-

海缆损坏大多是由于渔业活动、航运活动、海洋工程作业等人为因素造成的。为降低海缆损坏的风险,通常认为最经济、最有效的海缆保护方式是进行埋设保护。近年来,随着海洋经济的发展,海上工程活动的增加[1-2],国内外许多专家学者在海底电缆保护及埋深方面做了大量研究工作[3-5]。目前的方法大体上分成4类:(1)经验法;(2)概率法模型;(3)能量法力学模型;(4)试验及数值模拟法。其中,文献[6]基于经验要求:水下电缆不得悬空于水中,浅水区埋深不宜小于0.5 m,深水航道区埋深不宜小于2 m。文献[7]利用能量法利用简单的物理模型,理论分析锚的整个下落过程的运动状态,计算出锚的海底入土深度。文献[8]针对常用的大抓力锚,基于砂土和黏土中的室内模型试验,开展了不同土质条件中的下落深度研究。文献[9]基于太沙基极限承载力公式,运用能量法通过建立船锚落深的理论算法,并通过最小二乘法拟合试验数据,得出计算船锚刺入砂土深度。文献[10]基于模型试验和数值模拟的方法分析拖锚过程中船锚的啮土轨迹,提出船锚啮土深度与影响范围的理论计算方法。文献[11]描述锚泊作业的不同情况,基于概率分析,提出了锚与锚链撞击管道的概率及撞击能量的计算公式。文献[12-14]总结出各个国家和地区对海底管线挖埋深度的要求。但目前各行各业对海底电缆及管线的埋深都没有一个明确的方法,不同行业不同设计院对电缆及管线埋深设计的理解也不尽相同。

本文将在文献[7]基础上,基于能量法推导船锚垂直撞击海底入土深度的简化数学模型,并与实测数据对比探讨该数学模型在不同抗剪强度的海底基质、不同水深情况下的适用性及适用范围。

-

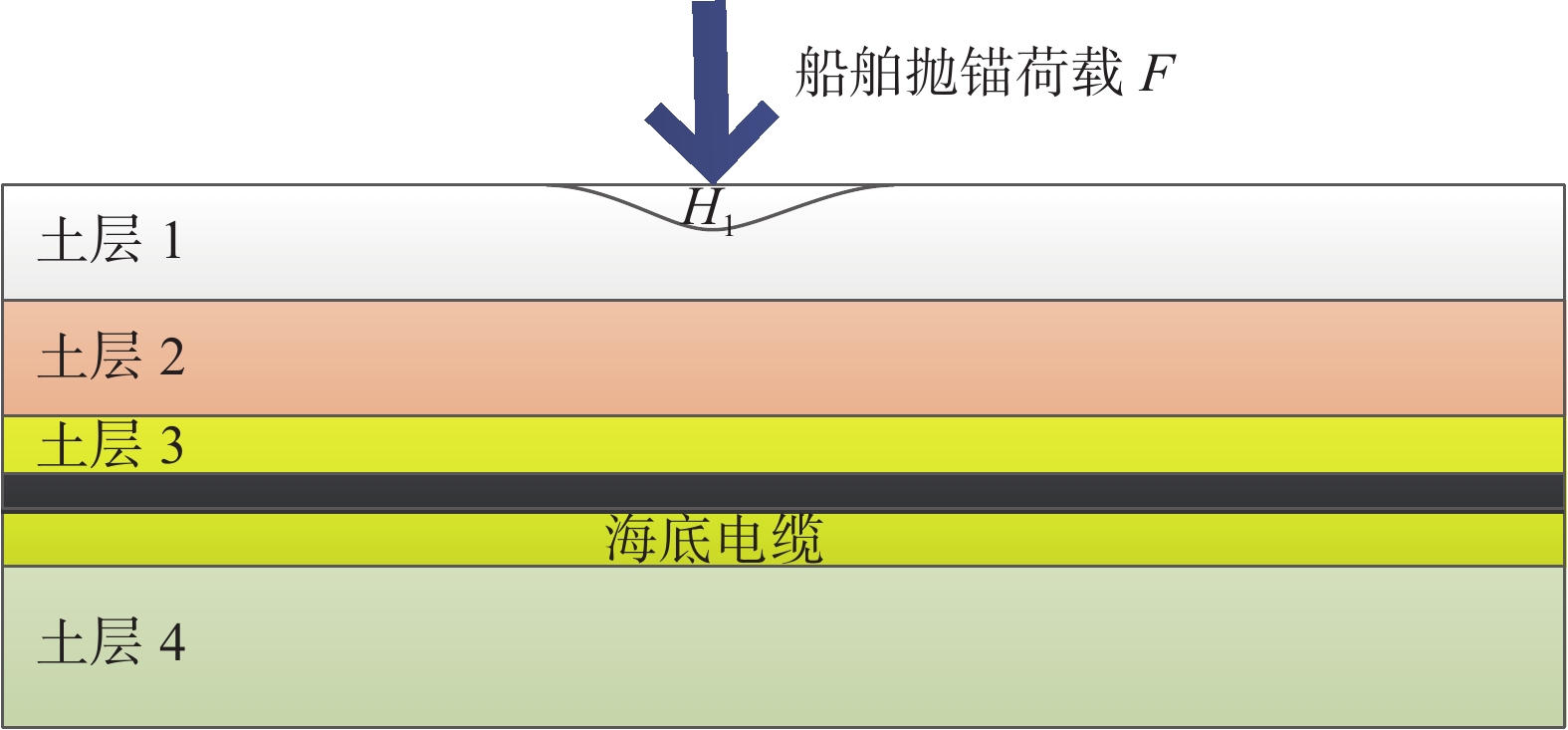

首先,在建立数学模型过程中,将船锚的抛锚、落锚的整个过程划分为以下3个阶段进行模拟[7]:(1)锚从初始位置到刚入水的瞬间;(2)锚从入水到锚落到海底表层;(3)锚从海底表层到最终贯入。以下将根据以上三个阶段的情况,建立相应模型。如图1所示。

为了简化计算,上述数学模型进行了一些假设:(1)假设船锚的阻力全部来自海底土体剪切力,忽略了船锚入土时来自正面的端阻力;(2)假设船锚为自由落体,未考虑海水流速及船只控制对船锚下落速度的影响。

-

船锚在自由抛锚的情况下,不考虑使用锚机刹车情况下进行抛锚。根据能量守恒定理,可以得到锚刚入水的速率按式(1)计算,如果采用锚机刹车,则

$ {v}_{1} $ 根据锚机设定的速度考虑。$$ {v}_{1}=\sqrt{2{\rm{g}}{h}_{1}} $$ (1) 式中:

$ {h}_{1} $ ——锚在空气中下降到水面的高度(m)。 -

锚在水中受重力

$ m{\rm{g}} $ 、浮力$ {F}_{{\rm{B}}} $ 及流体阻力$ f $ 作用。锚在水线下的受力方程为:$$ m{\rm{g}}-{F}_{{\rm{B}}}-f=m\dfrac{{\rm{d}}v}{{\rm{d}}t} $$ (2) 根据锚的重量可以推算出锚的体积,并计算出相应的浮力大小。

假设将锚的下落近似成标准球体下落的过程,则锚近似为球体的等效半径为r,锚在水中的阻力可按式(3)进行计算:

$$ f=kv=6{\text{π}} \eta rv $$ (3) 式中:

$ \eta $ ——海水的粘度(Pa·s);$r=\sqrt[3]{\dfrac{3V}{4{\text{π}} }}$ ——锚的近视计算等效半径(m);$ v $ ——锚在海水中的速率(m/s)。将式(3)代入式(2)方程两边同时除以k,得:

$$ \dfrac{m{\rm{g}}-{F}_{{\rm{B}}}}{k}-v=\dfrac{m}{k}\dfrac{{\rm{d}}v}{{\rm{d}}t} $$ (4) 令

$K=\dfrac{m{\rm{g}}-{F}_{{\rm{B}}}}{k}$ ,代入上式积分后解得:$$ {v}_{2}=K-(K-{v}_{1}){{\rm{e}}}^{-\dfrac{k}{m}T} $$ (5) 由于

${\rm{d}}x=v{\rm{d}}t$ ,可得

${\displaystyle \int }_{0}^{h2}{\rm{d}}x={\displaystyle \int }_{0}^{T}[K-(K-{v}_{1}\left){{\rm{e}}}^{-\frac{k}{m}T}\right]{\rm{d}}t$ 。解得

$ {h}_{2} $ :$$ {h_2} = TK - \left[ {\left( {K - {v_1}} \right){{\rm{e}}^{ - \dfrac{k}{m}T}}} \right]/\left( { - \dfrac{k}{m}} \right) + \left[ {\left( {K - {v_1}} \right)} \right]/\left( { - \dfrac{k}{m}} \right) $$ (6) 如果采用锚机刹车,则

$ {v}_{2} $ 计算值如果大于锚机设定的速度,则按锚机设定速率考虑。 -

锚从海底表面到最终的入土深度,考虑锚运动至海底表面的瞬间全部动能被锚所受到的阻力吸收。而不同的锚在不同的海底基质所受到的阻力不同,受力特性也不同,在此基础上进行简化,不考虑海底基质端阻力,将这部分作为安全储备,只考虑锚入土过程产生的剪切破坏,通过土体的剪切变形吸收船锚的动能,根据功能原理,冲击能等于土壤不排水抗剪强度吸收能力,由

$ \overline{F}={\int }_{0}^{h}\tau A{\rm{d}}h $ 代入能量公式可得式(7)入土深度:$$ h=\dfrac{m{v}_{2}^{2}}{2\overline{F}} $$ (7) 式中:

$ h $ ——锚垂直入海底土层的入土深度(m)。其中:对于粘性土

$\tau =c+\sigma \rm{tan}\varphi$ 或$\tau =\dfrac{{q}_{{\rm{u}}}}{2}$ 。 -

某一海域海深20 m,取平均水温20 ℃,落锚为570 kg的无杆锚(霍尔锚),以船锚从水面落下为基准,海底土壤抗剪强度假设为50 kPa。为了简化计算模型,将船锚简化为六面体,底面长宽同锚宽最大尺寸,高度同锚爪同高。本例中B=371 mm,L=950 mm,H=862 mm。

其中水的粘度

$ \eta $ 随温度变化而变化,其中在水温20 ℃时,$ \eta $ =1.002×10-3 Pa·s$$ V=\dfrac{m}{{\rho }_{\mathrm{锚}}}=\dfrac{570}{7\;850}=0.072\;6\;{{\rm{m}}}^{3} $$ $$ {F}_{{\rm{B}}}={\rho }_{\mathrm{水}}{V}_{\mathrm{锚}}\text{g=1\;000}\times \text{0.072\;6}\times \text{10=726\;N} $$ $$ r=\sqrt[3]{\dfrac{3V}{4{\text{π}}}}=\sqrt[3]{\dfrac{3\times 0.072\;6}{4{\text{π}} }}=0.26\;{\rm{m}} $$ $$ k=6{\text{π}} \eta r=6\times 3.14\times 1.002\times 1{0}^{-3}\times 0.25=4.91\times 1{0}^{-3}\;{\rm{Pa}}\cdot {\rm{s}}\cdot {\rm{m}} $$ $$ K=\dfrac{m{\rm{g}}-{F}_{{\rm{B}}}}{k}=\dfrac{570\times 10-726}{4.91\times 1{0}^{-3}}=1\;013\times 1{0}^{3}\;{\rm{m}}/{\rm{s}} $$ $$ {v}_{2}=K-(K-{v}_{1}){{\rm{e}}}^{-\dfrac{k}{m}T} =18.7\;{\rm{m}}/{\rm{s}} $$ 故入土深度为:

$$ h=\dfrac{m{v}_{2}^{2}}{2\overline{F}}=\dfrac{570\times 18.{7}^{2}}{2\times 50\;000\times (0.371+0.95)\times 2\times 0.862}=0.87\;{\rm{m}} $$ -

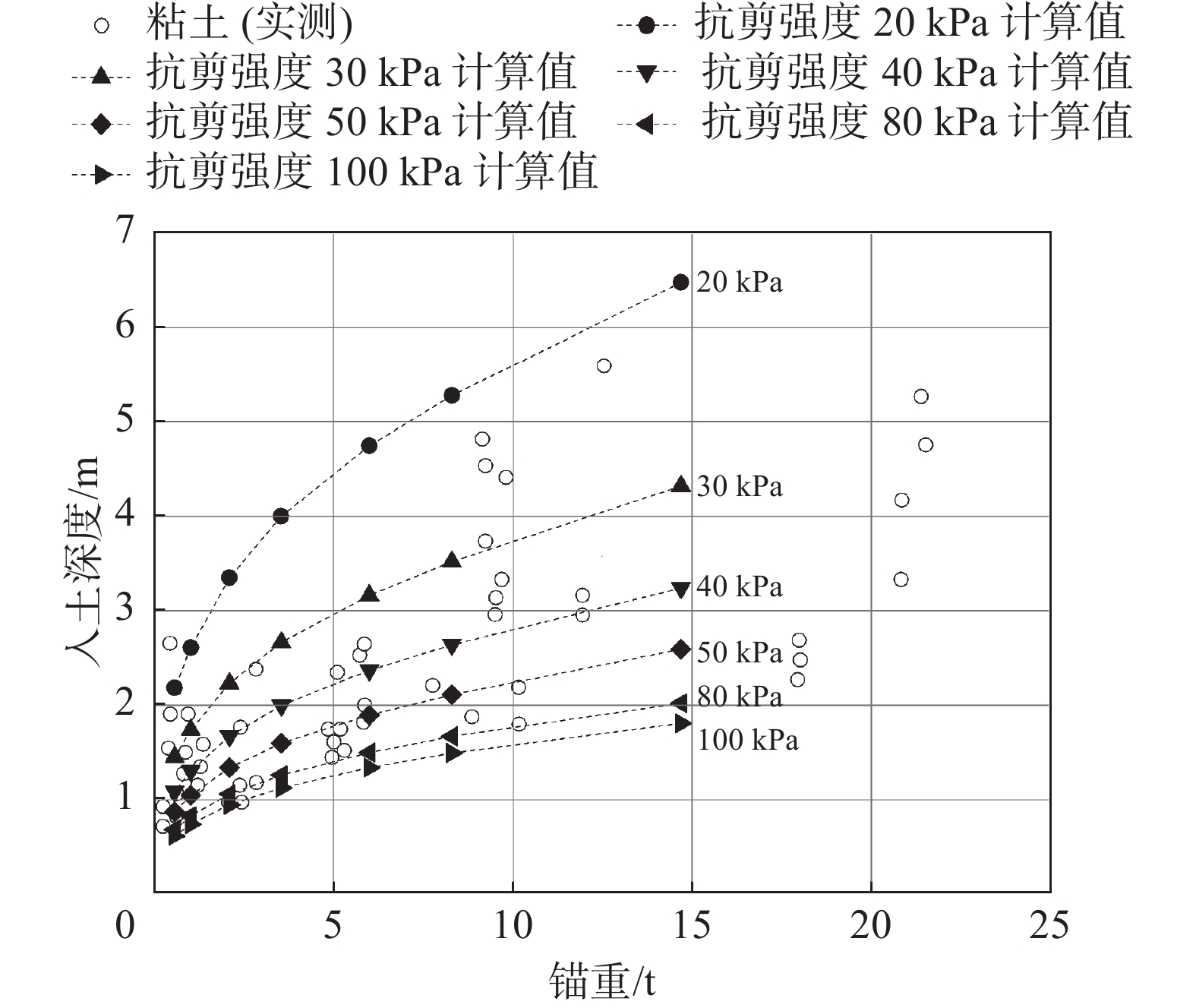

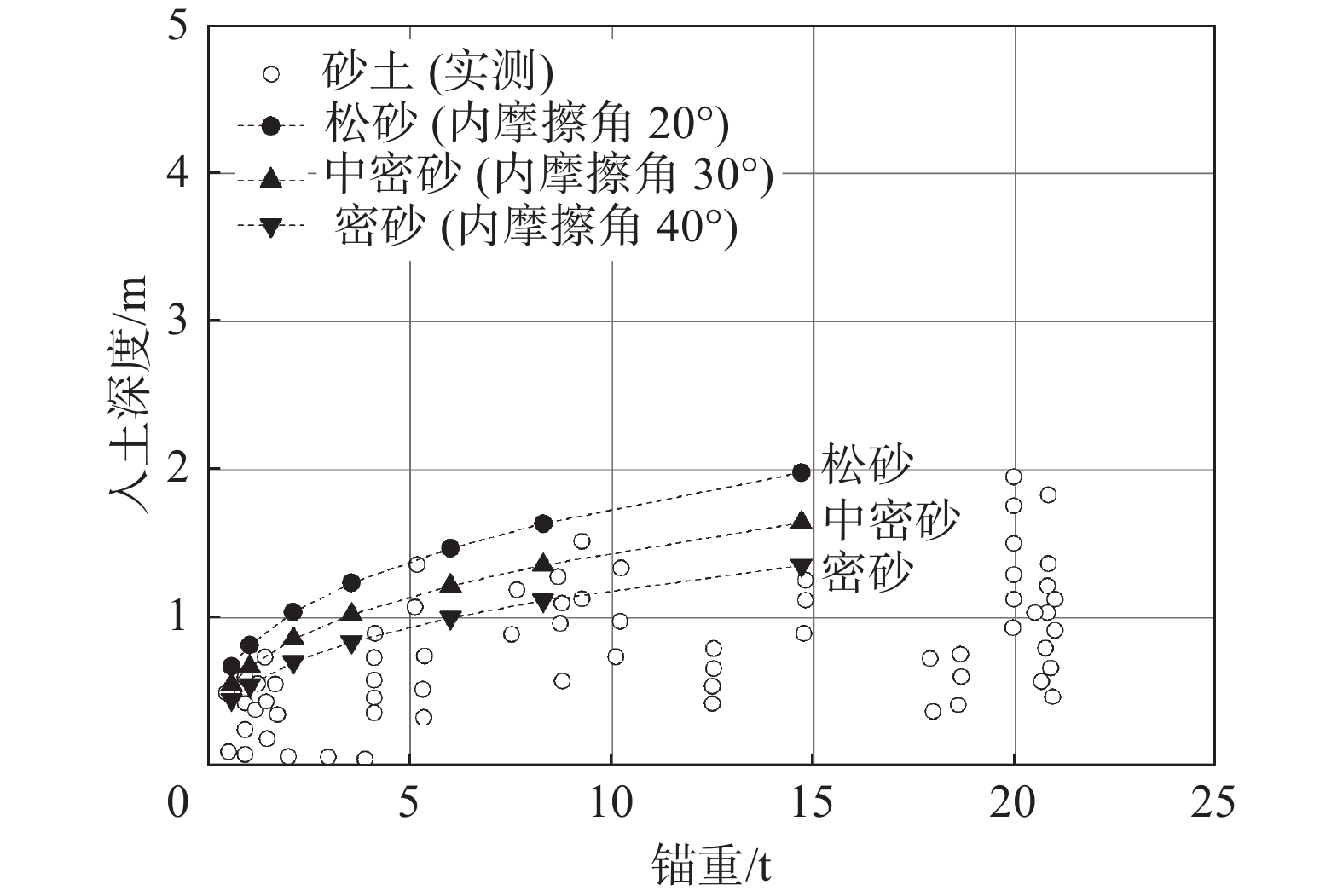

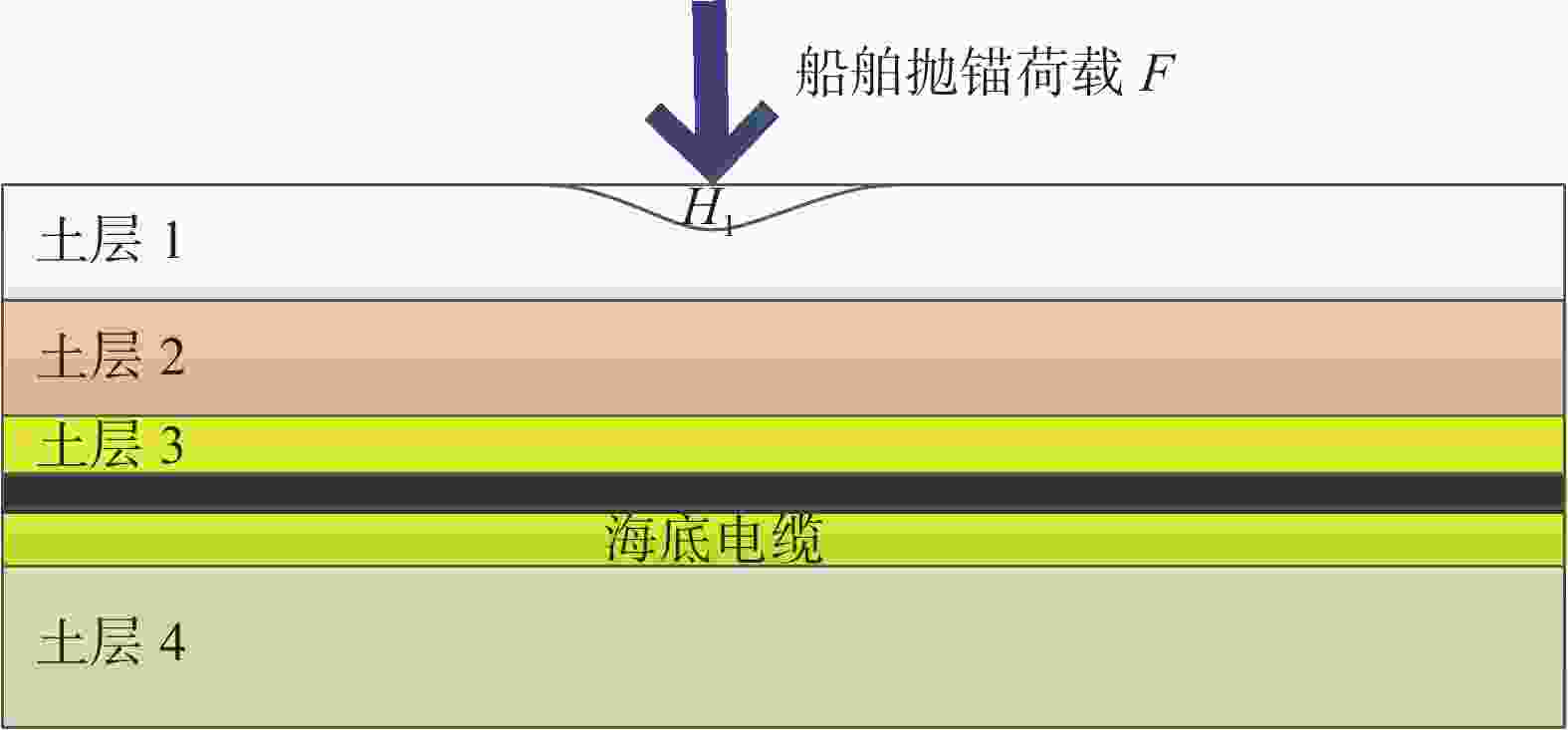

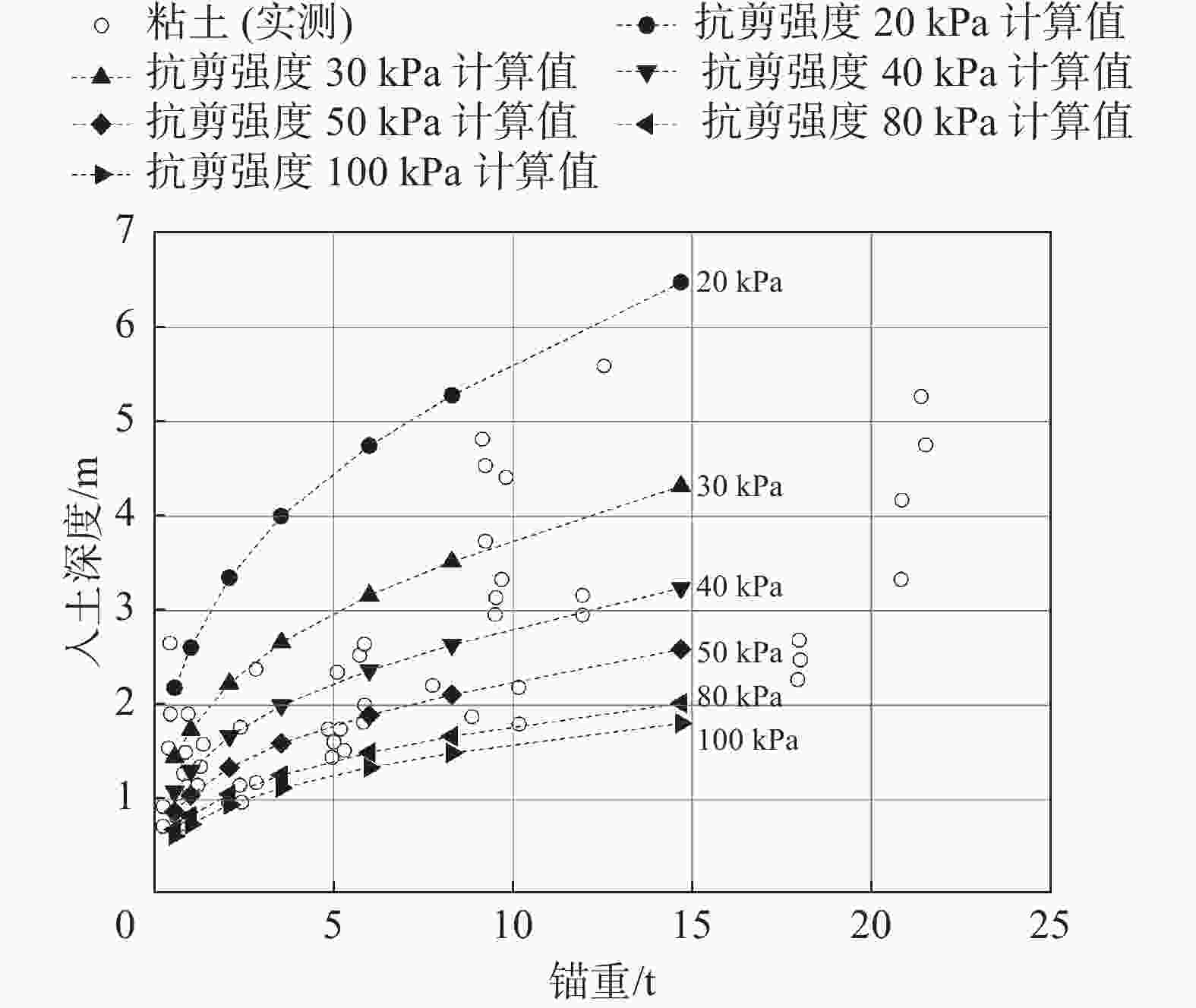

对锚重在570 kg~1.47 t的船锚,以20 m水深自由落锚,计算锚在海底土壤抗剪强度为20 kPa~100 kPa时的入土深度。同时将该计算结果与《城市电力电缆线路设计技术规定》(DL/T 5221-2016)条文说明[15]中引用的日本运输省港湾技术研究所的NO.215《投锚与入土深度试验》[16]现场实测报告值进行了对比。如图2、图3所示。

由图3可看出实测结果具有一致的规律性,在土体抗剪强度大的情况下,曲线斜率小,入土深度随锚重变化小;土体抗剪强度小的情况下,曲线斜率大,入土深度随锚重变化大。可以看出对于粘性土而言抗剪强度在20 kPa~100 kPa区间,计算值与实测基本较吻合。这主要是由于在粘性土中,土体的剪切变形由不排水抗剪强度控制,应力-应变曲线呈应变硬化型,船锚的贯入深度由锚重及土体剪切强度决定,抗剪强度越大,剪切变形越小。对于粘土抗剪强度在20 kPa~30 kPa之间时,由于入土深度变化幅度较大,且实测数据偏少,建议在工程应用时增加试验论证。

因此,该计算方法在海底土壤为粘性土时抗剪强度大于20 kPa,计算结果在实际工程中具有应用价值。

-

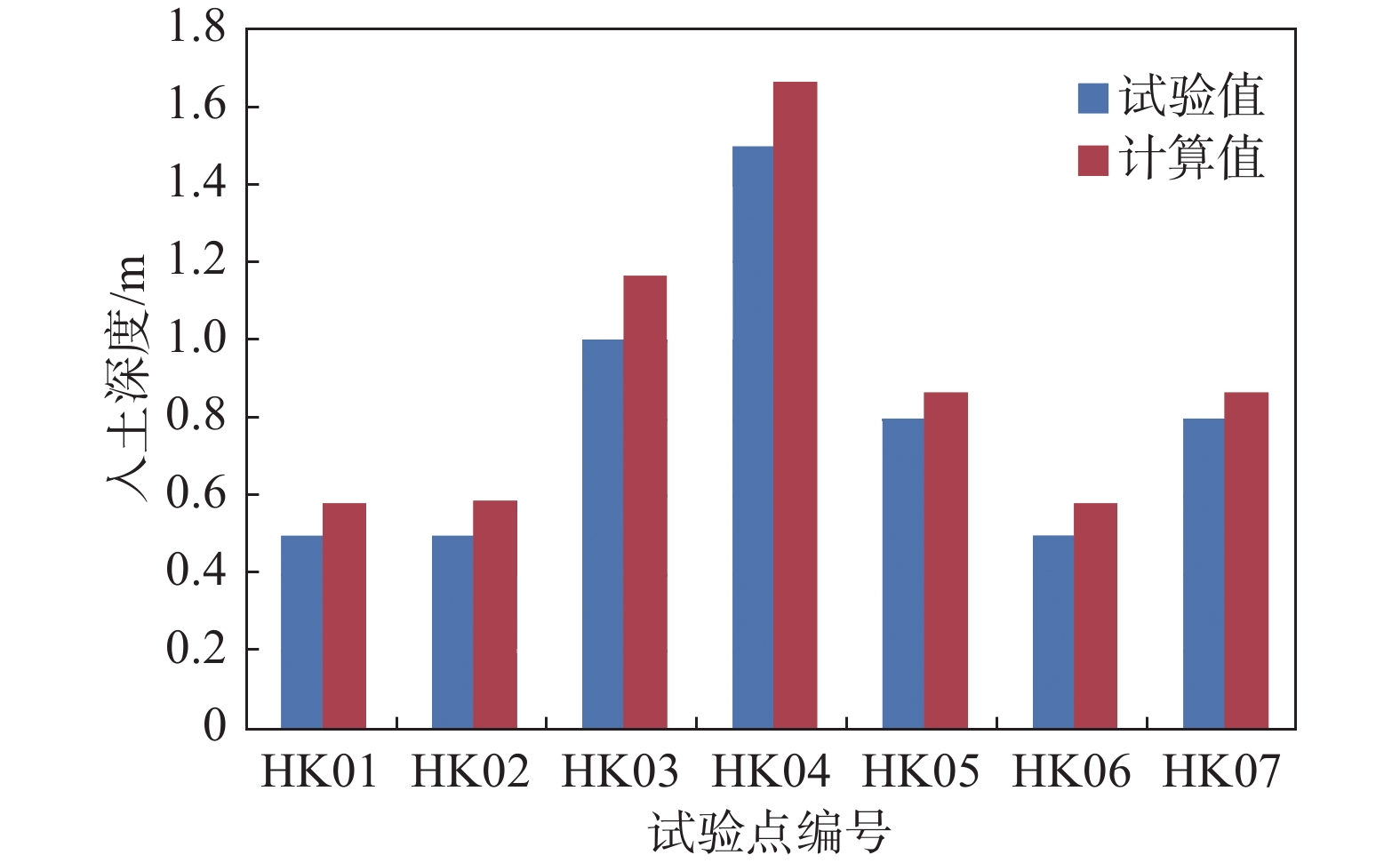

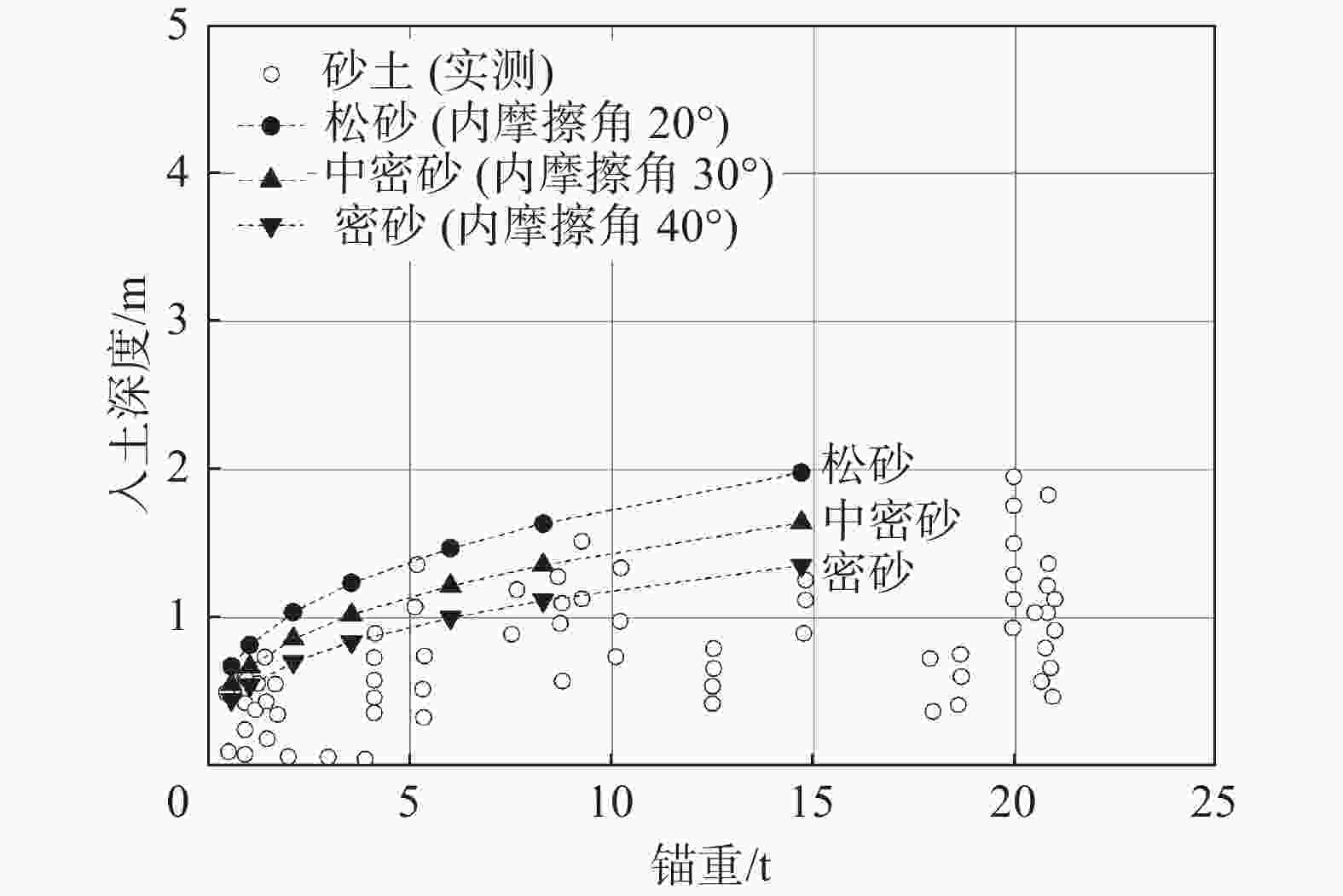

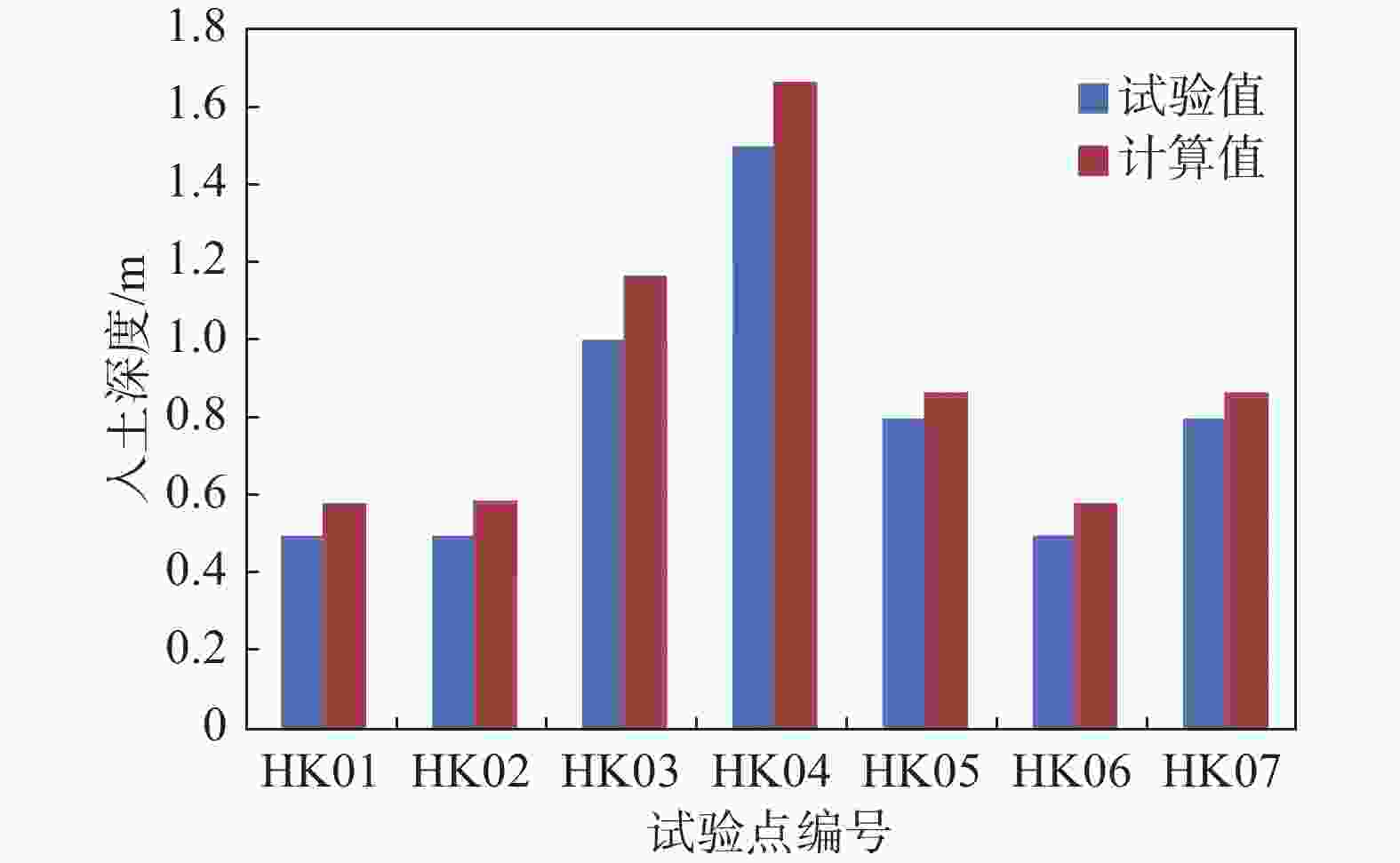

南澳863柔直示范项目海缆工程在进行路由勘探时,利用钻探船船锚对沿线7个点的船锚入土深度进行了现场试验,同时在相同条件下采用数学模型进行了理论计算,如表1所示。两者的对比情况如图4所示。

勘探点号 HK1 HK2 HK3 HK4 HK5 HK6 HK7 水深/m 3.51 5.07 7.93 10.14 9.95 10.06 11.05 海底底质类型 粉砂/淤泥 粉砂/淤泥 淤泥/淤泥质土 淤泥/淤泥质土 粉砂/淤泥质土/粉土 粉砂/粉土 粉砂/粉土 土质抗剪强度/kPa 22 30 15 15 25 40 28 实测船锚入土深度/m 0.5 0.5 1.0 1.5 0.8 0.5 0.8 计算船锚入土深度/m 0.58 0.59 1.17 1.66 0.87 0.58 0.87 Table 1. Statistics of anchor depth of drilling ship during survey

由表1及图4所示,采用数学模型计算的结果均高于现场实测值,偏差在8%~18%之间。这主要是由以下原因引起的:(1)数学模型进行了简化计算,假设船锚的阻力全部来自海底土体剪切力;(2)忽略了船锚入土时来自正面的端阻力,并将船锚简化为均匀的柱体考虑侧阻力。因此,计算结果与实测值比较会偏大。

-

通过上文的数学模型计算方法与实测结果比较分析可以得出以下结论:

1)该简化计算模型适用于抗剪强度大于20 kPa的粘性土计算船锚入土深度。

2)该计算模型忽略了端部阻力的影响,计算结果偏大8%~18%,在工程应用中,可将该部分作为设计裕度考虑,计算结果对敷设保护方案的影响在可接受范围。

3)影响船锚入土深度的边界条件是多方面的,包括船锚类型、重量、水深、抛锚方式、海底土质、流速等因素。为了能够满足特定条件下的计算需求,仅考虑部分主要边界条件得到的计算模型难免存在一定差异。

4)该方法还有待在实践中积累不同实测数据进行验证和拟合修正,并结合经验法和概率法进行分析,为海底电缆敷设保护提供设计依据。

Simplified Calculation Method and Applicability of Anchor Depth

doi: 10.16516/j.gedi.issn2095-8676.2023.01.014

- Received Date: 2022-05-19

- Rev Recd Date: 2022-07-20

- Available Online: 2022-12-15

- Publish Date: 2023-01-11

-

Key words:

- submarine cable /

- laying protection /

- anchoring /

- energy method /

- shear strength

Abstract:

| Citation: | CHEN Feng, XIAO Zhijun. Simplified Calculation Method and Applicability of Anchor Depth[J]. SOUTHERN ENERGY CONSTRUCTION, 2023, 10(1): 112-117. doi: 10.16516/j.gedi.issn2095-8676.2023.01.014 |

DownLoad:

DownLoad: