据文献[34-35],

$\lambda $ 为度电碳成本,取值为0.019元/kWh;$ {\delta _t} $ 为时间间隔,即每天的小时数(本文检修模型以天为尺度),取24 h;$ {\varpi }_{1}、{\varpi }_{2}、{\varpi }_{3} $ 分别为机组检修成本、运行成本、碳排放成本的权值,根据实际系统的碳惩罚需求而设定。 -

优化过程考虑机组检修约束、机组特性约束、系统运行控制约束等[36-38],为风水火联合系统制定合理的检修优化策略[39]。

-

1)水火电机组检修持续性约束

$$ {a}_{i}(t)=\left\{ {\begin{array}{c}0\text{,}t\notin [{{t}^{\prime }}_{\text{sta},i},{{t}^{\prime }}_{\text{end},i}]\\ 1\text{,}t\in [{{t}^{\prime }}_{\text{sta},i},{{t}^{\prime }}_{\text{end},i}]\end{array}} \right. $$ (14) 式中:

$ {t'_{{\text{sta}},i}} $ 、$ {t'_{{\text{end}},i}} $ ——机组i实际检修计划的开始时间和终止时间。2)水火电机组工期约束

$$ \displaystyle \sum\limits_{t = 1}^T {{a_i}(t) = {T_{{\text{cx}},i}}} $$ (15) 式中:

$ {T_{{\rm{cx}},i}} $ ——机组i的检修工期。 -

1)检修容量平衡方程

风电场的实际检修容量由检修0~1变量和预测检修容量决定,即系统地兼顾模型优化过程与外界多属性气象因子的共同作用。

$$ {\beta _w}(t) = {\beta '_w}(t) \cdot {b_w}(t) $$ (16) 式中:

$ {\beta '_w}(t) $ ——t时刻风电场w的预测检修容量,经第1节模型求得,即所述CHMM的隐状态对应值(式9);$ {b_w}(t) $ ——风电场检修0~1变量;$ {b_w}(t) = 1 $ 表示t时刻风电场w处于检修状态,$ {b_w}(t) = 0 $ 表示t时刻风电场w处于非检修状态。2)检修容量一致性约束

依据2.1节所述假设4,在优化得到的检修区间内,检修容量应保持固定且为区间最小值:

$$ \begin{gathered} {\beta _w}({{t'}_{{\text{sta}},w}}) = {\beta _w}({{t'}_{{\text{sta}},w}} + 1) = {\beta _w}({{t'}_{{\text{end}},w}}) \\ {\text{ }} = \min \left\{ {{\beta _w}({{t'}_{{\text{sta}},w}}),{\beta _w}({{t'}_{{\text{sta}},w}} + 1),{\beta _w}({{t'}_{{\text{end}},w}})} \right\} \\ \end{gathered} $$ (17) 式中:

$ {t'_{{\text{sta}},w}} $ 、$ {t'_{{\text{end}},w}} $ ——风电场w实际检修计划的开始时间和终止时间。3)检修持续性约束

$$ {b}_{w}(t)=\left\{ {\begin{array}{c}0\text{,}t\notin [{{t}^{\prime }}_{\text{sta},w},{{t}^{\prime }}_{\text{end},w}]\\ 1\text{,}t\in [{{t}^{\prime }}_{\text{sta},w},{{t}^{\prime }}_{\text{end},w}]\end{array}} \right. $$ (18) 4)检修工期约束

$$ \sum\limits_{t = 1}^T {{b_w}(t) = {T_{{\text{cx}},w}}} $$ (19) 式中:

$ {T_{{\text{cx}},w}} $ ——风电场w的检修工期,根据假设3,$ {T_{{\text{cx}},w}} = 3 $ 。 -

1)火电机组功率上下限约束

$$ [1 - {a_i}(t)]{P_{i,\min }} \leqslant {P_i}(t) \leqslant [1 - {a_i}(t)]{P_{i,\max }} $$ (20) 式中:

$ {P_{i,\min }} $ 、$ {P_{i,\max }} $ ($i \in {\varOmega _{T_{\rm{h}}}}$ )——火电机组i的最小技术出力、最大技术出力。2)水电机组功率上下限约束

$$ 0 \leqslant {P_i}(t) \leqslant [1 - {a_i}(t)]{P_{i,\max }} $$ (21) 式中:

$ {P_{i,\max }} $ ($i \in {\varOmega _{T_{\rm{m}}}}$ )——水电机组i的最大技术出力。3)风电场功率约束

$$ {P_w}(t) = {P'_w}(t) \cdot [1 - {\gamma _t}{b_w}(t)] $$ (22) 式中:

$ {P_w}(t) $ 、$ {P'_w}(t) $ ——风电场w的调度出力、预测出力;$ {\gamma _t} $ ——风电场检修容量占比,由第1节模型求得(式9)。 -

1)功率平衡约束

$$ \sum\limits_{i = 1}^Z {{P_i}(t)} + \sum\limits_{w = 1}^W {{P_w}(t)} \pm \sum\limits_{h = 1}^H {{P_h}(t)} = {D_t} $$ (23) 式中:

$ {P_h}(t) $ ——t时刻外区域与本区域电网的交换功率;H ——联络线总数;

Dt ——本区域的日最大负荷,为系统总负荷值。

2)系统备用约束

国内外学者在机组检修优化问题中很少详细考虑失负荷量,通常将失负荷量的考虑计入系统备用约束中[40-42],即:

$$ \sum\limits_{i = 1}^Z {{P_{i,\max }} - \sum\limits_{i = 1}^Z {{P_{i,\max }}} {a_i}(t) - (1 + \theta ){D_t} \geqslant 0} $$ (24) 式中:

$ \theta $ ——依据系统运行特点设定的最佳备用系数,本文取$ \theta = 0.05 $ 。3)系统潮流约束

$$ - {P_{l,\max }} \leqslant \sum\limits_{l \in L}^{} {[{P_i}(t)} + {P_w}(t) + {P_h}(t) - {D_t}] \leqslant {P_{l,\max }} $$ (25) 式中:

$ P_{l, {\rm{max}}} $ ——输电线路$ l $ 的最大传输功率;L ——线路总数。

-

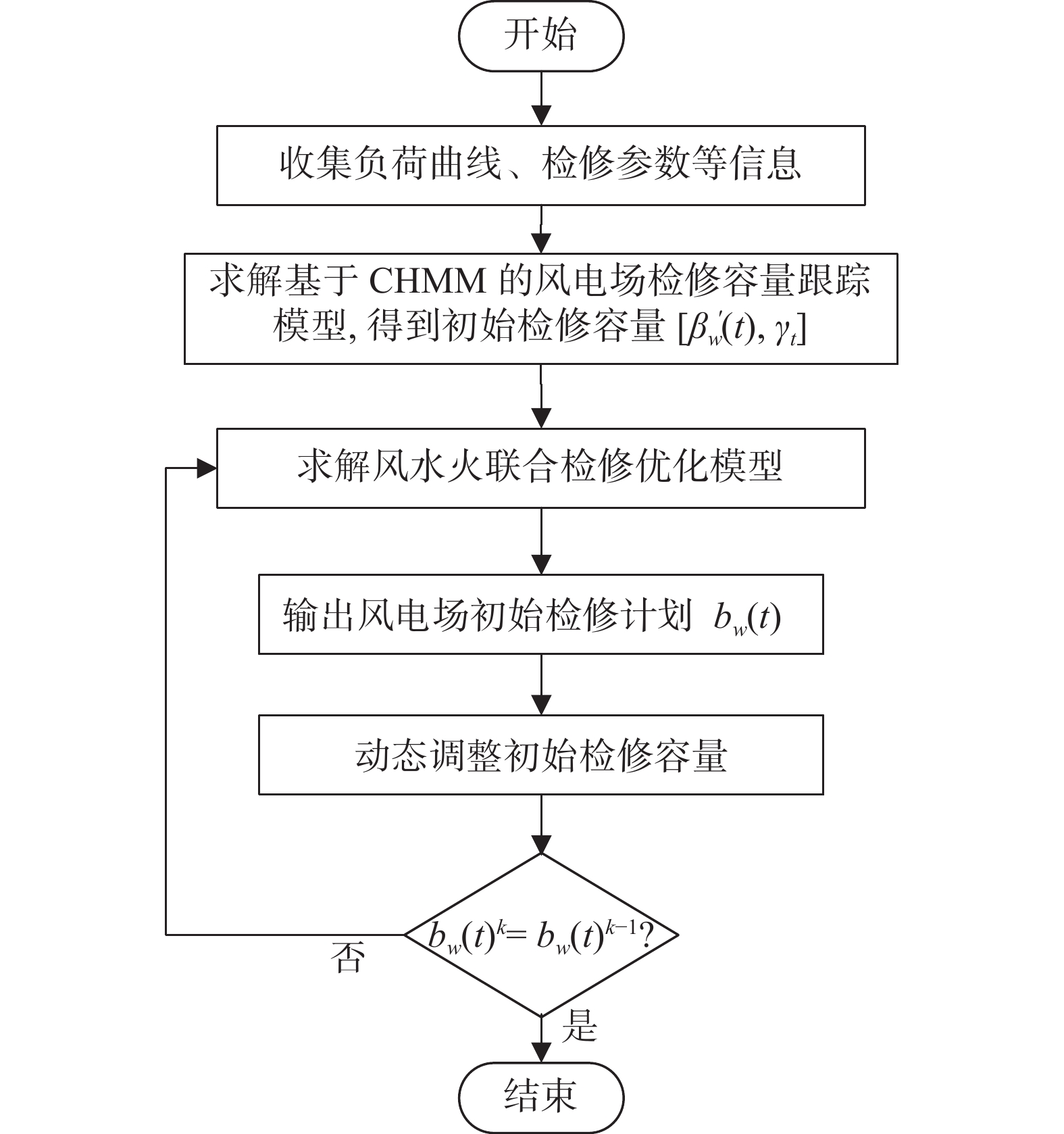

将第1节求出的风电场检修容量参数

$[{\beta '_w}(t),{\gamma _t}]$ 作为优化模型的边界条件,受制于同一检修工期内风电场的检修容量一致,即假设4和式(17)必须满足的要求下,本文迭代求解模型,求解流程如图3所示。具体步骤如下:

Figure 3. Solving steps of the optimization model for wind power, hydropower and thermal power combined low-carbon maintenance

1)将

$[{\beta '_w}(t),{\gamma _t}]$ 作为初始边界条件,求解风水火联合低碳检修优化模型,得到风电场初始检修计划$ {b_w}(t) $ 。2)按照式(17)修改检修工期

$ ({t'_{{\text{sta}},w}},{t'_{{\text{end}},w}}) $ 内的$ {\beta '_w}(t) $ 、$ {\gamma _t} $ 值,动态调整初始边界条件${[{\beta '_w}(t),{\gamma _t}]^k }$ (第$ k $ 次调整)。3)以调整后的

${[{\beta '_w}(t),{\gamma _t}]^k }$ 为边界条件循环求解优化模型,重复两阶段步骤,直至$ {b_w}{(t)^k } ={b_w}{(t)^{k - 1}} $ ($ k \geqslant 2 $ )。 -

基于模型特性和时效性拆分观测序列,以过去两年的数据为训练集,以未来一个月的数据为预测集。原始观测序列包含降雨量、风速、雷电危险度3个维度,前2个维度可由气象机构直接监测得到,雷电危险度受所在片区的气象数据、雷电天气强度和风机特性共同作用,设定原则参考文献[28]。原始观测序列数据集形式如表2所示。

日期 降雨量/mm 风速/(m·s−1) 雷电危险度 D38 15 1.68 0.3 D39 167 9.71 0.5 …… …… …… …… Table 2. Observation sequence data set form

-

经CHMM训练,采用Baum-Welch算法求解模型参数

$\lambda $ 如表3~表5所示。初始概率 ${s_1}$ ${s_2}$ ${s_3}$ ${s_4}$ ${s_5}$ ${\boldsymbol{\pi}}$ 1 0 0 0 0 Table 3. Initial state probability matrix

${\boldsymbol{\pi}} $ 隐状态 ${s_1}$ ${s_2}$ ${s_3}$ ${s_4}$ ${s_5}$ ${s_1}$ 0.263 0 0.483 9 0.161 9 0.035 0 0.056 2 ${s_2}$ 0.385 7 0.261 3 0.205 0 0.039 0 0.109 1 ${s_3}$ 0.301 9 0.122 5 0.373 2 0.177 1 0.025 3 ${s_4}$ 0.263 6 0.000 0 0.139 9 0.458 0 0.138 5 ${s_5}$ 0.211 0 0.156 2 0.288 5 0.055 6 0.288 7 Table 4. State transition probability matrix

${\boldsymbol{A}}$ -

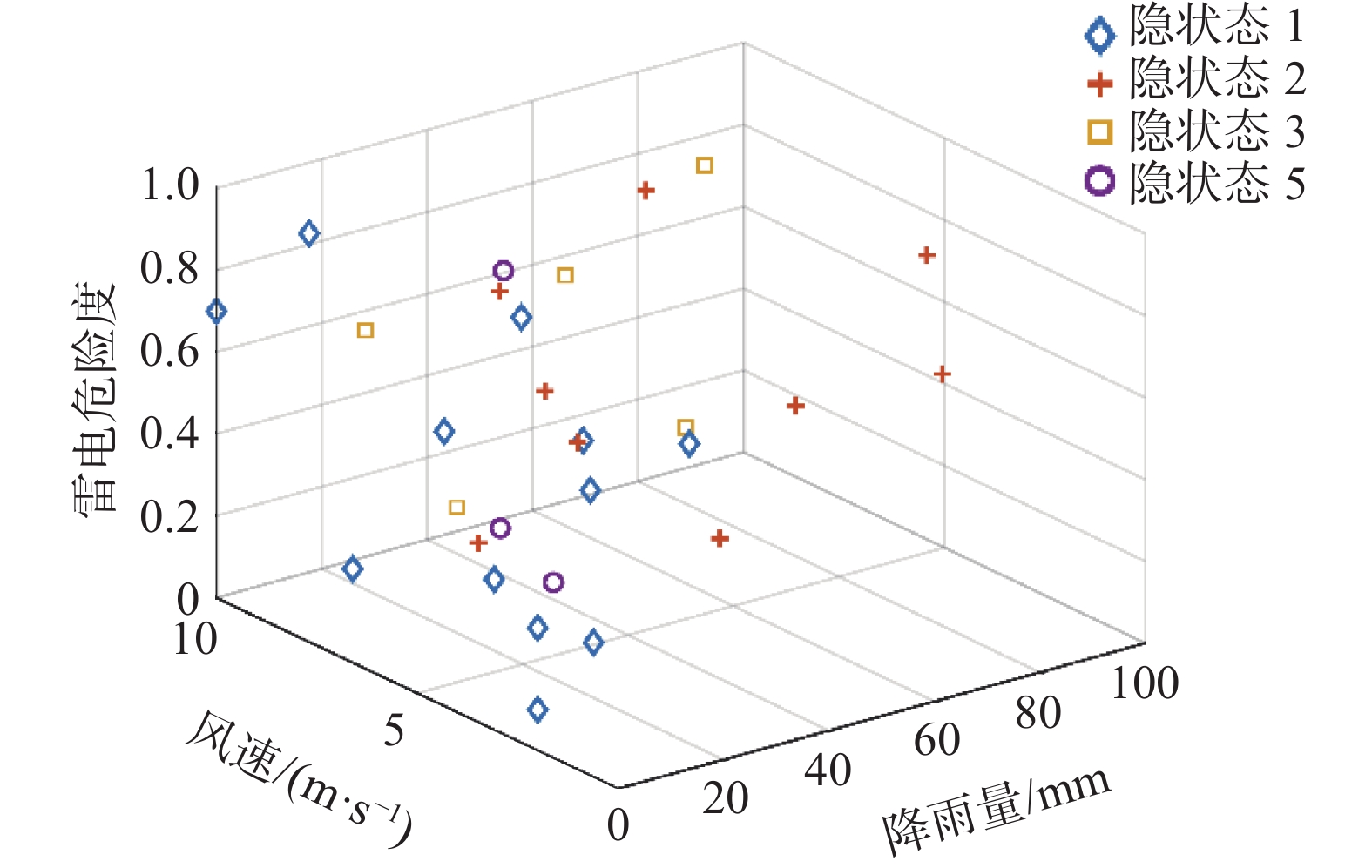

将3.1.2节求出的参数作为CHMM的最优参数

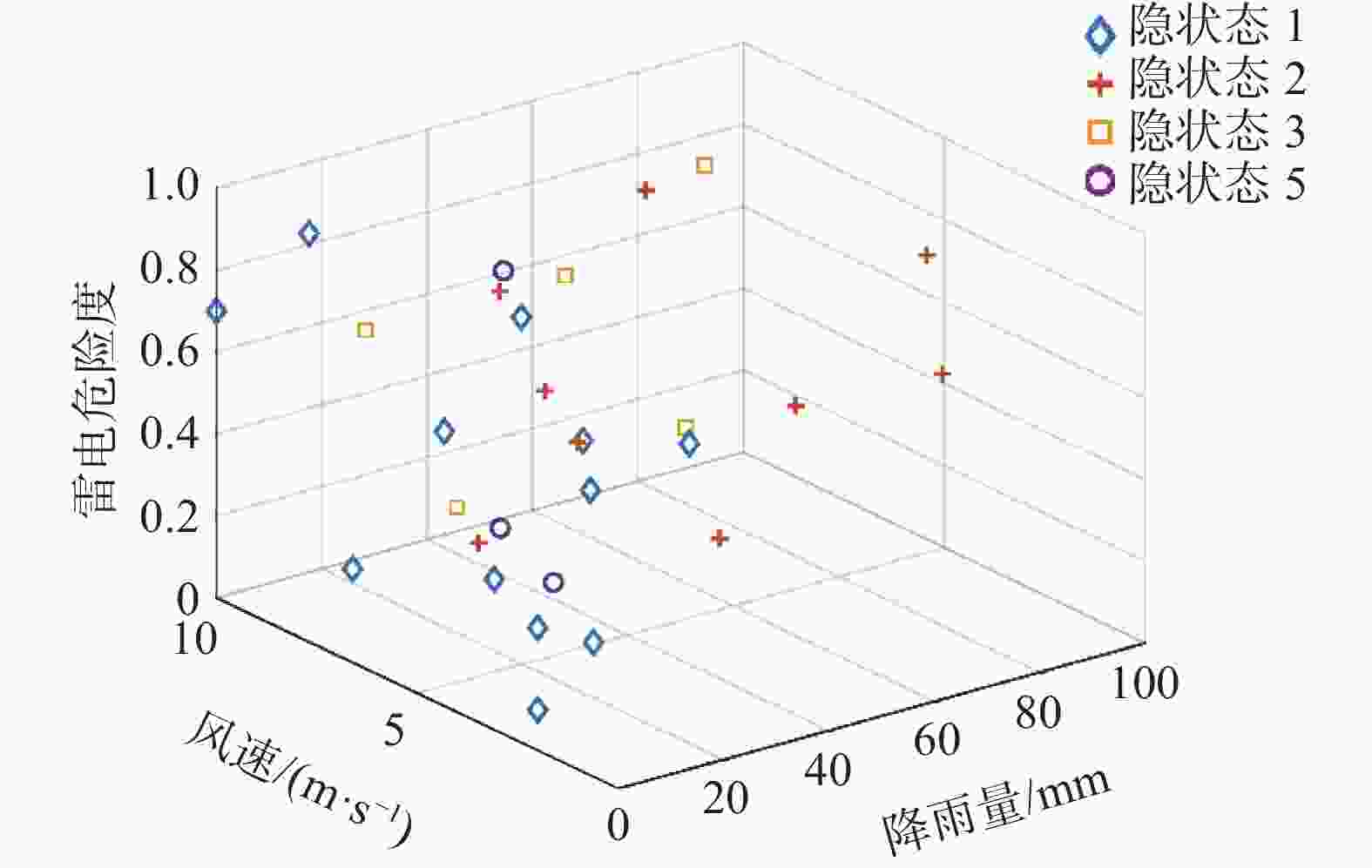

$\lambda $ ,采用Viterbi算法求解未来一个月与观测序列关联的最优隐状态序列,最优观测值-隐状态分布如图4所示,结果如表6所示。日期 s1 s2 s3 s4 s5 D1 0.791 624 7 0.207 005 4 0.001 272 4 0.000 086 1 0.000 011 3 D2 0.038 939 9 0.960 987 4 0.000 016 6 0.000 052 3 0.000 003 8 D3 0.001 347 6 0.998 619 9 0.000 000 4 0.000 031 2 0.000 000 9 D4 0.791 687 4 0.203 395 1 0.004 805 6 0.000 099 1 0.000 012 7 D5 0.785 881 3 0.212 917 9 0.001 102 6 0.000 086 8 0.000 011 4 …… …… …… …… …… …… Table 5. Hidden state probability matrix

${\boldsymbol{B}}$ 隐状态 天数/d 天数占比/% 1 12 40.0 2 10 33.3 3 5 16.7 4 0 0.0 5 3 10.0 Table 6. Optimal hidden state sequence for the next month

由上述图表可知,未来一个月内,检修容量处于隐状态1的天数最多,占比40%,大都分布在降雨量和雷电危险度较低的时刻,此时外界天气状况尚佳,有少部分(0%~50%)机组需要安排检修。处于隐状态4、隐状态5的天数较少,占比10%,即实际运行中安排90%以上机组检修的情况极为罕见,这与有限的检修资源(人力、预算等)、亟待满足的负荷需求密切相关。同时,隐状态2、隐状态3出现的频数高于隐状态5,且相应的天气状况整体更为恶劣,这是因为极其严峻的外部气象环境在加剧机组的损害,同时也给检修维护工作带来了极大的不便,此时,安排检修的机组比例相对更低。经CHMM求出的风电场检修容量充分考虑了外界气象因素对检修容量的影响,为风电场参与系统整体检修优化提供有利参照。

-

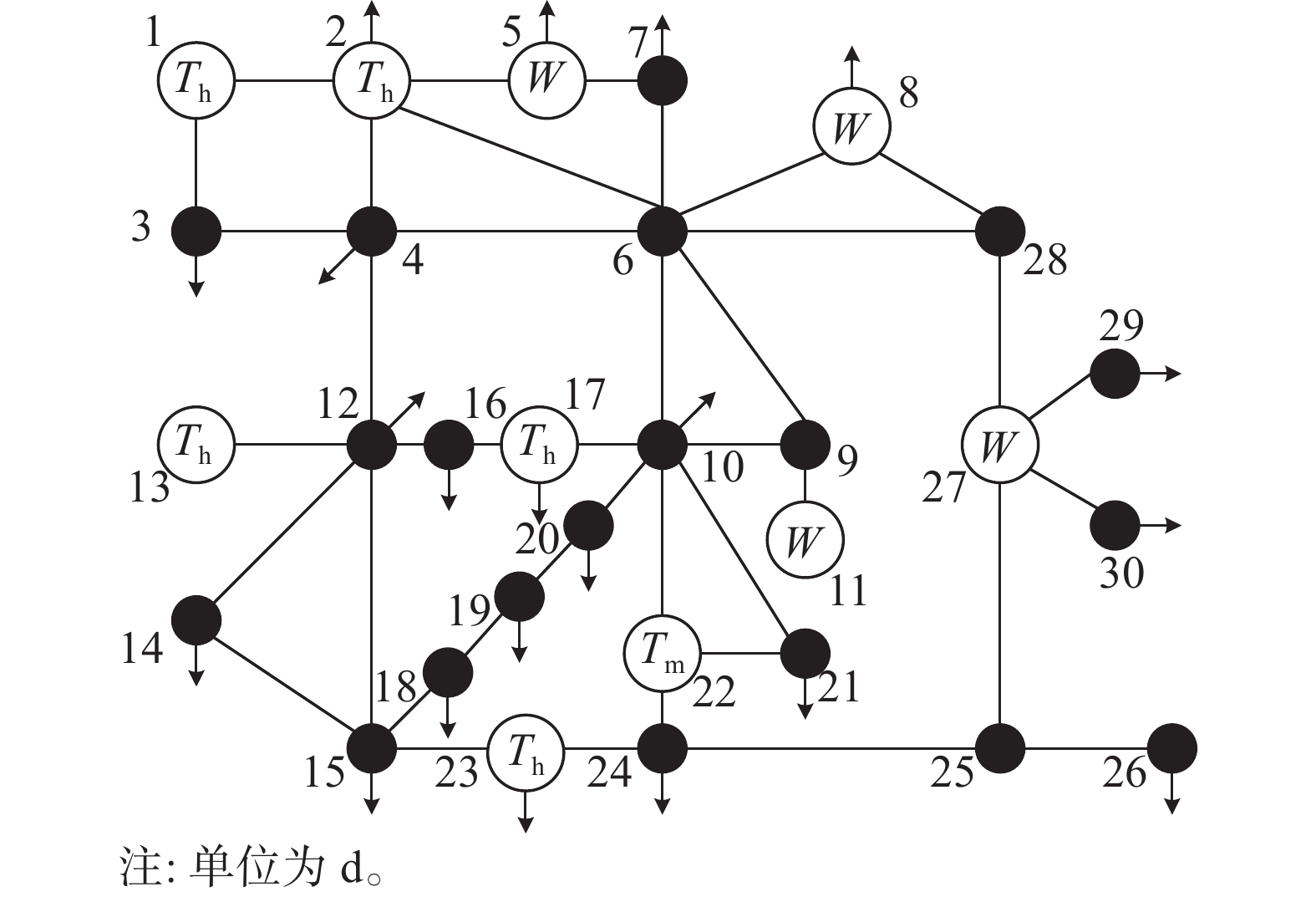

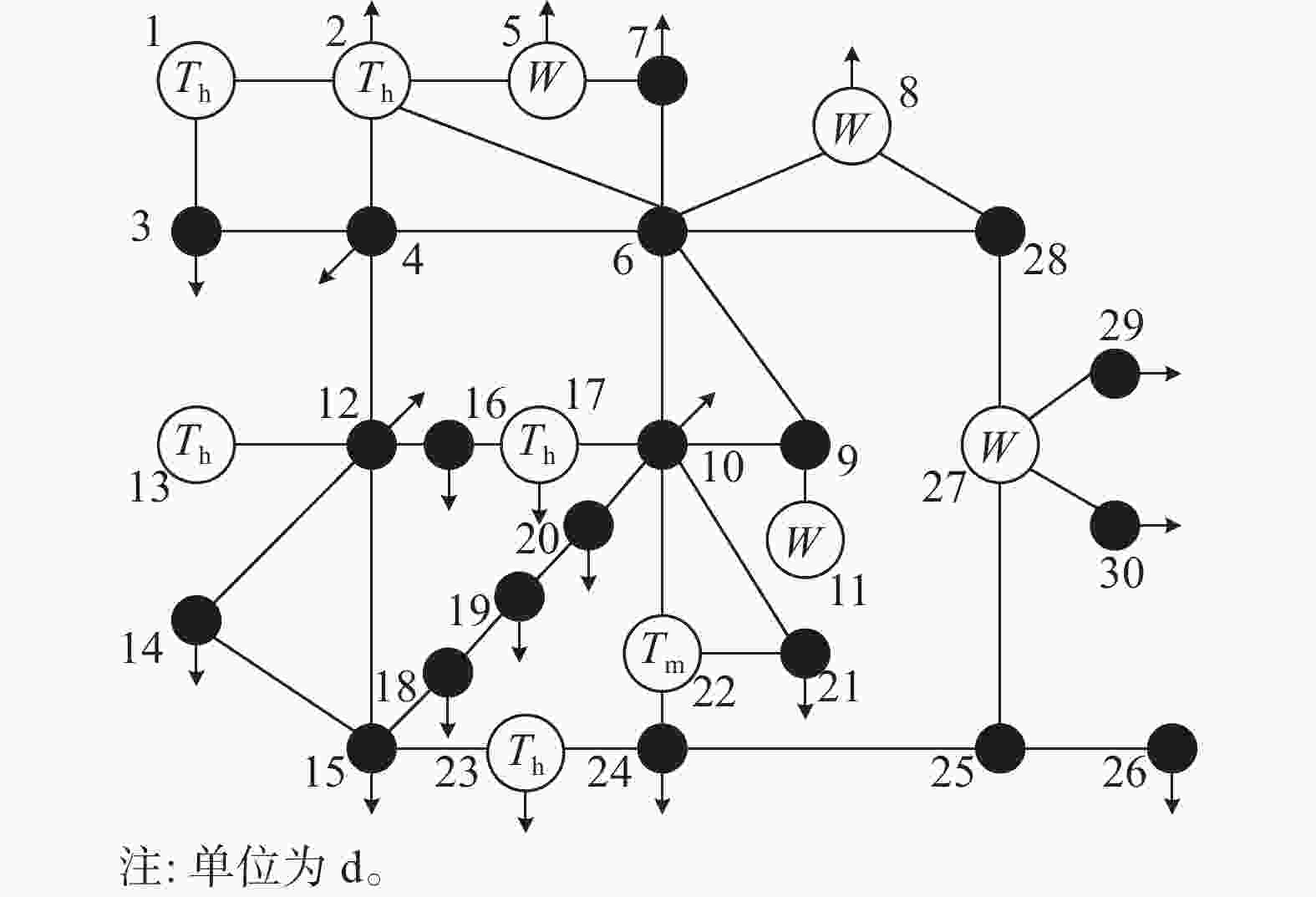

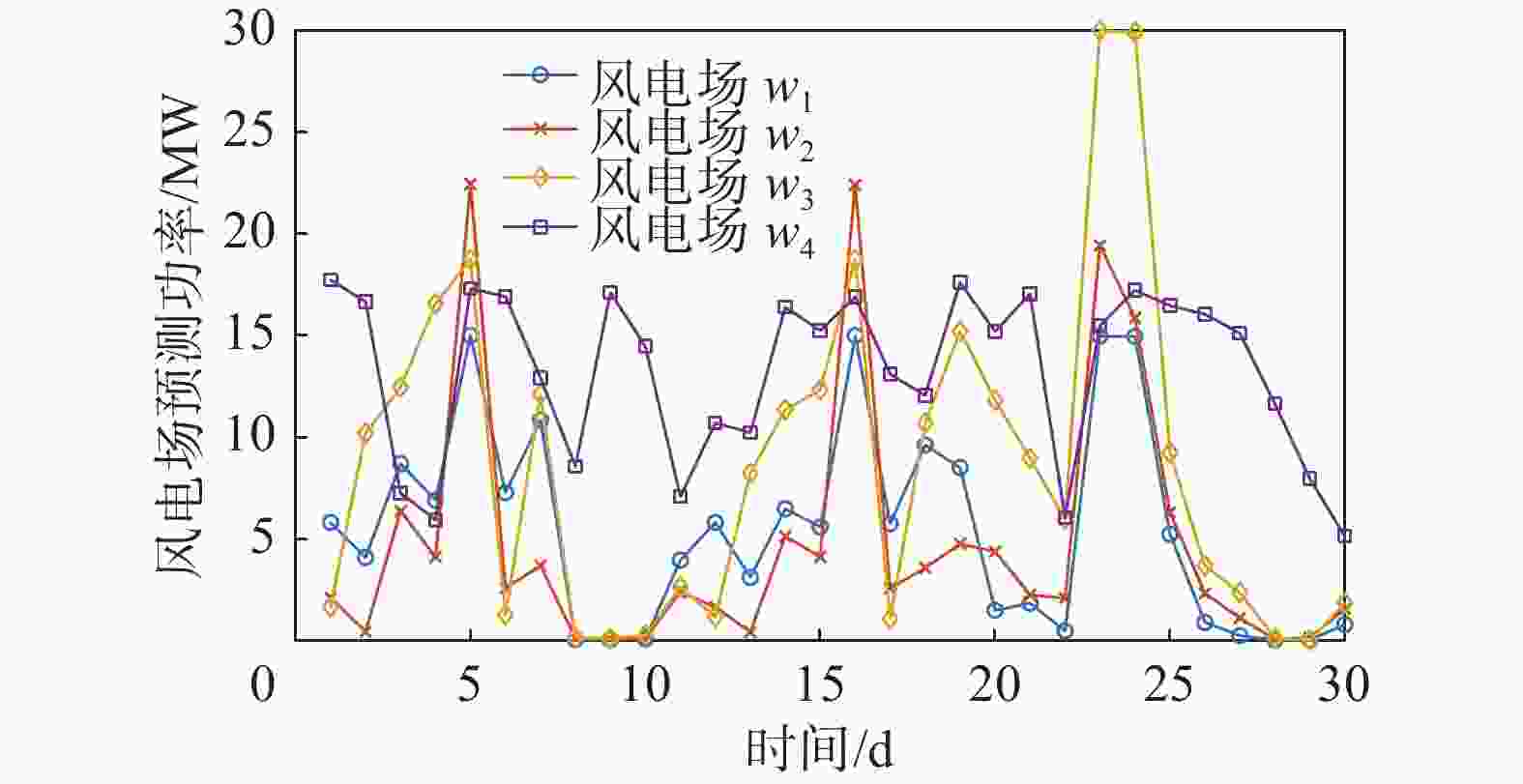

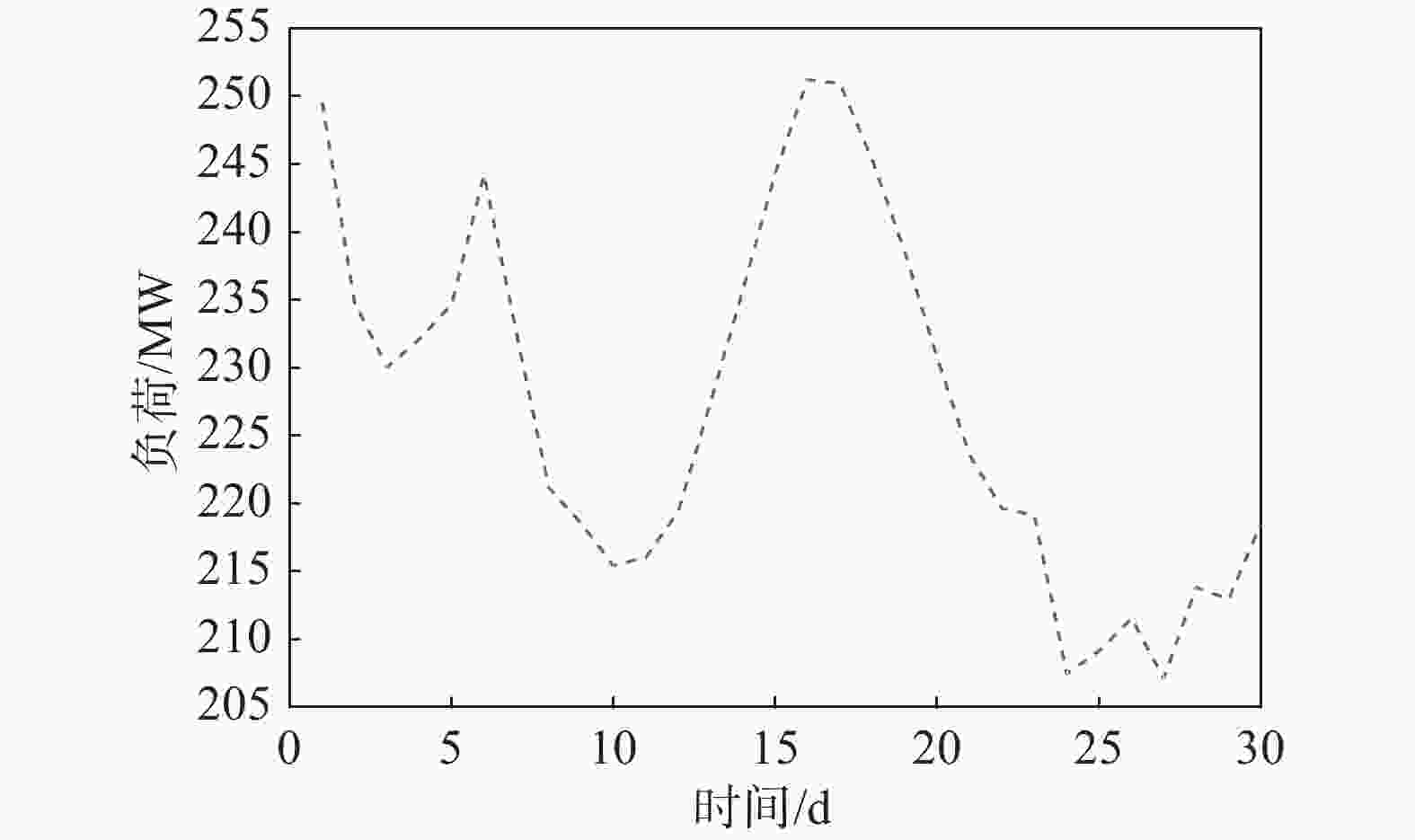

本文通过IEEE30节点系统算例验证模型(

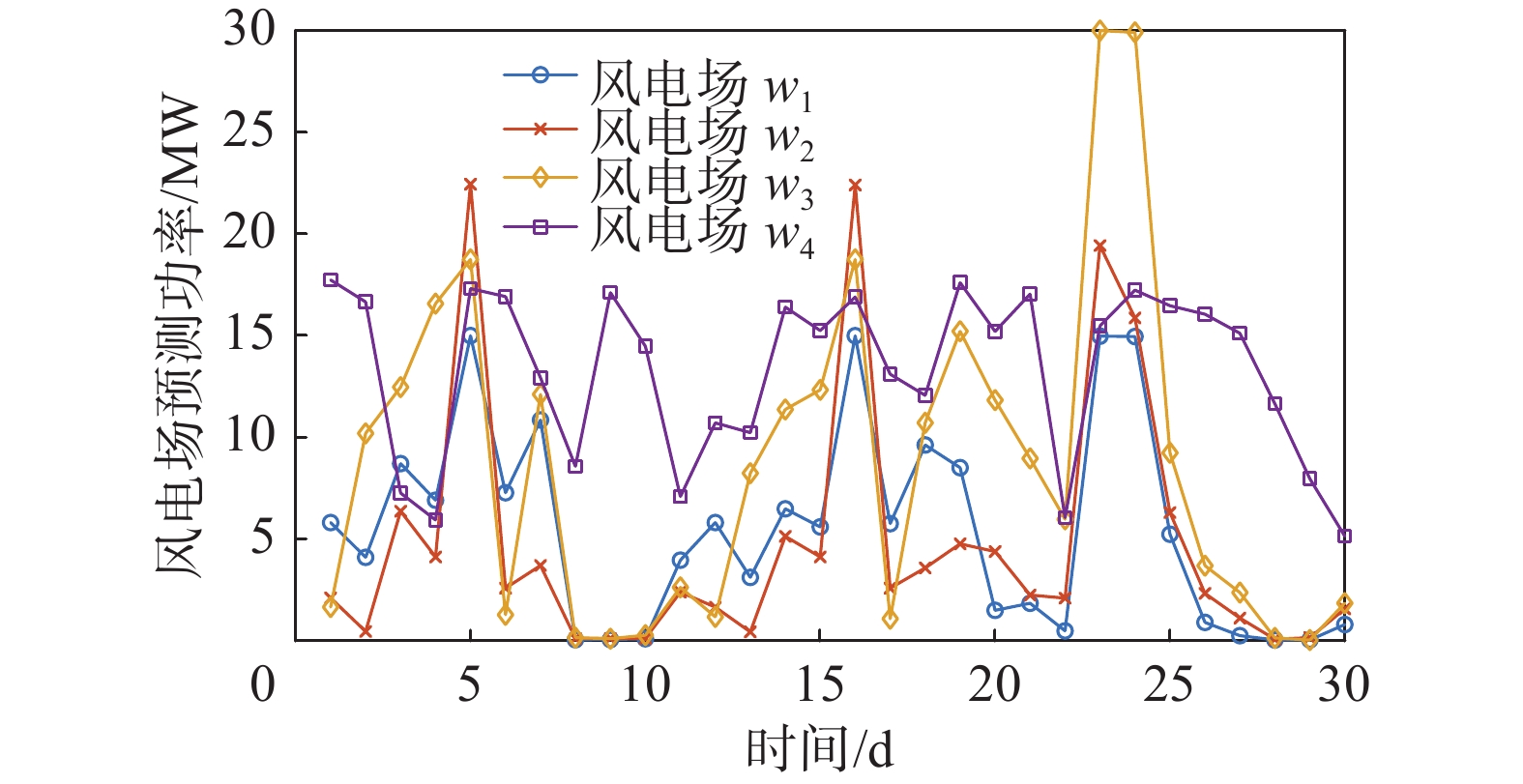

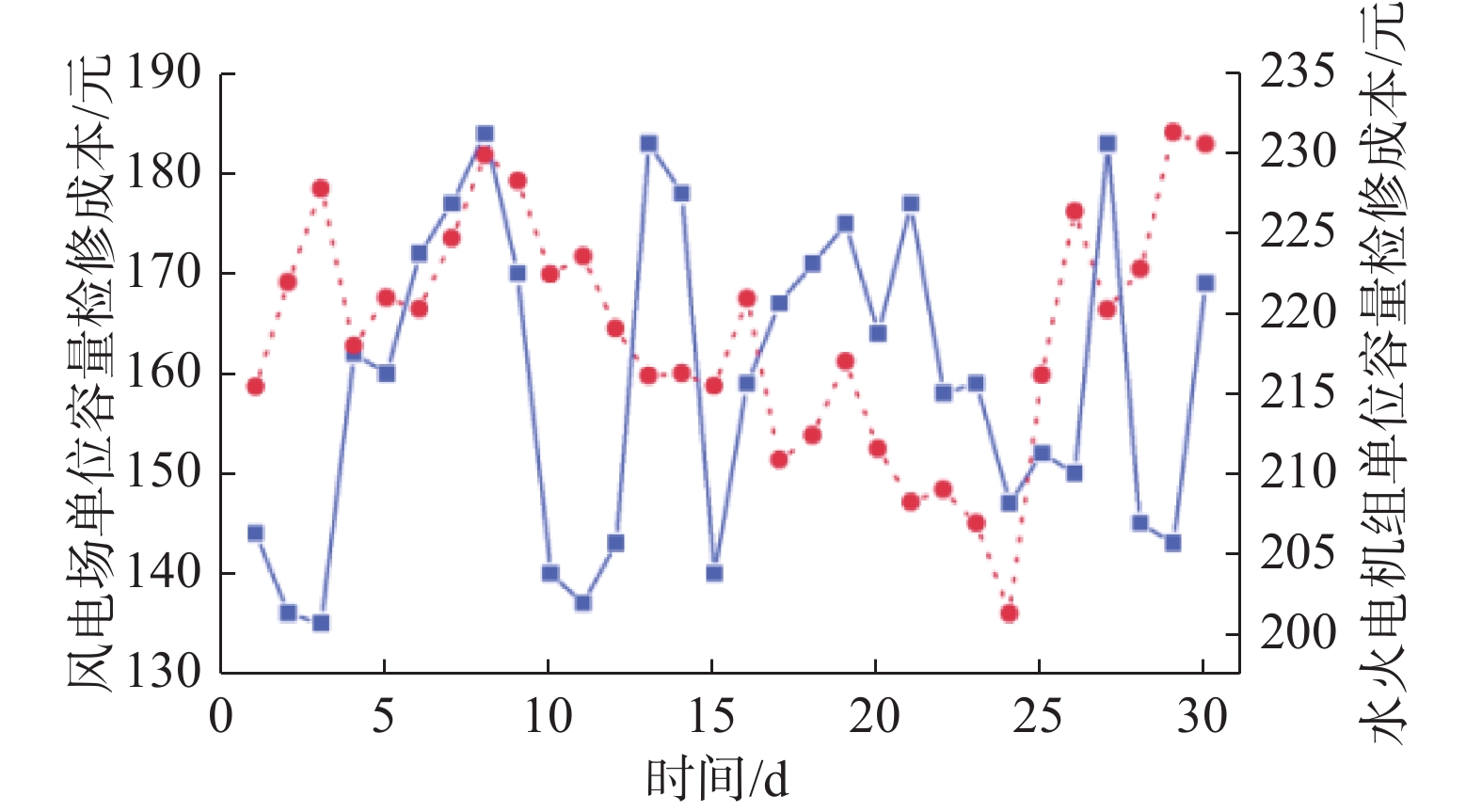

$ {\varpi }_{1}、 {\varpi }_{2}、{\varpi }_{3} $ 均取为1),系统包含30个节点、6台常规水火电机组、41条线路,在5、8、11、27节点接有4座风场。系统拓扑图如图5所示(W为风电,Th为火电,Tm为水电),4座风电场的预测功率曲线如图6所示,日负荷预测曲线如图7所示,以BPA运行数据中各节点负荷数据为基础,等比分配总负荷得到各节点负荷,各机组特性参数和检修工期如表7所示,水火电机组/风电场单位容量的检修费用曲线如图8所示。所采用的计算机为Inter(R) Core(TM) i7-9700 CPU @ 3.00GHz(8 CPUs)。机组 $ {P_{i,\max }} $/

MW$ {P_{i,\min }} $/

MWc2/

(元·MW−1)c1/

(元·MW−1)c0/

(元·MW−1)检修工期/

di1 80.0 0 0.140 0 14.00 0 10 i2 80.0 0 0.121 7 12.17 0 7 i3 50.0 0 - - - 4 i4 55.0 0 0.058 0 22.60 0 5 i5 30.0 0 0.173 9 20.86 0 3 i6 40.0 0 0.173 9 20.86 0 4 w1 15.0 0 - - - 3 w2 22.5 0 - - - 3 w3 30.0 0 - - - 3 w4 30.0 0 - - - 3 Table 7. Characteristic parameters and maintenance duration of each WTGS

-

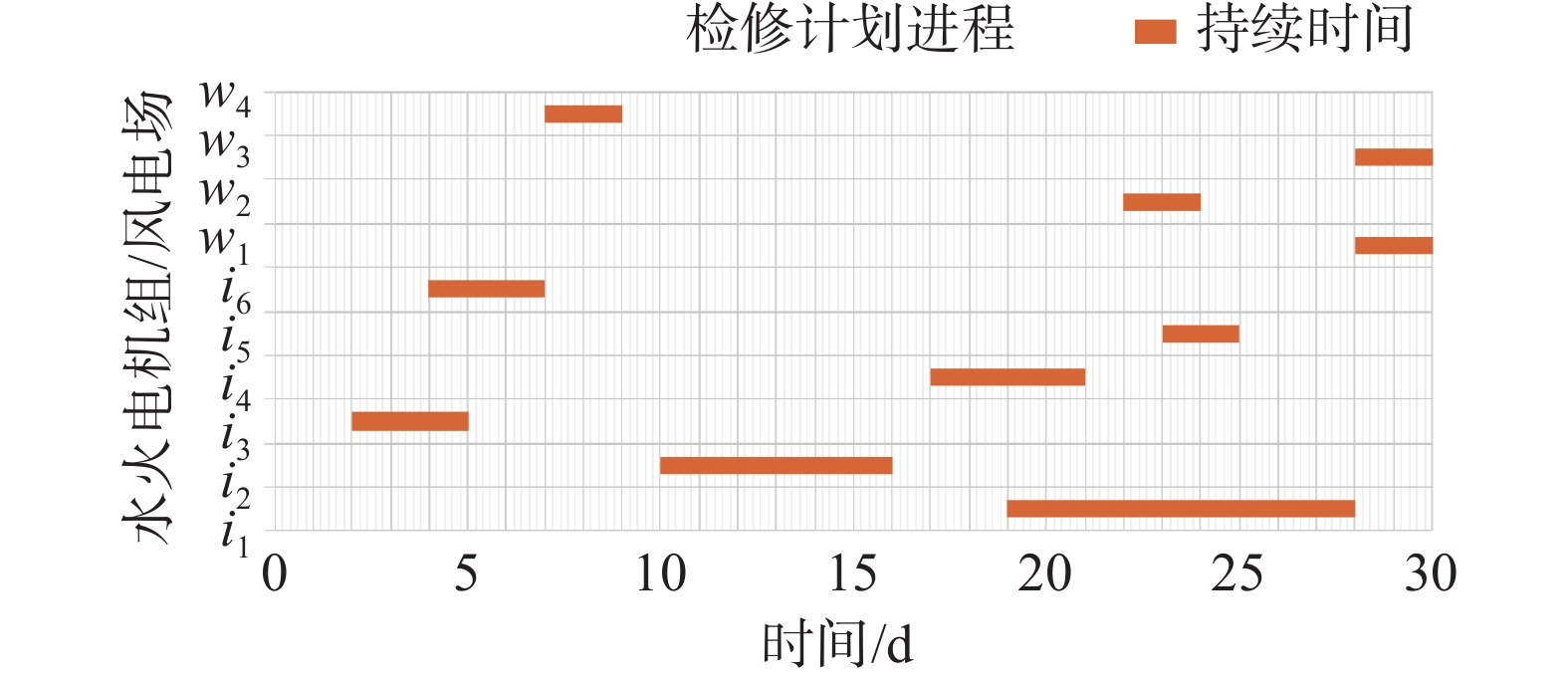

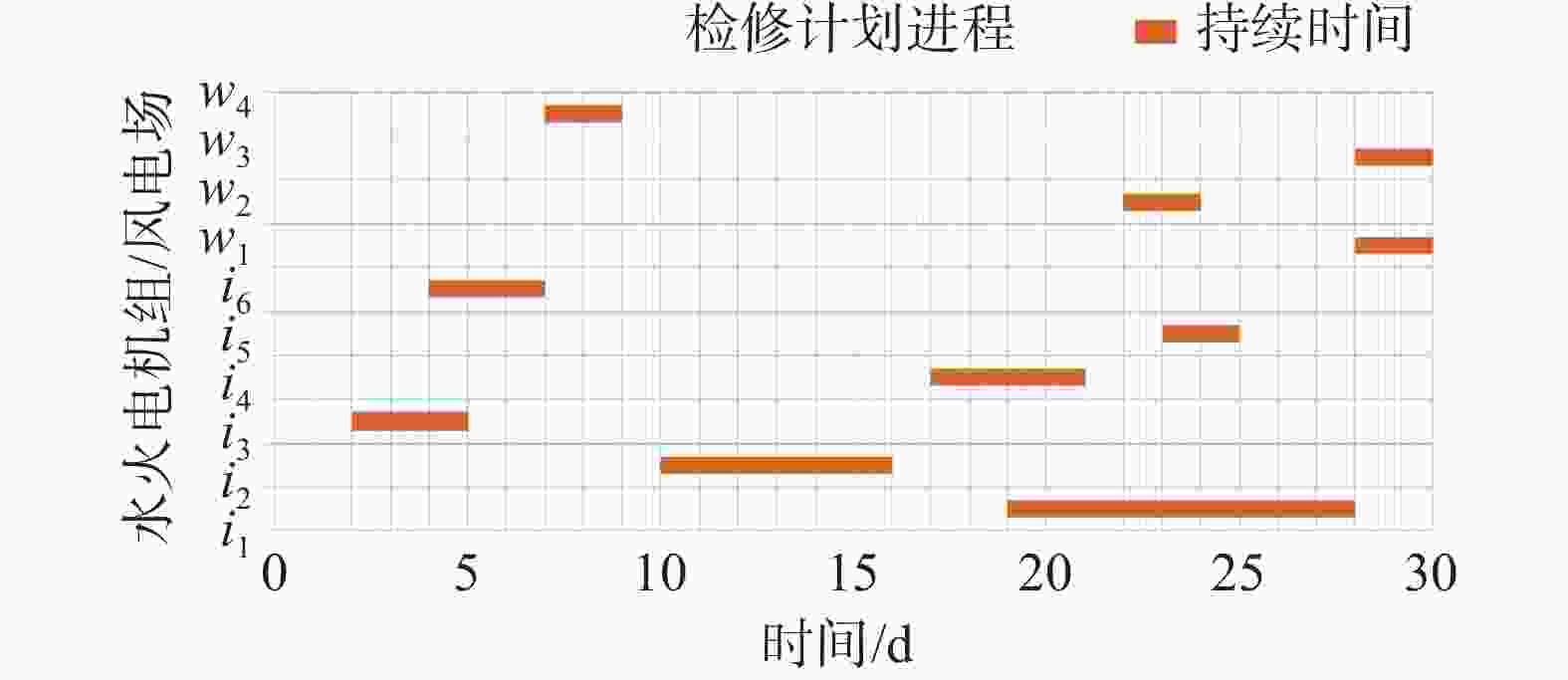

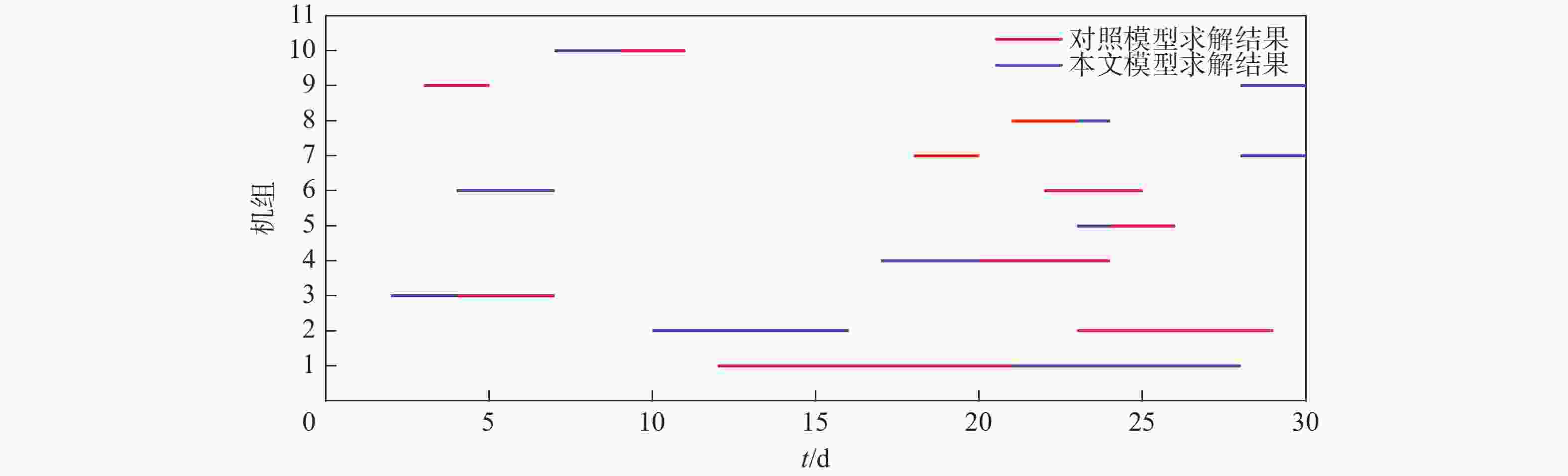

经GAMS仿真计算,规划周期内优化的各风电场检修安排如表8所示,各机组检修优化决策结果如图9所示。

风电场 开始时间/d 持续时间/d 结束时间/d 检修容量/MW w1 28 3 30 6.0 w2 22 3 25 13.5 w3 28 3 20 16.5 w4 7 3 9 22.5 Table 8. Maintenance arrangement of each wind farm within the planning period

由上述图表可知,风电场大都安排在月末检修,此时段处于负荷低谷期、单位容量检修费用较低时段,此检修安排兼顾系统运行稳定性与经济性。大部分水火电机组的检修安排在中下旬(D15~D25),此时段负荷需求呈现大幅度下降的趋势,如此可保证负荷高峰期内大部分机组处于持续运行状态,满足系统备用需求。整个规划周期内,实现了风水火的协同检修、错峰检修,保障了机组出力平稳,有力地促进系统“等备用运行”。

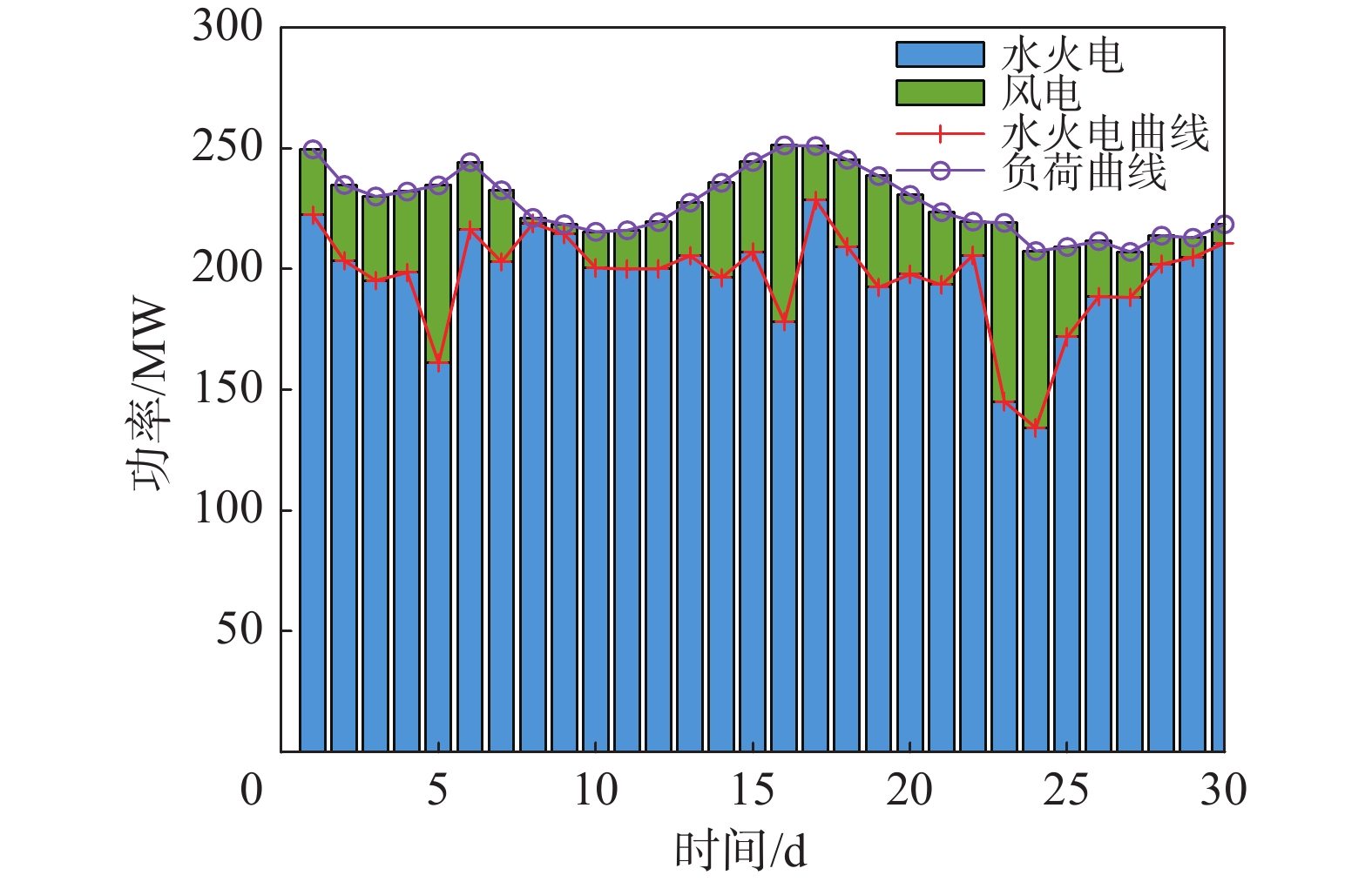

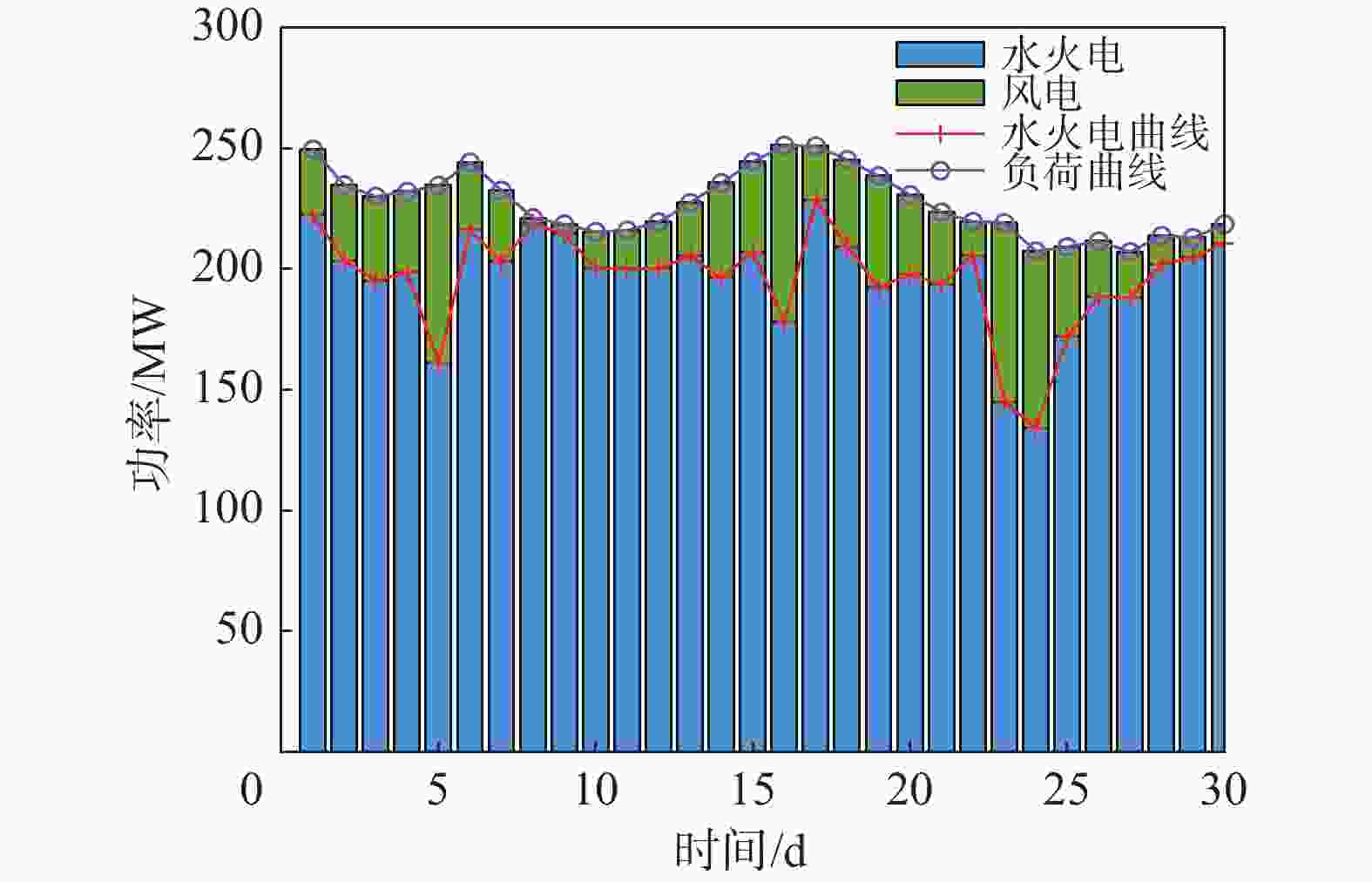

检修优化过程中,系统的水火电出力、风电出力随时间的变化曲线如图10所示。

由图10可知,水火电出力曲线与负荷曲线的变化趋势较为相近,负荷高峰期即水火电机组出力充裕时期。D5、D15、D24前后,受限于部分水火电机组的检修,呈现水火电出力欠缺、风电出力充足的运行特性。月末,风电场内部分机组需要检修,风电出力不足,此时段负荷需求几乎由水火电供给。整体上,各机组出力变化特性反映了优化模型对机组检修和系统运行的有效协同。

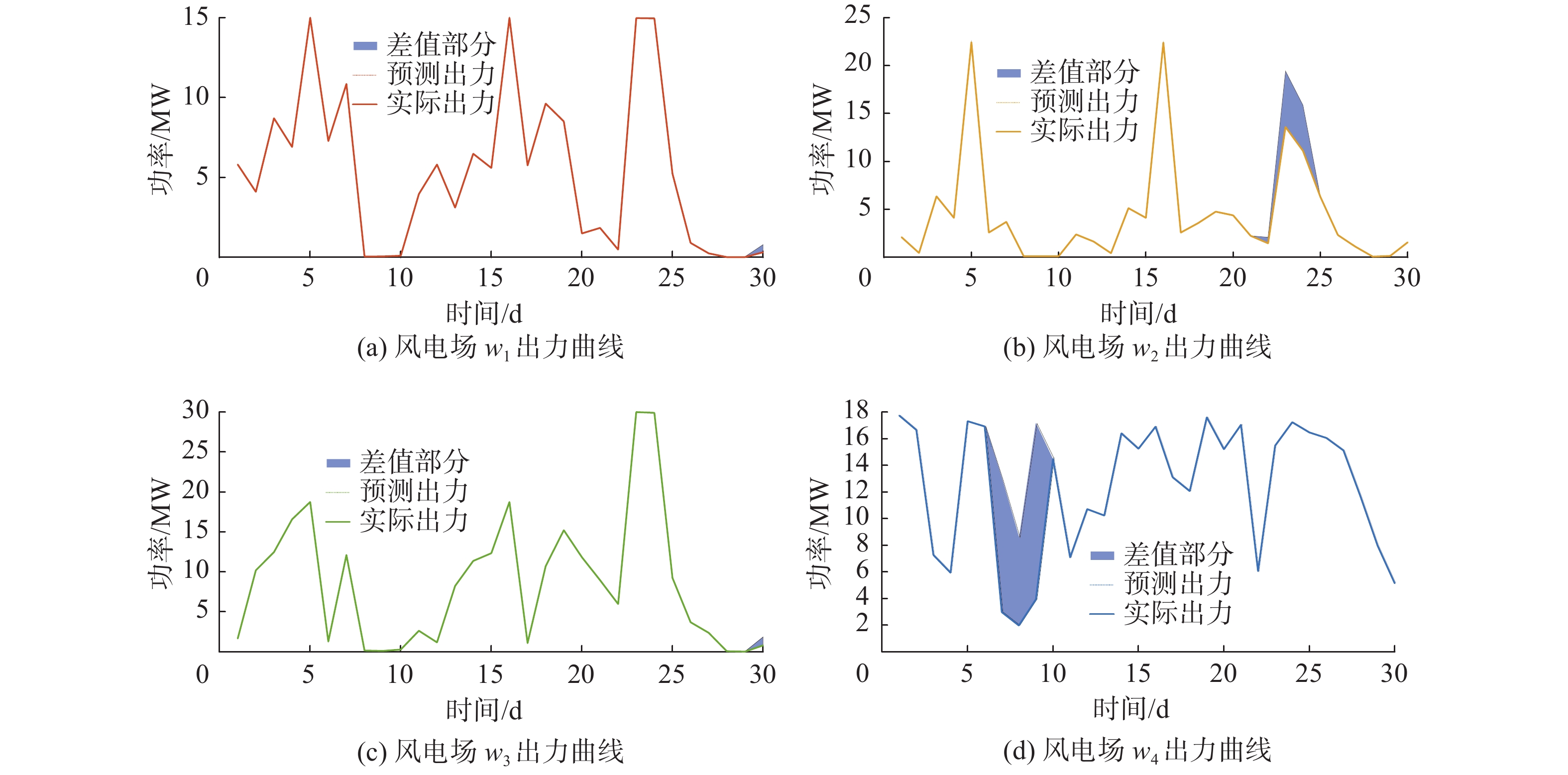

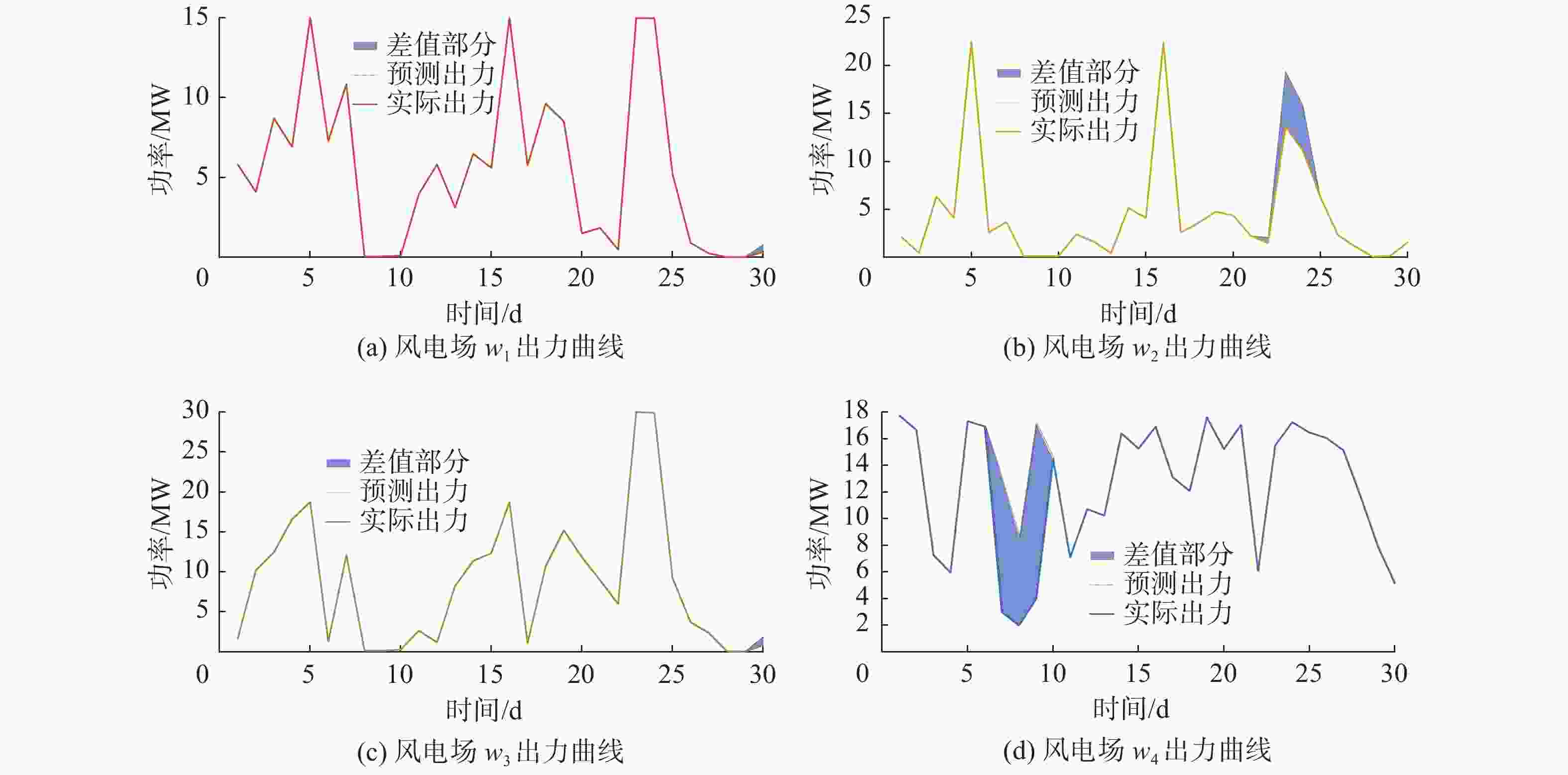

具体地,各风电场的出力曲线如图11所示,差值部分表征检修引起的出力缺额,各缺额时段对应检修区间。w1、w3检修工期内风电出力较低,出力缺额较少,检修对整个风电场出力的影响较小;w4检修工期内出力较高、检修容量最大,此时出力缺额最多,检修对出力的影响最为显著。综合分析,检修计划的优化充分考虑了风电场出力特性,符合将检修安排在出力低谷时段这一现实要求。

-

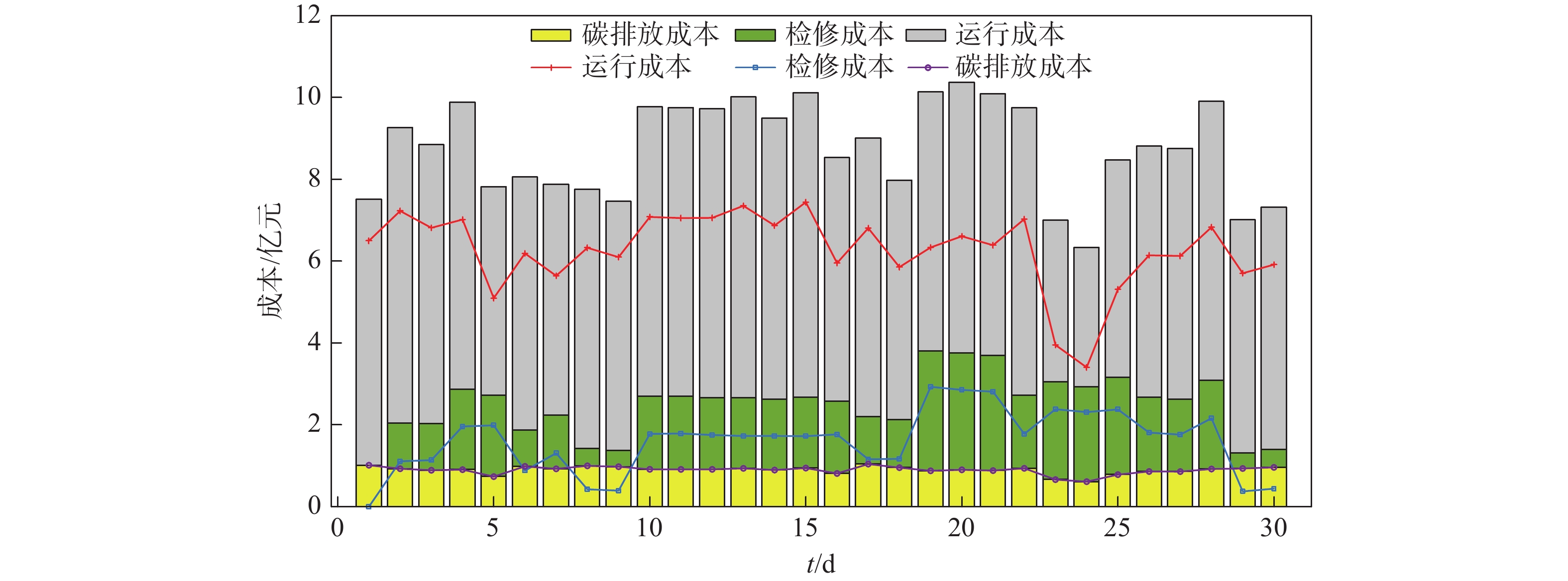

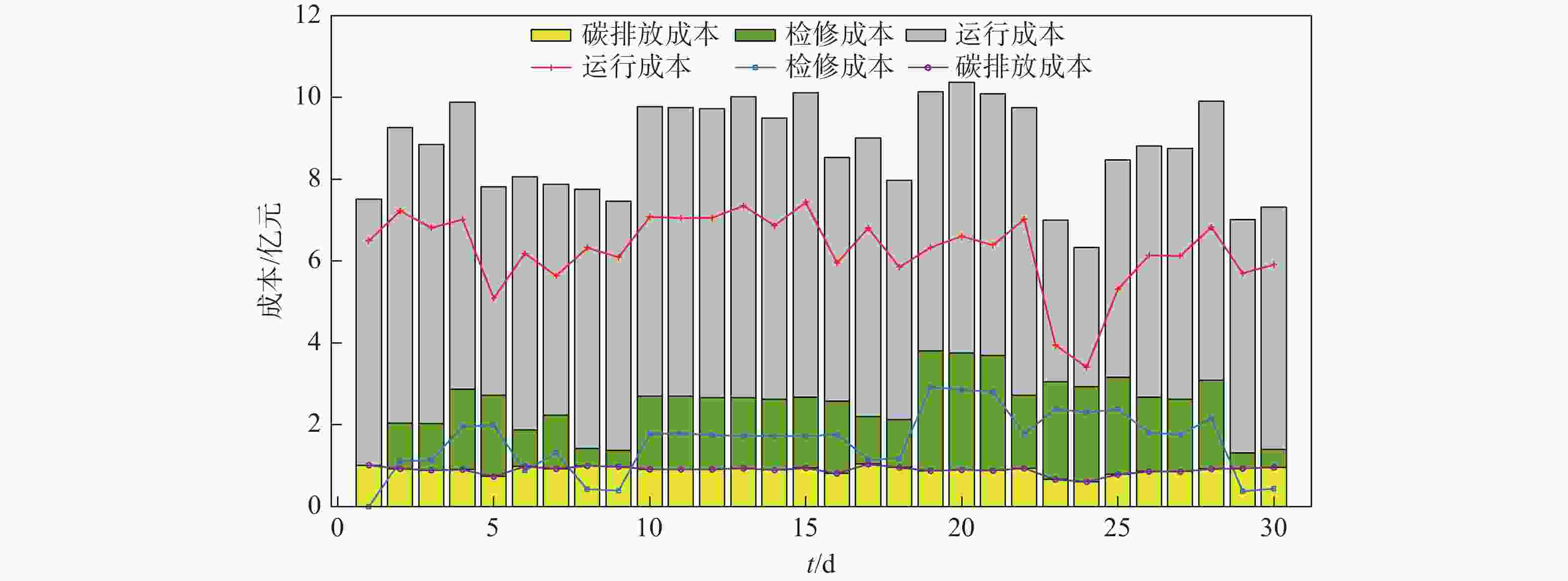

整个优化过程中,各成本变化曲线如图12所示。运行成本与火电出力紧密相关,两曲线呈现相同的变化趋势。D19~D22内检修成本曲线处于峰部,分析可知,此时容量较大的机组i1和i4处于检修状态。碳排放成本曲线较为平滑缓和,表明规划期内火电机组出力保持平稳。

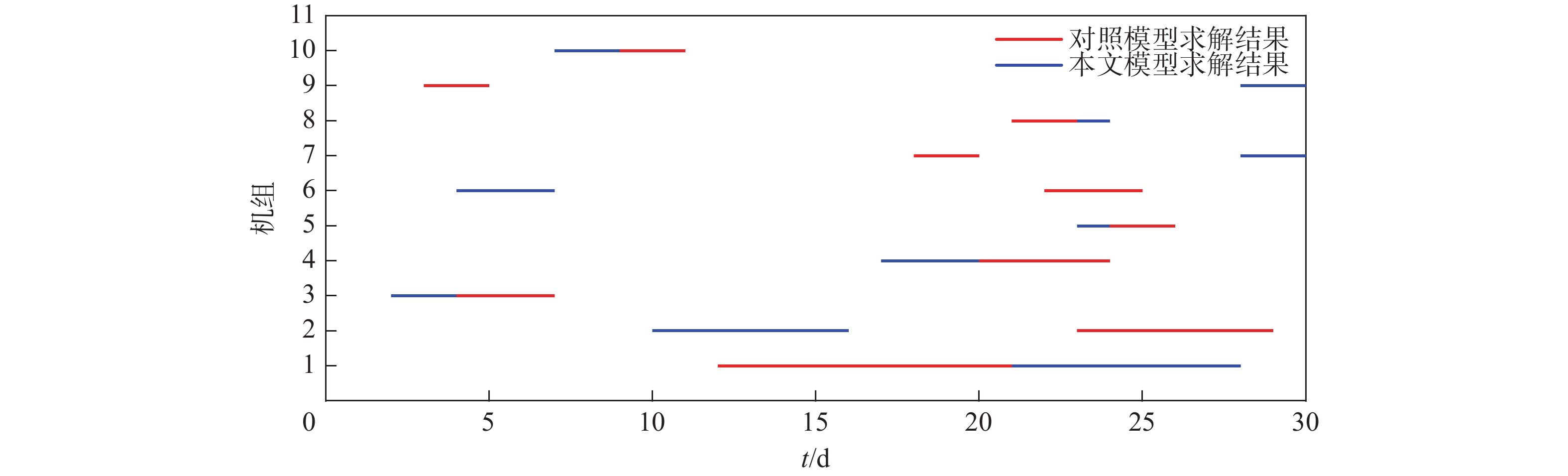

文献[43]模型在检修优化时忽略了对低碳的要求,为方便阐述,称文献[43]模型为“对照模型”。为验证本文模型的优越性,应用本文算例求解两模型,两模型求解检修区间对比图如图13所示,得到的各项子结果如表9所示。

参数 优化模型 对照模型 对比 总成本/元 2 628 384 2 629 746 −0.05% 碳排放成本/元 268 731.3 269 106 −0.14% 运行成本/元 1 881 674 1 892 588 −0.58% 检修成本/元 477 979 468 052.1 2.12% 水火电检修成本/元 450 653.2 447 661.8 0.67% 风电检修成本/元 27 325.8 20 390.33 34.01% 水火电出力/MW 5 893.229 5 901.448 −0.14% 风电出力/MW 922.654 2 914.435 9 0.90% Table 9. Comparison of solution results of different models

由表9可知,相比于对照模型,优化模型在目标函数中考虑了碳排放成本,求解得到的水火电出力、和碳排放成本均降低0.14%,运行成本降低15.8%,而风电出力增加0.9%,表明优化模型以促进风电出力来平抑水火电出力变化的影响。优化模型求解的检修区间内风机出力较小,有利于风电消纳、降低水火电出力,但此时段单位检修容量成本和检修容量值均更高(见图8),故总检修成本有所增加,由于优化模型优化的是3个子目标的加权求和,系统总成本降低0.05%,增加的检修成本得到有效补偿,表明优化模型以牺牲检修成本满足对经济效益的追求。对比各项指标,优化模型在改善风电出力、助力低碳、降低成本方面整体上优于对照模型,即优化模型在合理安排检修计划的同时,实现了系统的低碳、经济运行,为“双碳”战略下风水火的联合低碳检修优化提供有力支撑。

-

本文计及多属性气象因子,建立基于CHMM的风电场检修容量跟踪模型。以跟踪模型求解结果为边界,以低碳、经济运行为优化目标,统筹考虑机组运行特性、检修控制约束等,建立风水火联合低碳检修优化模型,通过IEEE30节点系统进行验证,得到以下结论:

1)本文充分计及多属性气象因子对风机检修的影响,制定合理的检修容量配置方案,为优化模型提供契合现实的数据。

2)本文兼顾多属性气象因子和系统运行优化的共同作用,风电场的检修大都被安排在出力低谷期,有力地促进了风电消纳。

3)本文模型综合考虑系统运行特性和低碳目标,实现了风水火协同检修、错峰检修,有效平抑机组出力波动性,助力系统平稳运行。

4)与对照模型相比,本文模型的优化程度更佳,更好地实现了“双碳”目标下的低碳检修和经济运行。

但本文也存在一些不足,受制于系统内风机性能、算例规模,模型的优化空间有限,下一步将完善模型,计及多类型电源,实现多场景下的机组联合低碳检修优化。

Wind Power, Hydropower and Thermal Power Combined Low-Carbon Maintenance Optimization Based on Continuous Hidden Markov Model

doi: 10.16516/j.gedi.issn2095-8676.2023.04.005

- Received Date: 2022-12-08

- Rev Recd Date: 2023-02-06

- Available Online: 2023-05-26

- Publish Date: 2023-07-10

-

Key words:

- wind power operation and maintenance /

- continuous hidden Markov /

- wind power hydropower and thermal power combined /

- low-carbon maintenance /

- economic benefit

Abstract:

| Citation: | HE Zhichun, XIE Min, HUANG Ying, LI Yisheng, ZHANG Shiping. Wind Power, Hydropower and Thermal Power Combined Low-Carbon Maintenance Optimization Based on Continuous Hidden Markov Model[J]. SOUTHERN ENERGY CONSTRUCTION, 2023, 10(4): 43-56. doi: 10.16516/j.gedi.issn2095-8676.2023.04.005 |

DownLoad:

DownLoad: