-

目前,海上风电工程中,风电机组最常用的基础结构是桩基础,桩体通常采用开口钢管桩。与其他类型的桩基础形式相比,开口钢管桩具有桩身强度高、承载能力大、抗弯性能好的优点,设计参数灵活,厂内预制方便,质量可靠,可根据工程实际要求设计成不同的桩长、桩径和壁厚。开口钢管桩对一般的黏土、砂土等地质具有良好的贯入能力,挤土效应弱,施工效率高[1]。

导管架风机基础是一种桩式基础结构,由钢质空间框架和钢管桩组成,适用于水深较大的海上风电场,且具有结构刚度大、抗弯承载力强、抗疲劳性能好等优点[2]。

随着海上风电建设向深水化、大型化方向发展,导管架风机基础将越来越多地被采用。同时,导管架风机基础也可以降低对大型海工装备的依赖,节约工程造价,降低海上施工风险,减少对海洋环境的污染。因此,导管架风机基础在海上风电项目中具有广阔的应用前景[3-4]。

目前,采用大直径短桩的导管架基础在国内已有所运用,但其目前仍较为接近弹性桩状态,随着海上风电发展,尤其在福建、广东等海域,存在着水深大,荷载大,覆盖层浅的建设条件制约,在这样的条件下大直径短桩导管架存在较大的运用空间。较导管架吸力筒,大直径短桩的导管架基础不依靠负压下沉,对负压贯入难度大的地质条件有较强的适用性,且能确保沉桩到位。通常导管架基础桩径采用3m直径以内小桩,而较常规小桩导管架,大直径短桩导管架适用于覆盖层更浅的地质条件[5]。

海洋岩土勘察中常用的原位测试方法有标准贯入试验(SPT)和孔压静力触探试验(CPTU)。相比于SPT,CPTU可以提高海上风电勘察的效率和质量,降低勘察成本。CPTU可以在动态定位的大型综合勘探船或固定平台上实施,利用海洋勘察窗口期进行连续作业,其贯入速度和深度都高于SPT[6]。CPTU可以减少钻孔取样的数量和深度,降低扰动和污染的风险[7-8]。

采用基于CPTU原位测试的桩基承载力计算方法能够更加快速、准确的评估桩基承载力。通常来说静载试验是单桩竖向极限承载力最为可靠的确定的方法,但静载试验难度大、成本高。实际工程中通常采用高应变数据反分析计算修正系数,然后建立贯入阻力与桩侧摩阻力、桩端阻力的经验关系式。CPTU可以在现场连续、快速、精确测得各土层的贯入阻力指标。采用CPTU测试数据可提高计算单桩竖向承载力的准确性和可靠性,以便可直接供工程设计使用,有利于后续基础结构方案优化设计[9]。

-

广东某海上风电场工程场址位于阳江市阳西县沙扒镇附近海域,水深23~32 m。两期场址面积共计87.9 km2,离岸距离约20 km,整个场址内覆盖层均较浅,岩面为10~50 m埋深。

-

本论文研究针对的场址A大直径桩基导管架应用台数为12台,场址B大直径桩基导管架应用台数为14台,本研究以其中4台典型机位为目标对象,采用CPTU计算方法、桩基规范计算公式及高应变检测数据,对比桩基抗压承载力,分析理论公式与实际的差异,并形成应用分析结论。工程风场导管架大直径桩基施工实景如图1所示。

-

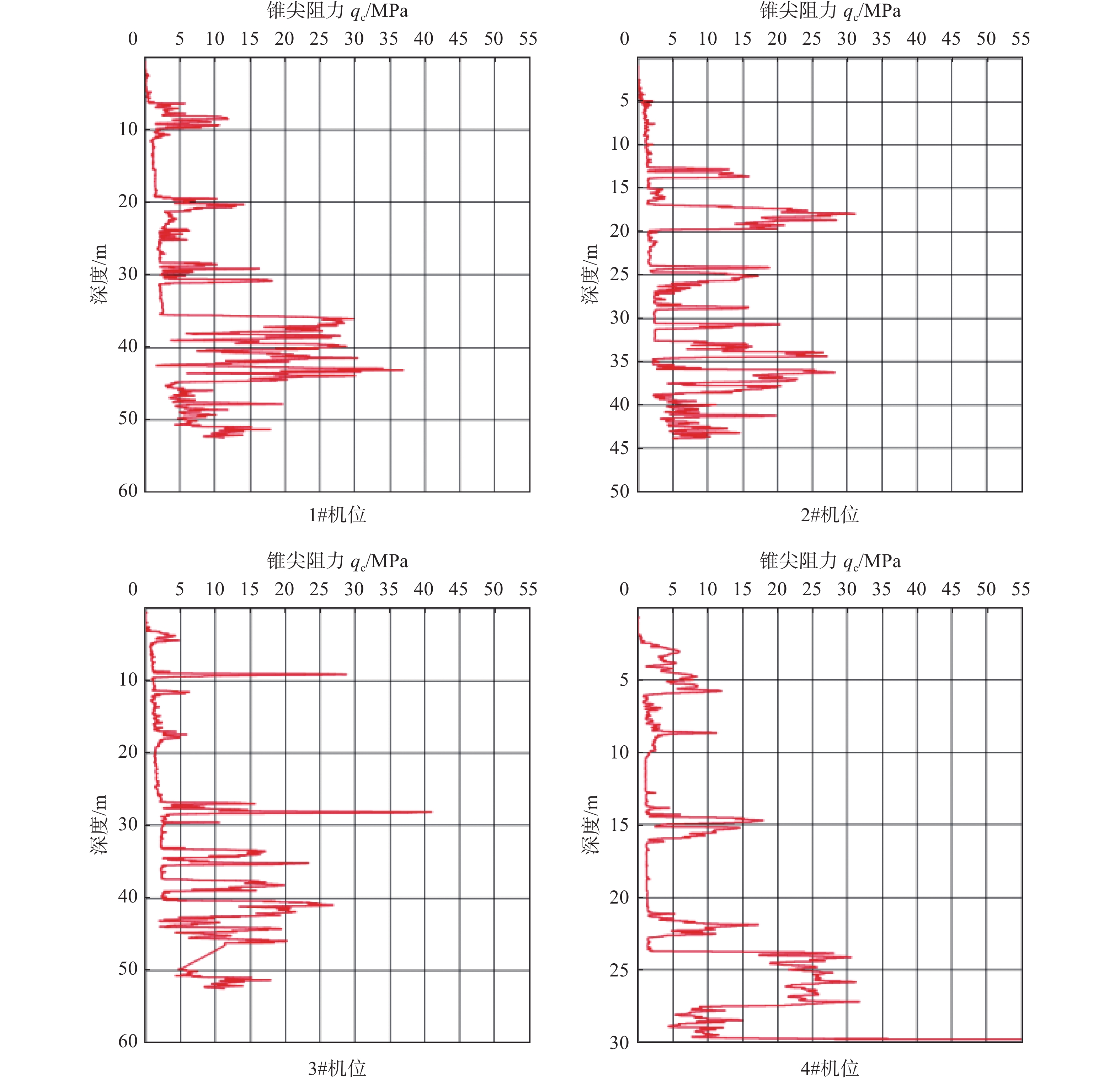

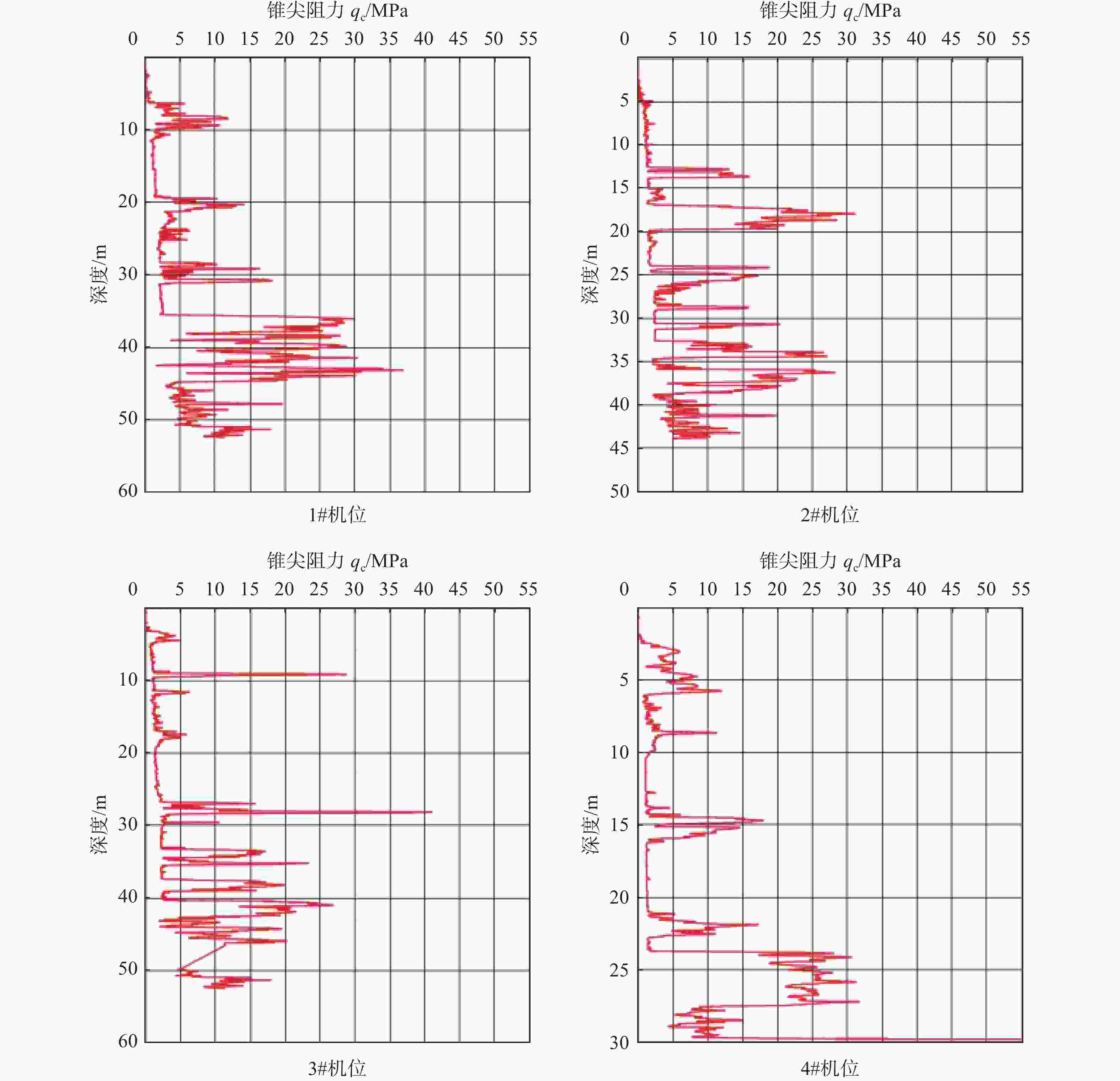

研究机位的土壤静探锥尖阻力曲线如图2所示,其中1#~3#机位采用3.5 m桩径,覆盖层深度约50 m,4#机位采用5 m桩径,覆盖层深度约为30 m,整体地质分层为表层为淤泥,以下为黏土与中粗砂的互层,中风化岩面以上为强风化岩及全风化岩。

-

孔压静力触探(CPTU)是一种新型的原位测试技术,它可以连续地测量锥尖阻力qc、侧壁摩阻力fs、孔隙水压力u[10],从而直接确定桩基的承载力。然而,在工程实际应用中,静力触探曲线经常会出现非常陡的“峰”或“谷”,这些异常现象主要与砂层的土性、强度的变化有关。目前,常用的桩基承载力计算方法,如建筑桩基规范法[11]、LCPC 法、欧洲法等,都是在CPTU 出现之前提出的,它们忽略了贯入过程中超孔隙水压力对锥尖阻力和侧壁摩阻力的影响,而且桩侧阻力是由锥尖阻力通过经验系数求得的,没有充分利用CPTU 测得的侧壁摩阻力数据。因此,在应用静力触探进行桩基承载力计算时,原始数据的处理方式及超孔压的产生和消散对桩基承载力的预测影响较大。

目前,国内外学者提出了诸多基于 CPTU 测试的桩基承载力计算公式,API RP 2GEO 规范[12]《Geotechnical and Foundation Design Considerations》中推荐的4种方法,并对相应公式进行了适当简化,即 ICP-05 方法[13]、UWA-05 方法[14-15]、NGI-05 方法[16]、Fugro-05 [17]方法,被认为是目前在海洋桩基工程中最为可靠的方法[18]。

其中ICP-05及UWA-05在风电工程的大直径桩基承载力计算中应用较多[19]。UWA-05方法整个框架来源于 ICP-05 方法,本质上是对 ICP -05方法的修改和简化,本文以下计算分析采用UWA-05方法进行承载力分析。

UWA-05方法是由西澳大学(University of Western Australia)提出的一种基于CPTU测试的桩基承载力计算方法,适用于在砂土中施工的开口和闭口钢管桩。该方法综合考虑了以下几个影响桩基承载力的因素:(1)桩安装过程中的土体位移效应;(2)摩阻疲劳;(3)砂-桩界面摩擦角;(4)桩加载过程中径向有效应力的变化;(5)加载方向的影响。其抗压承载力在API规范中采用的简化公式如下:

$$ {Q}_{{\rm{c}}}={Q}_{{\rm{f}},{\rm{c}}}+{Q}_{{\rm{p}}}={\text{π}} D{\displaystyle \int {f}_{{\rm{c}}}({\textit{z}})}d{\textit{z}}+q{A}_{{\rm{p}}} $$ (1) 式中:

Qc ——抗压极限承载力(kN);

Qf, c ——受压状态下桩侧摩阻力提供的承载力(kN);

Qp ——桩端承载力(kN);

fc(z) ——受压状态下桩侧摩阻力,深度z的函数(kPa);

q ——桩端阻力(kPa);

Ap ——桩端截面积(m2),考虑整个端面面积。

对于砂土fc(z)可按下式计算:

$$ {f}_{{\rm{c}}}({\textit{z}})=0.03{q}_{{\rm{c}}}({\textit{z}}){A}_{\text{r}}^{0.3}{\left[\mathrm{max}\left( {\dfrac{L-{\textit{z}}}{D},2} \right)\right]}^{-0.5}\mathrm{tan}{\delta }_{{\rm{cv}}} $$ (2) $$ {A}_{\text{r}}=1-\left( {\dfrac{{D}_{{\rm{i}}}}{D}} \right)^{2} $$ (3) 式中:

qc(z)——锥尖阻力(kPa);

Ar ——桩端环面积与端面积的比值;

Di ——桩身内径(m);

D ——桩身直径(m);

L ——桩入土长度(m);

z ——计算深度(m);

${\delta }_{{\rm{cv}}}$ ——桩土摩擦角(°)。对于黏土可按下式计算:

$$ {f}_{{\rm{c}}}({\textit{z}})={q}_{{\rm{c}}}({\textit{z}})/35 $$ (4) 桩端阻力q可按下式计算:

$$ q = {q_{{\rm{c}},{\rm{av}}1.5D}}(0.15 + 0.45{A_{\rm{r}}}) $$ (5) $$ {q_{{\rm{c}},{\rm{av}}1.5D}} = \int\limits_{L - 1.5D}^{L + 1.5D} {{q_{\rm{c}}}({\textit{z}})} {\rm{d}}{\textit{z}}/(3D) $$ (6) 式中:

${{q}_{{{\rm{c}},{\rm{av}}1}{.5D}}}$ ——桩端上下1.5D范围内的平均锥尖阻力(kPa)。按以上公式计算,研究1#~4#机位抗压承载力计算统计见表1。

序号 桩径/m 总土阻力/kN 桩侧阻力/kN 桩端阻力/kN 1# 3.5 51562 27908 23654 2# 3.5 38399 25290 13109 3# 3.5 50671 32015 18656 4# 5.0 103871 33916 69955 Table 1. The CPTU method calculates the side resistance and the end resistance of the pile foundation

-

高应变动力试桩法是一种通过重锤冲击桩顶,使桩周土发生塑性变形的试验方法。该方法可以在桩顶附近测量力和速度的时程曲线,并利用应力波理论分析桩土体系的相关性质,如单桩极限承载力、土阻力及其分布、桩身完整性等[20]。

工程钢管桩现场高应变测量设置见图3,现场高应变数据采集线缆及设备见图4。

实测曲线拟合法是一种基于实测力和速度信号,或上、下行波曲线,计算土阻力及其分布的数值分析方法。该方法首先设定桩身各层土阻力和其他参数,然后运用波动方程进行拟合计算,得到另一条曲线(如速度或力,下行波、上行波曲线),并与相应的实测曲线进行比较。通过不断调整参数,进行迭代计算,直到达到满意的拟合效果为止。最终确定符合实际桩土体系的各种参数值,并获得桩端阻力和桩周阻力分布。

由于现场1#~3#机位采集为高应变初打数据,4#机位采集数据为10 d后高应变复打数据,考虑到由于复打数据主要反映了沉桩后土体恢复的情况,与设计在位工况承载力更为匹配,因此根据同场址复打(10 d后高应变复打数据)与初打的平均土体恢复系数对比,将1#~3#机位初打数据乘以1.5倍的土体恢复系数,作为本次对比研究的实测依据。

1#~4#机位钢管桩高应变实测总土阻力、桩侧阻力及桩端阻力统计如表2所示。

序号 桩径/m 总土阻力/MN 桩侧阻力/MN 桩端阻力/MN 1 3.5 26.758 22.431 4.327 2 3.5 26.782 22.323 4.459 3 3.5 34.510 31.646 2.864 4 5.0 43.398 32.751 10.647 Table 2. Analysis of side resistance and end resistance of pile foundation with high strain measured on site

-

考虑到桩基承载力主要分为侧阻及端阻两部分,本研究将侧阻及端阻拆分对比进行研究[21]。

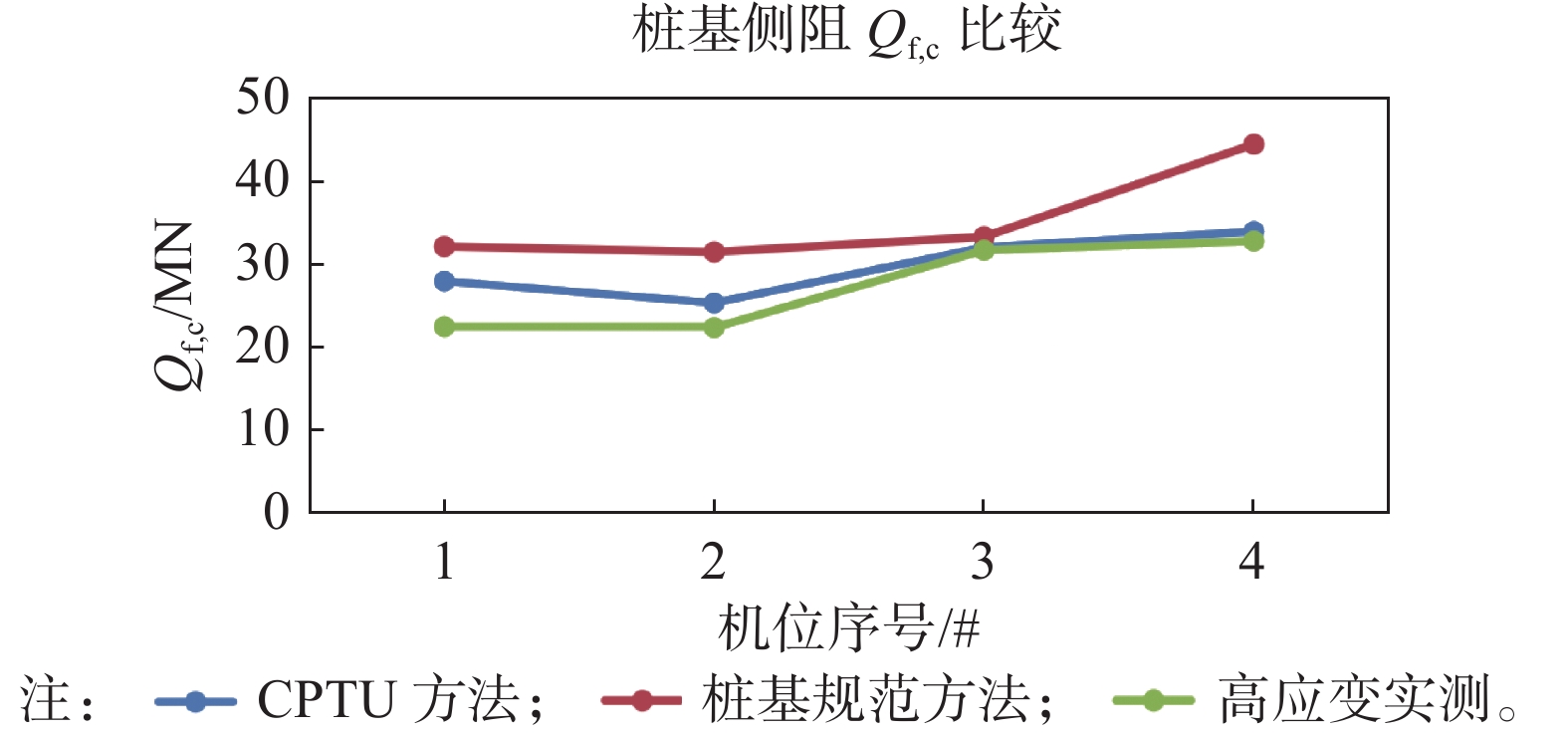

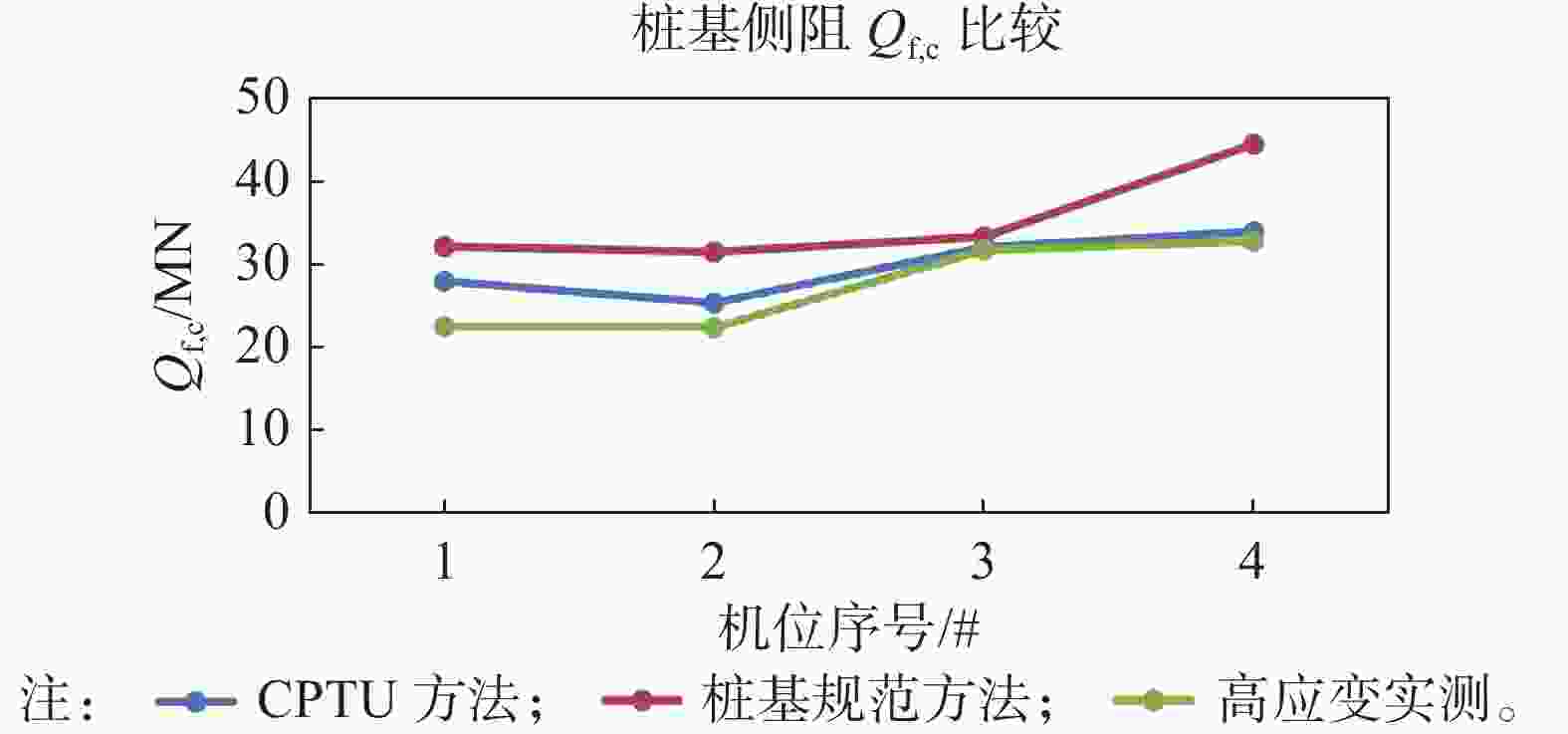

对于侧阻,结合CPTU方法计算结果与高应变实测结果进行了对比,考虑到国内常用水运工程桩基设计规范[22]公式计算桩基承载力,将该方法也纳入了对比。从图5的对比情况可见,在侧阻计算方面,无论CPTU方法计算结果还是桩基规范计算结果,均高于高应变实测值,分析原因主要是因为大直径桩挤土效应相对较弱,侧阻较原小桩有所折减,而目前国内外规范的研究,主要还是基于小直径长桩。两种方法进行对比,总体CPTU与实测数据拟合较好,而桩基规范相对偏离更大。

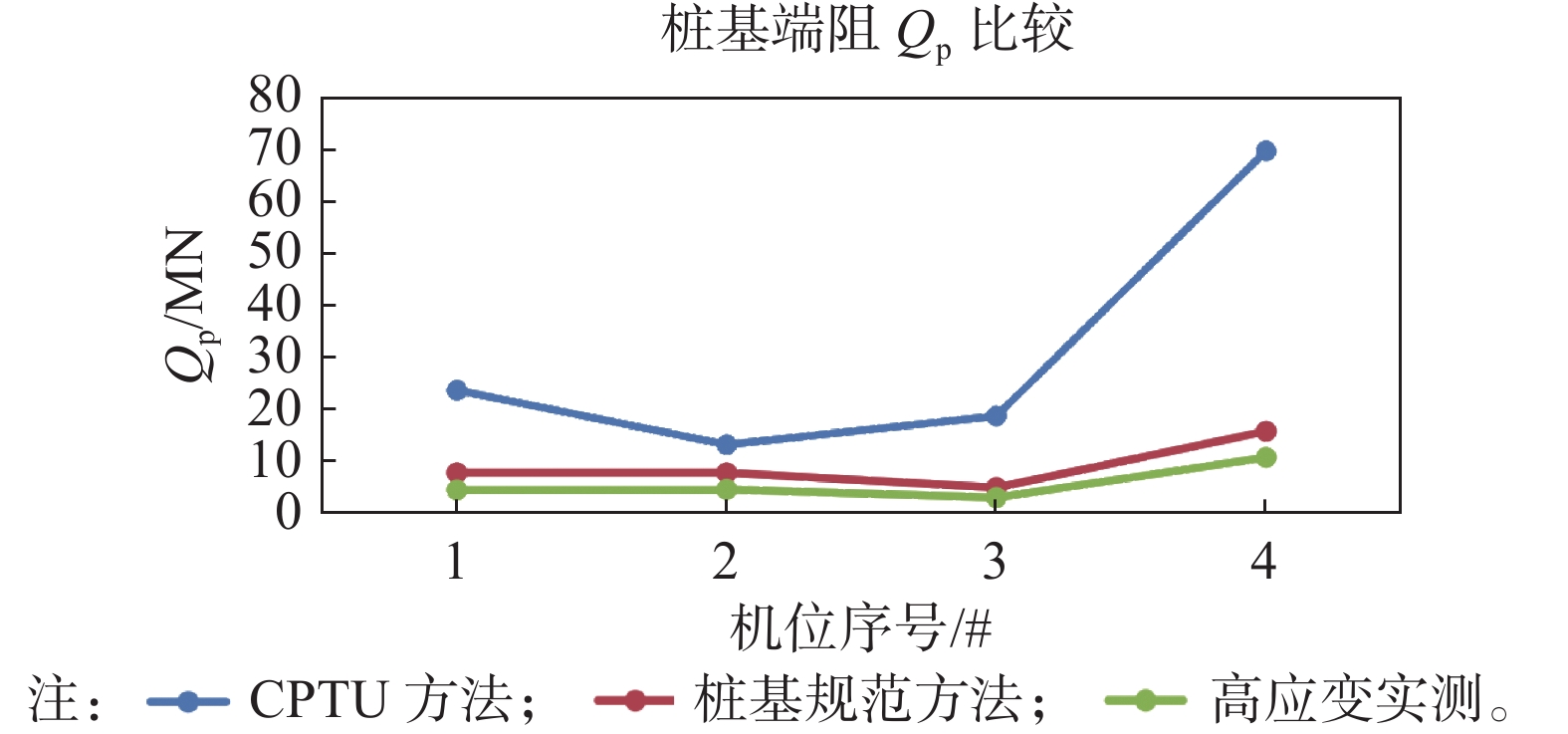

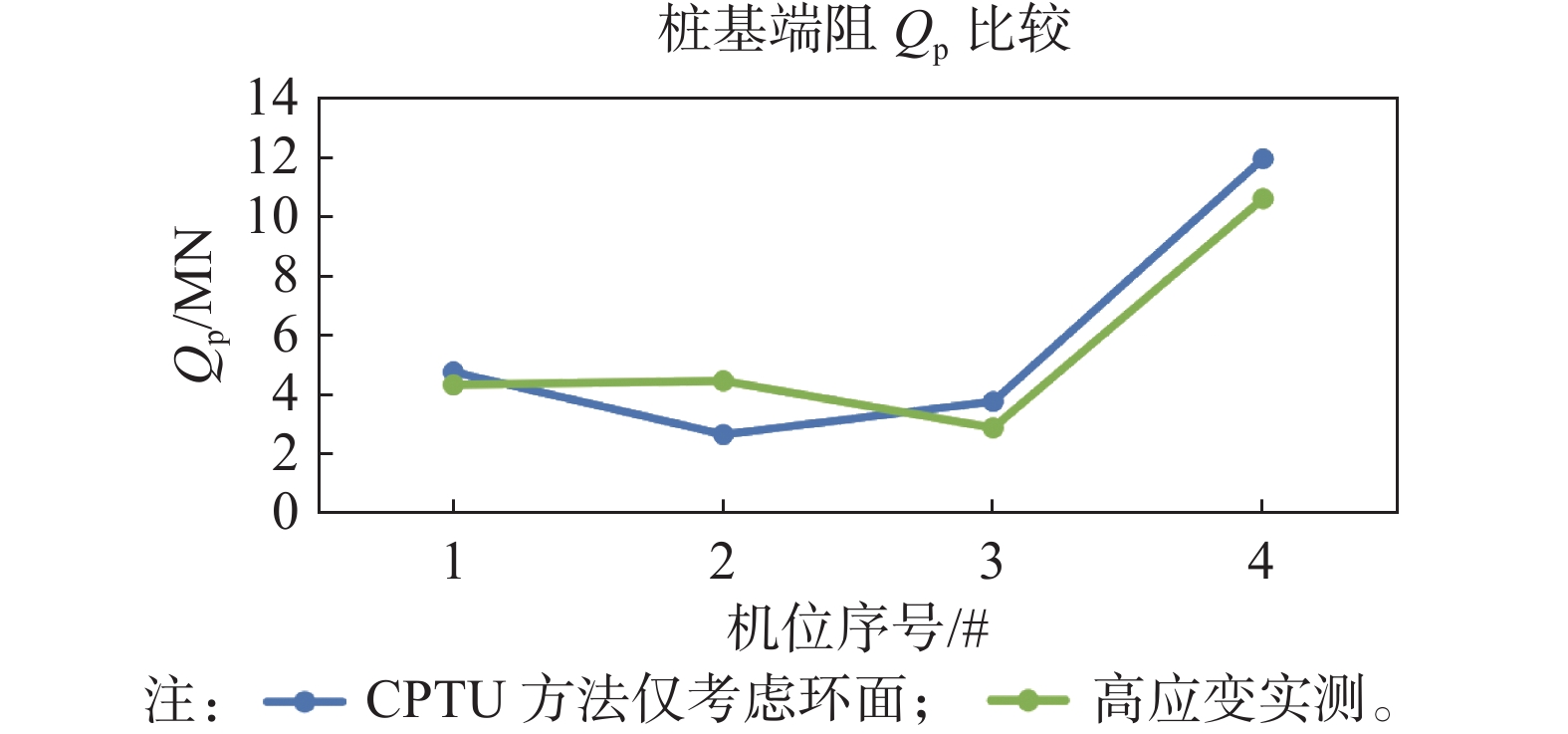

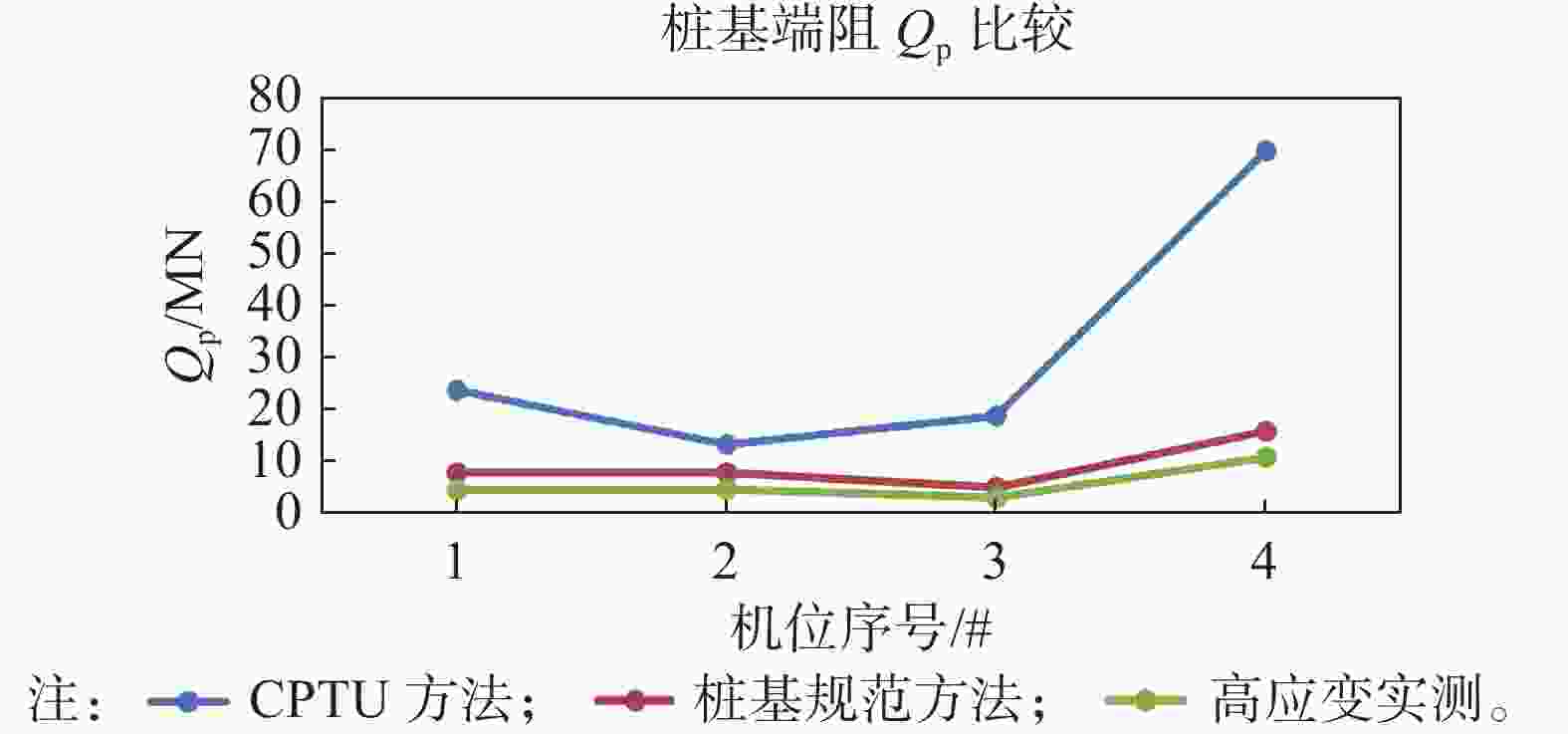

对于端阻,同样结合CPTU方法计算结果、桩基规范计算结果与高应变实测结果进行了对比,对比结果如图6所示,可以发现,由于大直径短桩在沉桩后基本不形成土塞,导致CPTU方法计算结果、桩基规范计算结果均高于实测值,其中桩基规范计算结果相对差异较小,但从绝对值差异方面分析,直接采用该两种方法计算桩基端阻均不合适。

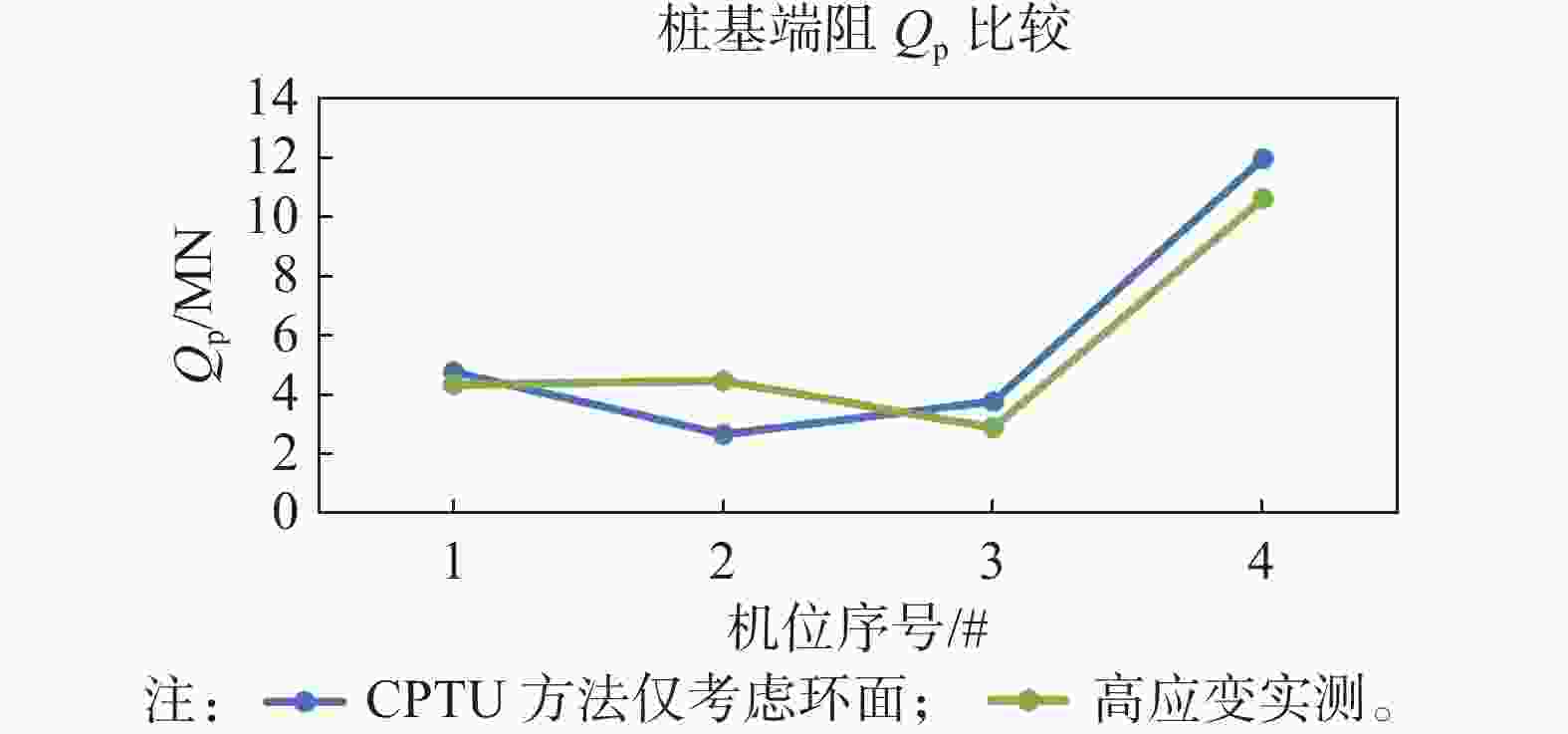

考虑到UWA-05方法中,端阻计算考虑整个桩端面积,在后续拟合中将该值改为桩端环面面积,而q值计算中的Ar为桩端环面积与端面积的比值,将该值调整为1,最终计算结果与高应变实测值拟合结果如图7所示,总体拟合情况较好。由对比结果可知,采用CPTU方法计算桩端阻力时,由于大直径桩很难形成有效土塞,仅考虑桩端环面贡献部分较为合适。

综合考虑以上分析结果,采用CPTU方法计算导管架大直径短桩承载力侧阻可靠性较高,但在计算端阻时,建议结合地区经验关注土塞是否形成,由于导管架大直径短桩难以形成有效土塞,从设计保守考虑建议不考虑土塞。

-

本文针对导管架大直径短桩承载力CPTU方法开展了应用分析研究,研究形成的主要结论如下:

1)CPTU作为原位的地勘手段,对土体扰动小,采用CPTU手段进行承载力复核为今后海上风电承载力计算的趋势。

2)采用CPTU方法中的UWA-05方法计算导管架大直径短桩桩身侧阻时,与实测数据拟合度较好。

3)导管架大直径短桩难以形成有效土塞,在采用CPTU方法计算端阻时,建议仅考虑端部环面积。

4)由于本研究仅针对单个风场进行拟合分析,实际在采用CPTU方法进行计算取值时建议结合试桩数据进行分析。

Application Analysis of CPTU Method for Jacket Large Diameter Short Pile Axial Bearing Capacity

doi: 10.16516/j.gedi.issn2095-8676.2023.04.020

- Received Date: 2023-06-12

- Rev Recd Date: 2023-06-28

- Available Online: 2023-07-25

- Publish Date: 2023-07-10

-

Key words:

- large diameter pile /

- bearing capacity /

- static touch probe /

- jacket /

- offshore wind power

Abstract:

| Citation: | WANG Liji. Application Analysis of CPTU Method for Jacket Large Diameter Short Pile Axial Bearing Capacity[J]. SOUTHERN ENERGY CONSTRUCTION, 2023, 10(4): 193-199. doi: 10.16516/j.gedi.issn2095-8676.2023.04.020 |

DownLoad:

DownLoad: